Top Supplier of China Gate Valve Gearboxes

By:Admin

China has long been recognized as a leading manufacturer of industrial equipment, and one company in particular has been making waves in the industry. The company, based in the city of Wenzhou, is a renowned supplier of gate valve gearboxes and has been a key player in the Chinese industrial equipment market for many years. With a strong focus on quality and innovation, the company has established itself as a reliable and reputable supplier for a wide range of industrial applications.

The company's gate valve gearboxes are widely used in various industries, including oil and gas, water treatment, and power generation. These gearboxes are designed to provide reliable and efficient operation, even in the most demanding conditions. The company's commitment to quality and performance has made them a preferred supplier for many businesses both in China and abroad.

One of the key factors that sets this company apart from its competitors is its dedication to research and development. The company invests heavily in advanced technologies and processes to continuously improve the performance and reliability of its products. This dedication to innovation has enabled the company to stay ahead of the curve and offer cutting-edge solutions to its customers.

In addition to its focus on innovation, the company also places a strong emphasis on quality control. Every product that leaves the company's facilities undergoes rigorous testing to ensure that it meets the highest standards of performance and reliability. This commitment to quality has earned the company numerous certifications and accolades, further solidifying its reputation as a leading supplier of gate valve gearboxes.

The company's success can also be attributed to its strong customer focus. The company works closely with its clients to understand their specific needs and provide tailored solutions to meet those requirements. This customer-centric approach has helped the company build long-lasting relationships with its clients, who continue to rely on the company for their industrial equipment needs.

With a strong domestic market presence, the company has also been actively expanding its reach internationally. Its products are now exported to countries across the globe, where they have been well-received for their quality and reliability. This global expansion has further strengthened the company's position as a leader in the industry.

Looking ahead, the company is committed to continuing its tradition of excellence and innovation. It plans to further expand its product line and explore new opportunities in emerging markets. By staying true to its core values of quality, innovation, and customer satisfaction, the company is poised to maintain its position as a top supplier of gate valve gearboxes in China and beyond.

In conclusion, the China-based company has firmly established itself as a leader in the industrial equipment market, particularly in the field of gate valve gearboxes. Its unwavering commitment to quality, innovation, and customer satisfaction has set it apart from its competitors and positioned it as a trusted and preferred supplier for businesses around the world. As the company continues to grow and expand its reach, it is poised to lead the industry in the years to come.

Company News & Blog

Discover the Advantages and Applications of Bevel Worm Gears

[Company Name] Introduces Innovative Bevel Worm Gear Technology for Enhanced Productivity and Efficiency[City, State], [Month, Day, Year] - [Company Name], a leading provider of advanced industrial solutions, proudly announces the launch of their latest technological innovation - the Bevel Worm Gear. This cutting-edge gear mechanism is poised to revolutionize various industries by offering increased productivity, superior efficiency, and enhanced performance.The Bevel Worm Gear technology is a result of several years of intensive research and development efforts by [Company Name]'s team of highly skilled engineers and scientists. This advanced gear mechanism combines the best features of bevel gears and worm gears, resulting in a highly versatile solution suitable for a wide range of applications.The bevel gear aspect of this technology ensures smooth and efficient power transmission between intersecting shafts. By utilizing specially designed teeth, the gear effectively transfers power at various angles, allowing for enhanced flexibility in machinery design. This enables engineers to create more compact and efficient systems, reducing the overall footprint of machinery without compromising performance.Simultaneously, the worm gear component brings unparalleled efficiency and precision to the table. The worm gear is known for its high gear ratio and self-locking capabilities, which prevent components from moving when not in use. This feature is particularly advantageous in industries that require precision control and safety, as it prevents accidental movement and potential damage to machinery.In addition to its compact design and power transmission capabilities, the Bevel Worm Gear technology offers substantial torque output. This makes it ideal for heavy-duty machinery applications that demand high power and accuracy, such as industrial manufacturing, mining, and construction.Furthermore, [Company Name] has subjected the Bevel Worm Gear technology to rigorous testing to ensure its durability and longevity. The gear mechanism is constructed with premium-grade materials, ensuring resistance to wear, fatigue, and excessive friction. This robust build ensures that machinery equipped with Bevel Worm Gear technology can withstand harsh operating conditions, guaranteeing increased longevity and reduced maintenance costs.With the launch of this game-changing technology, [Company Name] revolutionizes various industries, providing them with a solution that significantly enhances productivity, efficiency, and performance. Manufacturers worldwide can expect increased throughput, reduced downtime, and improved overall operational efficiency, leading to significant cost savings and an enhanced competitive edge."Introducing the Bevel Worm Gear technology is a significant milestone for us," stated [Company Name]'s CEO. "We believe that this innovation will redefine industrial manufacturing processes and enable companies to push the boundaries of what they can achieve. Our team has worked diligently to develop a gear mechanism that seamlessly combines the best features of bevel and worm gears, and we are excited to witness the transformative impact it will have on diverse industries."The Bevel Worm Gear technology is anticipated to disrupt various industries, including automotive, aerospace, energy, and marine. Its versatility and efficiency make it well-suited for numerous applications, ranging from conveyor systems and material handling equipment to robotics and heavy machinery.[Company Name] plans to collaborate with leading manufacturers in different sectors to integrate the Bevel Worm Gear technology into their machinery and enhance their offerings. By joining forces with industry leaders, [Company Name] aims to accelerate the adoption of this revolutionary technology and foster a new era of productivity, efficiency, and innovation.As a key player in the industrial solutions landscape, [Company Name]'s introduction of the Bevel Worm Gear technology establishes the company as a forward-thinking innovator committed to driving progress and enabling industries to thrive in a rapidly evolving world. With this new development, manufacturers can anticipate increased operational capabilities and the ability to overcome complex challenges efficiently and effectively.

