The Ultimate Guide to Automated Ball Valve Actuators: A Complete Overview

By:Admin

[Company Name], a pioneer in industrial automation technologies, has introduced its groundbreaking Automated Ball Valve Actuator, a state-of-the-art solution that is set to revolutionize numerous industries around the world. This cutting-edge technology is designed to enhance productivity, efficiency, and safety, making it a game-changer for businesses seeking to optimize their processes.

The Automated Ball Valve Actuator from [Company Name] combines precision engineering with intelligent control systems to offer unparalleled reliability and performance. This actuator provides seamless automation for ball valves, allowing for precise control of flow and pressure in a wide range of applications, including oil and gas, water treatment, chemical production, and manufacturing.

One of the standout features of this innovative product is its adaptability. The Automated Ball Valve Actuator is compatible with both new installations and retrofits, seamlessly integrating with existing infrastructure. Its flexible design allows it to operate in diverse environments, including extreme temperatures and corrosive conditions, making it a highly versatile choice for industrial facilities.

Safety is paramount in industrial settings, and the Automated Ball Valve Actuator addresses this concern through its advanced safety features. This technology incorporates redundant systems to ensure failsafe performance, reducing the risk of accidents, leaks, and other potentially hazardous incidents. Furthermore, the actuator's intelligent control system enables remote operation, minimizing workers' exposure to dangerous environments.

Efficiency is another significant advantage that the Automated Ball Valve Actuator brings to the table. Its precise control mechanism allows for accurate regulation of flow rates, ensuring optimal performance and reducing energy costs. By automating the valve control process, businesses can improve operational efficiency, minimize downtime, and optimize resource utilization.

The integration of smart technology sets [Company Name]'s Automated Ball Valve Actuator apart from its competitors. This actuator leverages cutting-edge Internet of Things (IoT) capabilities, enabling real-time monitoring and control from anywhere in the world. With this feature, industrial operators can remotely access valve performance data, receive alerts, and fine-tune valve settings, enhancing maintenance practices and troubleshooting efforts.

Beyond the core functionality, this automated actuator also offers a user-friendly interface. The control system is intuitive and easy to operate, ensuring that businesses can quickly adopt and implement this technology in their day-to-day operations. Furthermore, [Company Name] provides comprehensive training and support to customers, guaranteeing a smooth transition to the Automated Ball Valve Actuator.

The introduction of the Automated Ball Valve Actuator comes at a time when industries across the globe are striving for greater efficiency, sustainability, and safety. By leveraging advanced automation technology, businesses can overcome operational challenges, reduce costs, and enhance their competitiveness in the global market.

[Company Name] is committed to continuously improving and refining its products to meet the evolving needs of customers. With its expertise in industrial automation and a customer-centric approach, the company is poised to lead the way in introducing innovative solutions that transform industrial processes.

In conclusion, the Automated Ball Valve Actuator from [Company Name] is a game-changing product that combines precision engineering, intelligent control systems, and advanced safety features. Its adaptability, efficiency, and integration of smart technology make it an indispensable asset for various industries worldwide. [Company Name]'s commitment to providing exceptional support further solidifies its position as a reliable partner in industrial automation.

