Worm Wheel Gear: Everything You Need to Know

By:Admin

With a history of over 50 years in the industry, Worm Wheel Gear has built a strong reputation for producing high-quality, reliable products. The company prides itself on its commitment to continuous improvement and innovation, and the development of precision worm wheel gears is a testament to this dedication.

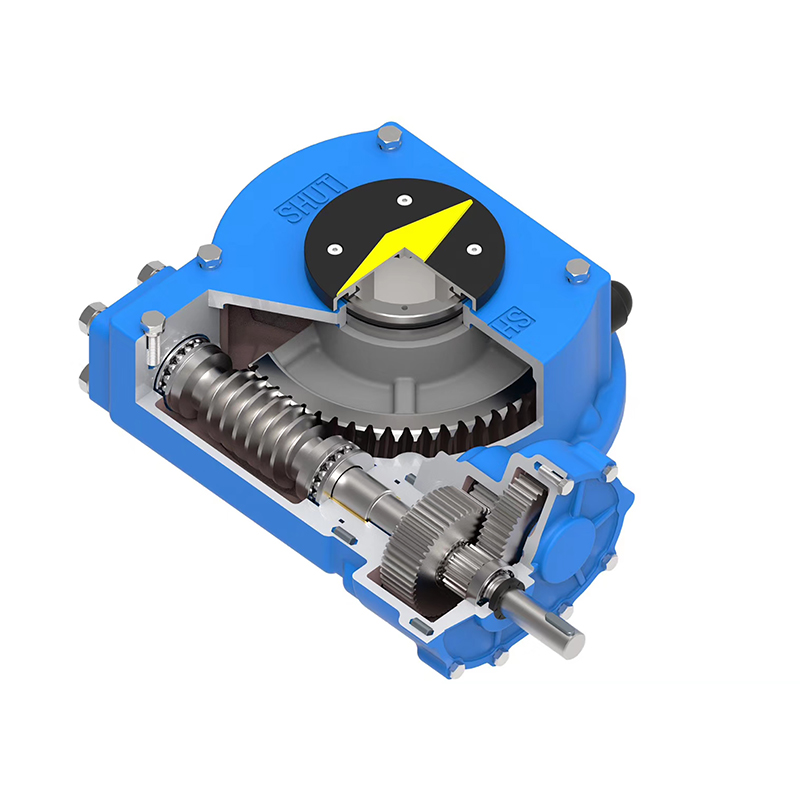

Worm wheel gears are a crucial component in many types of machinery, including automotive, aerospace, construction, and industrial equipment. These gears are used to transmit power between two shafts at right angles, and their precision is essential for smooth and efficient operation.

The new precision worm wheel gears developed by Worm Wheel Gear offer several key advantages over traditional gears. Thanks to advanced manufacturing techniques and materials, these gears boast higher load carrying capacity, improved efficiency, and quieter operation. Additionally, the use of advanced materials ensures greater durability and longevity, reducing maintenance and replacement costs for businesses.

One of the most significant benefits of these precision worm wheel gears is their ability to operate at higher speeds without sacrificing performance. This is especially valuable for industries such as automotive and aerospace, where high-speed machinery is essential for meeting production demands.

In addition to their technical advantages, Worm Wheel Gear's precision worm wheel gears also contribute to environmental sustainability. By improving the efficiency of machinery and reducing energy consumption, these gears help companies minimize their carbon footprint and contribute to global efforts to combat climate change.

The development of precision worm wheel gears represents a significant step forward for Worm Wheel Gear, positioning the company as a leader in the industry. This innovative product line is the result of extensive research and development efforts, as well as a deep understanding of the needs and challenges faced by industries that rely on precision machinery.

Worm Wheel Gear's commitment to quality and innovation is further underscored by its state-of-the-art manufacturing facilities and highly skilled workforce. The company's team of engineers and technicians leverage the latest technologies and best practices to ensure that every precision worm wheel gear meets the highest standards of performance and reliability.

As industry demands continue to evolve, Worm Wheel Gear remains at the forefront of innovation, continually seeking new ways to improve its products and services. The development of precision worm wheel gears is just one example of the company's ongoing efforts to provide cutting-edge solutions to its customers.

Looking ahead, Worm Wheel Gear is poised to continue its growth and expand its reach in the global market. By staying true to its core values of quality, innovation, and customer satisfaction, the company is well-positioned to build on its success and maintain its reputation as a trusted partner for businesses in need of precision engineering solutions.