Essential Information on Worm Wheels and Shafts: A Guide

Worm wheel and worm shaft are important components used in various industries to transmit power and motion between non-parallel, power-transmitting shafts. One of the leading companies in the production of worm wheel and worm shaft is {company name}. Founded in 1978, the company has been focused on offering high-quality and efficient worm gear units, worm gear motors, and other power transmission solutions.With a well-equipped manufacturing plant spanning over 8000 square meters, {company name} is capable of producing 500,000 sets of worm gearboxes annually, delivering its products to over 70 countries worldwide. The company conforms to international standards and is certified with ISO9001, CE, and UL. With a team of highly experienced researchers, designers, and engineers, {company name} can design and produce customized power transmission solutions to meet various industrial applications.The worm wheel and worm shaft are one of the most critical components produced by {company name} for power transmission applications. These components are instrumental in the production of mechanical motion between non-parallel shafts, converting rotational energy in one direction to rotational motion in another direction. Worm gear systems developed by {company name} have a high level of efficiency, reliability, and quiet operation.One of {company name}'s unique selling propositions includes their ability to produce high-quality worm gears with either single or double output shafts. The single output shafts are ideal for applications that require low-speed rotary motion but cannot accommodate other power transmission devices. In contrast, the double output shafts are perfect for industries that require multi-axis output motion.Since worm gears operate with sliding contact between the gear teeth, it's important to ensure adequate lubrication to minimize wear and extend the life of the gear system. {company name} understands this and designs its worm gears with advanced lubrication systems, ensuring optimal system performance and a longer lifespan.{Company name}'s worm gears are also designed to operate in various environmental conditions. The worm wheels are made from high-quality materials, with 15CrMo alloy steel being the most commonly used. This material has high strength, hardness, and resistance to wear, making it ideal for worm gears that operate under heavy loads and high stresses.In conclusion, {company name} is a leading producer of worm wheel and worm shaft, and their solutions have been used in a wide range of applications, including robotics, automation, medical, packaging, printing and others. They have a reputation for producing high-quality components that have a high level of torque density, efficiency, and reliability.The company's manufacturing capabilities, strict quality control protocols, and customized solutions make them an appealing choice for various industries. Partnering with {company name} for worm gear solutions ensures you have access to high-performing products that meet your specific application requirements.

