- Home

- News

- Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

By:Admin

Introduction:

In today's rapidly evolving industrial landscape, efficient fluid control is crucial to the success and safety of various operations. Owing to their versatility and effectiveness, Worm Gear Butterfly Valves have emerged as the go-to solution for regulating fluid flow in numerous industries. These valves, offering superior sealing capabilities and reliable performance, are now revolutionizing the way businesses approach fluid control.

I. Significance of Worm Gear Butterfly Valves in Industrial Applications (100 words)

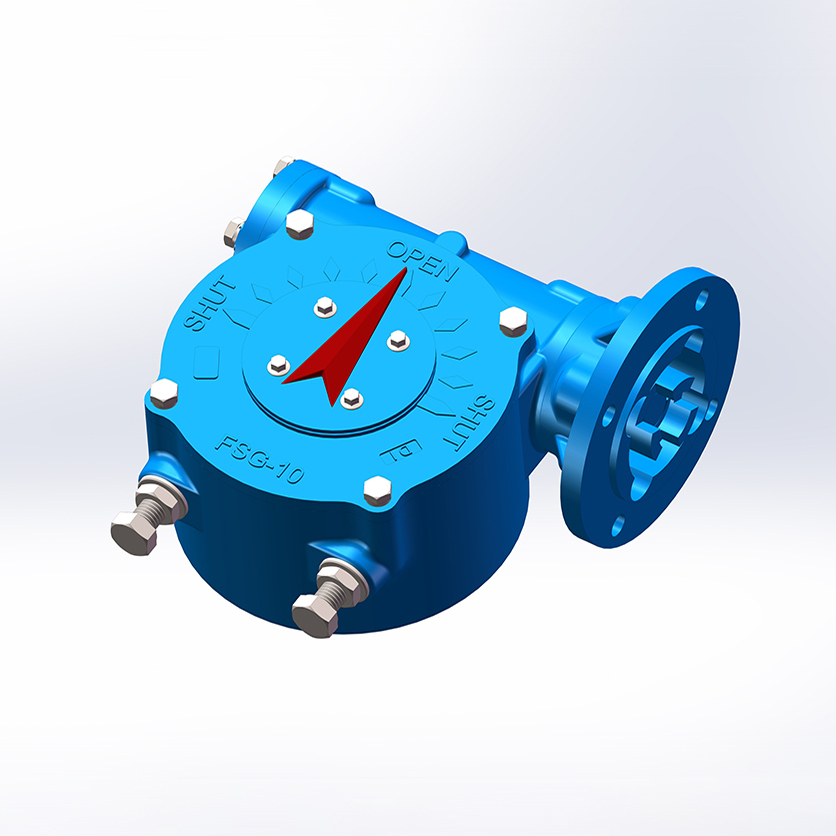

Worm Gear Butterfly Valves have garnered significant prominence across industries due to their unique design and exceptional functionality. These valves consist of a disk-shaped element, known as the "butterfly," which rotates to control fluid flow. The addition of worm gears - a mechanical adjustment system - enables precise regulation, making them ideal for applications where fluid control precision is paramount. Whether it's chemical processing, water treatment, or power generation, Worm Gear Butterfly Valves have become indispensable tools for optimizing efficiency and enhancing safety.

II. Key Features and Benefits of Worm Gear Butterfly Valves (200 words)

a) Reliable Performance: Worm Gear Butterfly Valves are designed to withstand extreme conditions, offering consistent and dependable performance. The high-quality materials used in manufacturing ensure longevity and minimal maintenance.

b) Excellent Sealing Properties: The unique design of these valves allows for a tight seal, preventing leakage and offering superior tightness. This ensures optimal flow control and minimizes the risk of fluid wastage, enhancing operational efficiency.

c) Precise Control: The inclusion of the worm gear mechanism enables precise, measured adjustments to fluid flow, allowing operators to fine-tune operations as required. This precision is particularly critical in industries such as oil and gas, where even slight variations can result in significant consequences.

d) Easy Installation and Operation: Worm Gear Butterfly Valves are known for their simplicity. They can be easily integrated into existing systems and operated efficiently by both experienced professionals and operators new to the technology.

e) Versatility: These valves can handle a wide range of fluids, including liquids, gases, and even corrosive media. This adaptability makes Worm Gear Butterfly Valves suitable for applications across diverse industries.