Company News & Blog

Mounting Bracket for Valve - The Latest Development in Valve Technology

Valve Mounting Bracket Launches: A Revolution in GamingValve, one of the leading companies in the gaming industry, has recently launched a new product that promises to revolutionize the way gamers play their favorite games. The Valve Mounting Bracket is a simple but powerful tool that allows gamers to mount their Steam machine to the back of their TV or monitor, freeing up space and improving the overall gaming experience.“We are thrilled to introduce the Valve Mounting Bracket to the gaming community,” said Gabe Newell, the founder and CEO of Valve. “We believe that this product will enhance the way gamers play their favorite games and make the gaming experience more enjoyable and convenient.”The Valve Mounting Bracket is a small, sleek device that is designed to fit onto the back of a TV or monitor using VESA mounting points. It is compatible with all Steam machines and is easy to install, requiring only a screwdriver and a few minutes of your time.With the Valve Mounting Bracket, gamers no longer need to have a separate standalone console taking up valuable shelf space. Instead, they can simply attach their Steam machine to their TV or monitor and enjoy a streamlined gaming experience. This also eliminates the need for messy cords and cables that can clutter a gaming station.The Valve Mounting Bracket is also great for gamers who prefer to play in a living room or family room setting. By mounting their Steam machine to the back of the TV, gamers can enjoy a more immersive gaming experience without the need for a bulky, separate console.“I’ve been using the Valve Mounting Bracket for a few weeks now and I absolutely love it,” said Adam, a gamer from New York. “It’s so convenient to have my Steam machine mounted to the back of my TV. My gaming station is much cleaner and organized now, and I can play my favorite games with ease.”The Valve Mounting Bracket is just the latest product from Valve, a company that is known for its innovative and cutting-edge gaming technology. Founded in 1996, Valve has been at the forefront of the gaming industry for decades, developing popular games such as Half-Life, Portal, and Team Fortress, as well as the Steam digital distribution platform.Valve’s focus on innovation and customer satisfaction has made it one of the most beloved companies in the gaming community. The Valve Mounting Bracket is just one example of the company’s commitment to providing gamers with the best possible experience.“We believe that our customers deserve the very best, and we are always working to provide them with the most innovative and cutting-edge gaming technology available,” said Newell. “The Valve Mounting Bracket is just the latest example of our commitment to excellence, and we hope that gamers everywhere will enjoy using it as much as we do.”With the Valve Mounting Bracket, gamers can look forward to a more streamlined, convenient, and immersive gaming experience. Whether you prefer to play in a living room or a home office, this product is sure to enhance your gaming setup and make your favorite games even more enjoyable. So what are you waiting for? Get your Valve Mounting Bracket today and start gaming like a pro!