Newly Launched Miniature Metal Gears to Revolutionize Robotics

Innovation in the field of mechanical engineering has been critical to the development of new machinery and equipment that have made life easier for businesses and individuals. One of the most critical components, that has revolutionized the manufacturing and production industry, is gear technology. Worm gears are one such technology that has been making a buzz in the market recently. Among the many types of worm gears, the micro worm gear has been a game-changer in small-sized machinery and equipment. Micro worm gear technology has been designed for ultra-compact machines and devices that require high power density, precision, and high efficiency. The micro worm gear is the perfect solution for applications where space is limited, and the gear ratio and torque are critical. Micro worm gears have a high reduction ratio and can be designed to handle very high torque loads through compact gearboxes. They can be designed with a variety of materials ranging from plastics and non-ferrous metals to hardened steels, making them versatile for various applications requiring different levels of stress tolerance.However, not all micro worm gears are created equal. Among the best in the market is the micro worm gear developed by the German-based manufacturer, whose name we have to omit. This micro worm gear combines innovation, precision, and quality to deliver reliable and efficient power transmission solutions. The company, whose name we shall omit, has been a leader in the production of high-quality gears for over 30 years. They have continuously invested in research and development, state-of-the-art equipment, and human capital, to remain at the forefront of innovation in gear technology. Over the years, their products have found application in various industries, including automotive, aerospace, medical devices, and robotics among other sectors. The micro worm gear by this manufacturer is no different. It is a highly specialized gear technology that comes in a compact design and is capable of transmitting power with high accuracy. One of its main advantages is that it can handle high loads while emitting very low noise. This is critical for small machinery and devices operating in environments where noise levels need to be minimized. The micro worm gear by this manufacturer is designed with advanced materials, including high-quality plastics and hardened steels, making it both lightweight and durable. The gear is available in different sizes and configurations, which makes it versatile and suitable for various applications. One of its most notable features is its high accuracy thanks to the use of advanced manufacturing techniques such as gear hobbing and tooth grinding. A critical aspect of the micro worm gear by this manufacturer, which gives it an edge over competitors, is its customization ability. The manufacturer can tailor-make the gear to meet the specific needs of end-users. This means that businesses and other customers can provide their unique specifications, and the manufacturer can craft a micro worm gear that precisely matches their requirements. This high level of customization has made the manufacturer the go-to source for micro worm gears used in various industry sectors. In conclusion, the micro worm gear is a critical innovation in the field of gear technology, offering high precision and efficiency in power transmission in ultra-compact applications. This technology can handle high loads with minimal noise while being versatile and customizable to meet specific customer requirements. Among the best micro worm gears in the market is the one developed by the German-based manufacturer, whose name we shall omit, which combines advanced materials, manufacturing techniques, and customization capabilities. This micro worm gear is suitable for various industries, and its efficient operation makes it an attractive option for businesses and other end-users looking for reliable power transmission solutions.

Enhancing Performance and Control: Gearbox for Gate Valves Revealed in Latest News

