Discover the Advantages and Applications of Bevel Worm Gears

By:Admin

[City, State], [Month, Day, Year] - [Company Name], a leading provider of advanced industrial solutions, proudly announces the launch of their latest technological innovation - the Bevel Worm Gear. This cutting-edge gear mechanism is poised to revolutionize various industries by offering increased productivity, superior efficiency, and enhanced performance.

The Bevel Worm Gear technology is a result of several years of intensive research and development efforts by [Company Name]'s team of highly skilled engineers and scientists. This advanced gear mechanism combines the best features of bevel gears and worm gears, resulting in a highly versatile solution suitable for a wide range of applications.

The bevel gear aspect of this technology ensures smooth and efficient power transmission between intersecting shafts. By utilizing specially designed teeth, the gear effectively transfers power at various angles, allowing for enhanced flexibility in machinery design. This enables engineers to create more compact and efficient systems, reducing the overall footprint of machinery without compromising performance.

Simultaneously, the worm gear component brings unparalleled efficiency and precision to the table. The worm gear is known for its high gear ratio and self-locking capabilities, which prevent components from moving when not in use. This feature is particularly advantageous in industries that require precision control and safety, as it prevents accidental movement and potential damage to machinery.

In addition to its compact design and power transmission capabilities, the Bevel Worm Gear technology offers substantial torque output. This makes it ideal for heavy-duty machinery applications that demand high power and accuracy, such as industrial manufacturing, mining, and construction.

Furthermore, [Company Name] has subjected the Bevel Worm Gear technology to rigorous testing to ensure its durability and longevity. The gear mechanism is constructed with premium-grade materials, ensuring resistance to wear, fatigue, and excessive friction. This robust build ensures that machinery equipped with Bevel Worm Gear technology can withstand harsh operating conditions, guaranteeing increased longevity and reduced maintenance costs.

With the launch of this game-changing technology, [Company Name] revolutionizes various industries, providing them with a solution that significantly enhances productivity, efficiency, and performance. Manufacturers worldwide can expect increased throughput, reduced downtime, and improved overall operational efficiency, leading to significant cost savings and an enhanced competitive edge.

"Introducing the Bevel Worm Gear technology is a significant milestone for us," stated [Company Name]'s CEO. "We believe that this innovation will redefine industrial manufacturing processes and enable companies to push the boundaries of what they can achieve. Our team has worked diligently to develop a gear mechanism that seamlessly combines the best features of bevel and worm gears, and we are excited to witness the transformative impact it will have on diverse industries."

The Bevel Worm Gear technology is anticipated to disrupt various industries, including automotive, aerospace, energy, and marine. Its versatility and efficiency make it well-suited for numerous applications, ranging from conveyor systems and material handling equipment to robotics and heavy machinery.

[Company Name] plans to collaborate with leading manufacturers in different sectors to integrate the Bevel Worm Gear technology into their machinery and enhance their offerings. By joining forces with industry leaders, [Company Name] aims to accelerate the adoption of this revolutionary technology and foster a new era of productivity, efficiency, and innovation.

As a key player in the industrial solutions landscape, [Company Name]'s introduction of the Bevel Worm Gear technology establishes the company as a forward-thinking innovator committed to driving progress and enabling industries to thrive in a rapidly evolving world. With this new development, manufacturers can anticipate increased operational capabilities and the ability to overcome complex challenges efficiently and effectively.