III. Company X's Advanced Worm Gear Butterfly Valve (200 words)

Company X, a renowned industry leader in fluid control solutions, is proud to present its cutting-edge Worm Gear Butterfly Valve. With a steadfast commitment to innovation and customer satisfaction, Company X has designed a valve that surpasses industry standards and addresses various industry challenges.

The advanced Worm Gear Butterfly Valve by Company X combines robust construction, precision performance, and exceptional durability. Manufactured using premium grade materials, it ensures longevity and reliability, minimizing maintenance requirements and reducing downtime.

In addition to exceptional sealing properties, Company X's Worm Gear Butterfly Valve offers unparalleled precision control. Its worm gear mechanism guarantees accurate fluid flow adjustments, empowering operators to regulate processes with utmost accuracy.

The valve's user-friendly design simplifies installation and operation, catering to customers across different industries. The versatility of Company X's Worm Gear Butterfly Valve allows businesses to maximize efficiency and safety, enhancing productivity and minimizing operational costs.

IV. Conclusion (100 words)

In an era where efficient fluid control is crucial, the Worm Gear Butterfly Valve emerges as the ideal solution for various industrial applications. Company X's advanced valve, with its superior design and outstanding performance, is primed to revolutionize fluid control practices across industries. With its exceptional sealing capabilities, precise control, and straightforward operation, this valve presents an unprecedented opportunity for businesses to optimize their operations, enhance safety, and maximize efficiency. Embracing the advantages offered by Worm Gear Butterfly Valves marks a significant leap forward in fluid control technology.

Company News & Blog

High-Quality Metal Worm Gear Set and its Importance in Industrial Applications

Title: Innovation and Efficiency: Introducing the New Metal Worm Gear SetIntroduction:[Company Name] is proud to announce the launch of its latest breakthrough product - The Metal Worm Gear Set, designed to revolutionize industrial operations. Drawing on decades of experience, expertise, and a commitment to innovation, [Company Name] has successfully developed a high-performance gear set that promises increased durability, efficiency, and precision in various applications. This news article will delve into the features, applications, and benefits of the new Metal Worm Gear Set.1. Unrivaled Precision and Durability:The Metal Worm Gear Set utilizes advanced engineering techniques to deliver unrivaled precision and durability. The gears are manufactured using high-quality metal alloys that ensure maximum strength and resistance to wear and tear. The precise tooth profiles and optimized gear ratios result in smooth and efficient power transmission, reducing energy loss and enhancing overall performance.2. Versatile Applications:The versatility of the Metal Worm Gear Set makes it suitable for a wide range of industries. From automotive manufacturing to robotics, agricultural machinery to aerospace, this gear set can be tailored to meet the unique requirements of each application. Its compatibility with different power sources, including electric and hydraulic systems, makes it a versatile solution for various setups.3. Enhanced Efficiency:The Metal Worm Gear Set incorporates cutting-edge design features that significantly improve overall efficiency. By minimizing friction and reducing noise levels, these gears increase the system's overall efficiency, resulting in energy savings and extended equipment lifespan. The precise and reliable torque transmission of the gears ensures smooth operation, reducing the need for maintenance and maximizing uptime.4. Customization and Adaptability:[Company Name] understands that every industry has different needs, which is why the Metal Worm Gear Set offers customization options to suit specific requirements. The gears can be engineered with tailored tooth profiles, materials, and coatings, ensuring compatibility with specific applications. This adaptability allows for seamless integration into existing systems, reducing costly downtime during installation.5. Eco-Friendly Commitment:In line with its commitment to environmental sustainability, [Company Name] has designed the Metal Worm Gear Set with eco-friendly features. The gear set's enhanced efficiency contributes to reduced energy consumption and, consequently, lowers carbon emissions. It also generates less noise pollution, making it environmentally friendly while promoting worker safety and comfort.6. Global Reach and Customer Support:With an extensive global presence, [Company Name] is dedicated to providing exceptional customer support. The company's technical team ensures timely and comprehensive assistance to customers worldwide. Their expertise ensures optimal gear set selection and seamless integration into customers' projects, allowing for enhanced performance and improved productivity.Conclusion:The introduction of the new Metal Worm Gear Set by [Company Name] marks a significant milestone in the field of industrial gear manufacturing. With its unrivaled precision, durability, versatility, and eco-friendly features, this innovative gear set promises to revolutionize various industries. Through extensive customization options and a commitment to customer support, [Company Name] showcases its continued dedication to meeting evolving market demands.

