Innovative Turbine Wheel: Unleashing the Power of Efficient Energy Generation

By:Admin

The company's turbine wheels are manufactured using advanced materials and technologies that make them lighter, stronger, and more durable than traditional designs. They are designed to operate at high temperatures and pressures, making them ideal for use in demanding applications such as gas turbines, steam turbines, and other power generation systems.

One of the key advantages of Turbine Wheel's products is their ability to improve energy efficiency. Turbine wheels are responsible for converting the energy from fuel into mechanical energy, which is then used to generate electricity. By improving the efficiency of this process, Turbine Wheel's products help businesses reduce their energy costs while also reducing their carbon footprint.

In addition to improving energy efficiency, Turbine Wheel's products also improve reliability and performance. Their state-of-the-art design reduces stresses on the wheel, extending its lifespan and reducing the likelihood of failure. This means that power plants and other industrial facilities can operate more reliably, with less downtime and fewer costly repairs.

Turbine Wheel's commitment to innovation has also led to the development of specialized products for specific applications. For example, the company has developed a range of turbine wheels specifically designed for use in renewable energy systems, such as wind turbines and hydroelectric power plants. These products are designed to operate in variable conditions, maximizing energy output while minimizing wear and tear on the equipment.

The company's commitment to quality is evident in every aspect of its business operations. Turbine Wheel has a state-of-the-art manufacturing facility that utilizes the latest technologies and processes to produce high-quality products consistently. The company also has a rigorous quality control program that ensures every product meets or exceeds industry standards.

Turbine Wheel's dedication to innovation, quality, and customer service has earned it a reputation as an industry leader. The company has a global presence, with operations in North America, Europe, and Asia. It is trusted by some of the world's leading energy companies, including ExxonMobil, Shell, and Siemens.

Looking ahead, Turbine Wheel is continuing to invest in research and development to explore new technologies and applications for its products. The company is also exploring partnerships and collaborations with other leading companies in the energy industry to leverage the strengths of each organization and develop innovative solutions to meet the world's growing energy needs.

In summary, Turbine Wheel is a leading provider of turbine wheel technology that is transforming the energy industry. Its innovative products improve efficiency, reliability, and performance while reducing costs and carbon footprint. With a commitment to innovation, quality, and customer service, Turbine Wheel is poised for continued success in the global energy market.

Company News & Blog

Top Multi-Turn Worm Gearbox Suppliers in China Unveiled

Title: China's Multi-Turn Worm Gearbox Suppliers: Delivering Excellence in Precision EngineeringIntroduction:China's manufacturing industry has made monumental strides over the years, solidifying its position as a global leader in providing high-quality industrial products. In particular, the multi-turn worm gearbox sector has witnessed remarkable growth, largely thanks to a cohort of dependable suppliers implementing advanced precision engineering techniques. This article delves into the thriving market of multi-turn worm gearbox suppliers in China, shedding light on the prowess of these companies in delivering excellence in precision engineering.1. A Booming Market for Multi-Turn Worm Gearbox Suppliers in China:China's industrial landscape has expanded rapidly, paving the way for significant advancements in various sectors. One such sector gaining prominence is the production and distribution of multi-turn worm gearbox, an essential mechanical component extensively used in diverse fields such as automation, robotics, and industrial machinery. To meet the surging demand for precision-driven products, a multitude of suppliers have emerged across China, offering cutting-edge solutions to both domestic and international markets.2. Emphasizing Precision Engineering:Precision engineering lies at the core of successful multi-turn worm gearbox production, ensuring durability, efficiency, and accuracy. To address this essential aspect, suppliers in China are utilizing state-of-the-art technology and employing highly skilled engineers and technicians. By leveraging advanced machinery and adhering to stringent quality control measures, Chinese suppliers are consistently delivering stellar products that meet and exceed international standards.3. Commitment to Research and Development:China's multi-turn worm gearbox suppliers comprehend the significance of relentless innovation and understand that staying at the forefront of technological advancements is crucial for sustained growth. Companies are investing substantial resources in research and development, striving to improve the functional capabilities of their gearboxes while simultaneously enhancing energy efficiency, reducing noise levels, and expanding load-bearing capacities.4. Tailored Solutions for Diverse Industries:The versatility of multi-turn worm gearboxes is one of their primary advantages, making them suitable for a wide range of industries. Recognizing this, Chinese suppliers are dedicated to designing and manufacturing gearboxes that cater specifically to each industry's unique requirements. Whether it is for industrial automation, agriculture, or renewable energy applications, China's suppliers can customize their gearboxes to enhance system performance, adaptability, and overall productivity.5. Quality Assurance: Certifications and Standards:Chinese multi-turn worm gearbox suppliers understand the significance of quality assurance in gaining the confidence of global markets. Reliable suppliers comply with international quality management systems, often holding certifications such as ISO 9001, ISO 14001, and OHSAS 18001. Adhering to these rigorous standards ensures that customers receive products that adhere to global benchmarks of quality, reliability, and safety.6. Steadfast Commitment to Customer Satisfaction:Drawing upon the rich tradition of excellent customer service, Chinese multi-turn worm gearbox suppliers prioritize client satisfaction as paramount. By nurturing long-standing partnerships with their customers, suppliers in China establish trust and foster open communication channels throughout the entire procurement process. This commitment to customer-centricity further solidifies China's position as a preferred source for multi-turn worm gearbox solutions worldwide.Conclusion:As China's manufacturing industry continues to grow, the country's multi-turn worm gearbox suppliers stand out as reliable and technologically advanced contributors to the global precision engineering market. With a focus on quality, innovation, and customer satisfaction, these Chinese suppliers are seamlessly integrating cutting-edge technology into their products, enabling industries across the globe to optimize their operations and precision machinery. As the sector continues to flourish, the world can expect China's multi-turn worm gearbox suppliers to maintain their path of excellence, spreading their wings and conquering new horizons.