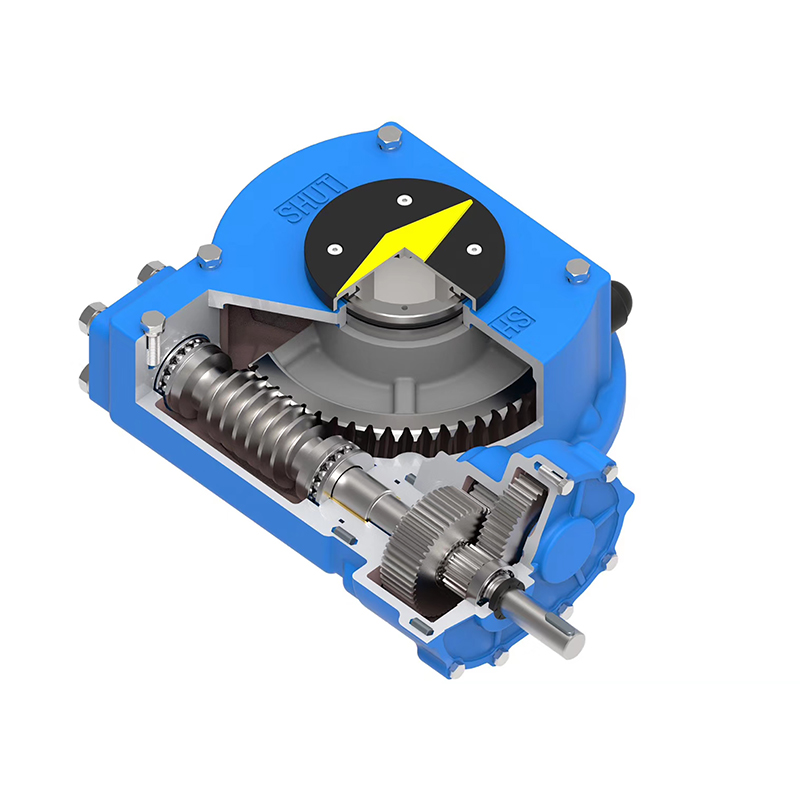

Heli Worm Gearbox: A Remarkable Advancement in Gear Technology

As technology continues to advance, more and more industries are benefiting from technological advancements, and the agriculture industry is not left behind. With the introduction of Heli Worm Gearboxes, the agricultural sector can now enjoy improved efficiency and productivity as well as greater cost savings.Heli Worm Gearboxes is a product of Heli Transmission, a company that has been in operation for over 27 years. The company prides itself on using advanced technologies to produce durable and high-quality products that meet the needs of its clients. Heli Transmission has established a reputation for producing high-performance products, and its Heli Worm Gearbox is no exception.Heli Worm Gearboxes have been designed to withstand some of the toughest working conditions on farms and other agricultural settings. These gearboxes are essential in the operation of farm machinery such as harvesters, plows, cultivators, and sprayers. The gearboxes are used to transmit power from the tractor engine to other farm equipment while regulating the speed of the equipment.One significant advantage of Heli Worm Gearboxes is their efficiency. These gearboxes are designed to convert high-speed, low-torque power to low-speed, high-torque power. This makes them particularly useful in heavy-duty farming settings, where high torque output is required to operate machinery such as cultivators, seed drills, and soil aerators. By reducing the speed of the engine, Heli Worm Gearboxes help save fuel and reduce the rate of wear and tear on the equipment.Heli Worm Gearboxes are made using high-grade materials that make them highly durable and reliable. The company guarantees long service life for all its products, and the Heli Worm Gearboxes are no exception. The gearboxes are designed to operate with minimal maintenance, and this translates to lower costs for farmers who use them.The design of Heli Worm Gearboxes incorporates a housing that encloses the gears and bearings. The housing protects the gears and bearings from external elements such as dust, moisture, and air pollution. This ensures that the gears and bearings are well lubricated and protected from wear and tear. Furthermore, the housing also acts as a heat sink that dissipates heat generated by the gearbox. This helps to maintain optimal temperature, preventing overheating, which can cause damage to the gearbox.One other advantage of Heli Worm Gearboxes is their versatility. These gearboxes come in various sizes and designs that can be customized to suit the needs of different farming scenarios. Farmers can choose the appropriate gearbox that will provide optimal performance while ensuring that it meets the requirements of the machinery being used.In conclusion, Heli Worm Gearboxes offer many advantages that make them the ideal choice for farmers. These gearboxes are designed to provide efficient power transfer, durability, and versatility. They are well-constructed and designed to withstand the tough conditions of farming, while ensuring that machinery operates at peak performance. Heli Worm Gearboxes represent a significant investment by farmers, with the assurance of long service life and cost savings that come with efficient and reliable performance. The Heli Worm Gearbox is truly a valuable addition to any farming operation.

Enhance Your Machinery with High-Quality Electric Actuators for Maximum Efficiency

Title: Groundbreaking Electric Actuator Revolutionizes Industrial AutomationIntroduction:In today's rapidly evolving industrial landscape, technological advancements continue to redefine efficiency and productivity. The latest innovation making waves in the automation sector is the cutting-edge Electric Actuator developed by a pioneering company (remove brand name), offering unprecedented precision and control. With applications ranging across diverse industries such as manufacturing, energy, and transportation, this revolutionary actuator is poised to transform industrial automation processes, optimizing productivity while reducing costs and environmental impact.Electric Actuator: Unleashing a New Era of Precision and ControlThe Electric Actuator, developed by (remove brand name), is an advanced electromechanical device designed to replace conventional pneumatic and hydraulic actuators, offering significantly improved precision, control, and reliability. With its compact and lightweight design, it is adaptable to a wide range of industrial operations, from valve control to material handling, robotics, and even 3D printing.Enhanced Precision and Control:Owing to its high-precision servo motor drive system, this Electric Actuator can deliver unparalleled positional accuracy and repeatability. By eliminating the traditional drawbacks associated with pneumatic and hydraulic systems, such as air leaks, pressure loss, and unpredictable performance, it ensures enhanced control over critical operations. Industrial processes dependent on precise movement, alignment, and positioning will greatly benefit from the increased accuracy and repeatability offered by this groundbreaking technology.Efficiency and Energy Savings:The Electric Actuator boasts remarkable energy efficiency, providing substantial cost savings to industries grappling with rising energy costs and environmental concerns. Its variable speed control, along with minimal energy loss during operation, leads to a significant reduction in energy consumption, ultimately resulting in a greener and more sustainable manufacturing environment. Moreover, the elimination of costly and maintenance-intensive hydraulic or pneumatic systems brings about substantial cost-cutting benefits, enhancing the overall cost-effectiveness of industrial operations.Remote Monitoring and Control:The incorporation of cutting-edge digital technology enables the Electric Actuator to be seamlessly integrated into Internet of Things (IoT) platforms. This empowers industries to monitor and control their operations remotely, even from a centralized control room. Real-time data feedback, preventive maintenance diagnostics, and predictive failure analysis capabilities prevent unexpected downtime, boosting operational efficiency and reducing production losses.Adaptability and Customization:Recognizing the diverse needs of different industries, the Electric Actuator offers a flexible framework that can be easily customized to suit specific application requirements. The actuator's operating parameters, force range, speed, stroke length, and various control interfaces can all be tailored to match the industrial processes, ensuring optimal performance and compatibility.Safety and Reliability:Reliability is a crucial aspect of any industrial automation technology, and the Electric Actuator meets the highest safety and durability standards. Equipped with advanced safety features such as overload protection and emergency stop functionality, it ensures worker safety while preventing costly accidents and equipment damage. Additionally, the Electric Actuator exhibits exceptional resistance to harsh environmental conditions, guaranteeing a long lifespan and minimal maintenance requirements.Future Outlook:As industries across the globe grapple with the challenges of increasing productivity while reducing environmental impact, the Electric Actuator developed by (remove brand name) offers a game-changing solution that addresses these concerns head-on. With its unparalleled precision, control, efficiency, and adaptability, this innovative technology holds immense potential for revolutionizing industrial automation across a wide range of sectors. By enabling industries to optimize their operations, streamline processes, and reduce costs, the Electric Actuator is poised to lead the next generation of industrial automation.

