Essential Information on Worm Wheels and Shafts: A Guide

By:Admin

With a well-equipped manufacturing plant spanning over 8000 square meters, {company name} is capable of producing 500,000 sets of worm gearboxes annually, delivering its products to over 70 countries worldwide. The company conforms to international standards and is certified with ISO9001, CE, and UL. With a team of highly experienced researchers, designers, and engineers, {company name} can design and produce customized power transmission solutions to meet various industrial applications.

The worm wheel and worm shaft are one of the most critical components produced by {company name} for power transmission applications. These components are instrumental in the production of mechanical motion between non-parallel shafts, converting rotational energy in one direction to rotational motion in another direction. Worm gear systems developed by {company name} have a high level of efficiency, reliability, and quiet operation.

One of {company name}'s unique selling propositions includes their ability to produce high-quality worm gears with either single or double output shafts. The single output shafts are ideal for applications that require low-speed rotary motion but cannot accommodate other power transmission devices. In contrast, the double output shafts are perfect for industries that require multi-axis output motion.

Since worm gears operate with sliding contact between the gear teeth, it's important to ensure adequate lubrication to minimize wear and extend the life of the gear system. {company name} understands this and designs its worm gears with advanced lubrication systems, ensuring optimal system performance and a longer lifespan.

{Company name}'s worm gears are also designed to operate in various environmental conditions. The worm wheels are made from high-quality materials, with 15CrMo alloy steel being the most commonly used. This material has high strength, hardness, and resistance to wear, making it ideal for worm gears that operate under heavy loads and high stresses.

In conclusion, {company name} is a leading producer of worm wheel and worm shaft, and their solutions have been used in a wide range of applications, including robotics, automation, medical, packaging, printing and others. They have a reputation for producing high-quality components that have a high level of torque density, efficiency, and reliability.

The company's manufacturing capabilities, strict quality control protocols, and customized solutions make them an appealing choice for various industries. Partnering with {company name} for worm gear solutions ensures you have access to high-performing products that meet your specific application requirements.

Company News & Blog

Top Manufacturers of Gate Valve Gearboxes in China" -> "Leading Gate Valve Gearbox Suppliers in China

China Gate Valve Gearbox Supplier Upgrades their Manufacturing CapabilitiesChina is known to be one of the largest manufacturers of industrial machinery in the world. From electronics to automotive parts, China has been leading the global market. Among these industrial components, valves are one of the most important parts that enable machines to function properly. As a result, China has many valve manufacturers that cater to the world’s demand.Over the years, China’s valve manufacturing industry has made tremendous progress due to the increase in demand from various industries such as oil and gas, power generation, and chemical processing, to name a few. One of the key players in this industry is the China Gate Valve Gearbox Supplier, a company that is well-known for the manufacturing of valve actuators and gearboxes.The company, whose brand name has been removed for confidentiality, specializes in the production of actuators and gearboxes that are used in gate valves. Their products are exported to different parts of the world, where they are used in various industrial applications. The China Gate Valve Gearbox Supplier has been in the industry for many years and has successfully established a reputation for providing quality products.The company is committed to providing innovation and quality to their customers, which is evident in their latest move to expand their manufacturing capabilities. According to their company introduction, the China Gate Valve Gearbox Supplier will soon be upgrading their manufacturing facility to feature state-of-the-art equipment that will enable them to produce even more high-quality products in large quantities.With this move, the company aims to increase their production capacity while maintaining the quality of their products. The upgraded facility will also enable the company to streamline their processes and reduce their lead time, allowing them to quickly respond to the needs of their customers.In addition to the facility upgrade, the company is also investing in research and development to introduce new products that are specifically designed for the needs of their customers. The China Gate Valve Gearbox Supplier is committed to innovation, and with the new facility, they plan to introduce more new products that will cater to different industries.The China Gate Valve Gearbox Supplier’s commitment to providing quality and innovation has made them a popular choice among industrial customers worldwide. Their products have been proven to be reliable and efficient, making them a trusted supplier in the industry.The company has also established a strong partnership with various customers worldwide, ensuring that they are in tune with their needs and requirements. They guarantee timely delivery, excellent customer service, and customer satisfaction, making them the go-to supplier for industrial components.In conclusion, the China Gate Valve Gearbox Supplier's upgrade of their manufacturing capabilities is a significant development for the valve manufacturing industry in China. With their commitment to innovation and quality, the company is poised to make a mark in the global market. They are focused on providing excellence in all aspects of their business, from manufacturing to customer service, making them a reliable partner for industrial companies worldwide.