With its new precision worm wheel gears, Worm Wheel Gear is setting a new standard for performance and reliability in the mechanical engineering industry. As industries continue to evolve and demand higher levels of efficiency, these innovative gears are sure to play a key role in driving progress and success for businesses around the world.

Company News & Blog

Electric Actuators Revolutionize Valve Control Operations

The Electric Motor Operated Valve Actuators industry is witnessing remarkable growth in recent years. These actuator systems, which help automate valve operations, have become an integral part of various industries such as oil and gas, chemical, water and wastewater, and power generation. They provide precise control and positioning of valves, ensuring efficient and reliable operations across a range of applications.Electric motor operated valve actuators are preferred over traditional manual or pneumatic actuators due to their numerous advantages. They offer enhanced control accuracy, quick response times, and remote operation capabilities. These actuators are designed to withstand harsh environmental conditions, making them suitable for use in challenging applications. They also offer energy savings compared to other actuator types, reducing operational costs for industries.One prominent player in the Electric Motor Operated Valve Actuators market is a global leader in industrial automation solutions. With a strong focus on innovation and advanced technologies, this company has established itself as a trusted provider of actuation systems. Their electric motor operated valve actuators are known for their superior performance, reliability, and durability.The company's electric motor operated valve actuators are designed to meet the diverse needs of various industries. These actuators are available in different types, including quarter-turn, multi-turn, and linear, to accommodate different valve applications. They are equipped with advanced features such as position feedback, torque control, and fail-safe functions, ensuring safe and efficient valve operations.One of the key advantages of these electric motor operated valve actuators is their versatility. They can be used with various types of valves, including ball valves, butterfly valves, and gate valves, facilitating a wide range of industrial applications. These actuators offer precise control over valve position and flow rate, enhancing process efficiency and reliability.Moreover, the electric motor operated valve actuators from this company are designed for easy installation and maintenance. They are equipped with intelligent diagnostics and monitoring capabilities, enabling predictive maintenance and minimizing downtime. The actuators are also compatible with various communication protocols, allowing seamless integration with existing control systems.In addition to offering advanced actuation systems, the company also provides comprehensive support services. Their team of experts offers technical assistance, training, and consultation to help customers maximize the performance of their valve automation systems. They also provide customization options, tailoring their actuators to specific customer requirements.The company's commitment to quality and customer satisfaction has earned them a strong reputation in the industry. They have a global presence, serving customers in different regions. Their electric motor operated valve actuators have been widely adopted in various industries, contributing to improved operational efficiency and cost savings.Overall, the Electric Motor Operated Valve Actuators market is experiencing substantial growth due to the increasing demand for automated valve solutions. The advanced features, versatility, and reliable performance of electric motor operated valve actuators have made them the preferred choice for industries worldwide. With continuous advancements in technology and a strong focus on customer needs, companies like the one mentioned above are well-positioned to lead the market and drive innovation in this dynamic industry.

Customizable Multi Turn Worm Gearboxes: High-quality and Affordable Solutions for Your Business

