High-Quality Worm Reducer for Sale - Find the Best Worm Reducer Today!

By:Admin

One of the key products in the company's portfolio is the premium worm reducer, a sophisticated piece of machinery that plays a crucial role in the operation of many industrial processes. This high-precision device is designed to reduce the speed of an input shaft, providing the necessary torque to drive machinery and equipment in a wide range of applications.

Recently, [Company Introduction] has announced the launch of its latest premium worm reducer, which promises to set a new standard for performance and reliability in the industry. The new product features a number of innovative design enhancements and technological advancements that will deliver significant benefits to businesses in terms of efficiency, durability, and overall productivity.

The premium worm reducer is a vital component in many industrial processes, providing the necessary torque and speed reduction to drive a wide variety of machinery and equipment. As such, the reliability and performance of this device are essential to the smooth operation of countless businesses in sectors such as manufacturing, construction, mining, and more.

The latest premium worm reducer from [Company Introduction] incorporates several key features that set it apart from other similar products on the market. One of the most significant improvements is the advanced gearing technology, which ensures smoother and more efficient power transmission. This not only leads to greater energy efficiency but also reduces wear and tear on the equipment, resulting in lower maintenance costs and longer operational lifespan.

In addition, the new premium worm reducer also boasts a more compact and lightweight design, without compromising on its strength and durability. This makes it easier to install and integrate into existing machinery, while also offering greater flexibility in terms of application and placement within the industrial setting.

Furthermore, the premium worm reducer is equipped with state-of-the-art safety features to ensure maximum protection for workers and equipment. This includes advanced overload protection and fail-safe mechanisms that help prevent accidents and costly damage to machinery.

The launch of the new premium worm reducer demonstrates [Company Introduction]'s commitment to innovation and technological advancement in the industrial equipment sector. By continuously improving its products and incorporating the latest engineering developments, the company aims to provide its customers with the most reliable and efficient solutions to meet their evolving needs and challenges.

In conclusion, the latest premium worm reducer from [Company Introduction] represents a significant advancement in industrial machinery technology. With its innovative design, advanced features, and robust performance, this new product is set to deliver substantial benefits to businesses across various sectors, helping to improve efficiency, reduce operating costs, and enhance overall productivity. As [Company Introduction] continues to push the boundaries of industrial equipment innovation, it is clear that the company remains a trusted and reliable partner for businesses seeking high-quality solutions for their operational needs.

Company News & Blog

Motorized Actuator Used for Butterfly Valves

[Company Introduction]In today's rapidly evolving industrial landscape, where the demand for high-performance and reliable valve solutions is on the rise, one company has emerged as a pioneer in the field. With a commitment to innovation and unparalleled product quality, this company has continuously delivered exceptional valve solutions that cater to diverse industries. By seamlessly blending modern technology with robust engineering, they have established themselves as a market leader, meeting the evolving needs of their customers.[News Content - Butterfly Valve Motorized Actuator]In line with their dedication to providing cutting-edge valve solutions, this renowned company is proud to introduce its latest product innovation – the Butterfly Valve Motorized Actuator. This state-of-the-art actuator is specifically designed to enhance the performance and functionality of butterfly valves, enabling precise flow control in a wide range of applications.The Butterfly Valve Motorized Actuator offers several key features that set it apart from its competitors. Firstly, it incorporates advanced motorized technology, allowing for seamless automation and remote control of valve operations. This ensures enhanced operational efficiency and eliminates the need for manual adjustments, thereby reducing labor costs and minimizing the risk of human error.Furthermore, this actuator boasts robust construction and durability, guaranteeing reliable performance even in the harshest environments. Its high-strength materials provide resistance to corrosion, wear, and tear, making it a suitable choice for industries such as oil and gas, water treatment, chemical processing, and HVAC systems.One of the standout features of this motorized actuator is its exceptional control accuracy. Equipped with precision sensors and an intelligent control system, it enables precise adjustment of valve opening and closure, ensuring optimal flow regulation. This level of accuracy enhances the overall operational efficiency, significantly improving process control and productivity.Moreover, the Butterfly Valve Motorized Actuator offers unmatched adaptability. Its modular design allows for easy integration and retrofitting with existing butterfly valves, eliminating the need for expensive valve replacements. This versatility not only saves time and costs but also ensures a seamless transition to automated operations.Safety is another critical aspect addressed by this innovative actuator. It incorporates failsafe mechanisms that ensure immediate response in emergency situations such as power failures or abnormal system conditions. Its intelligent sensing technology can detect anomalies and trigger appropriate actions, preventing accidents and safeguarding personnel and equipment.This breakthrough product also embraces sustainability principles. By optimizing energy consumption and reducing leakage risks, it promotes environmental consciousness while maintaining superior performance standards. Furthermore, its low maintenance requirements result in extended service life, ultimately reducing waste and enhancing overall sustainability.To ensure the highest level of client satisfaction, the company's Butterfly Valve Motorized Actuator is backed by a comprehensive customer support system. Their team of highly skilled professionals offers timely technical support, guidance in product selection, and assistance in installation and integration processes.In conclusion, the introduction of the Butterfly Valve Motorized Actuator marks a significant milestone for this industry-leading company. Unleashing the power of automation, precision, durability, and adaptability, this innovative actuator sets a new standard for valve solutions. With its exceptional features and unparalleled product quality, this company continues to prove its commitment to revolutionizing the valve industry and meeting the dynamic needs of customers across different sectors.