Company News & Blog

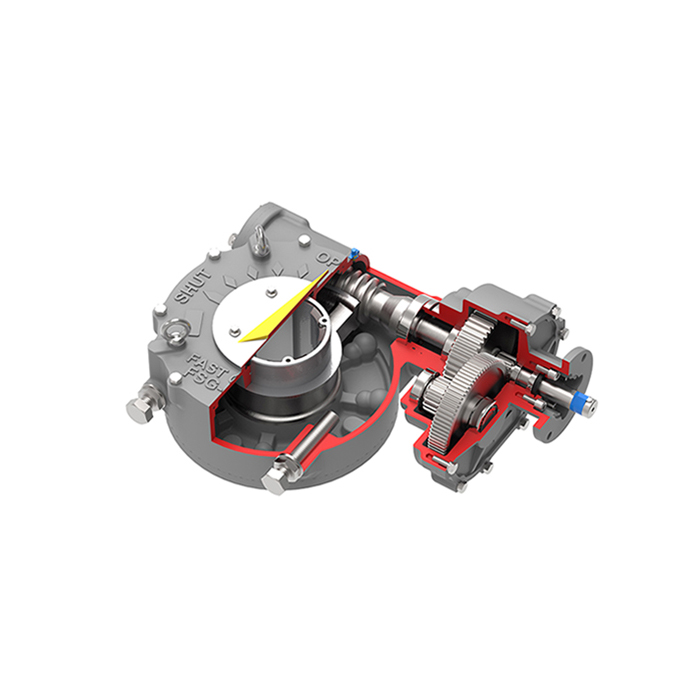

Motorized Actuator Used for Butterfly Valves

[Company Introduction]In today's rapidly evolving industrial landscape, where the demand for high-performance and reliable valve solutions is on the rise, one company has emerged as a pioneer in the field. With a commitment to innovation and unparalleled product quality, this company has continuously delivered exceptional valve solutions that cater to diverse industries. By seamlessly blending modern technology with robust engineering, they have established themselves as a market leader, meeting the evolving needs of their customers.[News Content - Butterfly Valve Motorized Actuator]In line with their dedication to providing cutting-edge valve solutions, this renowned company is proud to introduce its latest product innovation – the Butterfly Valve Motorized Actuator. This state-of-the-art actuator is specifically designed to enhance the performance and functionality of butterfly valves, enabling precise flow control in a wide range of applications.The Butterfly Valve Motorized Actuator offers several key features that set it apart from its competitors. Firstly, it incorporates advanced motorized technology, allowing for seamless automation and remote control of valve operations. This ensures enhanced operational efficiency and eliminates the need for manual adjustments, thereby reducing labor costs and minimizing the risk of human error.Furthermore, this actuator boasts robust construction and durability, guaranteeing reliable performance even in the harshest environments. Its high-strength materials provide resistance to corrosion, wear, and tear, making it a suitable choice for industries such as oil and gas, water treatment, chemical processing, and HVAC systems.One of the standout features of this motorized actuator is its exceptional control accuracy. Equipped with precision sensors and an intelligent control system, it enables precise adjustment of valve opening and closure, ensuring optimal flow regulation. This level of accuracy enhances the overall operational efficiency, significantly improving process control and productivity.Moreover, the Butterfly Valve Motorized Actuator offers unmatched adaptability. Its modular design allows for easy integration and retrofitting with existing butterfly valves, eliminating the need for expensive valve replacements. This versatility not only saves time and costs but also ensures a seamless transition to automated operations.Safety is another critical aspect addressed by this innovative actuator. It incorporates failsafe mechanisms that ensure immediate response in emergency situations such as power failures or abnormal system conditions. Its intelligent sensing technology can detect anomalies and trigger appropriate actions, preventing accidents and safeguarding personnel and equipment.This breakthrough product also embraces sustainability principles. By optimizing energy consumption and reducing leakage risks, it promotes environmental consciousness while maintaining superior performance standards. Furthermore, its low maintenance requirements result in extended service life, ultimately reducing waste and enhancing overall sustainability.To ensure the highest level of client satisfaction, the company's Butterfly Valve Motorized Actuator is backed by a comprehensive customer support system. Their team of highly skilled professionals offers timely technical support, guidance in product selection, and assistance in installation and integration processes.In conclusion, the introduction of the Butterfly Valve Motorized Actuator marks a significant milestone for this industry-leading company. Unleashing the power of automation, precision, durability, and adaptability, this innovative actuator sets a new standard for valve solutions. With its exceptional features and unparalleled product quality, this company continues to prove its commitment to revolutionizing the valve industry and meeting the dynamic needs of customers across different sectors.