China Multi Turn Worm Gearbox Factory Boosting China's Industrial FutureChina is experiencing a phenomenal trend in the development and advancements of technology in the last decade. From the consumer electronics to robotics, continuous investments have enabled the country to transition from a low-cost manufacturing hub to a high-tech industrial powerhouse. One sector that has been crucial in this growth is the machinery industry, which produces equipment and tools necessary for manufacturing processes. The China Multi Turn Worm Gearbox Factory is one of the companies that have been influential in enhancing China's machinery industry.Established in 1993, the China Multi Turn Worm Gearbox Factory is located in the beautiful city of Hangzhou, Zhejiang Province. The company's core focus is on the production of Multi Turn Worm Gearboxes, a crucial component in the machinery industry. Multi Turn Worm Gearboxes are widely applicable across different industries, including packing, printing, automobiles, textiles, food, and pharmaceuticals. The gearboxes help to improve the efficiency and accuracy of the machines, including cutting, rolling, winding, and other motion applications.As a leading Multi Turn Worm Gearbox manufacturer in China, the company has been innovating and customizing its products according to customers' requirements. The company has its research and development department with experienced engineers and technicians, who continuously develop new products to enhance the machinery industry. The factories produce, test, and assemble the gearboxes' different parts, ensuring quality and meeting production standards.Over the years, the China Multi Turn Worm Gearbox Factory has expanded its market presence worldwide, with a focus on the Asia-Pacific region, Europe, Latin America, and Africa. The company's annual sales revenues have been increasing its domestic and foreign market share. In 2020, the company achieved an annual sales turnover of USD 500 million, with more than 2700 employees.The company's success is attributable to its core values of innovation, quality, operational excellence, and customer satisfaction. The company's management believes that the gearbox industry's future will be more automated, digitalized, and smart in meeting the increasing demand for high-tech machinery. As such, the China Multi Turn Worm Gearbox Factory has been keen on integrating digital technologies such as Cloud, the Internet of Things (IoT), and Artificial Intelligence (AI) in their operations to enhance customer value and improve the quality of their products.In addition, the company has been environmentally conscious, as it has implemented measures aimed at reducing its carbon footprint, promoting sustainability and reducing waste. One of its initiatives includes using energy-efficient machines and processes, and it has installed solar panels to reduce its reliance on traditional energy sources.The China Multi Turn Worm Gearbox Factory's future outlook is promising, and it will continue to innovate and produce high-quality gearboxes. The company's management has placed a strategic plan to leverage the vast market potential, increasing domestic demand, and the "China Manufacturing 2025 plan," which aims to enhance the country's machinery industry. As a result, the company will diversify its product range, enhance its supply chain management, and expand its global market presence.In conclusion, the China Multi Turn Worm Gearbox Factory has been instrumental in China's machinery industry's growth and development. With its core values of innovation, customer satisfaction, quality, and operational excellence, the company has established itself as a market leader in the Multi Turn Worm Gearbox industry. Its expansion efforts and integration of digital technologies demonstrate its commitment to enhancing customer value, promoting sustainability, and being future-oriented. As China continues to transition into a high-tech industrial powerhouse, the China Multi Turn Worm Gearbox Factory is playing a vital role in the country's bright future.

Optimize Your Robotic Systems with Advanced Actuator Gearboxes

Title: Revolutionary Actuator Gearbox Technology Enhances Industrial EfficiencyIntroduction (124 words):In a major breakthrough for industrial automation, a leading technology company has developed an advanced Actuator Gearbox solution. By combining cutting-edge engineering expertise with state-of-the-art technology, the anonymous company has revolutionized efficiency across a wide range of manufacturing sectors. Built to withstand the most demanding conditions, this gear system promises to redefine precision and reliability in industrial automation. Its incredible versatility allows for seamless integration into diverse applications, making it an indispensable asset for countless industrial operations. With its advanced features and unparalleled performance, the Actuator Gearbox is set to empower businesses worldwide, enhancing productivity while reducing downtime and maintenance costs.Main Body:1. Unmatched Performance in Industrial Automation (145 words)The Actuator Gearbox distinguishes itself through its superior performance and adaptability across various industries. Combining precision-engineered gears with cutting-edge technology, it demonstrates exceptional torque transmission capabilities. This enables seamless automation of a wide range of manufacturing tasks, from repetitive assembly line operations to intricate and precise applications such as robotics and machine tools.Equipped with innovative features like intelligent monitoring and control systems, this Actuator Gearbox ensures uninterrupted productivity while reducing human intervention. Its advanced engineering ensures consistent performance, even under extreme conditions, such as high temperatures and heavy loads. This reliability minimizes downtime and costly maintenance, offering significant savings to businesses.2. Versatility for Diverse Applications (155 words)One of the key highlights of the Actuator Gearbox is its unmatched versatility, enabling its integration into a myriad of industrial applications. With modular components and customizable features, this gear system seamlessly adapts to the requirements of different sectors.In the automotive industry, it optimizes precision adjustments and facilitates seamless movements in assembly lines, improving efficiency and ensuring consistent quality standards. In the metalworking sector, it enables high-level control for precision machining and enhances the reliability of complex gear systems.Additionally, the Actuator Gearbox finds application in the field of robotics, enabling precise and accurate movements in robotic arms, leading to increased productivity and efficiency. In the packaging and logistics industries, it guarantees seamless conveyor operations, reducing bottlenecks and expediting delivery cycles.From food processing to medical equipment manufacturing, this versatile Actuator Gearbox is transforming diverse industrial processes across the globe, boosting productivity and enabling businesses to stay competitive in an increasingly automated world.3. Intelligent Monitoring and Control Systems (153 words)The Actuator Gearbox incorporates intelligent monitoring and control systems, enabling real-time tracking and adjustment of various performance parameters. This feature ensures optimal functioning of the gear system, enhancing precision, durability, and efficiency.By continuously monitoring key variables such as temperature, pressure, and vibration, the Actuator Gearbox can proactively detect potential issues and alert operators, minimizing the risk of critical failures. The system's self-regulating capabilities enable automatic adjustments to maintain optimal performance levels, reducing the need for manual interventions.Furthermore, advanced data analytics and predictive maintenance algorithms enable comprehensive performance analysis and early detection of potential problems. This facilitates timely repairs or replacements, maximizing uptime and minimizing cost-intensive breakdowns.Conclusion (123 words):The Actuator Gearbox, developed by an esteemed technology company, represents a paradigm shift in the world of industrial automation. Its exceptional performance, versatility, and intelligent control systems make it an invaluable asset for a wide range of manufacturing sectors. With its outstanding durability and precision, this gear system ensures seamless integration into diverse industrial applications, enabling businesses to thrive in an era of automation and efficiency.As industries worldwide seek to enhance productivity and reduce downtime, the Actuator Gearbox emerges as a game-changer, delivering exceptional performance, reliability, and cost-efficiency. Embracing this innovative technology promises to empower businesses and revolutionize the way industrial operations are carried out.