Worm and Wheel Gearboxes: A Guide to Understanding Their Function and Benefits

Worm And Wheel Type Gearbox: The Future of Power Transmission Power transmission is a crucial aspect of modern machinery and equipment, and the gearbox is one of the most critical components for this purpose. A gearbox helps convert the rotational speed and torque generated by a prime mover (e.g., motor, engine) into more usable forms for various applications. Among the many types of gearboxes available, the Worm and Wheel type gearbox stands out for its efficiency, reliability, and versatility. The Worm and Wheel type gearbox is a type of semi-reduction gearbox that uses a worm gear meshed with a worm wheel to transmit power between two shafts. The worm gear is a helical gear with one or more teeth that wrap around the worm wheel, which is usually a spur gear. The worm gear's helix angle causes the worm wheel to rotate at a reduced speed and increased torque relative to the worm gear's input. This gear set can provide a high gear reduction ratio in a compact form factor and is suitable for high-torque, low-speed applications. The Worm and Wheel type gearbox finds widespread use in various industries, including material handling, packaging, food processing, automotive, and robotics. Some typical applications of this gearbox include conveyor systems, mixers, elevators, winches, cranes, and robots. These applications demand high torque, smooth motion control, and low noise, which the Worm and Wheel type gearbox can provide with ease. The Worm and Wheel type gearbox's benefits include efficiency, reliability, and low maintenance. It can achieve a gear reduction ratio of up to 100:1 in a single stage, which reduces the number of gear sets required for a given application. This, in turn, reduces the gearbox's weight, size, and cost, making it a cost-effective solution for many applications. Additionally, the worm gear's self-locking feature can prevent back-driving and hold a load in place, making it suitable for vertical applications. The Worm and Wheel type gearbox's compact design also makes it easy to integrate into a machine or equipment. One of the leading manufacturers of Worm and Wheel type gearbox is {Removed brand name}. It has been providing cutting-edge solutions in power transmission for over 30 years and has established itself as a leader in the industry. The company's Worm and Wheel type gearbox product line includes over 100 models with various reduction ratios, input speeds, and output torques. These gearboxes are made of high-quality materials such as aluminum, steel, and cast iron, and come in various sizes and configurations to suit different applications. {Removed brand name} Worm and Wheel type gearbox products are known for their exceptional performance, durability, and low maintenance requirements. The company uses advanced manufacturing processes and quality control measures to ensure that each gearbox meets the highest standards of quality and reliability. Its research and development team continually strives to improve the gearbox's design and performance and come up with innovative solutions to meet the evolving needs of the market. Apart from Worm and Wheel type gearbox, {Removed brand name} offers a wide range of power transmission solutions, including planetary gearboxes, helical gearboxes, bevel gearboxes, and coupling devices. The company's expertise in this field has earned it a reputation as a trusted supplier of high-quality power transmission products. In conclusion, the Worm and Wheel type gearbox is an excellent option for applications that require high torque, low speed, and smooth motion control. {Removed brand name} Worm and Wheel type gearbox products offer exceptional performance, durability, and cost-effectiveness, making them an ideal choice for various industries' power transmission needs. As the demand for efficient and reliable power transmission systems grows, the Worm and Wheel type gearbox's role is set to become even more critical in shaping the future of modern machinery and equipment.