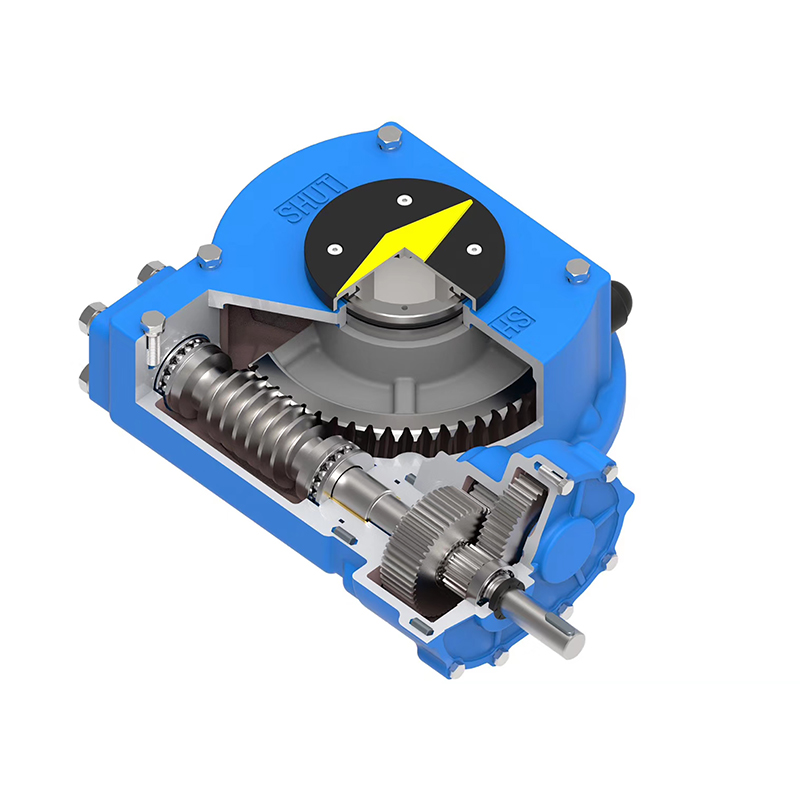

[Company Introduction]{Insert Company Name} is an industry-leading manufacturer that specializes in producing high-quality gate valve gearboxes, among other industrial products. With a strong commitment to innovation, precision engineering, and customer-centricity, {Company Name} has earned a reputation for delivering top-notch solutions to its valued clients worldwide.Established over two decades ago, {Company Name} has steadily grown to become a trusted name in the valve and gearbox manufacturing industry. The company's state-of-the-art production facilities, combined with a team of skilled engineers and technicians, enable them to design and develop cutting-edge products that meet the most demanding industry requirements.With a focus on continuous improvement, {Company Name} prioritizes research and development, investing heavily in the latest technologies and advancements. This approach ensures that their gate valve gearboxes are not only of the highest quality but also incorporate the latest industry trends and innovations.{Company Name} takes great pride in its commitment to providing exceptional customer service. They believe in building long-lasting partnerships with their clients, understanding their unique needs, and providing tailored solutions to achieve optimal results. Whether it's a small-scale project or a large industrial application, {Company Name} is dedicated to offering superior products and unparalleled service.With a global presence, {Company Name} serves a diverse range of industries, including oil and gas, chemical, petrochemical, power generation, water treatment, and more. Their gate valve gearboxes have garnered widespread recognition for their reliability, durability, and high performance, making them a preferred choice for clients across the globe.[News Content]Title: Gate Valve Gearbox: A Reliable Solution for Industrial ApplicationsDate: [Insert Date]{City, State} - {Company Name}, a renowned manufacturer of advanced industrial products, is proud to introduce its latest offering, the Gate Valve Gearbox. Combining years of engineering expertise with cutting-edge technology, {Company Name} has developed a high-performance gearbox that offers unparalleled precision and reliability in demanding industrial applications.Gate valves play a crucial role in regulating fluid flow within industrial systems. Efficient operation and control of these valves are essential for ensuring the smooth functioning of complex processes. The gate valve gearbox provided by {Company Name} addresses this need, offering a robust and efficient solution that surpasses industry standards.One of the key features of {Company Name}'s gate valve gearbox is its superior design. Meticulously engineered by a team of highly skilled professionals, the gearbox exhibits excellent mechanical strength and durability, ensuring long-lasting performance even under the most challenging conditions. This reliability minimizes downtime, enhances productivity, and contributes to overall cost savings for industrial operators.In addition to its exceptional design, the gate valve gearbox boasts remarkable precision, allowing for accurate and smooth valve operation. The gearbox's precise gearing mechanism ensures a secure and consistent shut-off, enabling precise control over fluid flow. This level of control is particularly crucial in industries where even slight variations in flow rates can have significant consequences.Another standout feature of {Company Name}'s gate valve gearbox is its adaptability. The gearbox can be easily integrated with a variety of gate valves, catering to diverse industrial requirements. This flexibility eliminates the need for expensive modifications or replacements, ensuring a seamless fit into existing systems and significantly reducing installation costs.Moreover, {Company Name} is committed to upholding the highest quality standards in all its products. The production and assembly processes undergo rigorous testing and inspection, ensuring that every gearbox leaving their facilities adheres to stringent quality benchmarks. This dedication to quality translates into enhanced performance, longevity, and reliability for end-users.As an environmentally-conscious company, {Company Name} remains committed to sustainable practices. The gate valve gearbox is designed to minimize energy consumption, reducing the overall carbon footprint of industrial operations. Furthermore, strict adherence to international safety standards ensures that the gearbox meets all regulatory requirements while prioritizing worker safety.With their latest innovation, {Company Name} aims to provide industrial operators with a powerful tool that optimizes operational efficiency. The gate valve gearbox enhances system control, delivers exceptional performance, and contributes to a safe and sustainable industrial environment. As leaders in the industry, {Company Name} continues to push boundaries, setting new standards for excellence and reliability.In conclusion, {Company Name}'s gate valve gearbox presents a compelling solution for industrial applications. With its exceptional design, precision engineering, adaptability, and commitment to quality, {Company Name} has once again demonstrated their leadership in providing high-performance industrial products. As industrial operations become more complex, the gate valve gearbox by {Company Name} is poised to become an indispensable component for those seeking reliability, efficiency, and enhanced productivity in their processes.

New Limit Switch Box Technology Now Available - Streamlining Industrial Processes