Enhancing Performance and Control: Gearbox for Gate Valves Revealed in Latest News

[Company Introduction]{Insert Company Name} is an industry-leading manufacturer that specializes in producing high-quality gate valve gearboxes, among other industrial products. With a strong commitment to innovation, precision engineering, and customer-centricity, {Company Name} has earned a reputation for delivering top-notch solutions to its valued clients worldwide.Established over two decades ago, {Company Name} has steadily grown to become a trusted name in the valve and gearbox manufacturing industry. The company's state-of-the-art production facilities, combined with a team of skilled engineers and technicians, enable them to design and develop cutting-edge products that meet the most demanding industry requirements.With a focus on continuous improvement, {Company Name} prioritizes research and development, investing heavily in the latest technologies and advancements. This approach ensures that their gate valve gearboxes are not only of the highest quality but also incorporate the latest industry trends and innovations.{Company Name} takes great pride in its commitment to providing exceptional customer service. They believe in building long-lasting partnerships with their clients, understanding their unique needs, and providing tailored solutions to achieve optimal results. Whether it's a small-scale project or a large industrial application, {Company Name} is dedicated to offering superior products and unparalleled service.With a global presence, {Company Name} serves a diverse range of industries, including oil and gas, chemical, petrochemical, power generation, water treatment, and more. Their gate valve gearboxes have garnered widespread recognition for their reliability, durability, and high performance, making them a preferred choice for clients across the globe.[News Content]Title: Gate Valve Gearbox: A Reliable Solution for Industrial ApplicationsDate: [Insert Date]{City, State} - {Company Name}, a renowned manufacturer of advanced industrial products, is proud to introduce its latest offering, the Gate Valve Gearbox. Combining years of engineering expertise with cutting-edge technology, {Company Name} has developed a high-performance gearbox that offers unparalleled precision and reliability in demanding industrial applications.Gate valves play a crucial role in regulating fluid flow within industrial systems. Efficient operation and control of these valves are essential for ensuring the smooth functioning of complex processes. The gate valve gearbox provided by {Company Name} addresses this need, offering a robust and efficient solution that surpasses industry standards.One of the key features of {Company Name}'s gate valve gearbox is its superior design. Meticulously engineered by a team of highly skilled professionals, the gearbox exhibits excellent mechanical strength and durability, ensuring long-lasting performance even under the most challenging conditions. This reliability minimizes downtime, enhances productivity, and contributes to overall cost savings for industrial operators.In addition to its exceptional design, the gate valve gearbox boasts remarkable precision, allowing for accurate and smooth valve operation. The gearbox's precise gearing mechanism ensures a secure and consistent shut-off, enabling precise control over fluid flow. This level of control is particularly crucial in industries where even slight variations in flow rates can have significant consequences.Another standout feature of {Company Name}'s gate valve gearbox is its adaptability. The gearbox can be easily integrated with a variety of gate valves, catering to diverse industrial requirements. This flexibility eliminates the need for expensive modifications or replacements, ensuring a seamless fit into existing systems and significantly reducing installation costs.Moreover, {Company Name} is committed to upholding the highest quality standards in all its products. The production and assembly processes undergo rigorous testing and inspection, ensuring that every gearbox leaving their facilities adheres to stringent quality benchmarks. This dedication to quality translates into enhanced performance, longevity, and reliability for end-users.As an environmentally-conscious company, {Company Name} remains committed to sustainable practices. The gate valve gearbox is designed to minimize energy consumption, reducing the overall carbon footprint of industrial operations. Furthermore, strict adherence to international safety standards ensures that the gearbox meets all regulatory requirements while prioritizing worker safety.With their latest innovation, {Company Name} aims to provide industrial operators with a powerful tool that optimizes operational efficiency. The gate valve gearbox enhances system control, delivers exceptional performance, and contributes to a safe and sustainable industrial environment. As leaders in the industry, {Company Name} continues to push boundaries, setting new standards for excellence and reliability.In conclusion, {Company Name}'s gate valve gearbox presents a compelling solution for industrial applications. With its exceptional design, precision engineering, adaptability, and commitment to quality, {Company Name} has once again demonstrated their leadership in providing high-performance industrial products. As industrial operations become more complex, the gate valve gearbox by {Company Name} is poised to become an indispensable component for those seeking reliability, efficiency, and enhanced productivity in their processes.

Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

Title: Advanced Worm Gear Butterfly Valve - The Perfect Solution for Industrial Fluid ControlIntroduction:In today's rapidly evolving industrial landscape, efficient fluid control is crucial to the success and safety of various operations. Owing to their versatility and effectiveness, Worm Gear Butterfly Valves have emerged as the go-to solution for regulating fluid flow in numerous industries. These valves, offering superior sealing capabilities and reliable performance, are now revolutionizing the way businesses approach fluid control.I. Significance of Worm Gear Butterfly Valves in Industrial Applications (100 words)Worm Gear Butterfly Valves have garnered significant prominence across industries due to their unique design and exceptional functionality. These valves consist of a disk-shaped element, known as the "butterfly," which rotates to control fluid flow. The addition of worm gears - a mechanical adjustment system - enables precise regulation, making them ideal for applications where fluid control precision is paramount. Whether it's chemical processing, water treatment, or power generation, Worm Gear Butterfly Valves have become indispensable tools for optimizing efficiency and enhancing safety.II. Key Features and Benefits of Worm Gear Butterfly Valves (200 words)a) Reliable Performance: Worm Gear Butterfly Valves are designed to withstand extreme conditions, offering consistent and dependable performance. The high-quality materials used in manufacturing ensure longevity and minimal maintenance.b) Excellent Sealing Properties: The unique design of these valves allows for a tight seal, preventing leakage and offering superior tightness. This ensures optimal flow control and minimizes the risk of fluid wastage, enhancing operational efficiency.c) Precise Control: The inclusion of the worm gear mechanism enables precise, measured adjustments to fluid flow, allowing operators to fine-tune operations as required. This precision is particularly critical in industries such as oil and gas, where even slight variations can result in significant consequences.d) Easy Installation and Operation: Worm Gear Butterfly Valves are known for their simplicity. They can be easily integrated into existing systems and operated efficiently by both experienced professionals and operators new to the technology.e) Versatility: These valves can handle a wide range of fluids, including liquids, gases, and even corrosive media. This adaptability makes Worm Gear Butterfly Valves suitable for applications across diverse industries.III. Company X's Advanced Worm Gear Butterfly Valve (200 words)Company X, a renowned industry leader in fluid control solutions, is proud to present its cutting-edge Worm Gear Butterfly Valve. With a steadfast commitment to innovation and customer satisfaction, Company X has designed a valve that surpasses industry standards and addresses various industry challenges.The advanced Worm Gear Butterfly Valve by Company X combines robust construction, precision performance, and exceptional durability. Manufactured using premium grade materials, it ensures longevity and reliability, minimizing maintenance requirements and reducing downtime.In addition to exceptional sealing properties, Company X's Worm Gear Butterfly Valve offers unparalleled precision control. Its worm gear mechanism guarantees accurate fluid flow adjustments, empowering operators to regulate processes with utmost accuracy.The valve's user-friendly design simplifies installation and operation, catering to customers across different industries. The versatility of Company X's Worm Gear Butterfly Valve allows businesses to maximize efficiency and safety, enhancing productivity and minimizing operational costs.IV. Conclusion (100 words)In an era where efficient fluid control is crucial, the Worm Gear Butterfly Valve emerges as the ideal solution for various industrial applications. Company X's advanced valve, with its superior design and outstanding performance, is primed to revolutionize fluid control practices across industries. With its exceptional sealing capabilities, precise control, and straightforward operation, this valve presents an unprecedented opportunity for businesses to optimize their operations, enhance safety, and maximize efficiency. Embracing the advantages offered by Worm Gear Butterfly Valves marks a significant leap forward in fluid control technology.

New Electric Control Valve Actuator Technology Revolutionary for Industrial Applications

