High-quality Worm Reduction Gear Box for Industrial Applications

By:Admin

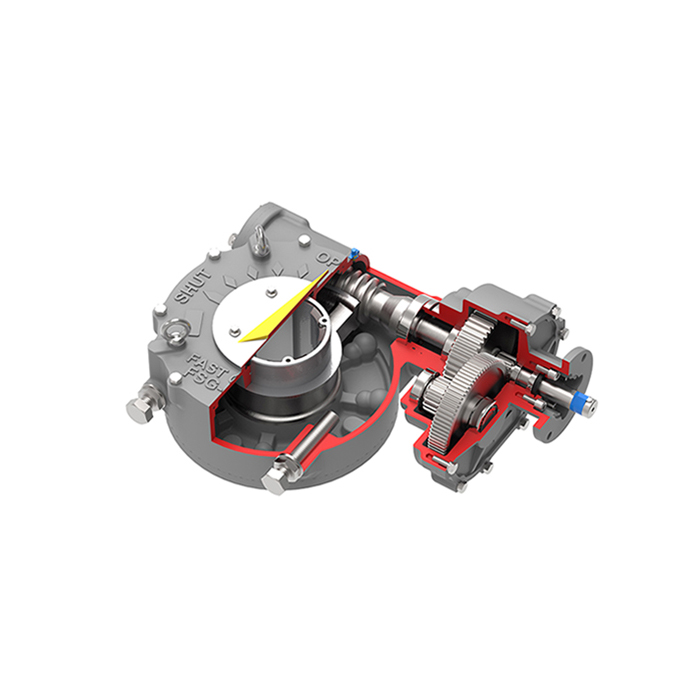

The Worm Reduction Gear Box, developed after years of intense research and development, is a state-of-the-art gearbox that is designed to provide exceptional performance and durability in various industrial applications. The gearbox is equipped with advanced features and a robust design that ensures smooth and precise operation, making it an ideal choice for a wide range of industrial machinery.

At the heart of this innovation is the advanced worm gear design, which provides superior torque transmission and efficiency. This allows the gearbox to handle heavy loads and deliver consistent performance, making it suitable for heavy-duty industrial machinery such as conveyors, mixers, agitators, and other applications that require reliable power transmission.

One of the key highlights of the Worm Reduction Gear Box is its compact and space-saving design. This makes it ideal for use in applications where space is limited, without compromising on performance. In addition, the gearbox is designed to be maintenance-free, reducing the need for frequent servicing and ensuring minimal downtime for the machinery it is used in.

The precision engineering of the Worm Reduction Gear Box ensures quiet operation and minimal vibration, providing a comfortable working environment for operators and reducing the wear and tear on the machinery. This results in long-term cost savings and increased productivity for industrial operations.

In addition to its superior performance, the Worm Reduction Gear Box is also designed with the latest safety features, ensuring the protection of the machinery and the safety of the operators. This includes built-in protection against overloading, overheating, and other potential hazards, providing peace of mind to the users and enhancing the overall reliability of the machinery.

(Company name) has a long-standing reputation for delivering high-quality and innovative machinery solutions to its customers. With the introduction of the Worm Reduction Gear Box, the company continues its tradition of excellence and commitment to meeting the evolving needs of the industrial market.

Speaking about the launch, (Spokesperson's name), the spokesperson of (Company name), expressed their excitement about the potential of the Worm Reduction Gear Box in the industrial machinery market. "We are thrilled to introduce the Worm Reduction Gear Box to our customers. This innovative technology reflects our dedication to providing reliable, efficient, and high-performance machinery solutions that meet the demands of modern industrial operations. We believe that this gearbox will set new benchmarks in the industry and provide immense value to our customers."

The Worm Reduction Gear Box is now available for purchase and is set to make a significant impact in the industrial machinery market. With its advanced features, reliable performance, and unparalleled durability, it is poised to become the gearbox of choice for industrial applications worldwide. For more information about the gearbox and other machinery solutions offered by (Company name), please visit their website or contact their sales team.