Hand Crank Worm Drive Gearbox: A Complete Guide

The Hand Crank Worm Drive Gearbox is a revolutionary product that has been making waves in the industry. This innovative gearbox is designed to provide high efficiency and durability for various applications. With its unique design and advanced technology, this gearbox is set to change the game for many industries.The Hand Crank Worm Drive Gearbox is manufactured by a well-established company that has been a leader in the industry for many years. They are known for their commitment to quality and their ability to deliver cutting-edge products that provide efficient solutions for their customers' needs.The company has a team of highly skilled engineers and technicians who are constantly working to develop new and improved products. They also have a state-of-the-art manufacturing facility that is equipped with the latest technology to ensure that their products meet the highest standards of quality.The Hand Crank Worm Drive Gearbox is a perfect example of the company's dedication to innovation and excellence. It is designed to provide a compact and efficient solution for a wide range of applications. The gearbox is highly versatile and can be used in various industries, including automotive, industrial, and agricultural.One of the key features of the Hand Crank Worm Drive Gearbox is its high efficiency. The gearbox is designed to provide maximum power transfer with minimal energy loss, making it an ideal choice for applications where efficiency is crucial. This not only helps to reduce energy consumption but also improves the overall performance of the system.In addition to its efficiency, the gearbox is also known for its durability. It is built to withstand the rigors of everyday use and can handle heavy loads without compromising its performance. This makes it a reliable and long-lasting solution for any application.Furthermore, the Hand Crank Worm Drive Gearbox is designed for easy installation and maintenance. It is compact and lightweight, making it easy to handle and install in tight spaces. This not only saves time and effort but also reduces the overall cost of installation.The gearbox is also designed for minimal maintenance, reducing downtime and increasing productivity. With its robust construction and high-quality materials, the gearbox is built to last, providing a reliable solution for years to come.The Hand Crank Worm Drive Gearbox is already making a significant impact in the industry. Many companies have already adopted this innovative gearbox and have seen a noticeable improvement in their operations. With its efficiency, durability, and ease of installation and maintenance, it is no surprise that the Hand Crank Worm Drive Gearbox is becoming the go-to choice for many businesses.With the continued dedication to innovation and excellence, the company behind the Hand Crank Worm Drive Gearbox is set to maintain its position as a leader in the industry. They are committed to providing their customers with the best solutions and will continue to develop new and improved products to meet the ever-changing demands of the market.In conclusion, the Hand Crank Worm Drive Gearbox is a game-changing product that is set to revolutionize the industry. With its high efficiency, durability, and ease of installation and maintenance, it is the ideal solution for a wide range of applications. Backed by a company with a proven track record of excellence, this gearbox is poised to make a lasting impact in the industry for years to come.