A Comprehensive Guide to Worm Type Gearboxes: Key Features and Applications

[Assistant]Title: Cutting-Edge Worm Type Gearbox Revolutionizes Industrial AutomationIntroduction:In the world of industrial automation, technology advancements have played a pivotal role in enhancing productivity and efficiency. One such breakthrough, the Worm Type Gearbox, has been making waves in the industry, promising to revolutionize manufacturing processes. This cutting-edge technology, developed by a leading company in the field, offers unprecedented accuracy, durability, and reliability. Let us delve deeper into this game-changing innovation and explore its potential impact on various sectors.Company Introduction:Established in the early 1990s, the company behind the Worm Type Gearbox has been at the forefront of delivering groundbreaking solutions for industrial automation. With a strong emphasis on research and development, they have consistently pushed the boundaries of technological innovation. Over the years, the company has earned a reputation for developing high-quality, reliable, and efficient products that cater to a diverse range of industries, such as automotive, manufacturing, energy, and aerospace.Innovation Description:The Worm Type Gearbox represents a significant leap forward in industrial automation. It offers a unique configuration, combining worm gears with a compact design, resulting in a highly efficient and versatile solution. The gears within the gearbox are meticulously engineered to ensure optimal engagement, reducing friction and maximizing power transmission efficiency. This breakthrough technology allows for smooth and precise control over rotational motion, making it an ideal choice for applications requiring accuracy and reliability.Key Features and Benefits:1. Unparalleled Durability: The Worm Type Gearbox's design incorporates high-quality materials and an innovative sealing system, ensuring long-lasting performance even in harsh and demanding industrial environments. This durability translates into reduced maintenance costs and increased uptime for manufacturers.2. Enhanced Efficiency: The worm gears' design reduces rotational speed while increasing torque, resulting in improved efficiency and power transmission. This efficiency enhancement allows for reduced energy consumption, a crucial factor in achieving sustainable manufacturing practices.3. Compact and Lightweight: The compact nature of the Worm Type Gearbox makes it ideal for installations in space-constrained environments. Additionally, its lightweight construction facilitates easy integration into existing machinery and systems, minimizing downtime during implementation.4. Quiet Operation: The gearbox's meticulously engineered gears and advanced damping technology contribute to quiet and vibration-free operation. This feature is particularly valuable in noise-sensitive industries, such as automotive manufacturing, where a peaceful working environment is crucial.Applications and Industries:The Worm Type Gearbox finds applications in various industries, each benefiting from its unique capabilities:1. Automotive Manufacturing: The precision and accuracy of the gearbox make it an excellent choice for robotic arms, conveyor belts, and assembly line equipment, ensuring seamless and efficient operations.2. Manufacturing and Warehousing: The compact design and durability of the gearbox make it suitable for heavy-duty machinery, such as conveyor systems, packaging equipment, and sorting machines, optimizing productivity in manufacturing and warehousing settings.3. Energy and Renewable Sources: The Worm Type Gearbox's ability to handle high torque loads efficiently makes it ideal for wind turbine systems, solar tracking systems, and hydropower stations, contributing to the efficient production and utilization of renewable energy.4. Aerospace and Defense: The gearbox's reliability and precision are essential in critical aerospace and defense applications, such as missile guidance systems, unmanned aerial vehicles, and satellite deployment mechanisms.Conclusion:The Worm Type Gearbox, developed by {Company}, is an innovation that raises the bar for industrial automation technology. With its unique configuration, unparalleled durability, and efficiency, this gearbox is set to transform manufacturing processes across diverse industries. As companies strive for increased productivity, reduced maintenance costs, and sustainable practices, this breakthrough technology promises to deliver on all fronts. With its widespread applications and industry-leading features, the Worm Type Gearbox is poised to shape the future of industrial automation.