Company News & Blog

Pneumatic Controls Limit Switch Factories in China: News and Updates

China Pneumatic Controls Limit Switch Factories (CPLS) is one of the leading manufacturers of pneumatic control limit switches in China. With years of experience and a strong reputation for quality and reliability, CPLS has become a trusted supplier for industries worldwide.Established in 1998, CPLS has always been committed to providing high-quality pneumatic control limit switches that meet the needs of various industrial applications. The company has invested heavily in research and development, continuously improving its products to meet the ever-changing demands of the market. CPLS has a state-of-the-art manufacturing facility equipped with the latest technology and machinery, ensuring the production of top-notch limit switches.CPLS offers a wide range of pneumatic control limit switches, including lever-operated, push-button, and rotary-type switches, among others. These switches are designed to provide precise control and reliable operation in industrial machinery and equipment. Whether it's for heavy-duty manufacturing or precision engineering, CPLS has a solution to meet the requirements of the most demanding applications.In addition to its standard product line, CPLS also offers custom solutions to meet specific customer needs. The company's team of experienced engineers works closely with clients to develop tailored pneumatic control limit switches that perfectly fit their unique requirements. This commitment to customization sets CPLS apart from its competitors, as it can deliver highly specialized products that cater to a wide range of industries and applications.The quality of CPLS's products is further reinforced by its dedication to strict adherence to international quality standards. The company has obtained ISO 9001 certification, ensuring that its manufacturing processes and products consistently meet the highest level of quality. This commitment to quality has earned CPLS a solid reputation in the industry and has allowed it to build strong and lasting relationships with its customers.CPLS's commitment to customer satisfaction extends beyond the quality of its products. The company also provides excellent customer service and technical support to its clients. Its knowledgeable and responsive team is always ready to assist customers with their inquiries and provide expert guidance on the selection and application of pneumatic control limit switches.As part of its continuous efforts to expand its reach and serve a wider customer base, CPLS has established a strong global presence. The company has a network of distributors and partners in various countries, ensuring that its products are readily available to customers worldwide. This global presence enables CPLS to be at the forefront of the industry, offering its cutting-edge pneumatic control limit switches to a diverse range of industries and applications.Looking ahead, CPLS is committed to further innovation and advancement in pneumatic control limit switch technology. The company continues to invest in research and development, aiming to develop new and improved products that meet the evolving needs of the market. With a strong focus on quality, customization, and customer satisfaction, CPLS is well-positioned to maintain its leadership in the industry and remain a preferred supplier for pneumatic control limit switches.In conclusion, China Pneumatic Controls Limit Switch Factories (CPLS) is a trusted and reputable manufacturer of pneumatic control limit switches. With a commitment to quality, customization, and customer satisfaction, CPLS has earned a strong position in the market and is well-equipped to meet the diverse needs of industries worldwide. As the company continues to innovate and expand its global reach, it is poised to remain a leading provider of top-notch pneumatic control limit switches for years to come.

The Latest Innovation in Worm and Worm Gear Technology

[Company Name] Introduces New Worm and Worm Gear Technology for Industrial Applications[City, State, Date] - [Company Name], a leading provider of industrial solutions, is proud to introduce its latest innovation in worm and worm gear technology. The new product line is designed to provide superior performance, durability, and efficiency for a wide range of industrial applications.The worm and worm gear technology is a critical component in many industrial machinery and equipment, including conveyor systems, elevators, and industrial automation systems. The design and performance of this technology can significantly impact the overall efficiency and reliability of these systems.The new worm and worm gear technology from [Company Name] is engineered to deliver exceptional performance and longevity in even the most demanding industrial environments. The precision-engineered components are manufactured to the highest standards, ensuring optimal performance and longevity.One of the key features of the new worm and worm gear technology is its enhanced efficiency. The design of the components minimizes friction and wear, resulting in lower energy consumption and reduced maintenance requirements. This can lead to significant cost savings for industrial operators, as well as improved environmental sustainability.In addition to improved efficiency, the new technology also offers exceptional durability and reliability. The components are constructed from high-quality materials and undergo rigorous testing to ensure they can withstand the harshest operating conditions. This can provide industrial operators with greater peace of mind, knowing that their equipment is built to last.Furthermore, the new worm and worm gear technology from [Company Name] is designed to be highly adaptable to a wide range of industrial applications. The company offers a variety of sizes and configurations to accommodate the specific needs of different industries and machinery. This flexibility makes it easier for industrial operators to find a solution that meets their unique requirements."We are thrilled to introduce our latest innovation in worm and worm gear technology," said [Spokesperson Name], [Title] at [Company Name]. "Our team has worked tirelessly to develop a product line that delivers exceptional performance, efficiency, and reliability for industrial applications. We believe this technology will make a significant impact on the industry and provide our customers with a competitive advantage."[Company Name] has a long-standing reputation for delivering high-quality industrial solutions. With a commitment to innovation and customer satisfaction, the company continues to push the boundaries of what is possible in industrial technology. The introduction of the new worm and worm gear technology is just the latest example of this dedication to excellence.Industrial operators who are interested in learning more about the new worm and worm gear technology from [Company Name] are encouraged to contact the company directly for more information. The company's team of experts is available to provide guidance and support to help customers find the right solution for their specific needs.To learn more about [Company Name] and its innovative worm and worm gear technology, please visit [Company Website] or contact the company directly at [Contact Information].About [Company Name]:[Company Name] is a leading provider of industrial solutions for a wide range of applications. The company offers a comprehensive portfolio of products and services, including custom-engineered solutions, to meet the unique needs of its customers. With a focus on innovation, quality, and customer satisfaction, [Company Name] continues to be a trusted partner for industrial operators around the world.