Discover the Relevance and Benefits of Rack And Worm Gear Systems

Title: Innovative Solution Revolutionizes Gear Systems: Rack And Worm Gear Pair Redefines Efficiency and PerformanceIntroduction:In an era of technological advancements, companies constantly strive to innovate and provide breakthrough solutions that reshape industries. One such company, dedicated to engineering excellence, has introduced a game-changing product: a cutting-edge implementation of Rack And Worm Gear (name removed) technology. This new development brings forth unparalleled efficiency and performance in gear systems, solidifying the company's position as a leader in the field. Let us delve deeper into this remarkable development and explore its potential impact across various industries.Section 1: Understanding Rack And Worm Gear TechnologyThe Rack And Worm Gear technology, pioneered by the company (name omitted), is a powerful force transmission system. It comprises a worm gear and a corresponding horizontal rack, ensuring torque conversion and motion transfer. This impressive design enables its application in diverse sectors, from automotive to industrial machinery, proving its versatility and adaptability.Section 2: Unveiling the Key Advantages2.1 Exceptional Efficiency:With a unique tooth profile and optimized gear geometry, the innovative Rack And Worm Gear solution exhibits exceptional efficiency. The gear system demonstrates reduced power loss, resulting in heightened performance and increased overall efficiency. This advancement translates to significant cost savings and resource conservation for industries adopting the technology.2.2 Enhanced Precision:The meticulous engineering behind Rack And Worm Gear technology guarantees high-precision motion control. Its capability to achieve smooth and accurate positioning facilitates seamless operation in various applications. Additionally, the gear system's self-locking mechanism reduces back-driving, ensuring stability and security, particularly in critical operations and heavy machinery.2.3 Increased Load Capacity:The new Rack And Worm Gear design revolutionizes load-bearing capabilities. Its superior load-carrying capacity allows for the handling of heavier loads, boosting operational capabilities for industries such as manufacturing, construction, and logistics. By providing robust gear systems that can withstand substantial stress, the technology ensures optimal performance, reliability, and longevity.Section 3: Applications Across Industries3.1 Automotive Industry:The automotive sector can significantly benefit from the implementation of Rack And Worm Gear technology. This innovative gear system offers precise steering control, ensuring improved responsiveness and accuracy. Furthermore, its exceptional efficiency enhances fuel economy, reducing environmental impact and meeting ever-stringent industry regulations.3.2 Robotics and Automation:In the realm of robotics and automation, precision and reliability are vital. Rack And Worm Gear technology provides an ideal solution for these demanding applications. The gear system's self-locking feature guarantees secure operation, enabling safe and precise movement control essential in advanced robotic systems.3.3 Industrial Machinery:Industries that rely on large-scale machinery, such as manufacturing and construction, can leverage the robustness and load-bearing capabilities of Rack And Worm Gear technology. Its ability to handle heavy loads, combined with enhanced precision, allows for smoother operations, improved productivity, and reduced downtime.Section 4: Company's Dedication to InnovationThe company's introduction of the Rack And Worm Gear technology exemplifies its commitment to driving innovation in the field. As a leader in the industry, the company's state-of-the-art research and development division continually explores new possibilities, pushing the boundaries of gear systems. With a focus on customer-centric solutions, the company aims to revolutionize industries while addressing the unique needs of its clients.Conclusion:The advent of Rack And Worm Gear technology represents a significant breakthrough in the realm of gear systems, promising enhanced efficiency, precision, and load-bearing capacities. As industries constantly strive to improve performance and reduce operational costs, this innovation presents an invaluable solution. The company (name removed) continues to pave the way for advancements in the field, solidifying its position as an industry leader committed to engineering excellence and customer satisfaction.