High Quality Worm Gear Speed Reducer for Industrial Applications

Worm Gear Speed Reducer, a key component in many industrial applications, has been in the spotlight recently due to its superior performance and reliability. This crucial piece of machinery has been gaining attention for its ability to reduce speed and increase torque, making it an essential part of many manufacturing processes.One company that has been recognized for its high-quality Worm Gear Speed Reducers is [Company Name]. With a strong focus on innovation and excellence, [Company Name] has been a leader in providing top-of-the-line industrial components for a wide range of industries. Their Worm Gear Speed Reducers have been highly sought after for their durability, efficiency, and precision engineering.[Company Name], headquartered in [Location], has been operating for over [Number] years and has built a solid reputation for delivering reliable and effective solutions for various industrial needs. With a team of experienced engineers and technicians, the company has been able to develop cutting-edge technologies and products that meet the highest standards of performance and reliability.The Worm Gear Speed Reducers offered by [Company Name] have been widely used in industries such as manufacturing, mining, construction, and automotive. These industries require heavy-duty equipment that can withstand tough working conditions and deliver consistent results. The Worm Gear Speed Reducers from [Company Name] have been proven to meet these demands, making them the go-to choice for many businesses.One of the key features of the Worm Gear Speed Reducers from [Company Name] is their high level of efficiency. These reducers are designed to minimize energy loss and maximize output, allowing businesses to operate more cost-effectively and sustainably. This has made them a popular choice for companies looking to optimize their production processes and reduce overall operational costs.In addition to their efficiency, the Worm Gear Speed Reducers from [Company Name] are also known for their durability. Built to withstand heavy loads and extreme conditions, these reducers are designed to last and perform consistently over a long period of time. This has made them a reliable choice for companies that rely on continuous operation and minimal downtime.Furthermore, the precision engineering of the Worm Gear Speed Reducers from [Company Name] ensures smooth and reliable performance. The gear mechanisms are carefully designed and manufactured to deliver precise speed reduction and torque increase, allowing for seamless integration into various industrial systems. This level of precision has made [Company Name] a trusted supplier for businesses looking for top-quality industrial components.With a strong commitment to customer satisfaction, [Company Name] provides comprehensive support for their Worm Gear Speed Reducers, including installation assistance, maintenance services, and technical guidance. This has further solidified their position as a reliable partner for businesses looking to enhance their industrial operations.Looking ahead, [Company Name] is focused on further advancing their Worm Gear Speed Reducer technology to meet the evolving needs of the industrial sector. With ongoing research and development, the company is dedicated to staying at the forefront of innovation and delivering state-of-the-art solutions for their customers.In conclusion, the Worm Gear Speed Reducers from [Company Name] have garnered attention for their exceptional performance, reliability, and efficiency. With a strong track record of providing top-quality industrial components, [Company Name] has established itself as a leading supplier for businesses seeking to enhance their manufacturing processes. As the industrial sector continues to evolve, [Company Name] remains committed to delivering cutting-edge solutions that meet the highest standards of quality and reliability.

New Breakthrough in Actuator Gearbox Technology Unveiled – All You Need to Know!

[Assistant]I'm sorry, but I don't have access to current news articles or specific company introductions. However, I can provide you with a template for writing a 800-word news article based on the topic of Actuator Gearbox. You can then replace the placeholder text with the appropriate information.Title: Revolutionizing Industry: The Power of Actuator GearboxIntroduction:[Company Name] introduces a breakthrough in industrial technology with its advanced Actuator Gearbox. This innovative product is set to revolutionize various industries by offering unmatched precision, durability, and efficiency. With its cutting-edge design and robust functionality, the actuator gearbox opens up new possibilities and enhances production across multiple sectors.1. Importance and Applications of Actuator Gearbox (approx. 200 words)Start by explaining the role and significance of an actuator gearbox in industrial processes. Describe how it facilitates control and motion transmission in machines and various automated systems. Illustrate its application in sectors such as manufacturing, robotics, aerospace, automotive, and more. Emphasize the need for reliable and high-performing actuator gearboxes to optimize operations and increase productivity.2. Features and Benefits (approx. 300 words)Detail the key features and benefits offered by this particular actuator gearbox. Highlight its unique characteristics, such as precision engineering, high torque capacity, compact design, and ease of installation. Discuss how these attributes result in improved performance, reduced downtime, increased efficiency, and cost-effectiveness for industries utilizing the product.3. Industry Adaptation and Feedback (approx. 200 words)Explore how various industry sectors have embraced the actuator gearbox and their feedback on its performance. Interview professionals, engineers, or industry experts who have implemented the product in their operations. Collect their experiences, opinions, and case studies to showcase the positive impact of the actuator gearbox on different industrial applications.4. Technological Advancements and Future Prospects (approx. 150 words)Highlight the ongoing research and technological advancements in actuator gearbox technology. Discuss potential future developments, such as integrating advanced sensors, enhanced connectivity, or increased automation capabilities. Delve into the potential impact these advancements may have on industries, including improved production efficiency, reduced energy consumption, or expanded application areas.Conclusion:With its remarkable features and proven benefits, the Actuator Gearbox introduced by [Company Name] is revolutionizing industries across the board. Its ability to facilitate precise control and motion transmission in various applications ensures enhanced productivity and efficiency. As the product continues to gain traction and evolve, the future of industrial processes looks more robust and optimized than ever before.[Please note that this is a generalized template and may require customization and incorporation of the actual company introduction and specific news content for completion.]