Top Multi Turn Spur Gearbox Manufacturer in China Featured in Latest News

China Multi Turn Spur Gearbox Manufacturer, one of the leading manufacturers of gears and gearboxes in China, has recently introduced a new line of products that offer advanced performance, reliability, and durability. The company has been a trusted supplier of gears and gearboxes for over a decade, and its latest offering builds on its reputation for quality and innovation.The new product line includes a range of multi-turn spur gearboxes that are designed to provide precise and efficient power transmission across a wide range of applications. These gearboxes are ideal for use in industries such as agriculture, construction, mining, and transportation, where precise control of torque and speed is essential for optimal performance.According to the company's spokesperson, the multi-turn spur gearboxes are made from the highest-quality materials and undergo rigorous testing to ensure that they meet the highest industry standards. "Our gearboxes are designed to withstand the toughest operating conditions and provide long-lasting performance," the spokesperson said. "We understand the importance of reliability and durability in our customers' operations, and we aim to provide them with products that exceed their expectations."The multi-turn spur gearboxes come in a variety of sizes and configurations, making them suitable for a wide range of applications. The gearboxes are also highly customizable, and the company offers a range of options to suit the specific needs of each customer.In addition to its new product line, China Multi Turn Spur Gearbox Manufacturer also offers a range of other products, including planetary gearboxes, worm gearboxes, helical gearboxes, and bevel gearboxes. The company has a team of experienced engineers and technicians who work closely with customers to provide tailored solutions for their unique requirements.The company prides itself on its commitment to customer service, and its team is available to provide support and guidance throughout the entire process, from initial consultation to installation and maintenance. "We understand that our customers rely on us to provide products and solutions that meet their specific needs, and we take that responsibility very seriously," the spokesperson said.In addition to its focus on quality and reliability, China Multi Turn Spur Gearbox Manufacturer is also committed to sustainability. The company has implemented a range of environmentally conscious practices, including the use of eco-friendly materials, efficient manufacturing processes, and responsible waste management."We recognize the importance of protecting our planet, and we aim to do our part by implementing sustainable practices in all aspects of our business," the spokesperson said. "We believe that our customers value sustainability, and we are proud to offer products that are both high-performing and environmentally responsible."Overall, China Multi Turn Spur Gearbox Manufacturer continues to be a leader in the gear and gearbox industry, offering innovative and reliable products that meet the evolving needs of its customers. The company's commitment to quality, customer service, and sustainability makes it a trusted partner for businesses around the world.

Innovative Turbine Wheel: Unleashing the Power of Efficient Energy Generation

Turbine Wheel, a leading provider of turbine wheel technology, is revolutionizing the energy industry with its innovative products that improve efficiency, reliability, and performance. The company's state-of-the-art technology is designed to meet the needs of power generation and other industrial applications, helping businesses reduce their carbon footprint while improving their bottom line.The company's turbine wheels are manufactured using advanced materials and technologies that make them lighter, stronger, and more durable than traditional designs. They are designed to operate at high temperatures and pressures, making them ideal for use in demanding applications such as gas turbines, steam turbines, and other power generation systems.One of the key advantages of Turbine Wheel's products is their ability to improve energy efficiency. Turbine wheels are responsible for converting the energy from fuel into mechanical energy, which is then used to generate electricity. By improving the efficiency of this process, Turbine Wheel's products help businesses reduce their energy costs while also reducing their carbon footprint.In addition to improving energy efficiency, Turbine Wheel's products also improve reliability and performance. Their state-of-the-art design reduces stresses on the wheel, extending its lifespan and reducing the likelihood of failure. This means that power plants and other industrial facilities can operate more reliably, with less downtime and fewer costly repairs.Turbine Wheel's commitment to innovation has also led to the development of specialized products for specific applications. For example, the company has developed a range of turbine wheels specifically designed for use in renewable energy systems, such as wind turbines and hydroelectric power plants. These products are designed to operate in variable conditions, maximizing energy output while minimizing wear and tear on the equipment.The company's commitment to quality is evident in every aspect of its business operations. Turbine Wheel has a state-of-the-art manufacturing facility that utilizes the latest technologies and processes to produce high-quality products consistently. The company also has a rigorous quality control program that ensures every product meets or exceeds industry standards.Turbine Wheel's dedication to innovation, quality, and customer service has earned it a reputation as an industry leader. The company has a global presence, with operations in North America, Europe, and Asia. It is trusted by some of the world's leading energy companies, including ExxonMobil, Shell, and Siemens.Looking ahead, Turbine Wheel is continuing to invest in research and development to explore new technologies and applications for its products. The company is also exploring partnerships and collaborations with other leading companies in the energy industry to leverage the strengths of each organization and develop innovative solutions to meet the world's growing energy needs.In summary, Turbine Wheel is a leading provider of turbine wheel technology that is transforming the energy industry. Its innovative products improve efficiency, reliability, and performance while reducing costs and carbon footprint. With a commitment to innovation, quality, and customer service, Turbine Wheel is poised for continued success in the global energy market.