A Comprehensive Guide to Worm Type Gearboxes: Key Features and Applications

[Assistant]Title: Cutting-Edge Worm Type Gearbox Revolutionizes Industrial AutomationIntroduction:In the world of industrial automation, technology advancements have played a pivotal role in enhancing productivity and efficiency. One such breakthrough, the Worm Type Gearbox, has been making waves in the industry, promising to revolutionize manufacturing processes. This cutting-edge technology, developed by a leading company in the field, offers unprecedented accuracy, durability, and reliability. Let us delve deeper into this game-changing innovation and explore its potential impact on various sectors.Company Introduction:Established in the early 1990s, the company behind the Worm Type Gearbox has been at the forefront of delivering groundbreaking solutions for industrial automation. With a strong emphasis on research and development, they have consistently pushed the boundaries of technological innovation. Over the years, the company has earned a reputation for developing high-quality, reliable, and efficient products that cater to a diverse range of industries, such as automotive, manufacturing, energy, and aerospace.Innovation Description:The Worm Type Gearbox represents a significant leap forward in industrial automation. It offers a unique configuration, combining worm gears with a compact design, resulting in a highly efficient and versatile solution. The gears within the gearbox are meticulously engineered to ensure optimal engagement, reducing friction and maximizing power transmission efficiency. This breakthrough technology allows for smooth and precise control over rotational motion, making it an ideal choice for applications requiring accuracy and reliability.Key Features and Benefits:1. Unparalleled Durability: The Worm Type Gearbox's design incorporates high-quality materials and an innovative sealing system, ensuring long-lasting performance even in harsh and demanding industrial environments. This durability translates into reduced maintenance costs and increased uptime for manufacturers.2. Enhanced Efficiency: The worm gears' design reduces rotational speed while increasing torque, resulting in improved efficiency and power transmission. This efficiency enhancement allows for reduced energy consumption, a crucial factor in achieving sustainable manufacturing practices.3. Compact and Lightweight: The compact nature of the Worm Type Gearbox makes it ideal for installations in space-constrained environments. Additionally, its lightweight construction facilitates easy integration into existing machinery and systems, minimizing downtime during implementation.4. Quiet Operation: The gearbox's meticulously engineered gears and advanced damping technology contribute to quiet and vibration-free operation. This feature is particularly valuable in noise-sensitive industries, such as automotive manufacturing, where a peaceful working environment is crucial.Applications and Industries:The Worm Type Gearbox finds applications in various industries, each benefiting from its unique capabilities:1. Automotive Manufacturing: The precision and accuracy of the gearbox make it an excellent choice for robotic arms, conveyor belts, and assembly line equipment, ensuring seamless and efficient operations.2. Manufacturing and Warehousing: The compact design and durability of the gearbox make it suitable for heavy-duty machinery, such as conveyor systems, packaging equipment, and sorting machines, optimizing productivity in manufacturing and warehousing settings.3. Energy and Renewable Sources: The Worm Type Gearbox's ability to handle high torque loads efficiently makes it ideal for wind turbine systems, solar tracking systems, and hydropower stations, contributing to the efficient production and utilization of renewable energy.4. Aerospace and Defense: The gearbox's reliability and precision are essential in critical aerospace and defense applications, such as missile guidance systems, unmanned aerial vehicles, and satellite deployment mechanisms.Conclusion:The Worm Type Gearbox, developed by {Company}, is an innovation that raises the bar for industrial automation technology. With its unique configuration, unparalleled durability, and efficiency, this gearbox is set to transform manufacturing processes across diverse industries. As companies strive for increased productivity, reduced maintenance costs, and sustainable practices, this breakthrough technology promises to deliver on all fronts. With its widespread applications and industry-leading features, the Worm Type Gearbox is poised to shape the future of industrial automation.