In the industrial world, there is no denying that safety is a top priority. With heavy machinery and equipment in use, workers need to remain safe while operating or maintaining these assets. In order to mitigate potential safety hazards, the use of limit switches has become an integral part of industrial processes. One such limit switch box that is making waves in the industry is Apl-210. Known for its reliability and simplicity, the Apl-210 limit switch box has quickly become a fan favorite among industrialists.This versatile switch box can be used in a myriad of industrial applications such as cranes, elevators, conveyors, packaging machines, and other automated machinery. The Apl-210 is housed in a compact yet rugged enclosure made from high-quality materials that provide superior resistance against harsh industrial environments. The housing is also designed to protect the internal components from dust, moisture, and other contaminants.One of the unique features of the Apl-210 limit switch box is its modular design. This design allows for quick and easy installation and maintenance. The switch box is comprised of various components that can be easily swapped out or replaced without the need for specialized tools or expertise. Moreover, the wiring of this limit switch box is easy to understand, making it simple to integrate into any application.The Apl-210 limit switch box is also known for its high-precision performance. It utilizes high-quality mechanical parts that allow for accurate and reliable switching. With its adjustable operating range, the limit switch box provides flexibility in its application. In addition, the switch box has a high degree of repeatability, ensuring the consistent operation of industrial equipment.The switch box is built with advanced safety features that ensure the safety of workers. It offers reliable protection against unexpected equipment movements, ensuring that workers remain safe during operation. Moreover, the APL-210 is designed to withstand extreme vibration and shock, which is a crucial factor in ensuring the longevity of the equipment.It is no surprise that the Apl-210 limit switch box has become a go-to solution for industrialists. Along with its exceptional performance, the company behind the product is renowned for its commitment to quality and excellent customer service. The company provides different customization options and works closely with its clients to provide tailored solutions that fit their unique needs. The Apl-210 limit switch box is a testament to the company's dedication to providing reliable and robust products to the industrial world.In conclusion, the Apl-210 limit switch box has set itself apart as a trusted safety solution for various mechanical and automated processes. With its mechanical precision, flexible application, and excellent safety features, it is no surprise that it has become a go-to solution for industrialists around the globe. With the product's reliable performance and the company's commitment to quality, it is evident that the Apl-210 limit switch box will continue to make waves in the industrial world for years to come.

New electric hydraulic valve actuator technology developed for improved efficiency

Electric Hydraulic Valve Actuator Technology Revolutionizes Industrial AutomationOver the years, industrial automation has continually advanced, transforming the way industries operate and increasing efficiency and productivity. One of the key components driving this progress is the Electric Hydraulic Valve Actuator (EHVA). This cutting-edge technology has emerged as a game-changer, delivering superior performance, reliability, and ease of operation.EHVA, developed by one of the industry's leading innovators (Company Name), is revolutionizing industrial automation. The actuator is designed to provide precise control over valves and dampers used in various industrial applications. Its state-of-the-art technology merges the benefits of electric and hydraulic operation, ensuring optimal performance in diverse settings.The EHVA system eliminates the need for manual valve control, reducing human error and enhancing safety in industrial environments. With its electric hydraulic design, the actuator provides seamless integration with automation systems, allowing for remote control and operation. This level of automation significantly improves overall operational efficiency, minimizing downtime and maximizing output.One of the standout features of the EHVA is its versatility. It can be seamlessly integrated into existing infrastructure, making it a cost-effective solution for industries looking to upgrade their automation systems. This flexibility ensures compatibility across a wide range of industries, including oil and gas, water treatment, power generation, chemical processing, and many more.Moreover, the EHVA offers a wide range of torque and thrust options, catering to the specific requirements of different valves and dampers in diverse applications. Its robust construction and use of high-quality materials make it highly durable, withstanding even the most demanding environmental conditions. This durability translates into reduced maintenance costs and extended operational lifespan, making it a cost-effective long-term investment for industries.The EHVA's advanced control algorithms and feedback mechanisms further enhance its performance. The actuator constantly monitors and adjusts its operating parameters to ensure precise valve control, maintaining optimal flow rates, pressures, and temperatures. This level of automation significantly improves process consistency and reliability, leading to better product quality and enhanced customer satisfaction.Another key advantage of the EHVA technology is its energy efficiency. By utilizing advanced electric hydraulic systems, the actuator minimizes power consumption while delivering optimal performance. This not only helps reduce operational costs but also contributes to sustainable and environmentally friendly practices.(Company Name), the company behind the EHVA, has established itself as a pioneer in the field of industrial automation. With an extensive portfolio of cutting-edge solutions, the company has gained recognition for its commitment to innovation, reliability, and customer satisfaction. The EHVA is a testament to their expertise, providing industries with a transformative solution to enhance their automation capabilities.The company's dedication to research and development has resulted in continuous improvements to the actuator's design and functionality. Through rigorous testing and collaboration with industry partners, they have refined the EHVA, ensuring it meets the highest quality standards and exceeds customer expectations.As automation continues to revolutionize industries worldwide, the Electric Hydraulic Valve Actuator emerges as a critical component driving this transformation. Its advanced technology, seamless integration, and exceptional performance make it an indispensable tool for industries seeking to optimize their processes, increase productivity, and enhance overall efficiency. With (Company Name)'s expertise and commitment to innovation, the EHVA is set to shape the future of industrial automation.