New Handwheel Gear Operator Launched to Improve Industrial Operations

[Headline]: Innovative Handwheel Gear Operator Revolutionizes Industrial Operations[Subheading]: Introducing a Groundbreaking solution to Efficient and Reliable Machinery Control[Date][City], [State] - In a bid to enhance the efficiency and precision of machinery control, a leading industrial automation company unveils its latest product - the Handwheel Gear Operator. Designed to optimize operations across various industries, this cutting-edge innovation is set to revolutionize the way industrial processes are carried out.[Company Name], a global leader in industrial automation solutions, has developed the Handwheel Gear Operator as a result of extensive research and development. Combining state-of-the-art technology with a user-friendly interface, this revolutionary device simplifies machinery control and ensures improved productivity.The Handwheel Gear Operator serves as a compact and versatile tool, suitable for a wide range of applications. From heavy industrial machinery to delicate precision instruments, this device provides operators with enhanced control and maneuverability. Its ergonomic design ensures comfortable operation, reducing fatigue and increasing efficiency in the workplace.One of the key features of the Handwheel Gear Operator is its seamless integration with existing machinery. This device can easily be retrofitted onto various equipment, making it a cost-effective and hassle-free solution for businesses looking to optimize their machinery control systems. The Handwheel Gear Operator also boasts compatibility with a range of industrial protocols, allowing for seamless communication and integration with existing control systems.Enhanced precision is another aspect that sets the Handwheel Gear Operator apart. Equipped with advanced digital technology, this device offers operators a high degree of accuracy in controlling speed, torque, and direction. This not only reduces the chances of human error but also enables smoother and more precise operations, resulting in improved product quality, reduced downtime, and increased overall productivity.Moreover, the Handwheel Gear Operator boasts advanced safety features, ensuring optimal worker protection. With its high-level fault detection mechanism and emergency shutdown capabilities, this device guarantees a safe operating environment for workers. By minimizing the risk of accidents and equipment damage, businesses can prioritize the well-being of their employees while maintaining continuous operations with minimal interruptions.To further enhance user experience, the Handwheel Gear Operator is equipped with a user-friendly interface. Its intuitive controls and digital display provide operators with real-time feedback, allowing for swift adjustments and monitoring of key parameters. Additionally, the device's modular design ensures easy maintenance and reduces downtime, further optimizing the overall operational efficiency."We are thrilled to introduce the Handwheel Gear Operator to the market," says [Company Name] spokesperson. "With its cutting-edge technology and extensive compatibility, we believe this device will transform the way industries operate, increasing productivity and ensuring a safer working environment for all."As industries continue to evolve and embrace automation and digitalization, the Handwheel Gear Operator offers a reliable and efficient solution to meet the growing demands of modern industrial processes. By integrating this innovative device into their operations, businesses can streamline their machinery control processes, reduce costs, and maximize productivity.About [Company Name]:[Company Name] is a leading global provider of industrial automation solutions, specializing in the design and manufacture of innovative devices to optimize industrial processes. With a strong commitment to quality and customer satisfaction, [Company Name] continues to revolutionize the industrial automation sector through cutting-edge technologies. For more information, please visit the company's website at [website URL].[Note: Please replace the [Company Name] placeholders with the actual name of the company.]