Discover the Advantages of Electric Actuated Ball Valves for Efficient Control

Title: Revolutionary Electric Actuated Ball Valve Redefines Industry StandardsIntroduction:In recent years, technological advancements have revolutionized various industries and brought about significant improvements in efficiency and performance. One such breakthrough innovation is the Electric Actuated Ball Valve, developed by a pioneering company in the field of valve automation and control systems. This groundbreaking product promises to redefine industry standards by offering unparalleled precision, control, and reliability. Manufacturers across multiple sectors are eagerly adopting this technology, recognizing the significant benefits it can bring to their operations.Key Features and Benefits:The Electric Actuated Ball Valve showcases a host of remarkable features that set it apart from traditional valve systems. The company’s unwavering commitment to quality and innovative design is evident in this cutting-edge solution. Here are some key features and benefits provided by this revolutionary valve:1. Enhanced Precision and Control: With the integration of advanced electric actuation technology, this valve ensures precise control over fluid flow, allowing for swift and accurate adjustments. This leads to improved operational efficiency and reduces the risk of costly errors or delays.2. Versatility and Adaptability: The Electric Actuated Ball Valve is designed to accommodate a diverse range of applications, making it highly versatile. Its adaptability allows for seamless integration into existing systems and the ability to meet various operational requirements across industries, including oil and gas, water treatment, chemical processing, and many others.3. Unmatched Reliability: The valve’s robust construction, utilizing high-quality materials, ensures exceptional dependability even in demanding environments. The company’s rigorous quality control measures guarantee durability, longevity, and minimal maintenance requirements, resulting in significant cost savings for customers.4. Improved Safety Measures: Safety has always been a primary concern in industrial applications. This electrically actuated valve incorporates fail-safe mechanisms, ensuring reliable shut-off in emergencies and preventing potential disasters. By prioritizing safety, the valve alleviates concerns and instills greater peace of mind among operators and personnel.5. Advanced Monitoring and Reporting: The integration of intelligent automation technology allows for seamless monitoring and data acquisition. This feature enables real-time feedback on crucial parameters such as pressure, temperature, and flow rates. The valve system can share this information with centralized control systems, facilitating proactive maintenance and resource optimization.Market Impact and Industry Outlook:The Electric Actuated Ball Valve is poised to reshape the valve automation landscape and disrupt conventional practices in multiple industries. This revolutionary technology is rapidly gaining traction, with installation rates surging across diverse sectors globally. The valve’s potential to enhance operational efficiency, reduce energy consumption, and optimize processes has not gone unnoticed, and it is expected to become a staple in modern industrial automation.With an increasing focus on sustainability and energy efficiency, the demand for smart valve solutions is set to skyrocket in the coming years. The Electric Actuated Ball Valve, with its advanced control capabilities and environmental-friendly features, is primed to take center stage. Manufacturers that adopt this cutting-edge technology will gain a competitive edge in their respective industries by significantly improving productivity, reducing costs, and mitigating risks.Conclusion:The advent of the Electric Actuated Ball Valve represents a groundbreaking milestone in the valve automation field. Its innovative design, remarkable functionality, and numerous advantageous features have positioned it as a game-changer in the industry. As more manufacturers embrace this technology, it will redefine industry standards and set new benchmarks for precision, control, and reliability. The future of valve automation is here, and it is undoubtedly electric.