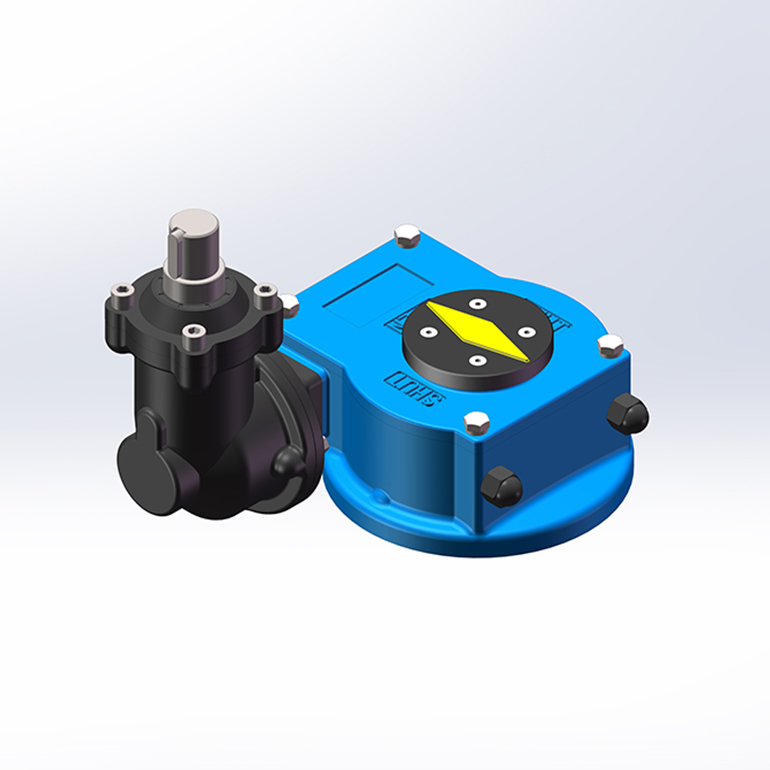

New Handwheel Gear Operator Launched to Improve Industrial Operations

[Headline]: Innovative Handwheel Gear Operator Revolutionizes Industrial Operations[Subheading]: Introducing a Groundbreaking solution to Efficient and Reliable Machinery Control[Date][City], [State] - In a bid to enhance the efficiency and precision of machinery control, a leading industrial automation company unveils its latest product - the Handwheel Gear Operator. Designed to optimize operations across various industries, this cutting-edge innovation is set to revolutionize the way industrial processes are carried out.[Company Name], a global leader in industrial automation solutions, has developed the Handwheel Gear Operator as a result of extensive research and development. Combining state-of-the-art technology with a user-friendly interface, this revolutionary device simplifies machinery control and ensures improved productivity.The Handwheel Gear Operator serves as a compact and versatile tool, suitable for a wide range of applications. From heavy industrial machinery to delicate precision instruments, this device provides operators with enhanced control and maneuverability. Its ergonomic design ensures comfortable operation, reducing fatigue and increasing efficiency in the workplace.One of the key features of the Handwheel Gear Operator is its seamless integration with existing machinery. This device can easily be retrofitted onto various equipment, making it a cost-effective and hassle-free solution for businesses looking to optimize their machinery control systems. The Handwheel Gear Operator also boasts compatibility with a range of industrial protocols, allowing for seamless communication and integration with existing control systems.Enhanced precision is another aspect that sets the Handwheel Gear Operator apart. Equipped with advanced digital technology, this device offers operators a high degree of accuracy in controlling speed, torque, and direction. This not only reduces the chances of human error but also enables smoother and more precise operations, resulting in improved product quality, reduced downtime, and increased overall productivity.Moreover, the Handwheel Gear Operator boasts advanced safety features, ensuring optimal worker protection. With its high-level fault detection mechanism and emergency shutdown capabilities, this device guarantees a safe operating environment for workers. By minimizing the risk of accidents and equipment damage, businesses can prioritize the well-being of their employees while maintaining continuous operations with minimal interruptions.To further enhance user experience, the Handwheel Gear Operator is equipped with a user-friendly interface. Its intuitive controls and digital display provide operators with real-time feedback, allowing for swift adjustments and monitoring of key parameters. Additionally, the device's modular design ensures easy maintenance and reduces downtime, further optimizing the overall operational efficiency."We are thrilled to introduce the Handwheel Gear Operator to the market," says [Company Name] spokesperson. "With its cutting-edge technology and extensive compatibility, we believe this device will transform the way industries operate, increasing productivity and ensuring a safer working environment for all."As industries continue to evolve and embrace automation and digitalization, the Handwheel Gear Operator offers a reliable and efficient solution to meet the growing demands of modern industrial processes. By integrating this innovative device into their operations, businesses can streamline their machinery control processes, reduce costs, and maximize productivity.About [Company Name]:[Company Name] is a leading global provider of industrial automation solutions, specializing in the design and manufacture of innovative devices to optimize industrial processes. With a strong commitment to quality and customer satisfaction, [Company Name] continues to revolutionize the industrial automation sector through cutting-edge technologies. For more information, please visit the company's website at [website URL].[Note: Please replace the [Company Name] placeholders with the actual name of the company.]