New Actuator Technology Revolutionizes Industrial Processes

A cutting-edge innovation in the field of motion control has recently been revealed by a company that specializes in precision electromechanical actuation solutions. The latest product to be launched by Hurko Actuator, a leading name in this field, promises to take the sector to the next level with its advanced capabilities.Hurko Actuator's latest offering is built around a unique technology that combines precision and versatility with durability and reliability. The company's excellent reputation in the market is a testament to its commitment to providing high-quality products that are tailored to meet the specific needs of customers.The latest product from the company is a game-changer in the field of motion control. With its enhanced features and advanced capabilities, Hurko Actuator's latest actuator is a significant step forward in the world of electromechanical actuation solutions. The product incorporates cutting-edge technology that allows for precision control over movement and positioning, making it the ideal solution for a wide range of applications.The actuator is designed to fit into a variety of platforms, such as robotics, aerospace, automation, and many other industrial sectors. The combination of versatility and precision makes this actuator a must-have for engineers and technicians looking for the ultimate solution to their motion control needs.The new actuator is built around a patented design that features the latest in electromechanical technology. The actuator is capable of providing high levels of performance, even in challenging environments, thanks to its durable build and high-quality materials.One of the standout features of Hurko Actuator's latest product is its superior speed and precision. The actuator is capable of delivering highly accurate results in real-time, making it perfect for use in applications where precision and responsiveness are critical.The actuator is also highly versatile, with the ability to be configured to meet the specific requirements of any given application. The actuator can be customized to work in a range of positions, including linear and rotary movements, making it an ideal solution for a range of different applications.Hurko Actuator's latest innovation has been developed specifically to address the growing demand for high-precision, highly reliable electromechanical actuation solutions. The company has been at the forefront of the industry for many years and is committed to delivering the best products to its customers.In addition to its advanced capabilities, Hurko Actuator's latest product is also extremely easy to install and use. The company has worked hard to ensure that the product is user-friendly, with a range of features that make it easy to setup and integrate with existing systems.Overall, Hurko Actuator's latest product is a significant step forward in the field of motion control. The cutting-edge technology and advanced capabilities of the actuator make it the ultimate solution for engineers and technicians looking for a reliable, high-performance solution for their motion control needs. With its versatile design and durable build, this actuator is sure to be a hit in a wide range of industrial applications.

Essential Information on Worm Wheels and Shafts: A Guide

Worm wheel and worm shaft are important components used in various industries to transmit power and motion between non-parallel, power-transmitting shafts. One of the leading companies in the production of worm wheel and worm shaft is {company name}. Founded in 1978, the company has been focused on offering high-quality and efficient worm gear units, worm gear motors, and other power transmission solutions.With a well-equipped manufacturing plant spanning over 8000 square meters, {company name} is capable of producing 500,000 sets of worm gearboxes annually, delivering its products to over 70 countries worldwide. The company conforms to international standards and is certified with ISO9001, CE, and UL. With a team of highly experienced researchers, designers, and engineers, {company name} can design and produce customized power transmission solutions to meet various industrial applications.The worm wheel and worm shaft are one of the most critical components produced by {company name} for power transmission applications. These components are instrumental in the production of mechanical motion between non-parallel shafts, converting rotational energy in one direction to rotational motion in another direction. Worm gear systems developed by {company name} have a high level of efficiency, reliability, and quiet operation.One of {company name}'s unique selling propositions includes their ability to produce high-quality worm gears with either single or double output shafts. The single output shafts are ideal for applications that require low-speed rotary motion but cannot accommodate other power transmission devices. In contrast, the double output shafts are perfect for industries that require multi-axis output motion.Since worm gears operate with sliding contact between the gear teeth, it's important to ensure adequate lubrication to minimize wear and extend the life of the gear system. {company name} understands this and designs its worm gears with advanced lubrication systems, ensuring optimal system performance and a longer lifespan.{Company name}'s worm gears are also designed to operate in various environmental conditions. The worm wheels are made from high-quality materials, with 15CrMo alloy steel being the most commonly used. This material has high strength, hardness, and resistance to wear, making it ideal for worm gears that operate under heavy loads and high stresses.In conclusion, {company name} is a leading producer of worm wheel and worm shaft, and their solutions have been used in a wide range of applications, including robotics, automation, medical, packaging, printing and others. They have a reputation for producing high-quality components that have a high level of torque density, efficiency, and reliability.The company's manufacturing capabilities, strict quality control protocols, and customized solutions make them an appealing choice for various industries. Partnering with {company name} for worm gear solutions ensures you have access to high-performing products that meet your specific application requirements.