Discover the Latest Innovation in Explosion-Proof Electric Actuator Technology

Explosion-Proof Electric Actuator Revolutionizes Industrial Safety MeasuresWith a steadfast commitment to innovation and industrial safety, a leading manufacturer (name removed) has recently unveiled its groundbreaking Explosion-Proof Electric Actuator. Designed to revolutionize the way industrial operations ensure worker safety in hazardous environments, this cutting-edge technology is set to transform the industry.To understand the significance of this breakthrough electric actuator, it is essential to delve into the company's rich history and dedication to creating solutions for industrial challenges. Established over three decades ago, (name removed) has consistently been at the forefront of developing innovative products that cater to the evolving needs of various industries. With an unwavering commitment to safety and reliability, the company has built a reputation as a trusted global supplier of industrial automation equipment.The introduction of the Explosion-Proof Electric Actuator represents a monumental milestone for the company. This state-of-the-art technology provides a robust and reliable solution for industrial applications requiring operations in potentially explosive atmospheres. By effectively eliminating the risk of electrical sparks or arcs that could trigger an explosion, this actuator ensures utmost safety in hazardous environments.A key feature of this revolutionary electric actuator is its compliance with global explosion-proof standards, making it suitable for use in a wide range of industries, including oil and gas, chemical processing, mining, and manufacturing. This compliance is critical in maintaining safe working conditions for technicians and operators, guaranteeing protection against the potential dangers posed by flammable gases, liquids, and dust.The Explosion-Proof Electric Actuator embodies a perfect synergy of robust construction and cutting-edge technology. Engineered with precision, its design incorporates high-quality materials that offer exceptional durability, guaranteeing a long service life even in the most challenging environments. Equipped with advanced automation capabilities, this actuator ensures precise control and seamless integration with various industrial systems.Installing the Explosion-Proof Electric Actuator promises to be a seamless process due to its modular design, facilitating easy integration into existing infrastructure. This ease of installation minimizes production downtime and ensures a swift transition to enhanced safety measures. Furthermore, the actuator's user-friendly interface enables operators to configure and monitor its performance effortlessly, reducing the complexity of operation.Central to its design is a comprehensive range of safety features tailored to protect against potential electrical hazards. Equipped with flame- and explosion-proof enclosures, the actuator successfully contains and dissipates any electrical energy safely, ensuring that any potential ignition sources are eliminated. Additionally, the actuator's robust seals and gaskets prevent hazardous substances from permeating the enclosure, preventing any further risks.In addition to its safety features, the Explosion-Proof Electric Actuator excels in performance. Its high torque output and precise positioning capabilities enable efficient and accurate control of valves, dampers, and other industrial devices. With the actuator's precise and reliable operation, industries can optimize their processes, enhancing productivity and reducing maintenance costs.With its newest innovation, the Explosion-Proof Electric Actuator, (name removed) once again demonstrates its leadership in industrial automation equipment. By introducing this ground-breaking technology, the company strives to raise the safety standards in hazardous environments worldwide. With its unparalleled reliability, advanced features, and compliance with global explosion-proof standards, this electric actuator is poised to become an indispensable asset to industries seeking to prioritize worker safety and productivity in challenging operating conditions.As the industry embraces this transformative electric actuator, (name removed) reinforces its commitment to driving innovation, revolutionizing industrial safety measures, and empowering businesses to thrive in hazardous environments securely. By staying true to their values, this innovative manufacturer continues to be a steadfast partner for industries navigating complex safety challenges, ensuring a brighter and safer future for all.