Worm Wheel Gear: Everything You Need to Know

Worm Wheel Gear, a leading manufacturer in the mechanical engineering industry, has recently made strides in the development of precision worm wheel gears. These innovative gears are revolutionizing the way various industries operate, providing enhanced efficiency and performance in a wide range of machinery and equipment.With a history of over 50 years in the industry, Worm Wheel Gear has built a strong reputation for producing high-quality, reliable products. The company prides itself on its commitment to continuous improvement and innovation, and the development of precision worm wheel gears is a testament to this dedication.Worm wheel gears are a crucial component in many types of machinery, including automotive, aerospace, construction, and industrial equipment. These gears are used to transmit power between two shafts at right angles, and their precision is essential for smooth and efficient operation.The new precision worm wheel gears developed by Worm Wheel Gear offer several key advantages over traditional gears. Thanks to advanced manufacturing techniques and materials, these gears boast higher load carrying capacity, improved efficiency, and quieter operation. Additionally, the use of advanced materials ensures greater durability and longevity, reducing maintenance and replacement costs for businesses.One of the most significant benefits of these precision worm wheel gears is their ability to operate at higher speeds without sacrificing performance. This is especially valuable for industries such as automotive and aerospace, where high-speed machinery is essential for meeting production demands.In addition to their technical advantages, Worm Wheel Gear's precision worm wheel gears also contribute to environmental sustainability. By improving the efficiency of machinery and reducing energy consumption, these gears help companies minimize their carbon footprint and contribute to global efforts to combat climate change.The development of precision worm wheel gears represents a significant step forward for Worm Wheel Gear, positioning the company as a leader in the industry. This innovative product line is the result of extensive research and development efforts, as well as a deep understanding of the needs and challenges faced by industries that rely on precision machinery.Worm Wheel Gear's commitment to quality and innovation is further underscored by its state-of-the-art manufacturing facilities and highly skilled workforce. The company's team of engineers and technicians leverage the latest technologies and best practices to ensure that every precision worm wheel gear meets the highest standards of performance and reliability.As industry demands continue to evolve, Worm Wheel Gear remains at the forefront of innovation, continually seeking new ways to improve its products and services. The development of precision worm wheel gears is just one example of the company's ongoing efforts to provide cutting-edge solutions to its customers.Looking ahead, Worm Wheel Gear is poised to continue its growth and expand its reach in the global market. By staying true to its core values of quality, innovation, and customer satisfaction, the company is well-positioned to build on its success and maintain its reputation as a trusted partner for businesses in need of precision engineering solutions.With its new precision worm wheel gears, Worm Wheel Gear is setting a new standard for performance and reliability in the mechanical engineering industry. As industries continue to evolve and demand higher levels of efficiency, these innovative gears are sure to play a key role in driving progress and success for businesses around the world.