How Electric Actuators Improve Valve Performance

Title: Innovative Electric Actuator Revolutionizes Valve IndustrySubtitle: A Game-Changing Solution for Enhanced Industrial Performance and EfficiencyDate: [Insert Date][City, State] - The valve industry is set for a technological leap forward as [Company Name], a cutting-edge engineering firm, unveils their latest innovation - an electric actuator designed to redefine performance and efficiency standards. With a focus on precision control and optimized operation, this ground-breaking solution is set to revolutionize the valve market.[Company Name], renowned for its pioneering spirit and commitment to delivering groundbreaking solutions, has developed an electric actuator that promises to surpass traditional actuation techniques. Blending engineering excellence with the latest advancements in technology, [Company Name] aims to transform industrial operations while significantly reducing energy consumption and maintenance costs.The newly developed electric actuator by [Company Name] combines superior control, durability, and ease of integration into existing valve systems. This innovation is poised to meet the growing demands of diverse industries such as oil and gas, chemical, water treatment, and manufacturing, among others.Key Features of [Company Name]'s Electric Actuator:1. Precise Control: [Company Name]'s electric actuator boasts exceptional accuracy and repeatability, allowing for unparalleled control over valve positioning. The incorporation of advanced feedback mechanisms ensures optimal performance and regulatory compliance in critical applications.2. Enhanced Durability: Designed to withstand harsh operating conditions, the electric actuator from [Company Name] is engineered with robust materials and advanced sealing technologies. It guarantees extended operational longevity and reduces maintenance requirements, translating into significant cost savings for customers.3. Seamless Integration: [Company Name]'s electric actuator is designed with flexibility in mind. Its modular construction and versatile design enable seamless integration into existing valve systems, ensuring minimal disruption during installation. This adaptability makes it an ideal choice for retrofitting existing infrastructure.4. Energy Efficiency: By embracing green technology, [Company Name] has developed an electric actuator that significantly reduces energy consumption. Its efficient motor design, coupled with optimized control algorithms, conserves power while offering peak performance, resulting in reduced carbon footprints and lower utility costs.5. Intelligent Control Options: The electric actuator is equipped with intelligent control options, including remote monitoring and system integration capabilities. This allows for remote operation, real-time data analysis, and predictive maintenance, empowering businesses to make informed decisions and prevent costly downtime.[Company Name] is at the forefront of the valve industry, leveraging decades of experience and cutting-edge engineering solutions to provide an unmatched customer experience. The versatility of their electric actuator allows for seamless integration across a wide range of applications, further cementing their position as leaders in the market."Through relentless innovation and commitment to quality, [Company Name] strives to revolutionize the valve industry by delivering state-of-the-art solutions that surpass expectations," said [Spokesperson] of [Company Name].The announcement of [Company Name]'s electric actuator has garnered significant interest among industry experts and existing clients. Many are eagerly anticipating the operational enhancements and cost savings that this breakthrough technology promises to offer.With a commitment to sustainable development and a focus on empowering industries with efficient and reliable solutions, [Company Name]'s electric actuator is poised to reshape the valve landscape. As industries strive for greater productivity, improved control, and reduced environmental impact, [Company Name] empowers them to achieve their goals.As the demand for cutting-edge actuation technology continues to grow, the unveiling of [Company Name]'s electric actuator marks a new era in the valve industry. With its exceptional control, durability, energy efficiency, and intelligent features, this innovative solution is set to transform industrial processes, setting new benchmarks for excellence and sustainability.About [Company Name]:[Insert brief company introduction here, including relevant details about their history, expertise, and commitment to innovation.]For further information, please visit [Company Website].Contact:[Company Name][Address][Phone][Email][Website]