Heli Worm Gearbox: A Remarkable Advancement in Gear Technology

As technology continues to advance, more and more industries are benefiting from technological advancements, and the agriculture industry is not left behind. With the introduction of Heli Worm Gearboxes, the agricultural sector can now enjoy improved efficiency and productivity as well as greater cost savings.Heli Worm Gearboxes is a product of Heli Transmission, a company that has been in operation for over 27 years. The company prides itself on using advanced technologies to produce durable and high-quality products that meet the needs of its clients. Heli Transmission has established a reputation for producing high-performance products, and its Heli Worm Gearbox is no exception.Heli Worm Gearboxes have been designed to withstand some of the toughest working conditions on farms and other agricultural settings. These gearboxes are essential in the operation of farm machinery such as harvesters, plows, cultivators, and sprayers. The gearboxes are used to transmit power from the tractor engine to other farm equipment while regulating the speed of the equipment.One significant advantage of Heli Worm Gearboxes is their efficiency. These gearboxes are designed to convert high-speed, low-torque power to low-speed, high-torque power. This makes them particularly useful in heavy-duty farming settings, where high torque output is required to operate machinery such as cultivators, seed drills, and soil aerators. By reducing the speed of the engine, Heli Worm Gearboxes help save fuel and reduce the rate of wear and tear on the equipment.Heli Worm Gearboxes are made using high-grade materials that make them highly durable and reliable. The company guarantees long service life for all its products, and the Heli Worm Gearboxes are no exception. The gearboxes are designed to operate with minimal maintenance, and this translates to lower costs for farmers who use them.The design of Heli Worm Gearboxes incorporates a housing that encloses the gears and bearings. The housing protects the gears and bearings from external elements such as dust, moisture, and air pollution. This ensures that the gears and bearings are well lubricated and protected from wear and tear. Furthermore, the housing also acts as a heat sink that dissipates heat generated by the gearbox. This helps to maintain optimal temperature, preventing overheating, which can cause damage to the gearbox.One other advantage of Heli Worm Gearboxes is their versatility. These gearboxes come in various sizes and designs that can be customized to suit the needs of different farming scenarios. Farmers can choose the appropriate gearbox that will provide optimal performance while ensuring that it meets the requirements of the machinery being used.In conclusion, Heli Worm Gearboxes offer many advantages that make them the ideal choice for farmers. These gearboxes are designed to provide efficient power transfer, durability, and versatility. They are well-constructed and designed to withstand the tough conditions of farming, while ensuring that machinery operates at peak performance. Heli Worm Gearboxes represent a significant investment by farmers, with the assurance of long service life and cost savings that come with efficient and reliable performance. The Heli Worm Gearbox is truly a valuable addition to any farming operation.