Top Multi-Turn Worm Gearbox Suppliers in China Unveiled

Title: China's Multi-Turn Worm Gearbox Suppliers: Delivering Excellence in Precision EngineeringIntroduction:China's manufacturing industry has made monumental strides over the years, solidifying its position as a global leader in providing high-quality industrial products. In particular, the multi-turn worm gearbox sector has witnessed remarkable growth, largely thanks to a cohort of dependable suppliers implementing advanced precision engineering techniques. This article delves into the thriving market of multi-turn worm gearbox suppliers in China, shedding light on the prowess of these companies in delivering excellence in precision engineering.1. A Booming Market for Multi-Turn Worm Gearbox Suppliers in China:China's industrial landscape has expanded rapidly, paving the way for significant advancements in various sectors. One such sector gaining prominence is the production and distribution of multi-turn worm gearbox, an essential mechanical component extensively used in diverse fields such as automation, robotics, and industrial machinery. To meet the surging demand for precision-driven products, a multitude of suppliers have emerged across China, offering cutting-edge solutions to both domestic and international markets.2. Emphasizing Precision Engineering:Precision engineering lies at the core of successful multi-turn worm gearbox production, ensuring durability, efficiency, and accuracy. To address this essential aspect, suppliers in China are utilizing state-of-the-art technology and employing highly skilled engineers and technicians. By leveraging advanced machinery and adhering to stringent quality control measures, Chinese suppliers are consistently delivering stellar products that meet and exceed international standards.3. Commitment to Research and Development:China's multi-turn worm gearbox suppliers comprehend the significance of relentless innovation and understand that staying at the forefront of technological advancements is crucial for sustained growth. Companies are investing substantial resources in research and development, striving to improve the functional capabilities of their gearboxes while simultaneously enhancing energy efficiency, reducing noise levels, and expanding load-bearing capacities.4. Tailored Solutions for Diverse Industries:The versatility of multi-turn worm gearboxes is one of their primary advantages, making them suitable for a wide range of industries. Recognizing this, Chinese suppliers are dedicated to designing and manufacturing gearboxes that cater specifically to each industry's unique requirements. Whether it is for industrial automation, agriculture, or renewable energy applications, China's suppliers can customize their gearboxes to enhance system performance, adaptability, and overall productivity.5. Quality Assurance: Certifications and Standards:Chinese multi-turn worm gearbox suppliers understand the significance of quality assurance in gaining the confidence of global markets. Reliable suppliers comply with international quality management systems, often holding certifications such as ISO 9001, ISO 14001, and OHSAS 18001. Adhering to these rigorous standards ensures that customers receive products that adhere to global benchmarks of quality, reliability, and safety.6. Steadfast Commitment to Customer Satisfaction:Drawing upon the rich tradition of excellent customer service, Chinese multi-turn worm gearbox suppliers prioritize client satisfaction as paramount. By nurturing long-standing partnerships with their customers, suppliers in China establish trust and foster open communication channels throughout the entire procurement process. This commitment to customer-centricity further solidifies China's position as a preferred source for multi-turn worm gearbox solutions worldwide.Conclusion:As China's manufacturing industry continues to grow, the country's multi-turn worm gearbox suppliers stand out as reliable and technologically advanced contributors to the global precision engineering market. With a focus on quality, innovation, and customer satisfaction, these Chinese suppliers are seamlessly integrating cutting-edge technology into their products, enabling industries across the globe to optimize their operations and precision machinery. As the sector continues to flourish, the world can expect China's multi-turn worm gearbox suppliers to maintain their path of excellence, spreading their wings and conquering new horizons.