Revolutionary Innovation in the World of Turbine Wheels Discovered by Experts

Title: Revolutionary Turbine Wheel Redefines Renewable Energy Production Introduction:In a groundbreaking development in the field of renewable energy, a cutting-edge turbine wheel has been unveiled, promising to revolutionize power generation around the world. Developed by an innovative company specializing in energy solutions, this turbine wheel harnesses the power of wind and converts it into clean and sustainable electricity. With its unprecedented efficiency and design, this new technology offers a shining beacon of hope for a greener future.[Provide a brief description of the company, highlighting its specialization in energy solutions and commitment to sustainable development. Emphasize their dedication to research and innovation in order to bring about positive changes in the global energy landscape.]Body:1. Turbine Wheel Unveiled - A New Era for Renewable Energy:The new turbine wheel, developed by the pioneering energy solutions company, marks a significant milestone in renewable energy technology. Designed to capitalize on wind energy, this innovative turbine wheel has been engineered to maximize efficiency and output, setting it apart from conventional wind turbines.2. Unleashing the Power of the Wind:The turbine wheel boasts state-of-the-art aerodynamic features that enable it to harness a greater amount of energy from even the slightest breeze. Its unique design enhances wind capture, enabling a more consistent and reliable power generation. Harnessing wind energy has never been more efficient or reliable than with this groundbreaking turbine wheel.3. Increased Efficiency Revolutionizes Energy Production:With its advanced technology, the turbine wheel surpasses its predecessors in terms of energy production. Through meticulous engineering, the company has vastly improved the turbine's ability to convert wind energy into electricity, significantly increasing its overall efficiency. This leap in efficiency is a significant step towards the widespread adoption of renewable energy solutions.4. Versatile Applications Open New Horizons:Efforts have been made to make this revolutionary turbine wheel applicable to a myriad of environments. By adapting and customizing the wheel design, it can be effectively utilized in various locations with different wind conditions. This versatility opens up new possibilities for renewable energy production, making it accessible for regions previously deemed unsuitable for wind-power generation.5. Paving the Way for Sustainable Future:By harnessing the immense power of the wind, this turbine wheel contributes directly to minimizing CO2 emissions and reducing reliance on fossil fuels. The implementation of this advanced technology will accelerate the transition towards a cleaner and more sustainable energy future. The turbine wheel is a testament to the company's commitment to combating climate change and mitigating its environmental impact.6. Overcoming Challenges and Ensuring Reliability:One of the key challenges faced in the renewable energy sector is intermittency. To combat this issue, the turbine wheel is equipped with mechanisms that ensure uninterrupted power supply regardless of wind variations. This innovative feature guarantees a more stable electricity generation, promoting grid reliability and minimizing any fluctuations in energy supply.7. Economic Benefits and Job Creation:The widespread adoption of this turbine wheel technology has the potential to stimulate economic growth. Investments in renewable energy projects using this groundbreaking technology would not only drive down energy costs over time but also create a significant number of sustainable jobs, boosting local economies in the process.8. Collaborative Efforts and Future Prospects:To maximize the impact of this revolutionary turbine wheel technology, the energy solutions company is actively engaging in partnerships and collaborations with governments, businesses, and scientific institutions. By fostering a cooperative spirit and sharing knowledge, they aim to facilitate the integration of this innovative technology into existing energy infrastructures worldwide, accelerating the global transition towards sustainable power generation.Conclusion:The unveiling of this groundbreaking turbine wheel represents a significant milestone in the renewable energy sector. With enhanced efficiency, reliability, and versatility, this technology promises to revolutionize wind energy generation and pave the way for a cleaner and greener future. By harnessing the power of the wind, the turbine wheel offers hope for a sustainable world, advancing the global fight against climate change and fostering economic growth through job creation. The energy solutions company has proven its commitment to innovation and sustainable development, solidifying its position as a leading force in the renewable energy revolution.

Latest Update: Prominent Developer Collaborates with Renowned Gaming Company for Exciting Upcoming Project

The Limitations of Pneumatic Controls on Switches Revealed in Latest News Coverage