Newly Launched Miniature Metal Gears to Revolutionize Robotics

Innovation in the field of mechanical engineering has been critical to the development of new machinery and equipment that have made life easier for businesses and individuals. One of the most critical components, that has revolutionized the manufacturing and production industry, is gear technology. Worm gears are one such technology that has been making a buzz in the market recently. Among the many types of worm gears, the micro worm gear has been a game-changer in small-sized machinery and equipment. Micro worm gear technology has been designed for ultra-compact machines and devices that require high power density, precision, and high efficiency. The micro worm gear is the perfect solution for applications where space is limited, and the gear ratio and torque are critical. Micro worm gears have a high reduction ratio and can be designed to handle very high torque loads through compact gearboxes. They can be designed with a variety of materials ranging from plastics and non-ferrous metals to hardened steels, making them versatile for various applications requiring different levels of stress tolerance.However, not all micro worm gears are created equal. Among the best in the market is the micro worm gear developed by the German-based manufacturer, whose name we have to omit. This micro worm gear combines innovation, precision, and quality to deliver reliable and efficient power transmission solutions. The company, whose name we shall omit, has been a leader in the production of high-quality gears for over 30 years. They have continuously invested in research and development, state-of-the-art equipment, and human capital, to remain at the forefront of innovation in gear technology. Over the years, their products have found application in various industries, including automotive, aerospace, medical devices, and robotics among other sectors. The micro worm gear by this manufacturer is no different. It is a highly specialized gear technology that comes in a compact design and is capable of transmitting power with high accuracy. One of its main advantages is that it can handle high loads while emitting very low noise. This is critical for small machinery and devices operating in environments where noise levels need to be minimized. The micro worm gear by this manufacturer is designed with advanced materials, including high-quality plastics and hardened steels, making it both lightweight and durable. The gear is available in different sizes and configurations, which makes it versatile and suitable for various applications. One of its most notable features is its high accuracy thanks to the use of advanced manufacturing techniques such as gear hobbing and tooth grinding. A critical aspect of the micro worm gear by this manufacturer, which gives it an edge over competitors, is its customization ability. The manufacturer can tailor-make the gear to meet the specific needs of end-users. This means that businesses and other customers can provide their unique specifications, and the manufacturer can craft a micro worm gear that precisely matches their requirements. This high level of customization has made the manufacturer the go-to source for micro worm gears used in various industry sectors. In conclusion, the micro worm gear is a critical innovation in the field of gear technology, offering high precision and efficiency in power transmission in ultra-compact applications. This technology can handle high loads with minimal noise while being versatile and customizable to meet specific customer requirements. Among the best micro worm gears in the market is the one developed by the German-based manufacturer, whose name we shall omit, which combines advanced materials, manufacturing techniques, and customization capabilities. This micro worm gear is suitable for various industries, and its efficient operation makes it an attractive option for businesses and other end-users looking for reliable power transmission solutions.

Customizable Multi Turn Worm Gearboxes: High-quality and Affordable Solutions for Your Business