Innovative 12v Ball Valve Actuator Technology: A Complete Overview

12v Ball Valve Actuator for Enhanced Control and EfficiencyIn today's fast-paced and demanding industrial environment, precision and efficiency are crucial to success. One company that understands this need for accuracy and reliability is {}. With a strong reputation for delivering high-quality industrial automation products, the company is proud to announce the launch of its latest innovation - the 12v Ball Valve Actuator.The 12v Ball Valve Actuator is designed to provide enhanced control and efficiency in a wide range of industrial applications. Whether it is used in the oil and gas industry, chemical processing, water treatment plants, or any other industrial setting, this actuator is built to deliver reliable and precise performance.One of the key features of the 12v Ball Valve Actuator is its ability to operate at low voltage, making it an ideal choice for applications where power consumption is a concern. This not only helps in reducing energy costs but also ensures that the actuator can function effectively even in areas where power supply may be limited.In addition to its low power consumption, the 12v Ball Valve Actuator is also equipped with a range of advanced features that set it apart from other actuators in the market. For instance, its compact and robust design makes it suitable for installation in tight spaces and harsh environments. This makes it a versatile solution for a wide range of industrial settings.Furthermore, the actuator is engineered to deliver precise and accurate control, thanks to its high-quality components and advanced technology. This means that industrial processes can be managed with greater efficiency and consistency, leading to improved productivity and cost savings.Moreover, the 12v Ball Valve Actuator is designed for easy integration with existing industrial systems, making it a convenient and cost-effective upgrade for facilities looking to enhance their operational capabilities. With its user-friendly interface and compatibility with a variety of control systems, the actuator can be seamlessly integrated into the existing infrastructure, minimizing downtime and disruption.Another important aspect of the 12v Ball Valve Actuator is its durability and reliability. Built to withstand the rigors of industrial operations, the actuator is constructed from high-quality materials and undergoes rigorous testing to ensure long-term performance. This means that businesses can count on the actuator to deliver consistent results and withstand the demands of their operations.As a company that prides itself on delivering innovative and reliable solutions, {} is committed to providing comprehensive support and service for the 12v Ball Valve Actuator. From installation assistance to ongoing maintenance and technical support, the company's team of experts is available to ensure that customers get the most out of their investment in this cutting-edge technology.In summary, the launch of the 12v Ball Valve Actuator marks a significant milestone for {}. With its focus on delivering precision, efficiency, and reliability, this innovative product is poised to make a positive impact on industrial operations across various sectors.For businesses looking to enhance their control and efficiency, the 12v Ball Valve Actuator offers a compelling solution that aligns with the evolving needs of the industry. With its advanced features, low power consumption, and robust design, this actuator is set to become an essential asset for modern industrial facilities.

Top Electric Motor Operated Valve Actuators for Efficient Control

Electric Motor Operated Valve Actuators have become an essential component in the industrial and commercial sectors. These state-of-the-art actuators are designed to efficiently regulate the flow of various liquids and gases in a wide range of applications, including power plants, water treatment facilities, oil and gas refineries, and chemical processing plants. One company that has been at the forefront of providing high-quality electric motor operated valve actuators is {}.{} is a leading provider of advanced automation and control solutions for a diverse range of industries. With a strong commitment to innovation and customer satisfaction, the company has established itself as a trusted partner for businesses seeking reliable and efficient valve actuation solutions. The electric motor operated valve actuators offered by {} are known for their exceptional performance, durability, and precision control. These actuators are designed to meet the most demanding requirements of modern industrial processes, providing reliable and efficient operation in even the harshest of environments. One of the key advantages of {}’s electric motor operated valve actuators is their ability to deliver precise and consistent valve positioning, ensuring optimal flow control and system performance. This level of accuracy is essential in processes where the precise regulation of flow rates and pressures is critical to maintaining operational efficiency and safety. In addition to their precision control capabilities, {}’s electric motor operated valve actuators are also renowned for their rugged construction and reliable performance. These actuators are built to withstand the rigors of industrial environments, including extreme temperatures, corrosive atmospheres, and high-pressure conditions. As a result, businesses can rely on {}’s actuators to provide long-lasting, trouble-free operation, reducing maintenance costs and downtime.Furthermore, {} offers a comprehensive range of electric motor operated valve actuators to suit various application requirements. Whether customers require on/off or modulating actuators, {} provides a diverse selection of products to meet their specific needs. The company also offers customized solutions, working closely with customers to develop tailored actuation systems that precisely match their requirements.{}’s electric motor operated valve actuators are also designed with ease of installation and maintenance in mind. The actuators are engineered for straightforward set-up and configuration, minimizing downtime during installation. Additionally, these actuators are equipped with advanced diagnostic and predictive maintenance features, allowing for proactive monitoring and upkeep, further reducing the total cost of ownership for businesses.In line with its commitment to customer satisfaction, {} provides comprehensive technical support and after-sales service for its electric motor operated valve actuators. The company’s team of experienced engineers and support staff are dedicated to assisting customers with product selection, installation, commissioning, and ongoing maintenance, ensuring that customers derive maximum value from {}’s products.With a track record of successful deployments in a wide range of industries and applications, {}’s electric motor operated valve actuators have earned a solid reputation for reliability, performance, and durability. Businesses around the world continue to trust {} for their valve actuation needs, relying on the company’s expertise and innovative solutions to optimize their processes and improve their operational efficiency.In conclusion, electric motor operated valve actuators from {} are at the forefront of valve actuation technology, offering precise control, reliability, and durability for a wide range of industrial applications. With a commitment to innovation and customer satisfaction, {} continues to be a trusted partner for businesses seeking high-quality valve actuation solutions. As industrial processes evolve and become more demanding, {} remains dedicated to providing cutting-edge solutions that meet the needs of its customers, further cementing its position as a leader in the industry.