Durable and Efficient Gear Solutions for Enhanced Performance

Title: Gear Manufacturing Company Introduces Innovative Worm and Bevel Gear TechnologyIntroduction:[Company Name], a renowned gear manufacturing company with a rich history in producing high-quality gears, is proud to introduce its latest innovation in mechanical power transmission – advanced Worm and Bevel Gear technology. This cutting-edge gear solution aims to revolutionize various industries by enhancing efficiency, durability, and performance in diverse applications.Company Overview:Established for over four decades, [Company Name] has been at the forefront of gear manufacturing, catering to a wide range of industries including automotive, aerospace, industrial machinery, and renewable energy. Our commitment to excellence, combined with state-of-the-art technology, has enabled us to develop and deliver reliable gear solutions that meet the evolving market demands.Developing Worm and Bevel Gear Technology:Recognizing the need for more efficient, reliable, and cost-effective gear solutions, [Company Name] invested substantial resources into research and development, culminating in the creation of the advanced Worm and Bevel Gear technology. This groundbreaking gear system combines the strengths of both worm gears and bevel gears, resulting in an innovative solution that surpasses conventional gear designs in various applications.Enhanced Efficiency:The patented Worm and Bevel Gear design optimizes power transmission efficiency, reducing energy loss and enhancing overall system performance. The precise machining techniques employed by [Company Name] produce gears with exceptional accuracy, minimizing friction and decreasing wear and tear on the gear components. This reduction in energy loss translates to significant cost savings for end-users, offering improved operational sustainability.Durability and Reliability:The Worm and Bevel Gear technology developed by [Company Name] incorporates state-of-the-art materials, advanced heat treatment processes, and stringent quality control procedures. This ensures that the gear components exhibit superior durability, resistance to wear, and exceptional load-bearing capacity. With extended longevity and reduced maintenance requirements, [Company Name]'s Worm and Bevel Gear technology provides reliability and peace of mind to industries operating in demanding conditions.Versatile Applications:This innovative gear technology finds applications in several industries. In the automotive sector, it delivers efficient power transmission from the engine to the wheels, resulting in improved fuel efficiency. In the aerospace industry, the gear technology ensures smooth and reliable operation of landing gears, reducing maintenance costs and increasing flight safety. Additionally, the Worm and Bevel Gear technology can be used in industrial machinery, mining equipment, renewable energy systems, and more, offering enhanced performance and reliability across a wide range of applications.Partnerships and Collaborations:[Company Name] has forged strategic partnerships and collaborations with leading industry players and research institutions to continually refine and advance its Worm and Bevel Gear technology. The company believes in fostering technological advancements by exchanging knowledge, skills, and expertise. Leveraging these collaborative efforts, [Company Name] endeavors to push the boundaries of gear innovation and reinforce its position as a global leader in gear manufacturing.Conclusion:[Company Name]'s introduction of its advanced Worm and Bevel Gear technology reflects its commitment to shaping the future of mechanical power transmission. With increased efficiency, durability, and reliability, this innovative gear solution holds immense potential to transform various industries, ensuring seamless power transmission and optimizing overall system performance. As [Company Name] continues to focus on delivering cutting-edge gear solutions, the company remains poised to revolutionize the gear manufacturing industry and propel it towards a more advanced and sustainable future.