China Multi Turn Worm Gearbox Factory Boosting China's Industrial FutureChina is experiencing a phenomenal trend in the development and advancements of technology in the last decade. From the consumer electronics to robotics, continuous investments have enabled the country to transition from a low-cost manufacturing hub to a high-tech industrial powerhouse. One sector that has been crucial in this growth is the machinery industry, which produces equipment and tools necessary for manufacturing processes. The China Multi Turn Worm Gearbox Factory is one of the companies that have been influential in enhancing China's machinery industry.Established in 1993, the China Multi Turn Worm Gearbox Factory is located in the beautiful city of Hangzhou, Zhejiang Province. The company's core focus is on the production of Multi Turn Worm Gearboxes, a crucial component in the machinery industry. Multi Turn Worm Gearboxes are widely applicable across different industries, including packing, printing, automobiles, textiles, food, and pharmaceuticals. The gearboxes help to improve the efficiency and accuracy of the machines, including cutting, rolling, winding, and other motion applications.As a leading Multi Turn Worm Gearbox manufacturer in China, the company has been innovating and customizing its products according to customers' requirements. The company has its research and development department with experienced engineers and technicians, who continuously develop new products to enhance the machinery industry. The factories produce, test, and assemble the gearboxes' different parts, ensuring quality and meeting production standards.Over the years, the China Multi Turn Worm Gearbox Factory has expanded its market presence worldwide, with a focus on the Asia-Pacific region, Europe, Latin America, and Africa. The company's annual sales revenues have been increasing its domestic and foreign market share. In 2020, the company achieved an annual sales turnover of USD 500 million, with more than 2700 employees.The company's success is attributable to its core values of innovation, quality, operational excellence, and customer satisfaction. The company's management believes that the gearbox industry's future will be more automated, digitalized, and smart in meeting the increasing demand for high-tech machinery. As such, the China Multi Turn Worm Gearbox Factory has been keen on integrating digital technologies such as Cloud, the Internet of Things (IoT), and Artificial Intelligence (AI) in their operations to enhance customer value and improve the quality of their products.In addition, the company has been environmentally conscious, as it has implemented measures aimed at reducing its carbon footprint, promoting sustainability and reducing waste. One of its initiatives includes using energy-efficient machines and processes, and it has installed solar panels to reduce its reliance on traditional energy sources.The China Multi Turn Worm Gearbox Factory's future outlook is promising, and it will continue to innovate and produce high-quality gearboxes. The company's management has placed a strategic plan to leverage the vast market potential, increasing domestic demand, and the "China Manufacturing 2025 plan," which aims to enhance the country's machinery industry. As a result, the company will diversify its product range, enhance its supply chain management, and expand its global market presence.In conclusion, the China Multi Turn Worm Gearbox Factory has been instrumental in China's machinery industry's growth and development. With its core values of innovation, customer satisfaction, quality, and operational excellence, the company has established itself as a market leader in the Multi Turn Worm Gearbox industry. Its expansion efforts and integration of digital technologies demonstrate its commitment to enhancing customer value, promoting sustainability, and being future-oriented. As China continues to transition into a high-tech industrial powerhouse, the China Multi Turn Worm Gearbox Factory is playing a vital role in the country's bright future.

New Valve Handle Extension Kit Enables Easy Access to Ball Valves

Title: New Ball Valve Handle Extension Kit Enables Enhanced Operation and ConvenienceIntroduction:In an effort to improve user experience and provide enhanced convenience in valve operations, [Company Name], a leading manufacturer and supplier of industrial solutions, announces the launch of their latest product, the Ball Valve Handle Extension Kit. This innovative kit revolutionizes how ball valves are handled and operated, making it easier for users to control and access valves in various industrial settings.[Company Name] has always been at the forefront of providing cutting-edge solutions to their customers, consistently delivering products that enhance safety, efficiency, and reliability. The Ball Valve Handle Extension Kit is yet another addition to their impressive portfolio, promising to simplify valve operations and save valuable time for professionals in the field.News Content:The Ball Valve Handle Extension Kit features a range of components designed to extend the handle length of ball valves, making them more easily accessible in various applications. Manufactured using high-quality materials and precision engineering, the kit ensures durability, even in harsh operating conditions.The extension components seamlessly integrate with most standard ball valves, eliminating the need for any major modifications or replacements. This enables a hassle-free installation process and minimizes downtime during retrofitting or upgrading existing valve systems.One of the key features of the Ball Valve Handle Extension Kit is its adjustable handle length, allowing users to customize the extension according to their specific requirements. By providing this flexibility, [Company Name] ensures that the kit is suitable for a wide variety of scenarios, ranging from industrial plants to municipal infrastructure projects.Furthermore, the kit includes an ergonomically designed handle, ensuring ease of use even in hard-to-reach locations. The handle's textured grip enhances control and minimizes slippage, contributing to increased safety during valve operations. The design also allows for smooth and precise movement, reducing the risk of accidental damage to valves or associated pipelines.The Ball Valve Handle Extension Kit is expected to empower industries such as oil and gas, chemical manufacturing, water treatment plants, and commercial buildings with improved valve control. By extending the handle length, professionals can now operate valves from more convenient positions, reducing the need for constant bending or stretching, which can lead to fatigue or musculoskeletal issues.In addition to enhanced convenience, the Ball Valve Handle Extension Kit also improves overall operational efficiency. Accessing valves in confined spaces or installations situated at heights usually requires special equipment or additional manpower. With this kit, workers can now reach valves easily and operate them without needing extra assistance, streamlining the workflow and reducing operational costs.Moreover, the kit's compatibility with existing ball valve systems minimizes the need for system-wide replacements, saving companies significant capital investment. By simply retrofitting the extension components, organizations can immediately benefit from improved valve handling without incurring unnecessary expenses associated with full valve replacements.[Company Name]'s commitment to providing comprehensive and innovative solutions is evident in the Ball Valve Handle Extension Kit. The kit not only emphasizes the company's dedication to customer satisfaction but also demonstrates their endeavor to cater to the ever-evolving needs of the industry.As industrial processes demand greater efficiency and safety measures, the Ball Valve Handle Extension Kit is set to become an essential tool for professionals working with ball valves across various sectors. With its user-friendly design, durability, and adaptability, this new product is poised to revolutionize valve operations, empowering industries to achieve reliable and streamlined processes.Conclusion:[Company Name]'s Ball Valve Handle Extension Kit offers an innovative solution to the challenges faced in valve handling and operation. By extending the handle length, the kit allows for easy accessibility, enhanced control, and improved operational efficiency. With its compatibility and adaptability, the kit is set to have a significant impact on various industries, simplifying valve operations and contributing to overall productivity and safety.