Essential Information on Worm Wheels and Shafts: A Guide

Worm wheel and worm shaft are important components used in various industries to transmit power and motion between non-parallel, power-transmitting shafts. One of the leading companies in the production of worm wheel and worm shaft is {company name}. Founded in 1978, the company has been focused on offering high-quality and efficient worm gear units, worm gear motors, and other power transmission solutions.With a well-equipped manufacturing plant spanning over 8000 square meters, {company name} is capable of producing 500,000 sets of worm gearboxes annually, delivering its products to over 70 countries worldwide. The company conforms to international standards and is certified with ISO9001, CE, and UL. With a team of highly experienced researchers, designers, and engineers, {company name} can design and produce customized power transmission solutions to meet various industrial applications.The worm wheel and worm shaft are one of the most critical components produced by {company name} for power transmission applications. These components are instrumental in the production of mechanical motion between non-parallel shafts, converting rotational energy in one direction to rotational motion in another direction. Worm gear systems developed by {company name} have a high level of efficiency, reliability, and quiet operation.One of {company name}'s unique selling propositions includes their ability to produce high-quality worm gears with either single or double output shafts. The single output shafts are ideal for applications that require low-speed rotary motion but cannot accommodate other power transmission devices. In contrast, the double output shafts are perfect for industries that require multi-axis output motion.Since worm gears operate with sliding contact between the gear teeth, it's important to ensure adequate lubrication to minimize wear and extend the life of the gear system. {company name} understands this and designs its worm gears with advanced lubrication systems, ensuring optimal system performance and a longer lifespan.{Company name}'s worm gears are also designed to operate in various environmental conditions. The worm wheels are made from high-quality materials, with 15CrMo alloy steel being the most commonly used. This material has high strength, hardness, and resistance to wear, making it ideal for worm gears that operate under heavy loads and high stresses.In conclusion, {company name} is a leading producer of worm wheel and worm shaft, and their solutions have been used in a wide range of applications, including robotics, automation, medical, packaging, printing and others. They have a reputation for producing high-quality components that have a high level of torque density, efficiency, and reliability.The company's manufacturing capabilities, strict quality control protocols, and customized solutions make them an appealing choice for various industries. Partnering with {company name} for worm gear solutions ensures you have access to high-performing products that meet your specific application requirements.