Efficient Worm and Wheel Steering Gear for Smooth Vehicle Handling

Worm And Wheel Steering Gear has been making waves in the automotive industry with its innovative technology that promises to improve the performance and safety of vehicles. The company, based in {location}, has been a leader in the development of steering gear systems that are used in a wide range of vehicles, including cars, trucks, and buses.The Worm And Wheel Steering Gear system is known for its precision and reliability, making it a popular choice among automakers and vehicle enthusiasts. It is designed to provide precise control and exceptional responsiveness, giving drivers a smooth and comfortable driving experience. The system also enhances safety by ensuring that vehicles can be maneuvered with ease and precision.The company has a team of experienced engineers and technicians who are dedicated to pushing the boundaries of automotive technology. They are constantly working on improving the Worm And Wheel Steering Gear system, ensuring that it meets the highest standards of quality and performance. This commitment to innovation has helped the company establish itself as a leader in the industry, garnering a strong reputation for excellence and reliability.In addition to designing and producing steering gear systems, the company also provides comprehensive support services to its clients. This includes technical assistance, maintenance, and repair services, ensuring that vehicles equipped with the Worm And Wheel Steering Gear system continue to perform at their best. The company's commitment to customer satisfaction has made it a trusted partner for automakers and vehicle owners alike.One of the key advantages of the Worm And Wheel Steering Gear system is its versatility. It is designed to be easily integrated into different types of vehicles, regardless of their size, weight, or intended use. This makes it an ideal choice for automakers looking to offer a high-performance steering system across their vehicle lineup. The system's adaptability also makes it a popular choice for vehicle enthusiasts who are looking to enhance the performance and handling of their vehicles.The company is also dedicated to sustainability and environmental responsibility. It actively seeks ways to reduce the environmental impact of its manufacturing processes and products. The Worm And Wheel Steering Gear system is designed to be energy-efficient and durable, making it an environmentally friendly choice for vehicle manufacturers and owners.Looking ahead, Worm And Wheel Steering Gear continues to innovate and explore new possibilities in automotive technology. It is committed to staying at the forefront of the industry, pioneering new solutions that will shape the future of vehicle performance and safety. The company's dedication to excellence and innovation has set it apart as a driving force in the automotive industry, and it is poised to continue leading the way in steering gear technology.As the demand for high-performance steering systems continues to grow, Worm And Wheel Steering Gear is well-positioned to meet the needs of the market. Its reputation for quality, reliability, and innovation makes it a preferred choice for automakers and vehicle enthusiasts around the world. With a strong foundation of expertise and a commitment to excellence, the company is poised to make an even greater impact on the automotive industry in the years to come.