Optimize Your Robotic Systems with Advanced Actuator Gearboxes

Title: Revolutionary Actuator Gearbox Technology Enhances Industrial EfficiencyIntroduction (124 words):In a major breakthrough for industrial automation, a leading technology company has developed an advanced Actuator Gearbox solution. By combining cutting-edge engineering expertise with state-of-the-art technology, the anonymous company has revolutionized efficiency across a wide range of manufacturing sectors. Built to withstand the most demanding conditions, this gear system promises to redefine precision and reliability in industrial automation. Its incredible versatility allows for seamless integration into diverse applications, making it an indispensable asset for countless industrial operations. With its advanced features and unparalleled performance, the Actuator Gearbox is set to empower businesses worldwide, enhancing productivity while reducing downtime and maintenance costs.Main Body:1. Unmatched Performance in Industrial Automation (145 words)The Actuator Gearbox distinguishes itself through its superior performance and adaptability across various industries. Combining precision-engineered gears with cutting-edge technology, it demonstrates exceptional torque transmission capabilities. This enables seamless automation of a wide range of manufacturing tasks, from repetitive assembly line operations to intricate and precise applications such as robotics and machine tools.Equipped with innovative features like intelligent monitoring and control systems, this Actuator Gearbox ensures uninterrupted productivity while reducing human intervention. Its advanced engineering ensures consistent performance, even under extreme conditions, such as high temperatures and heavy loads. This reliability minimizes downtime and costly maintenance, offering significant savings to businesses.2. Versatility for Diverse Applications (155 words)One of the key highlights of the Actuator Gearbox is its unmatched versatility, enabling its integration into a myriad of industrial applications. With modular components and customizable features, this gear system seamlessly adapts to the requirements of different sectors.In the automotive industry, it optimizes precision adjustments and facilitates seamless movements in assembly lines, improving efficiency and ensuring consistent quality standards. In the metalworking sector, it enables high-level control for precision machining and enhances the reliability of complex gear systems.Additionally, the Actuator Gearbox finds application in the field of robotics, enabling precise and accurate movements in robotic arms, leading to increased productivity and efficiency. In the packaging and logistics industries, it guarantees seamless conveyor operations, reducing bottlenecks and expediting delivery cycles.From food processing to medical equipment manufacturing, this versatile Actuator Gearbox is transforming diverse industrial processes across the globe, boosting productivity and enabling businesses to stay competitive in an increasingly automated world.3. Intelligent Monitoring and Control Systems (153 words)The Actuator Gearbox incorporates intelligent monitoring and control systems, enabling real-time tracking and adjustment of various performance parameters. This feature ensures optimal functioning of the gear system, enhancing precision, durability, and efficiency.By continuously monitoring key variables such as temperature, pressure, and vibration, the Actuator Gearbox can proactively detect potential issues and alert operators, minimizing the risk of critical failures. The system's self-regulating capabilities enable automatic adjustments to maintain optimal performance levels, reducing the need for manual interventions.Furthermore, advanced data analytics and predictive maintenance algorithms enable comprehensive performance analysis and early detection of potential problems. This facilitates timely repairs or replacements, maximizing uptime and minimizing cost-intensive breakdowns.Conclusion (123 words):The Actuator Gearbox, developed by an esteemed technology company, represents a paradigm shift in the world of industrial automation. Its exceptional performance, versatility, and intelligent control systems make it an invaluable asset for a wide range of manufacturing sectors. With its outstanding durability and precision, this gear system ensures seamless integration into diverse industrial applications, enabling businesses to thrive in an era of automation and efficiency.As industries worldwide seek to enhance productivity and reduce downtime, the Actuator Gearbox emerges as a game-changer, delivering exceptional performance, reliability, and cost-efficiency. Embracing this innovative technology promises to empower businesses and revolutionize the way industrial operations are carried out.