High-Quality Worm Reducer Gearbox for Industrial Use

The Worm Reducer Gearbox is a crucial component in various industrial and commercial applications, providing efficient and reliable power transmission. With its high torque capacity and compact design, the Worm Reducer Gearbox has become an essential part of many industries, including manufacturing, mining, construction, and automotive.{Company Name} is a leading manufacturer of Worm Reducer Gearboxes, providing high-quality and customized solutions to meet the specific needs of its customers. With a strong focus on innovation and technology, {Company Name} has established itself as a trusted partner for businesses seeking reliable power transmission solutions.The Worm Reducer Gearbox manufactured by {Company Name} is designed to deliver superior performance and durability, enabling businesses to optimize their operations and increase productivity. Its precision engineering and high-quality materials ensure smooth and efficient power transmission, even in the most demanding applications.{Company Name} offers a wide range of Worm Reducer Gearboxes, including single and double reduction models, with various ratios and sizes to accommodate different power requirements. Whether it's for heavy-duty industrial machinery or smaller-scale applications, {Company Name} can provide customized solutions to meet the specific needs of its customers.In addition to its high-performance gearboxes, {Company Name} also provides exceptional customer service, offering technical support, maintenance assistance, and on-site consultation to ensure that its products continue to perform at their best. With a team of experienced engineers and technicians, {Company Name} is committed to delivering value beyond its products, helping its customers maximize the efficiency and reliability of their power transmission systems.The Worm Reducer Gearbox manufactured by {Company Name} is also designed with sustainability in mind, incorporating energy-efficient features to minimize power consumption and reduce environmental impact. By helping its customers optimize their energy usage, {Company Name} contributes to a more sustainable and eco-friendly industrial sector.As a global leader in power transmission solutions, {Company Name} has established a strong presence in key markets around the world, serving a diverse range of industries and businesses. Its dedication to quality, innovation, and customer satisfaction has earned {Company Name} a solid reputation as a preferred partner for businesses seeking dependable and efficient power transmission solutions.Looking ahead, {Company Name} is committed to continuous improvement and innovation, investing in research and development to further enhance the performance and efficiency of its Worm Reducer Gearbox. By staying at the forefront of technology and industry trends, {Company Name} aims to remain a trusted and reliable partner for its customers, helping them achieve their operational goals and drive success in their respective industries.In conclusion, the Worm Reducer Gearbox manufactured by {Company Name} is a testament to the company's commitment to quality, performance, and sustainability. With its advanced engineering, custom solutions, and exceptional customer service, {Company Name} is a leading provider of power transmission solutions, empowering businesses to thrive and succeed in the ever-evolving industrial landscape.

Worm Gear Actuator Butterfly Valve: What You Need to Know

Worm Gear Actuator Butterfly Valves, also known as quarter-turn valves, are essential components in many industrial applications. These valves are used to regulate the flow of gases, liquids, and other materials by controlling the opening and closing of a disc inside the valve. One company at the forefront of producing these high-quality valves is {brand name}, a leading manufacturer and supplier of industrial valves and actuators.With a commitment to innovation and excellence, {brand name} has been providing top-of-the-line industrial solutions for over a decade. Their range of products includes a variety of valves, actuators, and control systems that are used in industries such as oil and gas, water treatment, chemical processing, and power generation.The worm gear actuator butterfly valves produced by {brand name} are known for their precision, durability, and reliability. These valves are designed to withstand high-pressure and high-temperature applications, making them suitable for a wide range of industrial processes. With a focus on quality and performance, {brand name} has established itself as a trusted supplier for companies around the world.One of the key features of {brand name}'s worm gear actuator butterfly valves is their ease of operation. The worm gear actuator allows for precise control of the valve's opening and closing, making it ideal for applications that require accurate flow regulation. Additionally, the valves are designed to minimize friction and wear, ensuring long-term performance and efficiency.In addition to their high-quality products, {brand name} is also committed to providing exceptional customer service. Their team of experienced professionals is dedicated to assisting customers with selecting the right valves for their specific needs. Whether it's providing technical support, offering custom valve solutions, or ensuring timely delivery, {brand name} goes above and beyond to meet their customers' requirements.Furthermore, {brand name} is deeply committed to sustainability and environmental responsibility. Their valves are designed with energy efficiency and environmental stewardship in mind, helping companies reduce their carbon footprint and operate more responsibly. By investing in research and development, {brand name} continues to innovate and develop new, eco-friendly valve solutions that meet the evolving needs of the industry.With a proven track record of delivering high-quality products and exceptional service, {brand name} is a trusted partner for companies around the world. Their worm gear actuator butterfly valves have been widely adopted in various industries, thanks to their reliability, durability, and performance. As the demand for industrial valves continues to grow, {brand name} remains at the forefront of innovation, providing cutting-edge solutions that meet the needs of the modern industrial landscape.In conclusion, the worm gear actuator butterfly valves produced by {brand name} are an essential component in industrial applications, providing precise control and reliable performance. With a commitment to quality, customer service, and sustainability, {brand name} has established itself as a leading supplier of industrial valves and actuators. As they continue to innovate and expand their product offerings, {brand name} remains a trusted partner for companies seeking top-of-the-line valve solutions.