High-Quality Worm and Gear Set for Efficient Power Transmission

Worm And Gear Set: The Backbone of Precision EngineeringPrecision engineering is integral to a wide range of industries, from automotive to aerospace, and everything in between. At the heart of this precision are often worm and gear sets, intricate and reliable mechanisms that make possible the smooth operation of many machines and devices.One company that has been at the forefront of producing high-quality worm and gear sets for over three decades is {}. With a strong commitment to innovation, quality, and customer satisfaction, they have become a trusted name in the world of precision engineering.Established in the late 1980s, {} has grown to become a leading manufacturer of worm and gear sets, serving a diverse range of industries including automotive, agriculture, and robotics. Their state-of-the-art manufacturing facilities, combined with a team of experienced engineers and technicians, enable them to produce worm and gear sets that meet the most stringent quality standards and technical requirements.The worm and gear set is a type of power transmission mechanism that is used to transfer motion and power between two shafts at right angles to each other. The worm, which is a screw-like gear, meshes with the gear (sometimes referred to as a worm wheel), and when the worm is turned, it drives the gear. This results in a smooth and efficient transfer of power, making worm and gear sets ideal for applications where precision and reliability are crucial.{}'s worm and gear sets are designed and manufactured with precision in mind. Using the latest CAD/CAM software and CNC machining technology, they are able to ensure that each component of the worm and gear set meets the exact specifications required for optimal performance. This attention to detail is what sets {} apart from its competitors, and has earned them a reputation for delivering worm and gear sets of the highest quality.In addition to their standard range of worm and gear sets, {} also offers custom design and manufacturing services, allowing them to meet the specific needs of their customers. Whether it's a unique gear ratio, a special material, or a particular size requirement, {} has the capability to design and produce worm and gear sets that are tailored to individual customer specifications.With a focus on continuous improvement and innovation, {} is constantly investing in research and development to stay ahead of the curve in the precision engineering industry. Their team of engineers is always looking for new ways to improve the performance and efficiency of their worm and gear sets, ensuring that they remain at the forefront of technological advancements in the field.Looking to the future, {} is poised to continue its success as a leading manufacturer of worm and gear sets. With a strong commitment to quality, innovation, and customer satisfaction, they are well-positioned to meet the evolving needs of the precision engineering industry, and to continue providing their customers with the high-quality worm and gear sets that have become synonymous with the {} name.In conclusion, worm and gear sets are an essential component of many machines and devices, and {} has established itself as a trusted manufacturer of these precision engineering components. With a focus on quality, innovation, and customer satisfaction, they continue to lead the way in the industry, delivering worm and gear sets that meet the most stringent technical requirements and provide reliable performance across a wide range of applications.

Discover the Latest Innovations in Electric Wafer Butterfly Valves

Title: Innovative Electric Wafer Butterfly Valve Revolutionizes Industrial Flow Control SystemsIntroduction: In today's rapidly advancing world of automation and industrial processes, businesses are constantly looking for innovative solutions to enhance productivity and efficiency. The introduction of the Electric Wafer Butterfly Valve by a leading company marks a significant milestone in the realm of flow control systems. This cutting-edge valve promises to revolutionize industrial operations by providing advanced functionality, exceptional reliability, and increased control precision.1. Overview of the Electric Wafer Butterfly Valve:The Electric Wafer Butterfly Valve is a technologically advanced flow control solution that offers unique advantages over conventional valves. Designed for a wide range of applications, this valve combines improved performance, enhanced durability, and sophisticated control features. Its simplistic, compact design ensures ease of installation and maintenance, making it an ideal choice for diverse industries.2. Superior Performance and Reliability:This Electric Wafer Butterfly Valve embodies state-of-the-art technology that guarantees superior performance and reliability. With an innovative actuation system, it enables efficient and precise control of flow rates, boosting overall system productivity. The valve's advanced sealing mechanism minimizes leakage, preventing costly wastage and reducing environmental impact. Rigorously tested for durability, it can withstand extreme working conditions, ensuring long-lasting performance for years to come.3. Enhanced Control and Monitoring Capabilities:The Electric Wafer Butterfly Valve is equipped with cutting-edge control and monitoring features, setting it apart from conventional valves. Integrated with smart sensor technology, it provides real-time data on flow rates, temperature, and pressure, allowing operators to make informed decisions and optimize processes. Seamless integration with automation systems enables remote monitoring and control, providing added convenience and efficiency.4. Versatility and Application Areas:This innovative valve's versatility allows it to cater to diverse industry sectors. Whether it is chemical and petrochemical plants, water and wastewater treatment facilities, power generation plants, or HVAC systems, the Electric Wafer Butterfly Valve adapts seamlessly to these applications. Its robust construction and compatibility with various mediums such as liquid, gas, and slurries make it a reliable choice for a broad range of industries.5. Energy Efficiency and Cost Savings:An inherent feature of the Electric Wafer Butterfly Valve is its exceptional energy efficiency. By employing cutting-edge technology, it ensures precise flow control, reducing unnecessary energy consumption. This environmentally friendly design lowers operational costs by minimizing energy waste, resulting in significant cost savings for businesses over time.6. Safety and Compliance Standards:Meeting stringent safety and compliance standards, the Electric Wafer Butterfly Valve prioritizes the well-being of employees and the environment. With fail-safe measures and emergency shut-off capabilities, it enhances operational safety and mitigates potential risks. Adhering to industry guidelines and certifications, this valve ensures compliance with regulations and facilitates smooth operations for businesses.Conclusion:The introduction of the Electric Wafer Butterfly Valve by a leading company signifies a major breakthrough in the field of flow control systems. Its superior performance, enhanced control and monitoring features, versatility, energy efficiency, and adherence to safety standards make it a game-changer in the industry. With this innovative valve, businesses can expect enhanced productivity, cost savings, and improved operational efficiency. As technology continues to advance, the Electric Wafer Butterfly Valve marks a new chapter in the evolution of industrial flow control systems.