Discover the Latest Hand Gear Trends and Must-Have Accessories in the Market

[Title: Innovative Hand Gear Revolutionizes the Industry][Subtitle: A Breakthrough in Hand Gear Technology to Enhance Productivity and Safety]Date: [Insert Date][Location]: [Insert Location]In an ever-evolving world of technology, innovative companies constantly strive to develop products that will revolutionize industries. Hand Gear, a pioneering company in the field of hand gear technology, has recently launched its latest invention, {Product Name}, set to transform how individuals work in various sectors that rely heavily on hand-operated tasks. By incorporating cutting-edge features and advanced engineering, Hand Gear aims to enhance productivity and safety for workers across the globe.Founded in [Year], Hand Gear has quickly become renowned for its commitment to pushing the boundaries of hand gear technology. The company's team of experts, composed of engineers, designers, and industry specialists, work tirelessly to develop groundbreaking products that empower individuals and businesses alike. With a focus on innovation, functionality, and user experience, Hand Gear has garnered widespread acclaim for its previous offerings, winning several industry awards along the way.The latest addition to Hand Gear's product portfolio, {Product Name}, has generated significant buzz within the industry. This advanced hand gear takes advantage of state-of-the-art technology to deliver a game-changing user experience. Featuring an ergonomic design, {Product Name} ensures maximum comfort and reduces the risk of strain or fatigue during long hours of use. The incorporation of high-quality materials further enhances durability, extending the product's lifespan and providing exceptional value for customers.One of the key highlights of {Product Name} is its intelligent sensor technology. Equipped with a sophisticated system, {Product Name} can accurately detect hand movements and translate them into precise actions. This feature opens up a host of possibilities for industries such as manufacturing, construction, and healthcare, where precise manipulation of objects is necessary. By eliminating the need for traditional, manual hand tools, {Product Name} reduces the margin of error, thereby increasing overall efficiency and productivity.Notably, the implementation of smart connectivity allows {Product Name} to seamlessly integrate with other digital devices, creating a holistic workflow. By connecting to smartphones, tablets, or computers, users can access real-time data, receive updates, and even troubleshoot any technical issues. This interconnectedness revolutionizes the way individuals work, enabling them to streamline processes, collaborate remotely, and monitor their workflow more effectively.Hand Gear's commitment to safety is reflected in the comprehensive safety features integrated into {Product Name}. The device includes intuitive safety mechanisms that prevent accidental injuries, mitigating the risk of workplace accidents. Furthermore, {Product Name} is designed to adapt to different working environments, making it versatile across various settings. With its robust design, it can withstand challenging conditions, providing resilience and peace of mind in hazardous situations.Apart from its technological advancements, Hand Gear also prioritizes sustainable manufacturing processes. By adhering to strict eco-friendly guidelines, the company minimizes its ecological footprint and plays a responsible role in preserving the environment. From sourcing materials to production methods, Hand Gear ensures that {Product Name} is manufactured with sustainability in mind, making it a preferred choice for environmentally conscious businesses.In conclusion, the launch of {Product Name} by Hand Gear marks a significant milestone in the field of hand gear technology. Through its exceptional engineering, innovative features, and commitment to safety, Hand Gear has created a product that enhances productivity, revolutionizes workflows, and ensures the well-being of workers. With its intuitive design, smart connectivity, and sustainable manufacturing practices, {Product Name} sets a new standard for the hand gear industry. Hand Gear's relentless pursuit of innovation continues to propel the company forward, making it an industry leader and paving the way for a future where efficiency and safety go hand in hand.