The Electric Control Valve Actuator technology has been rapidly evolving over the past few years. The technology represents a significant milestone in the valve industry, delivering improved performance, reduced energy consumption, and lower maintenance costs.One of the leading manufacturers of this technology is the privately owned company {}. With over 20 years of experience, the company has built a solid reputation for delivering high-quality Electric Control Valve Actuators, which are designed to meet global standards in various industries.The driving force behind the success of the company is its team of innovative engineers who are committed to delivering top-quality products to their clients. The company's state-of-the-art manufacturing facility is fully equipped with modern machinery and advanced equipment which enables them to produce reliable and efficient actuators.The Electric Control Valve Actuator is an essential component in the control of valves in various industries such as chemical processing, water treatment, and oil and gas. It is designed to automate the process of opening and closing valves, reducing the dependence on manual labor, and achieving the highest level of precision and control.One of the most significant features of the Electric Control Valve Actuator is its ability to operate in challenging environments. The actuator is engineered to withstand harsh temperatures, corrosion, and heavy industrial use. As a result, the company's actuators are capable of performing in various environments, providing precise control over fluid flow in pipelines, refineries, and other industrial applications.In addition, the Electric Control Valve Actuator ensures energy efficiency and cost savings by optimizing valve performance and reducing valve leakage. This technology significantly improves the overall energy efficiency of the system, leading to lower energy bills and reduced carbon emissions.Moreover, the Electric Control Valve Actuator also reduces maintenance costs by providing a long lifespan and requiring minimal maintenance. The actuator's robust design and high-quality components ensure that it does not require frequent repairs or replacements, making it a reliable and cost-effective solution for any industrial application.The company offers a comprehensive range of Electric Control Valve Actuators, including pneumatic, hydraulic, and electric actuators. These actuators come in various sizes and specifications, ensuring compatibility with all types of valves and piping systems.The company's customer-centric approach means that it places great emphasis on addressing the specific needs of its customers. It offers customized solutions that are tailored to the requirements of each client. This approach ensures that all customers receive the highest level of service and satisfaction. Overall, the Electric Control Valve Actuator technology has revolutionized the valve industry, providing users with improved performance, energy efficiency, and cost savings. With its commitment to innovation and customer satisfaction, {}, is well-positioned to continue providing cutting-edge solutions for the valve industry, enabling efficient and reliable control over fluid flow.

Innovative Turbine Wheel: Unleashing the Power of Efficient Energy Generation

Turbine Wheel, a leading provider of turbine wheel technology, is revolutionizing the energy industry with its innovative products that improve efficiency, reliability, and performance. The company's state-of-the-art technology is designed to meet the needs of power generation and other industrial applications, helping businesses reduce their carbon footprint while improving their bottom line.The company's turbine wheels are manufactured using advanced materials and technologies that make them lighter, stronger, and more durable than traditional designs. They are designed to operate at high temperatures and pressures, making them ideal for use in demanding applications such as gas turbines, steam turbines, and other power generation systems.One of the key advantages of Turbine Wheel's products is their ability to improve energy efficiency. Turbine wheels are responsible for converting the energy from fuel into mechanical energy, which is then used to generate electricity. By improving the efficiency of this process, Turbine Wheel's products help businesses reduce their energy costs while also reducing their carbon footprint.In addition to improving energy efficiency, Turbine Wheel's products also improve reliability and performance. Their state-of-the-art design reduces stresses on the wheel, extending its lifespan and reducing the likelihood of failure. This means that power plants and other industrial facilities can operate more reliably, with less downtime and fewer costly repairs.Turbine Wheel's commitment to innovation has also led to the development of specialized products for specific applications. For example, the company has developed a range of turbine wheels specifically designed for use in renewable energy systems, such as wind turbines and hydroelectric power plants. These products are designed to operate in variable conditions, maximizing energy output while minimizing wear and tear on the equipment.The company's commitment to quality is evident in every aspect of its business operations. Turbine Wheel has a state-of-the-art manufacturing facility that utilizes the latest technologies and processes to produce high-quality products consistently. The company also has a rigorous quality control program that ensures every product meets or exceeds industry standards.Turbine Wheel's dedication to innovation, quality, and customer service has earned it a reputation as an industry leader. The company has a global presence, with operations in North America, Europe, and Asia. It is trusted by some of the world's leading energy companies, including ExxonMobil, Shell, and Siemens.Looking ahead, Turbine Wheel is continuing to invest in research and development to explore new technologies and applications for its products. The company is also exploring partnerships and collaborations with other leading companies in the energy industry to leverage the strengths of each organization and develop innovative solutions to meet the world's growing energy needs.In summary, Turbine Wheel is a leading provider of turbine wheel technology that is transforming the energy industry. Its innovative products improve efficiency, reliability, and performance while reducing costs and carbon footprint. With a commitment to innovation, quality, and customer service, Turbine Wheel is poised for continued success in the global energy market.