Top Electric Motor Operated Valve Actuators for Efficient Control

Electric Motor Operated Valve Actuators have become an essential component in the industrial and commercial sectors. These state-of-the-art actuators are designed to efficiently regulate the flow of various liquids and gases in a wide range of applications, including power plants, water treatment facilities, oil and gas refineries, and chemical processing plants. One company that has been at the forefront of providing high-quality electric motor operated valve actuators is {}.{} is a leading provider of advanced automation and control solutions for a diverse range of industries. With a strong commitment to innovation and customer satisfaction, the company has established itself as a trusted partner for businesses seeking reliable and efficient valve actuation solutions. The electric motor operated valve actuators offered by {} are known for their exceptional performance, durability, and precision control. These actuators are designed to meet the most demanding requirements of modern industrial processes, providing reliable and efficient operation in even the harshest of environments. One of the key advantages of {}’s electric motor operated valve actuators is their ability to deliver precise and consistent valve positioning, ensuring optimal flow control and system performance. This level of accuracy is essential in processes where the precise regulation of flow rates and pressures is critical to maintaining operational efficiency and safety. In addition to their precision control capabilities, {}’s electric motor operated valve actuators are also renowned for their rugged construction and reliable performance. These actuators are built to withstand the rigors of industrial environments, including extreme temperatures, corrosive atmospheres, and high-pressure conditions. As a result, businesses can rely on {}’s actuators to provide long-lasting, trouble-free operation, reducing maintenance costs and downtime.Furthermore, {} offers a comprehensive range of electric motor operated valve actuators to suit various application requirements. Whether customers require on/off or modulating actuators, {} provides a diverse selection of products to meet their specific needs. The company also offers customized solutions, working closely with customers to develop tailored actuation systems that precisely match their requirements.{}’s electric motor operated valve actuators are also designed with ease of installation and maintenance in mind. The actuators are engineered for straightforward set-up and configuration, minimizing downtime during installation. Additionally, these actuators are equipped with advanced diagnostic and predictive maintenance features, allowing for proactive monitoring and upkeep, further reducing the total cost of ownership for businesses.In line with its commitment to customer satisfaction, {} provides comprehensive technical support and after-sales service for its electric motor operated valve actuators. The company’s team of experienced engineers and support staff are dedicated to assisting customers with product selection, installation, commissioning, and ongoing maintenance, ensuring that customers derive maximum value from {}’s products.With a track record of successful deployments in a wide range of industries and applications, {}’s electric motor operated valve actuators have earned a solid reputation for reliability, performance, and durability. Businesses around the world continue to trust {} for their valve actuation needs, relying on the company’s expertise and innovative solutions to optimize their processes and improve their operational efficiency.In conclusion, electric motor operated valve actuators from {} are at the forefront of valve actuation technology, offering precise control, reliability, and durability for a wide range of industrial applications. With a commitment to innovation and customer satisfaction, {} continues to be a trusted partner for businesses seeking high-quality valve actuation solutions. As industrial processes evolve and become more demanding, {} remains dedicated to providing cutting-edge solutions that meet the needs of its customers, further cementing its position as a leader in the industry.