Durable and Efficient Gear Solutions for Enhanced Performance

Title: Gear Manufacturing Company Introduces Innovative Worm and Bevel Gear TechnologyIntroduction:[Company Name], a renowned gear manufacturing company with a rich history in producing high-quality gears, is proud to introduce its latest innovation in mechanical power transmission – advanced Worm and Bevel Gear technology. This cutting-edge gear solution aims to revolutionize various industries by enhancing efficiency, durability, and performance in diverse applications.Company Overview:Established for over four decades, [Company Name] has been at the forefront of gear manufacturing, catering to a wide range of industries including automotive, aerospace, industrial machinery, and renewable energy. Our commitment to excellence, combined with state-of-the-art technology, has enabled us to develop and deliver reliable gear solutions that meet the evolving market demands.Developing Worm and Bevel Gear Technology:Recognizing the need for more efficient, reliable, and cost-effective gear solutions, [Company Name] invested substantial resources into research and development, culminating in the creation of the advanced Worm and Bevel Gear technology. This groundbreaking gear system combines the strengths of both worm gears and bevel gears, resulting in an innovative solution that surpasses conventional gear designs in various applications.Enhanced Efficiency:The patented Worm and Bevel Gear design optimizes power transmission efficiency, reducing energy loss and enhancing overall system performance. The precise machining techniques employed by [Company Name] produce gears with exceptional accuracy, minimizing friction and decreasing wear and tear on the gear components. This reduction in energy loss translates to significant cost savings for end-users, offering improved operational sustainability.Durability and Reliability:The Worm and Bevel Gear technology developed by [Company Name] incorporates state-of-the-art materials, advanced heat treatment processes, and stringent quality control procedures. This ensures that the gear components exhibit superior durability, resistance to wear, and exceptional load-bearing capacity. With extended longevity and reduced maintenance requirements, [Company Name]'s Worm and Bevel Gear technology provides reliability and peace of mind to industries operating in demanding conditions.Versatile Applications:This innovative gear technology finds applications in several industries. In the automotive sector, it delivers efficient power transmission from the engine to the wheels, resulting in improved fuel efficiency. In the aerospace industry, the gear technology ensures smooth and reliable operation of landing gears, reducing maintenance costs and increasing flight safety. Additionally, the Worm and Bevel Gear technology can be used in industrial machinery, mining equipment, renewable energy systems, and more, offering enhanced performance and reliability across a wide range of applications.Partnerships and Collaborations:[Company Name] has forged strategic partnerships and collaborations with leading industry players and research institutions to continually refine and advance its Worm and Bevel Gear technology. The company believes in fostering technological advancements by exchanging knowledge, skills, and expertise. Leveraging these collaborative efforts, [Company Name] endeavors to push the boundaries of gear innovation and reinforce its position as a global leader in gear manufacturing.Conclusion:[Company Name]'s introduction of its advanced Worm and Bevel Gear technology reflects its commitment to shaping the future of mechanical power transmission. With increased efficiency, durability, and reliability, this innovative gear solution holds immense potential to transform various industries, ensuring seamless power transmission and optimizing overall system performance. As [Company Name] continues to focus on delivering cutting-edge gear solutions, the company remains poised to revolutionize the gear manufacturing industry and propel it towards a more advanced and sustainable future.