New Actuator Technology Revolutionizes Industrial Processes

A cutting-edge innovation in the field of motion control has recently been revealed by a company that specializes in precision electromechanical actuation solutions. The latest product to be launched by Hurko Actuator, a leading name in this field, promises to take the sector to the next level with its advanced capabilities.Hurko Actuator's latest offering is built around a unique technology that combines precision and versatility with durability and reliability. The company's excellent reputation in the market is a testament to its commitment to providing high-quality products that are tailored to meet the specific needs of customers.The latest product from the company is a game-changer in the field of motion control. With its enhanced features and advanced capabilities, Hurko Actuator's latest actuator is a significant step forward in the world of electromechanical actuation solutions. The product incorporates cutting-edge technology that allows for precision control over movement and positioning, making it the ideal solution for a wide range of applications.The actuator is designed to fit into a variety of platforms, such as robotics, aerospace, automation, and many other industrial sectors. The combination of versatility and precision makes this actuator a must-have for engineers and technicians looking for the ultimate solution to their motion control needs.The new actuator is built around a patented design that features the latest in electromechanical technology. The actuator is capable of providing high levels of performance, even in challenging environments, thanks to its durable build and high-quality materials.One of the standout features of Hurko Actuator's latest product is its superior speed and precision. The actuator is capable of delivering highly accurate results in real-time, making it perfect for use in applications where precision and responsiveness are critical.The actuator is also highly versatile, with the ability to be configured to meet the specific requirements of any given application. The actuator can be customized to work in a range of positions, including linear and rotary movements, making it an ideal solution for a range of different applications.Hurko Actuator's latest innovation has been developed specifically to address the growing demand for high-precision, highly reliable electromechanical actuation solutions. The company has been at the forefront of the industry for many years and is committed to delivering the best products to its customers.In addition to its advanced capabilities, Hurko Actuator's latest product is also extremely easy to install and use. The company has worked hard to ensure that the product is user-friendly, with a range of features that make it easy to setup and integrate with existing systems.Overall, Hurko Actuator's latest product is a significant step forward in the field of motion control. The cutting-edge technology and advanced capabilities of the actuator make it the ultimate solution for engineers and technicians looking for a reliable, high-performance solution for their motion control needs. With its versatile design and durable build, this actuator is sure to be a hit in a wide range of industrial applications.

Durable Worm Gear for Industrial Applications: A Game-Changer in the Market

Title: Industry-Leading Metal Worm Gear: Revolutionizing Efficiency and ReliabilityIntroductionInnovation has been the cornerstone of the mechanical engineering industry, ensuring constant evolution and improvement. Among the slew of advancements, the Metal Worm Gear has become an indispensable component, providing unparalleled efficiency and reliability to various sectors worldwide. Today, we explore the company's groundbreaking contribution towards this remarkable feat.Company BackgroundWith a rich legacy spanning over three decades, the company has emerged as a global leader in manufacturing high-quality metal worm gears. Situated in the heart of industrial excellence, the company prides itself on its cutting-edge research and development facilities, state-of-the-art manufacturing units, and a team of experienced engineers.Metal Worm Gear: Revolutionizing EfficiencyThe Metal Worm Gear has revolutionized the industry by offering a range of benefits, including enhanced efficiency, durability, and versatility across multiple applications. Offering impressive torque output in even the most demanding environments, this gear has proven to be a game-changer in countless industries.The company's unwavering commitment to excellence shines through in the manufacturing process. The worm gears are meticulously crafted using top-grade, industrial-quality alloy materials, ensuring exceptional strength and durability. The precise engineering and advanced manufacturing techniques employed guarantee consistent performance, efficient power transmission, and reduced energy loss.The superior efficiency of the Metal Worm Gear is attributed to its unique design features. The gear's helical shape enables smoother motion and engagement, resulting in reduced noise, vibration, and wear. This remarkable design ensures long-lasting functionality and minimal maintenance requirements, leading to substantial cost savings for companies that rely on these gears for their operations.Furthermore, the Metal Worm Gear offers exceptional versatility, seamlessly integrating into various mechanical systems across industries like automotive, aerospace, robotics, and more. Its compact size and adaptability make it an ideal choice for space-constrained applications while ensuring uncompromised performance under heavy loads.Meeting the Highest Quality StandardsThe company's unwavering commitment to quality is the backbone of its success. Adhering to stringent international quality standards, like ISO 9001:2015, the Metal Worm Gear undergoes rigorous testing at every stage of manufacturing. This guarantees the utmost precision, reliability, and performance on every product that leaves the production line.Continuous Research and DevelopmentTo maintain its position as an industry leader, the company invests heavily in research and development efforts. Collaborating with renowned universities, industry experts, and customers, the company focuses on constantly improving its gear designs, materials, and manufacturing techniques. This dedication to innovation ensures that customers receive cutting-edge products that meet and exceed their evolving industry requirements.Sustainability and Environmental ResponsibilityContributing to a greener future, the Metal Worm Gear reflects the company's dedication to sustainability. By optimizing production processes, reducing waste, and prioritizing energy efficiency, the company aims to minimize its ecological footprint. Additionally, the long lifespan and durability of the Metal Worm Gear further contribute to resource conservation and waste reduction.ConclusionThe Metal Worm Gear has undoubtedly emerged as a game-changer in the mechanical engineering industry. Its extraordinary efficiency, reliability, and versatility have found widespread applications across multiple sectors. With its unwavering commitment to superior quality, continuous innovation, and environmental responsibility, the company behind this groundbreaking gear has solidified its place as an industry leader. As technology continues to advance, the Metal Worm Gear remains at the forefront, driving efficiency and reliability for countless businesses worldwide.