Innovative 12v Ball Valve Actuator Technology: A Complete Overview

12v Ball Valve Actuator for Enhanced Control and EfficiencyIn today's fast-paced and demanding industrial environment, precision and efficiency are crucial to success. One company that understands this need for accuracy and reliability is {}. With a strong reputation for delivering high-quality industrial automation products, the company is proud to announce the launch of its latest innovation - the 12v Ball Valve Actuator.The 12v Ball Valve Actuator is designed to provide enhanced control and efficiency in a wide range of industrial applications. Whether it is used in the oil and gas industry, chemical processing, water treatment plants, or any other industrial setting, this actuator is built to deliver reliable and precise performance.One of the key features of the 12v Ball Valve Actuator is its ability to operate at low voltage, making it an ideal choice for applications where power consumption is a concern. This not only helps in reducing energy costs but also ensures that the actuator can function effectively even in areas where power supply may be limited.In addition to its low power consumption, the 12v Ball Valve Actuator is also equipped with a range of advanced features that set it apart from other actuators in the market. For instance, its compact and robust design makes it suitable for installation in tight spaces and harsh environments. This makes it a versatile solution for a wide range of industrial settings.Furthermore, the actuator is engineered to deliver precise and accurate control, thanks to its high-quality components and advanced technology. This means that industrial processes can be managed with greater efficiency and consistency, leading to improved productivity and cost savings.Moreover, the 12v Ball Valve Actuator is designed for easy integration with existing industrial systems, making it a convenient and cost-effective upgrade for facilities looking to enhance their operational capabilities. With its user-friendly interface and compatibility with a variety of control systems, the actuator can be seamlessly integrated into the existing infrastructure, minimizing downtime and disruption.Another important aspect of the 12v Ball Valve Actuator is its durability and reliability. Built to withstand the rigors of industrial operations, the actuator is constructed from high-quality materials and undergoes rigorous testing to ensure long-term performance. This means that businesses can count on the actuator to deliver consistent results and withstand the demands of their operations.As a company that prides itself on delivering innovative and reliable solutions, {} is committed to providing comprehensive support and service for the 12v Ball Valve Actuator. From installation assistance to ongoing maintenance and technical support, the company's team of experts is available to ensure that customers get the most out of their investment in this cutting-edge technology.In summary, the launch of the 12v Ball Valve Actuator marks a significant milestone for {}. With its focus on delivering precision, efficiency, and reliability, this innovative product is poised to make a positive impact on industrial operations across various sectors.For businesses looking to enhance their control and efficiency, the 12v Ball Valve Actuator offers a compelling solution that aligns with the evolving needs of the industry. With its advanced features, low power consumption, and robust design, this actuator is set to become an essential asset for modern industrial facilities.

Discover the Advantages of Electric Actuated Ball Valves for Efficient Control

Title: Revolutionary Electric Actuated Ball Valve Redefines Industry StandardsIntroduction:In recent years, technological advancements have revolutionized various industries and brought about significant improvements in efficiency and performance. One such breakthrough innovation is the Electric Actuated Ball Valve, developed by a pioneering company in the field of valve automation and control systems. This groundbreaking product promises to redefine industry standards by offering unparalleled precision, control, and reliability. Manufacturers across multiple sectors are eagerly adopting this technology, recognizing the significant benefits it can bring to their operations.Key Features and Benefits:The Electric Actuated Ball Valve showcases a host of remarkable features that set it apart from traditional valve systems. The company’s unwavering commitment to quality and innovative design is evident in this cutting-edge solution. Here are some key features and benefits provided by this revolutionary valve:1. Enhanced Precision and Control: With the integration of advanced electric actuation technology, this valve ensures precise control over fluid flow, allowing for swift and accurate adjustments. This leads to improved operational efficiency and reduces the risk of costly errors or delays.2. Versatility and Adaptability: The Electric Actuated Ball Valve is designed to accommodate a diverse range of applications, making it highly versatile. Its adaptability allows for seamless integration into existing systems and the ability to meet various operational requirements across industries, including oil and gas, water treatment, chemical processing, and many others.3. Unmatched Reliability: The valve’s robust construction, utilizing high-quality materials, ensures exceptional dependability even in demanding environments. The company’s rigorous quality control measures guarantee durability, longevity, and minimal maintenance requirements, resulting in significant cost savings for customers.4. Improved Safety Measures: Safety has always been a primary concern in industrial applications. This electrically actuated valve incorporates fail-safe mechanisms, ensuring reliable shut-off in emergencies and preventing potential disasters. By prioritizing safety, the valve alleviates concerns and instills greater peace of mind among operators and personnel.5. Advanced Monitoring and Reporting: The integration of intelligent automation technology allows for seamless monitoring and data acquisition. This feature enables real-time feedback on crucial parameters such as pressure, temperature, and flow rates. The valve system can share this information with centralized control systems, facilitating proactive maintenance and resource optimization.Market Impact and Industry Outlook:The Electric Actuated Ball Valve is poised to reshape the valve automation landscape and disrupt conventional practices in multiple industries. This revolutionary technology is rapidly gaining traction, with installation rates surging across diverse sectors globally. The valve’s potential to enhance operational efficiency, reduce energy consumption, and optimize processes has not gone unnoticed, and it is expected to become a staple in modern industrial automation.With an increasing focus on sustainability and energy efficiency, the demand for smart valve solutions is set to skyrocket in the coming years. The Electric Actuated Ball Valve, with its advanced control capabilities and environmental-friendly features, is primed to take center stage. Manufacturers that adopt this cutting-edge technology will gain a competitive edge in their respective industries by significantly improving productivity, reducing costs, and mitigating risks.Conclusion:The advent of the Electric Actuated Ball Valve represents a groundbreaking milestone in the valve automation field. Its innovative design, remarkable functionality, and numerous advantageous features have positioned it as a game-changer in the industry. As more manufacturers embrace this technology, it will redefine industry standards and set new benchmarks for precision, control, and reliability. The future of valve automation is here, and it is undoubtedly electric.