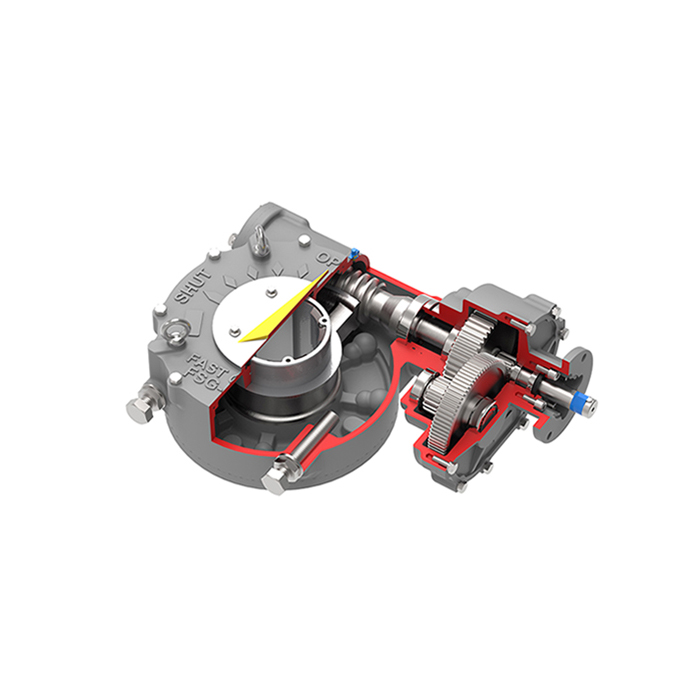

New Handwheel Gear Operator Launched to Improve Industrial Operations

[Headline]: Innovative Handwheel Gear Operator Revolutionizes Industrial Operations[Subheading]: Introducing a Groundbreaking solution to Efficient and Reliable Machinery Control[Date][City], [State] - In a bid to enhance the efficiency and precision of machinery control, a leading industrial automation company unveils its latest product - the Handwheel Gear Operator. Designed to optimize operations across various industries, this cutting-edge innovation is set to revolutionize the way industrial processes are carried out.[Company Name], a global leader in industrial automation solutions, has developed the Handwheel Gear Operator as a result of extensive research and development. Combining state-of-the-art technology with a user-friendly interface, this revolutionary device simplifies machinery control and ensures improved productivity.The Handwheel Gear Operator serves as a compact and versatile tool, suitable for a wide range of applications. From heavy industrial machinery to delicate precision instruments, this device provides operators with enhanced control and maneuverability. Its ergonomic design ensures comfortable operation, reducing fatigue and increasing efficiency in the workplace.One of the key features of the Handwheel Gear Operator is its seamless integration with existing machinery. This device can easily be retrofitted onto various equipment, making it a cost-effective and hassle-free solution for businesses looking to optimize their machinery control systems. The Handwheel Gear Operator also boasts compatibility with a range of industrial protocols, allowing for seamless communication and integration with existing control systems.Enhanced precision is another aspect that sets the Handwheel Gear Operator apart. Equipped with advanced digital technology, this device offers operators a high degree of accuracy in controlling speed, torque, and direction. This not only reduces the chances of human error but also enables smoother and more precise operations, resulting in improved product quality, reduced downtime, and increased overall productivity.Moreover, the Handwheel Gear Operator boasts advanced safety features, ensuring optimal worker protection. With its high-level fault detection mechanism and emergency shutdown capabilities, this device guarantees a safe operating environment for workers. By minimizing the risk of accidents and equipment damage, businesses can prioritize the well-being of their employees while maintaining continuous operations with minimal interruptions.To further enhance user experience, the Handwheel Gear Operator is equipped with a user-friendly interface. Its intuitive controls and digital display provide operators with real-time feedback, allowing for swift adjustments and monitoring of key parameters. Additionally, the device's modular design ensures easy maintenance and reduces downtime, further optimizing the overall operational efficiency."We are thrilled to introduce the Handwheel Gear Operator to the market," says [Company Name] spokesperson. "With its cutting-edge technology and extensive compatibility, we believe this device will transform the way industries operate, increasing productivity and ensuring a safer working environment for all."As industries continue to evolve and embrace automation and digitalization, the Handwheel Gear Operator offers a reliable and efficient solution to meet the growing demands of modern industrial processes. By integrating this innovative device into their operations, businesses can streamline their machinery control processes, reduce costs, and maximize productivity.About [Company Name]:[Company Name] is a leading global provider of industrial automation solutions, specializing in the design and manufacture of innovative devices to optimize industrial processes. With a strong commitment to quality and customer satisfaction, [Company Name] continues to revolutionize the industrial automation sector through cutting-edge technologies. For more information, please visit the company's website at [website URL].[Note: Please replace the [Company Name] placeholders with the actual name of the company.]