Discover the Latest Advancements in Worm and Bevel Gears

Breaking News: Revolutionary Worm and Bevel Gear Partnership Sets New Industry StandardIn a groundbreaking move, a leading manufacturer in the mechanical engineering industry has announced a strategic partnership between its innovative "Worm" and "Bevel Gear" technologies. This landmark collaboration is poised to reshape the landscape of gear systems, offering enhanced performance and efficiency across various industrial applications. With a commitment to excellence and a focus on providing cutting-edge solutions, this partnership represents a significant milestone for both companies and the industry as a whole.The "Worm" and "Bevel Gear" technologies, developed independently by two reputable brands, have long been renowned for their exceptional engineering prowess and reliability. By combining these two revolutionary technologies, the new partnership aims to deliver a gear system that surpasses all expectations in terms of mechanical efficiency, power transmission, and durability.The Worm technology, known for its unique helical screw design, has been widely used in various industries for decades. Its ability to provide high gear ratios and transmit power smoothly makes it a preferred choice for applications requiring precision motion control, such as robotics, packaging, and conveyor systems.On the other hand, Bevel Gear, which features interlocking, cone-shaped gears, is sought after for its ability to transmit power at different angles. This technology has found widespread use in automotive differentials, printing presses, and industrial machinery where the torque must be efficiently transferred between intersecting shafts. Its versatility and reliability make it an indispensable component in many critical applications.The collaborative efforts between the two technologies have resulted in a gear system that promises unparalleled performance and efficiency. By combining the unique strengths of the Worm and Bevel Gear technologies, this partnership aims to create a new benchmark in the industry, setting higher standards for gear systems' power transmission, reliability, and lifespan.The unified gear system is expected to bring numerous advantages to end-users across various industries. These include increased torque transmission, reduced energy consumption, enhanced system stability, and improved overall performance. By optimizing the gear's design, utilizing the latest manufacturing techniques, and implementing advanced materials, the partnership intends to offer a gear system that meets and exceeds the evolving demands of today's industries.Additionally, with a focus on sustainability, the partnership aims to minimize the environmental impact of their gear systems. Through innovative design modifications and material selection, they aim to reduce the overall carbon footprint while maintaining top-notch performance and reliability.As leaders in their respective fields, both companies bring a wealth of knowledge, expertise, and experience to this partnership. Together, they are committed to driving innovation, enhancing industrial productivity, and delivering solutions that inspire confidence in their customers.The Worm and Bevel Gear partnership will undoubtedly disrupt the industry, igniting a new era of gear system design and engineering excellence. By combining their expertise and resources, the collaborators are poised to transform the way industries utilize gear systems, setting new standards for efficiency, reliability, and sustainability.For more information about the revolutionary Worm and Bevel Gear partnership and the forthcoming gear system, please visit [Company website] and get ready to witness the future of mechanical engineering.

Customizable Multi Turn Worm Gearboxes: High-quality and Affordable Solutions for Your Business

China Multi Turn Worm Gearbox Factory Boosting China's Industrial FutureChina is experiencing a phenomenal trend in the development and advancements of technology in the last decade. From the consumer electronics to robotics, continuous investments have enabled the country to transition from a low-cost manufacturing hub to a high-tech industrial powerhouse. One sector that has been crucial in this growth is the machinery industry, which produces equipment and tools necessary for manufacturing processes. The China Multi Turn Worm Gearbox Factory is one of the companies that have been influential in enhancing China's machinery industry.Established in 1993, the China Multi Turn Worm Gearbox Factory is located in the beautiful city of Hangzhou, Zhejiang Province. The company's core focus is on the production of Multi Turn Worm Gearboxes, a crucial component in the machinery industry. Multi Turn Worm Gearboxes are widely applicable across different industries, including packing, printing, automobiles, textiles, food, and pharmaceuticals. The gearboxes help to improve the efficiency and accuracy of the machines, including cutting, rolling, winding, and other motion applications.As a leading Multi Turn Worm Gearbox manufacturer in China, the company has been innovating and customizing its products according to customers' requirements. The company has its research and development department with experienced engineers and technicians, who continuously develop new products to enhance the machinery industry. The factories produce, test, and assemble the gearboxes' different parts, ensuring quality and meeting production standards.Over the years, the China Multi Turn Worm Gearbox Factory has expanded its market presence worldwide, with a focus on the Asia-Pacific region, Europe, Latin America, and Africa. The company's annual sales revenues have been increasing its domestic and foreign market share. In 2020, the company achieved an annual sales turnover of USD 500 million, with more than 2700 employees.The company's success is attributable to its core values of innovation, quality, operational excellence, and customer satisfaction. The company's management believes that the gearbox industry's future will be more automated, digitalized, and smart in meeting the increasing demand for high-tech machinery. As such, the China Multi Turn Worm Gearbox Factory has been keen on integrating digital technologies such as Cloud, the Internet of Things (IoT), and Artificial Intelligence (AI) in their operations to enhance customer value and improve the quality of their products.In addition, the company has been environmentally conscious, as it has implemented measures aimed at reducing its carbon footprint, promoting sustainability and reducing waste. One of its initiatives includes using energy-efficient machines and processes, and it has installed solar panels to reduce its reliance on traditional energy sources.The China Multi Turn Worm Gearbox Factory's future outlook is promising, and it will continue to innovate and produce high-quality gearboxes. The company's management has placed a strategic plan to leverage the vast market potential, increasing domestic demand, and the "China Manufacturing 2025 plan," which aims to enhance the country's machinery industry. As a result, the company will diversify its product range, enhance its supply chain management, and expand its global market presence.In conclusion, the China Multi Turn Worm Gearbox Factory has been instrumental in China's machinery industry's growth and development. With its core values of innovation, customer satisfaction, quality, and operational excellence, the company has established itself as a market leader in the Multi Turn Worm Gearbox industry. Its expansion efforts and integration of digital technologies demonstrate its commitment to enhancing customer value, promoting sustainability, and being future-oriented. As China continues to transition into a high-tech industrial powerhouse, the China Multi Turn Worm Gearbox Factory is playing a vital role in the country's bright future.