Discover the Latest Innovation in Worm Type Gear Boxes

Title: Innovative Worm Type Gear Box Revolutionizes Industrial ApplicationsIntroduction:In an era of continuous technological advancements, companies around the world are constantly striving to improve efficiency and productivity in various industries. One such enterprise has taken a giant leap forward with the development of an advanced Worm Type Gear Box, poised to transform the landscape of industrial applications.Company Background:Founded in [], [Company Name] has established itself as a pioneer in engineering and manufacturing solutions for numerous sectors. Its commitment to innovation, extensive research and development, and dedication to customer satisfaction have made it a trusted name among industry leaders.The Development of the Worm Type Gear Box:[Company Name]'s team of experienced engineers and designers have been working tirelessly to develop a revolutionary Worm Type Gear Box. This technological breakthrough stands poised to optimize the performance of machinery across a wide range of industries including manufacturing, energy, transportation, and more.Key Features and Benefits:1. Enhanced Efficiency: The Worm Type Gear Box employs cutting-edge design techniques that significantly enhance operational efficiency. This allows for smoother torque transmission and lower energy consumption compared to conventional gear systems.2. Durability and Longevity: Engineered with the highest quality materials, the Worm Type Gear Box is built to withstand even the harshest environmental conditions. Its robust construction ensures exceptional durability, reducing maintenance costs and increasing overall productivity.3. Versatility: The versatile design of the Worm Type Gear Box caters to a broad spectrum of industrial applications. From heavy-duty machinery to complex precision systems, this gear box has been meticulously crafted to cater to the diverse needs of multiple sectors.4. Noise Reduction: Noise pollution within industrial environments is a common concern. The Worm Type Gear Box incorporates advanced noise reduction technology, minimizing operational noise levels and creating a more desirable working environment.5. Compact Design: Space optimization is crucial in modern industrial setups. The Worm Type Gear Box offers a compact form factor without compromising on performance, making it the perfect choice for machinery working in limited space.Applications and Potential Impact:The groundbreaking Worm Type Gear Box has the potential to revolutionize a multitude of industries. Here are some key applications:1. Manufacturing Industry: The gear box can be integrated into assembly lines, conveyor systems, and robotic machinery, enabling significant improvements in production efficiency and product quality.2. Energy Sector: The Worm Type Gear Box can be utilized in wind turbines, solar power systems, and hydroelectric plants, contributing to increased renewable energy generation capacity and reduced carbon emissions.3. Transportation: This innovative gear box can enhance the performance of electric vehicles, locomotives, and ships, resulting in improved energy efficiency and reduced maintenance costs.Conclusion:The advent of the Worm Type Gear Box developed by [Company Name] represents a significant milestone in industrial automation and efficiency. Its advanced features, versatility, and durability make it an ideal choice for companies across various sectors seeking to optimize performance while simultaneously reducing costs and environmental impact. As the momentum of industrial innovation continues to accelerate, [Company Name] remains committed to pushing the boundaries of engineering solutions, making a profound impact on the global industrial landscape.

Electric Actuators Revolutionize Valve Control Operations

The Electric Motor Operated Valve Actuators industry is witnessing remarkable growth in recent years. These actuator systems, which help automate valve operations, have become an integral part of various industries such as oil and gas, chemical, water and wastewater, and power generation. They provide precise control and positioning of valves, ensuring efficient and reliable operations across a range of applications.Electric motor operated valve actuators are preferred over traditional manual or pneumatic actuators due to their numerous advantages. They offer enhanced control accuracy, quick response times, and remote operation capabilities. These actuators are designed to withstand harsh environmental conditions, making them suitable for use in challenging applications. They also offer energy savings compared to other actuator types, reducing operational costs for industries.One prominent player in the Electric Motor Operated Valve Actuators market is a global leader in industrial automation solutions. With a strong focus on innovation and advanced technologies, this company has established itself as a trusted provider of actuation systems. Their electric motor operated valve actuators are known for their superior performance, reliability, and durability.The company's electric motor operated valve actuators are designed to meet the diverse needs of various industries. These actuators are available in different types, including quarter-turn, multi-turn, and linear, to accommodate different valve applications. They are equipped with advanced features such as position feedback, torque control, and fail-safe functions, ensuring safe and efficient valve operations.One of the key advantages of these electric motor operated valve actuators is their versatility. They can be used with various types of valves, including ball valves, butterfly valves, and gate valves, facilitating a wide range of industrial applications. These actuators offer precise control over valve position and flow rate, enhancing process efficiency and reliability.Moreover, the electric motor operated valve actuators from this company are designed for easy installation and maintenance. They are equipped with intelligent diagnostics and monitoring capabilities, enabling predictive maintenance and minimizing downtime. The actuators are also compatible with various communication protocols, allowing seamless integration with existing control systems.In addition to offering advanced actuation systems, the company also provides comprehensive support services. Their team of experts offers technical assistance, training, and consultation to help customers maximize the performance of their valve automation systems. They also provide customization options, tailoring their actuators to specific customer requirements.The company's commitment to quality and customer satisfaction has earned them a strong reputation in the industry. They have a global presence, serving customers in different regions. Their electric motor operated valve actuators have been widely adopted in various industries, contributing to improved operational efficiency and cost savings.Overall, the Electric Motor Operated Valve Actuators market is experiencing substantial growth due to the increasing demand for automated valve solutions. The advanced features, versatility, and reliable performance of electric motor operated valve actuators have made them the preferred choice for industries worldwide. With continuous advancements in technology and a strong focus on customer needs, companies like the one mentioned above are well-positioned to lead the market and drive innovation in this dynamic industry.