Worm and Wheel Gearboxes: A Guide to Understanding Their Function and Benefits

Worm And Wheel Type Gearbox: The Future of Power Transmission Power transmission is a crucial aspect of modern machinery and equipment, and the gearbox is one of the most critical components for this purpose. A gearbox helps convert the rotational speed and torque generated by a prime mover (e.g., motor, engine) into more usable forms for various applications. Among the many types of gearboxes available, the Worm and Wheel type gearbox stands out for its efficiency, reliability, and versatility. The Worm and Wheel type gearbox is a type of semi-reduction gearbox that uses a worm gear meshed with a worm wheel to transmit power between two shafts. The worm gear is a helical gear with one or more teeth that wrap around the worm wheel, which is usually a spur gear. The worm gear's helix angle causes the worm wheel to rotate at a reduced speed and increased torque relative to the worm gear's input. This gear set can provide a high gear reduction ratio in a compact form factor and is suitable for high-torque, low-speed applications. The Worm and Wheel type gearbox finds widespread use in various industries, including material handling, packaging, food processing, automotive, and robotics. Some typical applications of this gearbox include conveyor systems, mixers, elevators, winches, cranes, and robots. These applications demand high torque, smooth motion control, and low noise, which the Worm and Wheel type gearbox can provide with ease. The Worm and Wheel type gearbox's benefits include efficiency, reliability, and low maintenance. It can achieve a gear reduction ratio of up to 100:1 in a single stage, which reduces the number of gear sets required for a given application. This, in turn, reduces the gearbox's weight, size, and cost, making it a cost-effective solution for many applications. Additionally, the worm gear's self-locking feature can prevent back-driving and hold a load in place, making it suitable for vertical applications. The Worm and Wheel type gearbox's compact design also makes it easy to integrate into a machine or equipment. One of the leading manufacturers of Worm and Wheel type gearbox is {Removed brand name}. It has been providing cutting-edge solutions in power transmission for over 30 years and has established itself as a leader in the industry. The company's Worm and Wheel type gearbox product line includes over 100 models with various reduction ratios, input speeds, and output torques. These gearboxes are made of high-quality materials such as aluminum, steel, and cast iron, and come in various sizes and configurations to suit different applications. {Removed brand name} Worm and Wheel type gearbox products are known for their exceptional performance, durability, and low maintenance requirements. The company uses advanced manufacturing processes and quality control measures to ensure that each gearbox meets the highest standards of quality and reliability. Its research and development team continually strives to improve the gearbox's design and performance and come up with innovative solutions to meet the evolving needs of the market. Apart from Worm and Wheel type gearbox, {Removed brand name} offers a wide range of power transmission solutions, including planetary gearboxes, helical gearboxes, bevel gearboxes, and coupling devices. The company's expertise in this field has earned it a reputation as a trusted supplier of high-quality power transmission products. In conclusion, the Worm and Wheel type gearbox is an excellent option for applications that require high torque, low speed, and smooth motion control. {Removed brand name} Worm and Wheel type gearbox products offer exceptional performance, durability, and cost-effectiveness, making them an ideal choice for various industries' power transmission needs. As the demand for efficient and reliable power transmission systems grows, the Worm and Wheel type gearbox's role is set to become even more critical in shaping the future of modern machinery and equipment.