Valve Company Plans to Sell Spare Parts for Customers' Convenience

Valve enthusiasts have something to be excited about as the latest brand of Spare Parts has entered the market. The company's offerings promise to simplify the customer experience while delivering top-quality Valve components. A relatively new player in the industry, the company has been making quite a buzz with rave reviews from its customers.While there is an abundance of brands offering Valve components, the Spare Parts (name removed) brand distinguishes itself with its unique approach towards customer satisfaction. The company believes that although Valve components might be complex and daunting for the average person, customers should be able to have an easy and satisfactory experience when purchasing and installing them.The company's mantra is reflected in their product line, as they offer an extensive range of Valve components covering everything from Strainer Valves to Pressure Relief Valves. All of their products are rigorously tested to ensure that they meet the highest possible standards of quality and efficiency.The brand boasts an impressive array of Valve components that cater to different customers’ requirements. These include ball valves, butterfly valves, gate valves, globe valves, and check valves, all of which are designed to handle various fluid control applications. Additionally, the company provides tailor-made products to meet the exact needs of customers.One of the brand's most significant strengths is their innovative approach to product design. The company leverages the latest technology advancements in the industry to ensure that their components are efficient, reliable, and easy to install. They also invest heavily in research and development to continue improving their products and make the installation process even more straightforward for customers.Another strength of the Spare Parts (name removed) brand is its customer-centric philosophy. The company recognizes the importance of providing a seamless and comprehensive customer experience to build lasting relationships with their clients. Spare Parts (name removed) values customer satisfaction as the top priority, and this is reflected in their customer service policies. Their teams of experts are always readily available to assist customers with technical queries or issues related to the installation process.Despite its relative youth in the industry, Spare Parts (name removed) has already established an extensive network of distributors across the world. This network guarantees that customers around the globe can obtain their products quickly and efficiently. The company has also set up an advanced logistics infrastructure, which enables them to deliver their products on time and efficiently to their customers.The Spare Parts (name removed) brand is also mindful of the impact of its products and services on the environment. The company is constantly working on developing environmentally friendly products, and they have implemented innovative processes to reduce their carbon footprint. They understand the importance of sustainability and strive to ensure that their products and processes are in compliance with industry regulations.In conclusion, fans of Valve components have a reason to be excited about the Spare Parts (name removed) brand. With their focus on customer satisfaction, innovative products, extensive product range and distribution network, the company has established itself as a leading player in the industry. Their unique approach, coupled with their commitment to sustainability, will undoubtedly pave the way for further growth and success for the brand.