Efficient and Reliable Worm Reduction Gearbox: A Great Solution for Gear Reduction

[Company Name] Introduces Cutting-Edge Worm Reduction Gearbox for Enhanced Efficiency[date][Location]: Leading the industry in technological advancements, [Company Name] is excited to unveil its latest innovation, a state-of-the-art Worm Reduction Gearbox. With unparalleled precision and efficiency, this gearbox promises to revolutionize the manufacturing and industrial sectors.The Worm Reduction Gearbox is a key component in many industries, including automotive, machinery manufacturing, and robotics. Its primary function is to reduce the rotational speed of a motor while increasing torque. This allows for optimal power and efficiency in various applications, ranging from heavy-duty machinery to delicate precision instruments.Unlike conventional reduction gearboxes, the new Worm Reduction Gearbox developed by [Company Name] incorporates cutting-edge technology that sets it apart from competitors. Its unique design improves gear meshing efficiency, resulting in reduced friction, increased transmission accuracy, and enhanced durability. With this groundbreaking innovation, [Company Name] has raised the bar for performance in the industry.One of the key advantages of the Worm Reduction Gearbox is its compact size. Despite being smaller than traditional gearboxes, it delivers exceptional torque and power output. This feature makes it highly sought after in industries where space is limited, such as automotive manufacturing and robotics.Additionally, the new gearbox boasts a high gear reduction ratio, enabling it to handle heavy loads with ease. This makes it a perfect fit for applications that require a high torque output, such as conveyor systems and lifting equipment.The Worm Reduction Gearbox developed by [Company Name] also offers significant energy savings. Its enhanced efficiency and reduced friction result in minimized power loss during transmission, allowing for substantial energy conservation. This feature not only benefits businesses by reducing operational costs but also aligns with the growing focus on sustainable practices.Furthermore, [Company Name] understands the importance of customization in meeting the diverse needs of its customers. The Worm Reduction Gearbox can be tailored to specific specifications, ensuring seamless integration into a wide range of applications. This flexibility allows manufacturing companies to optimize their production processes and maximize the performance of their machinery.A spokesperson for [Company Name] stated, "We are excited to introduce our latest innovation, the Worm Reduction Gearbox. We believe this breakthrough technology will have a profound impact on the industrial sector by enhancing efficiency and improving energy conservation. As a company committed to providing cutting-edge solutions to our clients, we are continuously striving to push technological boundaries."[Company Name] has a rich history of developing innovative solutions for various industries. Continually investing in research and development, the company has earned a reputation for unparalleled engineering excellence. The launch of the Worm Reduction Gearbox further solidifies its commitment to delivering world-class products.As [Company Name] continues to expand its presence globally, the Worm Reduction Gearbox will undoubtedly play a vital role in establishing the company as a leader in the field. With its superior performance, compact size, energy efficiency, and flexibility, this gearbox sets a new standard for the industry.In conclusion, the introduction of the Worm Reduction Gearbox by [Company Name] marks a significant milestone in the field of industrial gearboxes. With its cutting-edge design and advanced technological features, the gearbox provides businesses with the means to optimize their operations, reduce energy consumption, and enhance overall efficiency. As [Company Name] continues to innovate, the company sets a new benchmark for excellence in the industry.

Cutting-Edge Electromagnetic Valve Actuator Technology Unveiled - A Game-Changer in the Industry