Pneumatic Controls Limit Switch Leads the Way in Industrial AutomationThe industrial automation sector has been revolutionized by the introduction of advanced technology and innovative solutions. Pneumatic Controls, a renowned industry leader, has recently unveiled their groundbreaking Pneumatic Controls Limit Switch. Widely acclaimed for its reliability, efficiency, and precision, this cutting-edge product is set to redefine automation processes across various industries.Pneumatic Controls has long been recognized as a frontrunner in the field of industrial control systems. The company's continuous commitment to research and development has resulted in a portfolio of products that consistently exceed customer expectations. With the launch of the Pneumatic Controls Limit Switch, the company aims to address the ever-increasing demand for advanced automation solutions, providing customers with a game-changing device that offers superior performance and robustness.The Pneumatic Controls Limit Switch boasts a host of features that set it apart from traditional control switches. One of its key attributes is its pneumatic actuation mechanism. This innovative design provides enhanced reliability and durability, allowing the switch to perform flawlessly even in harsh industrial environments. The pneumatic actuation also ensures a quick response time, making it ideal for high-speed processes where precision is crucial.Another remarkable feature of the Pneumatic Controls Limit Switch is its exceptional accuracy. Equipped with state-of-the-art sensing technology, this switch can detect even the slightest variations in movement or pressure, ensuring precise control and preventing errors. This level of accuracy improves overall efficiency and productivity, minimizing waste and optimizing operations.Furthermore, the Pneumatic Controls Limit Switch has been engineered to offer maximum versatility. With a wide range of configuration options and adjustable settings, this switch can be customized to suit specific automation requirements. Its modular design allows for easy integration with existing systems, reducing downtime and simplifying installation and maintenance processes.Safety is a paramount concern in industrial automation, and Pneumatic Controls understands this. The Pneumatic Controls Limit Switch is equipped with multiple safety features to ensure uninterrupted and secure operation. Built-in fail-safe mechanisms, redundant sensing systems, and comprehensive error monitoring capabilities provide peace of mind and help prevent accidents and system failures.The application range for the Pneumatic Controls Limit Switch is diverse and extensive. It can be utilized in various industries such as manufacturing, food processing, packaging, and automotive. Its compatibility with different control systems and protocols makes it a versatile choice for both small-scale operations and large-scale industrial facilities.Pneumatic Controls has gained a solid reputation in the market due to its exceptional customer service and support. The company's dedicated team of experts assists customers throughout the entire product lifecycle, from initial design and selection to installation and after-sales service. This commitment to customer satisfaction has earned Pneumatic Controls a loyal client base and positions them as a trusted partner in the industrial automation industry.With the introduction of the Pneumatic Controls Limit Switch, Pneumatic Controls has once again proven its commitment to innovation and excellence. This state-of-the-art control switch is set to revolutionize automation processes, offering unparalleled reliability, precision, and versatility. As industries continue to embrace automation solutions, Pneumatic Controls is leading the way in providing advanced and efficient products that empower businesses to thrive in the modern era of industrial control.

Different Types and Uses of Worm Wheel Gears Explained

The Worm Wheel Gear (WWG) is a unique and advanced technology that is revolutionizing the manufacturing industry. The WWG works by transmitting rotational motion at a right angle with the help of worm gear and wheel. This innovative design has made the WWG the go-to choice for companies that desire precision, efficiency and cost savings in their manufacturing processes.WWG is a product of German ingenuity and has been in existence for over 100 years. Today, it is widely used in the automotive industry, pharmaceuticals, food, and beverage, as well as numerous other industrial applications. The technology behind the WWG has been fine-tuned over the years to deliver maximum results with minimal human intervention.One of the greatest advantages of WWG is that it offers high torque capacity, making it ideal for applications requiring low speed, high torque requirements. Additionally, the WWG is less prone to damage from shock loading and can tolerate misalignment between the worm gear and the wheel. This has led to improved performance and durability and a decrease in downtime due to mechanical failures.The WWG is manufactured with high-quality materials and precision engineering, ensuring reliability and longevity. WWG manufacturers are consistently upgrading their technology to meet the industries’ ever-changing demands. For example, many producers have incorporated computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to increase accuracy, reduce waste, and decrease production time.As a responsible corporate citizen, a reputable company has ventured into the production of WWG with an eye on environmental sustainability. A select range of environmentally-friendly gear oils was introduced to work with the WWG to maintain superior performance while reducing environmental impact.Moreover, the production process of Worm Wheel Gears has been honed to reduce environmental damage from waste. The manufacturing waste such as trimmings and filings is recycled into raw material for the production of new WWGs. Because of this, the company's production process is zero-waste. Additionally, the energy used for production is generated wholly from renewable energy sources, thereby reducing the carbon footprint.The success of WWG has continued to grow since its inception, with more and more companies understanding its benefits, building their machines around it. The technology serves large corporations and small to medium enterprises (SME); it boasts of reducing operation costs, increasing productivity, and providing the highest-quality products for manufacturing companies.In conclusion, the WWG is a revolutionary technology that is shaking up the manufacturing industry. The benefits of its use are numerous, including precision, efficiency, durability, cost savings, and environmental sustainability. WWG has become the preferred choice for many companies worldwide, and its growth is predicted to continue as more businesses understand its advantages. Companies that adopt WWG in their production processes will undoubtedly experience a significant improvement, both in their efficiency and output.