Revolutionary Actuator Technology Set to Overhaul Industry Standards

Actuators are an essential component in the modern world of automation and control systems. In the case of industrial processes, a linear actuator refers to the devices that convert rotational motion into linear motion. An excellent example of such devices is the Neumax Actuator, which is tailored to a broad range of industrial applications.The Neumax Actuator is designed by professionals who have over the years accumulated vast experience in the industrial automation sector. The Neumax Actuator is designed with powerful, durable, and efficient components, ensuring that it meets the stringent demands of modern industrial processes.One of the most significant benefits of the Neumax Actuator is its flexibility and adaptability to a wide range of tasks. It has the ability to execute varied functions, including gate opening and closing in a water treatment facility, control of valves in pipelines, and regulation of pressure in chemical processing plants.The Neumax Actuator is also designed to ensure exceptional performance. It operates with a high level of precision and accuracy, which is essential for controlling processes with minimal error rates. Additionally, its robust design ensures that it can withstand extreme conditions such as harsh weather, high humidity, and mechanical strain.Another significant attribute of the Neumax Actuator is the low rate of maintenance required to keep the system in optimal condition. One of the major advantages of using the Neumax Actuator is the low rate of wear and tear of the components, which translates into reduced downtime and associated costs. Additionally, the operational parameters of the actuator are easy to monitor, making it easier to identify potential issues before they escalate into serious problems.The Neumax Actuator is also easy to install, which translates into reduced installation time and costs. The actuator can be customized to fit different system specifications, making it an ideal solution for many industrial automation processes.The Neumax Actuator is also designed to be energy efficient, reducing the overall cost of operation. The actuator is designed with components that consume less power, making it ideal for use in applications where energy efficiency is a priority.The Neumax Actuator is an excellent solution for different industrial settings, including oil and gas, food processing, and water treatment facilities. The actuator is tested and certified to meet international standards, ensuring that it meets the strict regulatory requirements.The company behind the Neumax Actuator boasts of an experienced and highly skilled team of professionals dedicated to producing high-quality industrial automation solutions. The company prides itself on its ability to deliver customized solutions tailored to the specific needs of each client.The company believes that investing in research and development is essential to provide innovative solutions that meet the evolving needs of clients. The Neumax Actuator is the product of years of research and development, aimed at providing a reliable and efficient solution to industrial automation.The company's commitment to quality is unwavering. It has established stringent quality control procedures at every stage of the production process, ensuring that every component that leaves the facility conforms to the highest quality standards.In conclusion, the Neumax Actuator is an innovative solution to industrial automation needs. It is designed with quality, efficiency, reliability, and flexibility in mind, making it an ideal solution for a wide range of industrial applications. The company behind the product is committed to delivering innovative solutions that meet the evolving needs of clients in the industrial automation sector. With the Neumax Actuator, clients can be assured of exceptional performance, energy efficiency, and a low rate of maintenance, translating into overall cost savings in the long run.

New Limit Switch Box Technology Now Available - Streamlining Industrial Processes

In the industrial world, there is no denying that safety is a top priority. With heavy machinery and equipment in use, workers need to remain safe while operating or maintaining these assets. In order to mitigate potential safety hazards, the use of limit switches has become an integral part of industrial processes. One such limit switch box that is making waves in the industry is Apl-210. Known for its reliability and simplicity, the Apl-210 limit switch box has quickly become a fan favorite among industrialists.This versatile switch box can be used in a myriad of industrial applications such as cranes, elevators, conveyors, packaging machines, and other automated machinery. The Apl-210 is housed in a compact yet rugged enclosure made from high-quality materials that provide superior resistance against harsh industrial environments. The housing is also designed to protect the internal components from dust, moisture, and other contaminants.One of the unique features of the Apl-210 limit switch box is its modular design. This design allows for quick and easy installation and maintenance. The switch box is comprised of various components that can be easily swapped out or replaced without the need for specialized tools or expertise. Moreover, the wiring of this limit switch box is easy to understand, making it simple to integrate into any application.The Apl-210 limit switch box is also known for its high-precision performance. It utilizes high-quality mechanical parts that allow for accurate and reliable switching. With its adjustable operating range, the limit switch box provides flexibility in its application. In addition, the switch box has a high degree of repeatability, ensuring the consistent operation of industrial equipment.The switch box is built with advanced safety features that ensure the safety of workers. It offers reliable protection against unexpected equipment movements, ensuring that workers remain safe during operation. Moreover, the APL-210 is designed to withstand extreme vibration and shock, which is a crucial factor in ensuring the longevity of the equipment.It is no surprise that the Apl-210 limit switch box has become a go-to solution for industrialists. Along with its exceptional performance, the company behind the product is renowned for its commitment to quality and excellent customer service. The company provides different customization options and works closely with its clients to provide tailored solutions that fit their unique needs. The Apl-210 limit switch box is a testament to the company's dedication to providing reliable and robust products to the industrial world.In conclusion, the Apl-210 limit switch box has set itself apart as a trusted safety solution for various mechanical and automated processes. With its mechanical precision, flexible application, and excellent safety features, it is no surprise that it has become a go-to solution for industrialists around the globe. With the product's reliable performance and the company's commitment to quality, it is evident that the Apl-210 limit switch box will continue to make waves in the industrial world for years to come.