Worm and Wheel Gearboxes: A Guide to Understanding Their Function and Benefits

Worm And Wheel Type Gearbox: The Future of Power Transmission Power transmission is a crucial aspect of modern machinery and equipment, and the gearbox is one of the most critical components for this purpose. A gearbox helps convert the rotational speed and torque generated by a prime mover (e.g., motor, engine) into more usable forms for various applications. Among the many types of gearboxes available, the Worm and Wheel type gearbox stands out for its efficiency, reliability, and versatility. The Worm and Wheel type gearbox is a type of semi-reduction gearbox that uses a worm gear meshed with a worm wheel to transmit power between two shafts. The worm gear is a helical gear with one or more teeth that wrap around the worm wheel, which is usually a spur gear. The worm gear's helix angle causes the worm wheel to rotate at a reduced speed and increased torque relative to the worm gear's input. This gear set can provide a high gear reduction ratio in a compact form factor and is suitable for high-torque, low-speed applications. The Worm and Wheel type gearbox finds widespread use in various industries, including material handling, packaging, food processing, automotive, and robotics. Some typical applications of this gearbox include conveyor systems, mixers, elevators, winches, cranes, and robots. These applications demand high torque, smooth motion control, and low noise, which the Worm and Wheel type gearbox can provide with ease. The Worm and Wheel type gearbox's benefits include efficiency, reliability, and low maintenance. It can achieve a gear reduction ratio of up to 100:1 in a single stage, which reduces the number of gear sets required for a given application. This, in turn, reduces the gearbox's weight, size, and cost, making it a cost-effective solution for many applications. Additionally, the worm gear's self-locking feature can prevent back-driving and hold a load in place, making it suitable for vertical applications. The Worm and Wheel type gearbox's compact design also makes it easy to integrate into a machine or equipment. One of the leading manufacturers of Worm and Wheel type gearbox is {Removed brand name}. It has been providing cutting-edge solutions in power transmission for over 30 years and has established itself as a leader in the industry. The company's Worm and Wheel type gearbox product line includes over 100 models with various reduction ratios, input speeds, and output torques. These gearboxes are made of high-quality materials such as aluminum, steel, and cast iron, and come in various sizes and configurations to suit different applications. {Removed brand name} Worm and Wheel type gearbox products are known for their exceptional performance, durability, and low maintenance requirements. The company uses advanced manufacturing processes and quality control measures to ensure that each gearbox meets the highest standards of quality and reliability. Its research and development team continually strives to improve the gearbox's design and performance and come up with innovative solutions to meet the evolving needs of the market. Apart from Worm and Wheel type gearbox, {Removed brand name} offers a wide range of power transmission solutions, including planetary gearboxes, helical gearboxes, bevel gearboxes, and coupling devices. The company's expertise in this field has earned it a reputation as a trusted supplier of high-quality power transmission products. In conclusion, the Worm and Wheel type gearbox is an excellent option for applications that require high torque, low speed, and smooth motion control. {Removed brand name} Worm and Wheel type gearbox products offer exceptional performance, durability, and cost-effectiveness, making them an ideal choice for various industries' power transmission needs. As the demand for efficient and reliable power transmission systems grows, the Worm and Wheel type gearbox's role is set to become even more critical in shaping the future of modern machinery and equipment.