Discover the Remarkable Features and Applications of a Large Worm Gear

Title: Innovative Worm Gear Revolutionizes Large-Scale Industrial ApplicationsIntroduction:In the realm of large-scale industrial applications, a significant breakthrough has been achieved with the development of an advanced worm gear system. This cutting-edge technology, designed by an industry-leading company (), promises to revolutionize various sectors by enhancing efficiency, reliability, and sustainability. With its exceptional performance capabilities, this worm gear system is set to address challenges faced by industries worldwide and propel them towards a more productive and environmentally conscious future.Section 1: Worm Gear Enigma UnveiledThe newly developed worm gear system showcases an innovative design that surpasses the limitations of traditional gearbox solutions. Its primary components, the worm wheel and gear, have been meticulously engineered to ensure exceptional power transmission efficiency. Through precision manufacturing techniques and advanced materials, this worm gear achieves higher torque capacity, reduced frictional losses, and improved wear resistance.Section 2: Industry ApplicationsThe versatility of this worm gear system enables its integration across various industries. In the mining sector, it offers a reliable and efficient solution for heavy machinery and extraction equipment. Additionally, the system's ability to handle large loads makes it ideal for applications in rail transportation, enabling smooth and precise movement of trains and trams.In the renewable energy sector, the worm gear system proves to be a significant asset in wind turbine installations. Its robust design ensures optimal power transmission, enhancing the energy output and operational lifespan of these structures. By harnessing the power of this advanced gear system, renewable energy generation can be maximized, thereby contributing to a greener environment.Section 3: Importance of Efficiency and ReliabilityEfficiency and reliability are pivotal aspects in any industry. The worm gear system offers considerably higher efficiency compared to traditional gearboxes. Its advanced lubrication system reduces power losses and heat generation, resulting in more efficient operations. Moreover, the enhanced wear resistance capabilities of this system contribute to prolonged equipment lifespan, reducing maintenance costs and downtime.Section 4: Sustainable Manufacturing TechniquesIn line with the escalating global concern over sustainability, the company responsible for introducing this worm gear system () is committed to adopting sustainable manufacturing practices. By incorporating eco-friendly materials, reducing energy consumption during production, and optimizing resource usage, the company strives to minimize its carbon footprint. This dedication to sustainability aligns with the company's broader mission to contribute to a more environmentally friendly industrial landscape.Section 5: Future Prospects and ConclusionAs industries continue to demand enhanced performance and sustainability, the worm gear system emerges as a game-changer. The innovative design, coupled with its ability to improve efficiency, reliability, and sustainability, positions this gear system as the ultimate solution for large-scale industrial applications. With its successful integration in various sectors, efficiency gains and cost savings are expected to be realized, benefitting both businesses and the environment alike.In conclusion, the introduction of a state-of-the-art worm gear system showcases a breakthrough in the field of large-scale industrial applications. The advanced design, efficiency, and reliability offered by this gear system have the potential to transform industries such as mining, transportation, and renewable energy. By prioritizing sustainability in its manufacturing process, the company () demonstrates its commitment to a greener future. With the revolutionary worm gear technology, industries worldwide can achieve higher productivity, reduced costs, and a more sustainable approach to operations.