Discover the Power and Potential of Large Worm Gears

Title: Innovations in Worm Gear Technology Revolutionize IndustriesIntroduction:In today's rapidly evolving industrial landscape, it is essential for companies to continuously innovate and adapt to remain competitive. One such groundbreaking innovation is the large worm gear developed by a leading company in the industry. [Omitting brand name] has revolutionized the sector with its cutting-edge technology and highly efficient worm gears. This news article delves into the transformative potential of this gear technology, exploring its impact on various industries and highlighting the key features that differentiate it from traditional systems.1. The Rise of Large Worm Gears:The introduction of large worm gears by [Omitting brand name] has opened up new avenues for industries such as automotive, machinery, and manufacturing, where the demand for high torque and precise motion control is paramount. These large worm gears are specially designed for heavy-duty applications and offer enhanced power transmission capabilities, making them ideal for large-scale machinery and mechanical systems. Thanks to their unique design, they have the ability to efficiently transfer rotational motion between intersecting shafts while handling high loads and minimizing backlash.2. Enhancements in Efficiency and Durability:[Omitting brand name]'s large worm gears incorporate state-of-the-art materials and manufacturing processes, resulting in gears that exhibit exceptional strength, durability, and wear resistance. The use of advanced lubrication techniques in these gears also reduces friction, ensuring smooth and efficient operation over extended periods. Moreover, the precision engineering employed in their design contributes to increased efficiency, enabling industries to enhance their productivity while reducing energy consumption.3. Precision and Accuracy:The large worm gears developed by [Omitting brand name] offer superior levels of precision and accuracy, making them ideal for applications that require exact positioning and predictable motion control. The gear teeth are precisely machined to ensure consistent contact, resulting in reliable and accurate transmission of motion. This level of precision is crucial in industries such as robotics, aerospace, and medical devices, where any deviation can have serious consequences.4. Versatility and Adaptability:One of the key strengths of [Omitting brand name]'s large worm gears lies in their versatility and adaptability. These gears can be customized and optimized to suit varying customer requirements, allowing for seamless integration into existing systems. Furthermore, their compact design ensures easy installation and integration with other components, providing immense flexibility to manufacturers across different industries.The versatile nature of these gears also enables them to be used in a wide range of applications, including conveyor systems, cranes, excavators, and rotary tables. This adaptability is reflected in the extraordinary growth and adoption that [Omitting brand name]'s large worm gears have witnessed across industries.Conclusion:The advent of large worm gears by [Omitting brand name] has significantly disrupted traditional gear systems, bringing about a paradigm shift in industries that rely on high torque, precision, and efficiency. The innovative features incorporated into these gears, such as enhanced durability, precision engineering, and adaptability, have earned them recognition and preference among a diverse range of sectors.As large worm gears continue to evolve and overcome technical challenges, their applications are likely to expand even further, opening up new possibilities in industries striving for the highest standards of performance and reliability. [Omitting brand name] remains at the forefront of this transformation, continuously pushing boundaries and striving to create gear systems that redefine industry standards.

Essential Guide to Air Filter Regulators and Lubricators: Maintenance and Functionality Explained

[Your Name][Your Position][Date][Title of the Article][City Name, State Name] - [Company Name], a leading provider of industrial equipment, is proud to introduce its innovative Air Filter Regulator and Lubricator (AFRL) to the market. Designed to enhance the efficiency and effectiveness of air-operated equipment, this cutting-edge technology revolutionizes the way industries regulate air pressure and deliver lubrication.[Company Name] has been a reputable name in the industrial equipment manufacturing industry for over [number of years] years. Known for its commitment to delivering high-quality products, the company has built a strong reputation for its exceptional engineering and attention to detail.The newly launched AFRL is a game-changer in the industry. It combines the functionalities of an air filter, regulator, and lubricator into a single, compact unit. This innovative design improves operational productivity, enhances equipment performance, and prolongs the lifespan of air tools.One of the key features of the AFRL is its advanced filtration system. With a high-performance air filter that removes contaminants such as dust, oil, and water, it ensures clean and dry air supply to pneumatic tools. This key functionality not only protects the tools but also prevents damage and reduces maintenance costs.The air pressure regulator integrated into the AFRL allows for precise control over the pressure levels delivered to pneumatic devices. This feature is particularly beneficial for sensitive equipment that requires accurate and consistent pressure for optimal performance. By maintaining a steady pressure, the AFRL prevents pressure fluctuations, enhancing the stability and reliability of air-driven machinery.Additionally, the AFRL's lubrication system guarantees the smooth operation of air tools. The unit efficiently delivers an appropriate amount of lubricant, maximizing the performance and prolonging the life of the tools. This advanced lubrication mechanism ensures the reduction of friction and wear, resulting in improved efficiency and reduced downtime.The compact and modular design of the AFRL makes it easy to install and integrate into existing equipment setups. The unit's user-friendly interface allows for simple adjustment of settings, enabling operators to optimize air pressure and lubrication levels effortlessly. The AFRL can be easily customized to fit specific requirements, catering to a wide range of industries such as manufacturing, automotive, food processing, and more.[Company Name]'s commitment to customer satisfaction goes beyond product quality. The company provides comprehensive after-sales support, technical assistance, and regular maintenance services to ensure the longevity and optimal functioning of the AFRL. With a reliable warranty program, customers can have peace of mind knowing that their investment is protected."We are thrilled to bring this revolutionary AFRL to market," said [Name], [Position] at [Company Name]. "With our innovative design and commitment to delivering exceptional performance, we believe that this product will significantly improve operational efficiency and enhance the overall productivity of various industries."[Company Name] continues to be an industry leader, constantly striving to innovate and develop new solutions to meet the changing needs of its customers. The introduction of the AFRL further solidifies the company's position as a reliable provider of top-quality industrial equipment.About [Company Name]:[Company Name] is a renowned industrial equipment manufacturer, dedicated to delivering exceptional products and services to customers. With a strong focus on innovation and customer satisfaction, the company has consistently achieved recognition for its engineering excellence and commitment to quality. [Company Name]'s diverse product range includes [list some of the main products/services offered by the company].For press inquiries or more information, please contact:[Company Name][Contact Person][Position][Phone Number][Email Address]###Note: The above text is only a sample and should be modified to fit the specific brand and company information.