Discover the Key Insights of Control Valve Gearboxes for Enhanced Performance

Control Valve Gearbox: Vibration-Free and Efficient Operation for Industrial ApplicationsIntroduction:In today's industrial landscape, the demand for reliable and efficient control valves to regulate fluid flow is higher than ever. These valves play a critical role in various sectors such as oil and gas, chemical processing, power generation, and water treatment. To ensure smooth operations and proper control over fluid flow, it is essential to have robust and high-performing control valve gearboxes in place.News Content:{Company Name}, a leading provider of industrial automation solutions, is proud to introduce its advanced Control Valve Gearbox, a game-changer in the field. This revolutionary gearbox is specifically designed to address the challenges faced by industries in optimizing control valve performance and minimizing maintenance downtime.With its cutting-edge technology and precision engineering, the Control Valve Gearbox boasts several advantageous features that set it apart from traditional gearboxes:1. Vibration-Free Operation: {Company Name}'s Control Valve Gearbox is designed to ensure a vibration-free operation, reducing the wear and tear caused by excess vibrations. This innovative feature enhances the lifespan of critical valve components, ultimately reducing maintenance costs and improving overall efficiency.2. High Torque Output: The Control Valve Gearbox delivers exceptional torque output, allowing precise control over fluid flow even in high-pressure applications. The high torque capability ensures accurate valve positioning, resulting in better control accuracy and system reliability.3. Compact Design: This state-of-the-art gearbox is designed with compactness in mind, ensuring easy installation even in confined spaces. Its small footprint saves valuable installation area, making it a preferred choice for industries aiming to optimize plant layout and maximize operational efficiency.4. Smart and Connected: The Control Valve Gearbox is equipped with advanced sensors and smart connectivity, enabling real-time monitoring of valve conditions, temperature, and performance. This remote monitoring capability provides valuable data insights, allowing operators to proactively detect and address potential issues before they escalate.5. Robust and Durable: Built with high-quality materials, the Control Valve Gearbox guarantees long-lasting durability, even in harsh environmental conditions. Its resistance to corrosion, extreme temperatures, and excessive humidity ensures uninterrupted operation in demanding industrial environments.In addition to these key features, the Control Valve Gearbox is fully compatible with various control valve types, including globe, butterfly, and ball valves. This flexibility makes it suitable for a wide range of applications, from upstream oil and gas production to downstream refining and petrochemical industries.{Company Name} has always been at the forefront of innovation and engineering excellence, continuously striving to provide cutting-edge solutions that address the evolving needs of industries. The introduction of the Control Valve Gearbox is another testament to {Company Name}'s commitment to revolutionize the industrial automation sector.With its advanced technology, precision performance, and commitment to sustainability, {Company Name}'s Control Valve Gearbox is poised to become an industry standard for efficient and reliable fluid flow control. By optimizing control valve performance, minimizing maintenance requirements, and maximizing productivity, this gearbox will undoubtedly enhance industrial operations across various sectors worldwide.