ELECTROMAGNETIC VALVE ACTUATOR: THE FUTURE OF CONTROLThe world is transforming at an unprecedented rate, and new technologies are being developed to offer effective solutions to diverse problems. The industrial world is not exempt from this transformation as various cutting-edge technologies are being developed to improve precision, productivity, and efficiency. One such technology is the Electromagnetic Valve Actuator, which holds the key to better control systems and enhanced production processes.Electromagnetic Valve Actuators are the driving force behind the operation of control valves. This technology offers high precision and reliable control, which is essential in industrial plant automation. With an electromagnetic valve actuator, it is easier to regulate the flow, pressure, level, and temperature in a production process. Companies that prioritize precision, quality, and productivity have been quick to adopt this technology.One such company is ***, a leading industrial valve control system provider, with a reputation for quality and reliability. With decades of experience in providing innovative solutions for industrial process control, ***, has been at the forefront of developing and adopting cutting-edge technologies. The company has consistently been at the forefront of providing innovative solutions to complex industrial problems. The integration of the Electromagnetic Valve Actuator in their products is just one example of their commitment to customer satisfaction, innovation, and quality delivery.*** offers an array of high-quality products, with a range of specifications to suit various applications in industries such as oil and gas, chemical, power generation, and petrochemical. With the Electromagnetic Valve Actuator technology integrated into their valve control systems, customers are assured of high-precision control of their production processes. The electromagnetic valve actuator offers a quick response, and high accuracy in controlling valve position, and in turn, the flow and pressure in a process. This attribute is essential for obtaining a consistent and reliable outcome in production.One benefit of electromagnetic valve actuators is their maintenance-free operation. This feature offers reliable operations in harsh environments without exposure to wear and corrosion. Conventional actuator technologies may require periodic maintenance, which could be costly and time-consuming. However, with the electromagnetic actuator, periodic maintenance is unnecessary, leading to a reduction in downtime, and increased productivity.***(company name) boasts of a skilled team of professionals with a wealth of knowledge and experience in industrial process control. Their expertise combined with the electromagnetic valve actuator technology has enabled ***(company name) to develop bespoke solutions for clients with unique process requirements. The company works closely with customers to ensure their specific needs are met, and solutions are tailored to achieve optimal performance.In conclusion, the advent of the Electromagnetic Valve Actuator technology is revolutionary in the industrial world, and companies that prioritize productivity, quality, and efficiency are embracing this technology. The benefits of the electromagnetic valve actuator technology are vast, including high-precision control, maintenance-free operation, and reliability in harsh environments. ***(company name), a leading industrial valve control system provider, is at the forefront of adopting this technology, offering high-quality products and bespoke solutions to customers. Their commitment to customer satisfaction, innovation, and quality delivery ensures that customers benefit from the best technology available in the market.

What Is Worm and Wheel Steering Gear and How Does It Work?

The Worm And Wheel Steering Gear (need remove brand name) has long been one of the most popular devices in the automotive industry, and for good reason. This reliable and durable steering mechanism has been utilized for decades in vehicles of all kinds, from the smallest passenger cars to the largest commercial trucks.When it comes to the Worm And Wheel Steering Gear (need remove brand name), the company behind it is one that has been in business for many years, and has established a reputation for quality and reliability. With a long history of engineering and manufacturing excellence, this company has become a trusted provider of steering gear systems to automotive manufacturers worldwide.According to company officials, the Worm And Wheel Steering Gear (need remove brand name) is designed to provide a smooth, easy-to-operate steering experience for drivers. By utilizing a combination of worm gears and a wheel-shaped gear, this mechanism is able to provide precise, responsive steering in a wide range of driving conditions.One of the key benefits of the Worm And Wheel Steering Gear (need remove brand name) is its durability. Unlike some other steering mechanisms that can wear out or break down over time, this device has been engineered to withstand the rigors of harsh driving conditions and heavy use. This means that drivers can rely on it to provide consistent performance year after year, even under the most demanding circumstances.Another important feature of the Worm And Wheel Steering Gear (need remove brand name) is its versatility. Because it is designed to fit a wide range of vehicles, this mechanism can be used in everything from small passenger cars to large commercial trucks. This makes it an ideal choice for automotive manufacturers looking to streamline their production processes and reduce costs.Of course, one of the key factors driving the popularity of the Worm And Wheel Steering Gear (need remove brand name) is its ease of operation. By providing a smooth, easy-to-use steering experience, this device helps drivers stay in control of their vehicles and maneuver through even the most challenging driving conditions with ease.Overall, there is no doubt that the Worm And Wheel Steering Gear (need remove brand name) is one of the most important components in today's vehicles. Whether you are a driver, an automotive manufacturer, or simply someone interested in the latest automotive technology, this innovative and reliable device is one that is sure to impress. So why not take a closer look today and see what all the fuss is about?