Heli Worm Gearbox: A Remarkable Advancement in Gear Technology

As technology continues to advance, more and more industries are benefiting from technological advancements, and the agriculture industry is not left behind. With the introduction of Heli Worm Gearboxes, the agricultural sector can now enjoy improved efficiency and productivity as well as greater cost savings.Heli Worm Gearboxes is a product of Heli Transmission, a company that has been in operation for over 27 years. The company prides itself on using advanced technologies to produce durable and high-quality products that meet the needs of its clients. Heli Transmission has established a reputation for producing high-performance products, and its Heli Worm Gearbox is no exception.Heli Worm Gearboxes have been designed to withstand some of the toughest working conditions on farms and other agricultural settings. These gearboxes are essential in the operation of farm machinery such as harvesters, plows, cultivators, and sprayers. The gearboxes are used to transmit power from the tractor engine to other farm equipment while regulating the speed of the equipment.One significant advantage of Heli Worm Gearboxes is their efficiency. These gearboxes are designed to convert high-speed, low-torque power to low-speed, high-torque power. This makes them particularly useful in heavy-duty farming settings, where high torque output is required to operate machinery such as cultivators, seed drills, and soil aerators. By reducing the speed of the engine, Heli Worm Gearboxes help save fuel and reduce the rate of wear and tear on the equipment.Heli Worm Gearboxes are made using high-grade materials that make them highly durable and reliable. The company guarantees long service life for all its products, and the Heli Worm Gearboxes are no exception. The gearboxes are designed to operate with minimal maintenance, and this translates to lower costs for farmers who use them.The design of Heli Worm Gearboxes incorporates a housing that encloses the gears and bearings. The housing protects the gears and bearings from external elements such as dust, moisture, and air pollution. This ensures that the gears and bearings are well lubricated and protected from wear and tear. Furthermore, the housing also acts as a heat sink that dissipates heat generated by the gearbox. This helps to maintain optimal temperature, preventing overheating, which can cause damage to the gearbox.One other advantage of Heli Worm Gearboxes is their versatility. These gearboxes come in various sizes and designs that can be customized to suit the needs of different farming scenarios. Farmers can choose the appropriate gearbox that will provide optimal performance while ensuring that it meets the requirements of the machinery being used.In conclusion, Heli Worm Gearboxes offer many advantages that make them the ideal choice for farmers. These gearboxes are designed to provide efficient power transfer, durability, and versatility. They are well-constructed and designed to withstand the tough conditions of farming, while ensuring that machinery operates at peak performance. Heli Worm Gearboxes represent a significant investment by farmers, with the assurance of long service life and cost savings that come with efficient and reliable performance. The Heli Worm Gearbox is truly a valuable addition to any farming operation.

New Limit Switch Box Technology Now Available - Streamlining Industrial Processes

In the industrial world, there is no denying that safety is a top priority. With heavy machinery and equipment in use, workers need to remain safe while operating or maintaining these assets. In order to mitigate potential safety hazards, the use of limit switches has become an integral part of industrial processes. One such limit switch box that is making waves in the industry is Apl-210. Known for its reliability and simplicity, the Apl-210 limit switch box has quickly become a fan favorite among industrialists.This versatile switch box can be used in a myriad of industrial applications such as cranes, elevators, conveyors, packaging machines, and other automated machinery. The Apl-210 is housed in a compact yet rugged enclosure made from high-quality materials that provide superior resistance against harsh industrial environments. The housing is also designed to protect the internal components from dust, moisture, and other contaminants.One of the unique features of the Apl-210 limit switch box is its modular design. This design allows for quick and easy installation and maintenance. The switch box is comprised of various components that can be easily swapped out or replaced without the need for specialized tools or expertise. Moreover, the wiring of this limit switch box is easy to understand, making it simple to integrate into any application.The Apl-210 limit switch box is also known for its high-precision performance. It utilizes high-quality mechanical parts that allow for accurate and reliable switching. With its adjustable operating range, the limit switch box provides flexibility in its application. In addition, the switch box has a high degree of repeatability, ensuring the consistent operation of industrial equipment.The switch box is built with advanced safety features that ensure the safety of workers. It offers reliable protection against unexpected equipment movements, ensuring that workers remain safe during operation. Moreover, the APL-210 is designed to withstand extreme vibration and shock, which is a crucial factor in ensuring the longevity of the equipment.It is no surprise that the Apl-210 limit switch box has become a go-to solution for industrialists. Along with its exceptional performance, the company behind the product is renowned for its commitment to quality and excellent customer service. The company provides different customization options and works closely with its clients to provide tailored solutions that fit their unique needs. The Apl-210 limit switch box is a testament to the company's dedication to providing reliable and robust products to the industrial world.In conclusion, the Apl-210 limit switch box has set itself apart as a trusted safety solution for various mechanical and automated processes. With its mechanical precision, flexible application, and excellent safety features, it is no surprise that it has become a go-to solution for industrialists around the globe. With the product's reliable performance and the company's commitment to quality, it is evident that the Apl-210 limit switch box will continue to make waves in the industrial world for years to come.