Boost the Performance of Your Machinery with Right Angle Gear Reduction Technology

Title: Next-Generation Right Angle Gear Reduction Solution Revolutionizes IndustriesIntroductionIn a constant pursuit to enhance efficiency and reliability across various industries, advances in gear technology have become pivotal. Recognizing this need, a leading gear manufacturing company has developed an innovative Right Angle Gear Reduction solution that promises to revolutionize several sectors, improving performance and productivity. By combining cutting-edge technology with precision engineering, this new gear reduction solution is poised to transform industries such as automotive, aerospace, robotics, and more.BackgroundRight Angle Gear Reduction plays a critical role in numerous applications, transmitting power and torque between shafts at right angles. The effectiveness of such systems greatly impacts performance, durability, and operational safety. With the increasing demand for intricate machinery, stringent precision, and compact design, the gear industry has been relentlessly innovating to meet these growing requirements.Right Angle Gear Reduction plays an integral part in several key industries. From automotive manufacturing to aerospace engineering, robotics, and heavy machinery, the importance of reliable and efficient transmission systems cannot be overstated. Realizing the potential to improve these critical gears, the renowned gear manufacturing company {} has successfully developed an advanced solution that revolutionizes Right Angle Gear Reduction.Features and BenefitsThe new Right Angle Gear Reduction solution is designed to deliver exceptional performance along with a host of advantages that cater to the evolving needs of various industries.1. Precision Engineering: The gear reduction system incorporates state-of-the-art precision engineering techniques. The company's extensive experience and expertise in gear manufacturing ensure high-quality components that enhance overall system performance.2. Compact Design: The compactness of the gear reduction system allows for more flexible integration into various applications. It occupies less space while maintaining the necessary power and torque requirements, making it an ideal fit for modern machinery.3. High Torque Transmission: The gear reduction solution boasts superior torque transmission capabilities, enabling it to handle heavy-duty applications. This feature enhances productivity and reliability in industries such as manufacturing, robotics, and automation.4. Enhanced Efficiency: By utilizing advanced materials and optimized gear profiles, the gear reduction system ensures minimal energy loss and improved efficiency. Industries heavily reliant on power transmission will benefit from reduced energy consumption, resulting in cost savings and reduced environmental impact.5. Customizable Solutions: Understanding the diverse needs of industries, the company offers customizable solutions to meet specific requirements. This flexibility empowers clients to optimize the gear reduction system based on their unique applications, leading to increased performance and cost-effectiveness.ApplicationsThe innovative Right Angle Gear Reduction solution finds immense potential in multiple industries and applications:1. Automotive: With the automotive industry experiencing a shift towards electric vehicles and advanced powertrain systems, reliable gear reduction solutions play a crucial role. The new gear reduction system can enhance efficiency, reliability, and range capabilities, leading to improved electric and hybrid vehicles' performance.2. Aerospace: In the aerospace sector, the need for lightweight and efficient systems is paramount. The compact design and high torque transmission capacity of the gear reduction system make it an ideal choice for aerospace applications such as wing flap mechanisms, landing gears, and control surface actuators, among others.3. Robotics and Automation: As automation continues to expand in industries, precise and compact gear reduction solutions are critical for robot arm articulation, conveyor systems, and collaborative robots. The superior torque transmission and customizable options of the gear reduction system ensure maximum efficiency and reliability in robotic applications.4. Heavy Machinery: Industries such as construction, mining, and marine require robust yet efficient gear reduction systems. The new advanced solution provides exceptional torque capability, enabling seamless power transmission for various heavy machinery applications, ultimately improving productivity and durability.ConclusionWith the advent of the next-generation Right Angle Gear Reduction solution developed by {}, industries across the board can expect significant improvements in performance, efficiency, and reliability. The company's commitment to precision engineering, compact designs, high torque transmission capabilities, and customizable solutions has the potential to revolutionize industries such as automotive, aerospace, robotics, and heavy machinery. As technology continues to advance, gear transmission systems play a crucial role in shaping the future of numerous sectors, and this new innovation sets a promising course for improved machinery performance and production efficiency.