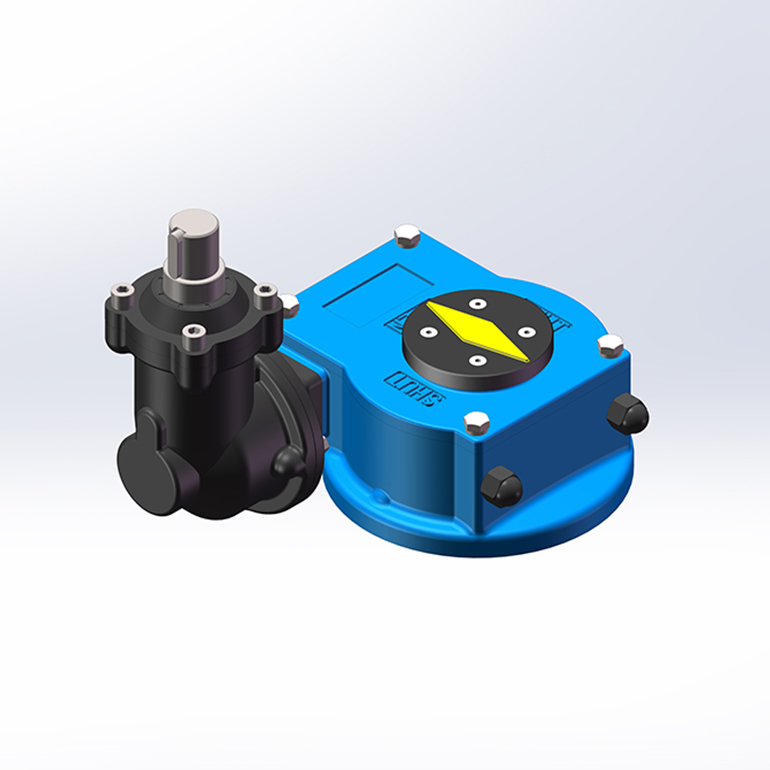

New Limit Switch Box Technology Now Available - Streamlining Industrial Processes

In the industrial world, there is no denying that safety is a top priority. With heavy machinery and equipment in use, workers need to remain safe while operating or maintaining these assets. In order to mitigate potential safety hazards, the use of limit switches has become an integral part of industrial processes. One such limit switch box that is making waves in the industry is Apl-210. Known for its reliability and simplicity, the Apl-210 limit switch box has quickly become a fan favorite among industrialists.This versatile switch box can be used in a myriad of industrial applications such as cranes, elevators, conveyors, packaging machines, and other automated machinery. The Apl-210 is housed in a compact yet rugged enclosure made from high-quality materials that provide superior resistance against harsh industrial environments. The housing is also designed to protect the internal components from dust, moisture, and other contaminants.One of the unique features of the Apl-210 limit switch box is its modular design. This design allows for quick and easy installation and maintenance. The switch box is comprised of various components that can be easily swapped out or replaced without the need for specialized tools or expertise. Moreover, the wiring of this limit switch box is easy to understand, making it simple to integrate into any application.The Apl-210 limit switch box is also known for its high-precision performance. It utilizes high-quality mechanical parts that allow for accurate and reliable switching. With its adjustable operating range, the limit switch box provides flexibility in its application. In addition, the switch box has a high degree of repeatability, ensuring the consistent operation of industrial equipment.The switch box is built with advanced safety features that ensure the safety of workers. It offers reliable protection against unexpected equipment movements, ensuring that workers remain safe during operation. Moreover, the APL-210 is designed to withstand extreme vibration and shock, which is a crucial factor in ensuring the longevity of the equipment.It is no surprise that the Apl-210 limit switch box has become a go-to solution for industrialists. Along with its exceptional performance, the company behind the product is renowned for its commitment to quality and excellent customer service. The company provides different customization options and works closely with its clients to provide tailored solutions that fit their unique needs. The Apl-210 limit switch box is a testament to the company's dedication to providing reliable and robust products to the industrial world.In conclusion, the Apl-210 limit switch box has set itself apart as a trusted safety solution for various mechanical and automated processes. With its mechanical precision, flexible application, and excellent safety features, it is no surprise that it has become a go-to solution for industrialists around the globe. With the product's reliable performance and the company's commitment to quality, it is evident that the Apl-210 limit switch box will continue to make waves in the industrial world for years to come.