Essential Guide to Air Filter Regulators and Lubricators: Maintenance and Functionality Explained

[Your Name][Your Position][Date][Title of the Article][City Name, State Name] - [Company Name], a leading provider of industrial equipment, is proud to introduce its innovative Air Filter Regulator and Lubricator (AFRL) to the market. Designed to enhance the efficiency and effectiveness of air-operated equipment, this cutting-edge technology revolutionizes the way industries regulate air pressure and deliver lubrication.[Company Name] has been a reputable name in the industrial equipment manufacturing industry for over [number of years] years. Known for its commitment to delivering high-quality products, the company has built a strong reputation for its exceptional engineering and attention to detail.The newly launched AFRL is a game-changer in the industry. It combines the functionalities of an air filter, regulator, and lubricator into a single, compact unit. This innovative design improves operational productivity, enhances equipment performance, and prolongs the lifespan of air tools.One of the key features of the AFRL is its advanced filtration system. With a high-performance air filter that removes contaminants such as dust, oil, and water, it ensures clean and dry air supply to pneumatic tools. This key functionality not only protects the tools but also prevents damage and reduces maintenance costs.The air pressure regulator integrated into the AFRL allows for precise control over the pressure levels delivered to pneumatic devices. This feature is particularly beneficial for sensitive equipment that requires accurate and consistent pressure for optimal performance. By maintaining a steady pressure, the AFRL prevents pressure fluctuations, enhancing the stability and reliability of air-driven machinery.Additionally, the AFRL's lubrication system guarantees the smooth operation of air tools. The unit efficiently delivers an appropriate amount of lubricant, maximizing the performance and prolonging the life of the tools. This advanced lubrication mechanism ensures the reduction of friction and wear, resulting in improved efficiency and reduced downtime.The compact and modular design of the AFRL makes it easy to install and integrate into existing equipment setups. The unit's user-friendly interface allows for simple adjustment of settings, enabling operators to optimize air pressure and lubrication levels effortlessly. The AFRL can be easily customized to fit specific requirements, catering to a wide range of industries such as manufacturing, automotive, food processing, and more.[Company Name]'s commitment to customer satisfaction goes beyond product quality. The company provides comprehensive after-sales support, technical assistance, and regular maintenance services to ensure the longevity and optimal functioning of the AFRL. With a reliable warranty program, customers can have peace of mind knowing that their investment is protected."We are thrilled to bring this revolutionary AFRL to market," said [Name], [Position] at [Company Name]. "With our innovative design and commitment to delivering exceptional performance, we believe that this product will significantly improve operational efficiency and enhance the overall productivity of various industries."[Company Name] continues to be an industry leader, constantly striving to innovate and develop new solutions to meet the changing needs of its customers. The introduction of the AFRL further solidifies the company's position as a reliable provider of top-quality industrial equipment.About [Company Name]:[Company Name] is a renowned industrial equipment manufacturer, dedicated to delivering exceptional products and services to customers. With a strong focus on innovation and customer satisfaction, the company has consistently achieved recognition for its engineering excellence and commitment to quality. [Company Name]'s diverse product range includes [list some of the main products/services offered by the company].For press inquiries or more information, please contact:[Company Name][Contact Person][Position][Phone Number][Email Address]###Note: The above text is only a sample and should be modified to fit the specific brand and company information.