Ultimate Guide to Bevel Gear Operators for Efficient Operations

Bevel Gear Operator: An Industrial Revolution for Gear CuttingIn the world of industrial machinery and equipment, gears are considered as one of the most essential components. Gears are widely used because of their significant role in motion transmission especially in rotating machineries such as engines, turbines, and machines used in the manufacturing of a wide range of products. Gears come in different shapes, sizes and styles. The one type that is widely used in industry is the bevel gear.Bevel gears are a type of gear that is used for transmitting power between intersecting shafts. They are typically classified into straight and spiral bevel gears. Straight bevel gears are associated with simple setups while the spiral bevel gears are popular for both simple and complex setups. Spiral bevel gears are lapped to provide better accuracy and durability.One of the essential components of the gear manufacturing industry is the bevel gear operator. Bevel gear operator is a machine designed to cut teeth on bevel gears to very tight tolerances. The bevel gear operator removes material from the gear blank in order to produce the desired gear teeth. The gear teeth can be of different sizes and angles, depending on the application and manufacturing requirements.The bevel gear operator (name to be removed) is one of the most advanced gears cutting machine available today. It is a precision gear cutting machine that is designed to deliver high accuracy and productivity. The machine is equipped with a number of features that make it easy to operate and maintain.The machine has a compact design that makes it easy to install in any gear manufacturing facility. In addition, the operator has an intuitive user interface that allows the machine operator to quickly and easily set up the machine for any bevel gear cutting task. The operator also has a built-in tool changer that allows the machine to automatically change the cutting tool based on the requirements of the job.Moreover, the bevel gear operator is equipped with advanced automation features. The operator is designed to automatically manage the cutting process, including material feed, material positioning, and tool speed. This allows the machine operator to focus on other tasks and be more productive.The machine is also highly flexible, able to cut bevel gears from a variety of materials includng steel, stainless steel, brass, aluminum, and even plastic. The operator is designed with a high-power spindle motor that can deliver high torque at low speeds, which is essential when cutting tough materials that require high forces.The bevel gear operator is also designed to deliver high speed and high accuracy. It is equipped with a high-speed spindle that can reach up to 10,000 RPM while keeping a tight tolerance with a repeatable accuracy of 3 microns. This allows the machine to cut gears quickly and accurately, reducing cycle times and increasing productivity.The bevel gear operator could be an ideal machine for gear manufacturing companies who want to streamline their production process and improve their output. Its high accuracy and productivity will increase company revenue by reducing manufacturing costs and providing optimal operational efficiency. The operator’s advanced features and flexibility make it the ultimate gear manufacturing machine for any gear manufacturing company looking to improve their operations.In conclusion, the bevel gear operator is a highly advanced gear cutting machine. It is designed to deliver high accuracy, productivity, flexibility, and speed. Its advanced automation features and intuitive user interface make it easy to operate, while its flexibility and reliability make it the perfect machine for any gear manufacturing company. Moreover, its high-speed spindle and repeatable accuracy provide outstanding results, allowing it to compete in a fiercely competitive gear manufacturing landscape. Therefore, the bevel gear operator is an exceptional machine and is highly recommended for gear manufacturing companies that want to take their businesses to the next level.

High-Quality Worm Gearbox Manufacturers for Industrial Applications

Worm Gearbox Manufacturers, a leading company in the production of high-quality gearboxes, has been making waves in the industrial sector with its innovative and reliable products. With a focus on delivering top-notch solutions for a wide range of industries, the company has established itself as a trusted name in the market.The company's success can be attributed to its commitment to quality and innovation. By leveraging cutting-edge technology and a team of experienced engineers, Worm Gearbox Manufacturers has been able to develop gearboxes that not only meet the performance requirements of its customers but also offer unmatched reliability and durability.In addition to its technical prowess, the company also places a strong emphasis on customer service. From the initial inquiry to after-sales support, Worm Gearbox Manufacturers strives to provide the highest level of service to its clients. This dedication to customer satisfaction has earned the company a loyal customer base and has helped solidify its reputation as a leader in the industry.One of the key factors that sets Worm Gearbox Manufacturers apart from its competitors is its ability to customize solutions to meet the unique needs of its clients. By working closely with customers to understand their specific requirements, the company is able to develop tailored gearbox solutions that deliver optimal performance and efficiency. This flexibility has allowed Worm Gearbox Manufacturers to cater to a diverse range of industries, including automotive, mining, construction, and manufacturing.Furthermore, Worm Gearbox Manufacturers is committed to sustainable and environmentally friendly manufacturing practices. The company continuously seeks to improve its processes to minimize waste and reduce its environmental footprint. By prioritizing sustainability, the company not only fulfills its corporate social responsibility but also contributes to a cleaner and greener future.The company's dedication to excellence has not gone unnoticed in the industry. Worm Gearbox Manufacturers has received numerous accolades and certifications for its exceptional products and services. These recognitions serve as a testament to the company's unwavering commitment to quality and customer satisfaction.Looking ahead, Worm Gearbox Manufacturers is poised for further growth and expansion. The company has ambitious plans to invest in research and development to continue innovating and delivering state-of-the-art gearbox solutions. Additionally, Worm Gearbox Manufacturers is exploring opportunities to expand its presence in new markets and industries to serve an even broader range of customers.In conclusion, Worm Gearbox Manufacturers has emerged as a trailblazer in the gearbox manufacturing industry. Through its dedication to quality, innovation, customer service, and sustainability, the company has set itself apart as a leader in the market. With a strong foundation and a clear vision for the future, Worm Gearbox Manufacturers is well-positioned to continue its success and make a lasting impact on the industrial sector.