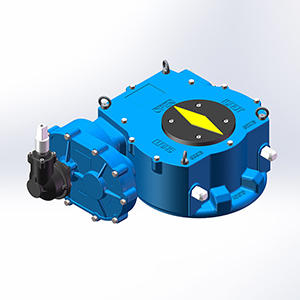

Understanding the Function of Single Acting Pneumatic Actuators

By:Admin

{Company} is leading the way in innovative automation solutions with its revolutionary Single Acting Pneumatic Actuator. This cutting-edge technology is providing industrial companies with a reliable and efficient solution to their automation needs. With its superior performance and advanced features, {Company}'s Single Acting Pneumatic Actuator is taking the industry by storm.

{Company} has established a solid reputation for delivering high-quality automation products to a wide range of industries. With a focus on innovation and customer satisfaction, the company has become a trusted name in the industry. The new Single Acting Pneumatic Actuator is the latest addition to its impressive lineup of automation solutions, and it is already making a significant impact.

The Single Acting Pneumatic Actuator is designed to provide a reliable and cost-effective solution for automation systems. It is ideal for applications where a fail-safe operation is required, making it a perfect choice for critical processes. The actuator is also equipped with advanced features that enhance its performance and reliability, such as high-speed operation and precise control.

One of the key advantages of {Company}'s Single Acting Pneumatic Actuator is its compact and lightweight design. This makes it easy to install and integrate into existing automation systems, saving valuable time and resources for industrial companies. The actuator is also designed for durability and long-term performance, ensuring a low total cost of ownership for users.

Another standout feature of the Single Acting Pneumatic Actuator is its high-level performance. With its advanced pneumatic technology, the actuator delivers fast and accurate operation, improving overall efficiency and productivity in industrial processes. It also offers a wide range of torque capabilities, providing flexibility for various applications.

In addition to its impressive performance, {Company}'s Single Acting Pneumatic Actuator is also designed with user-friendly features. The actuator is easy to commission and operate, making it convenient for industrial workers to maintain and manage. Its simple and intuitive interface allows for seamless integration into automation systems, further enhancing its overall usability.

Furthermore, the Single Acting Pneumatic Actuator is backed by {Company}'s exceptional customer support and service. The company is committed to providing comprehensive assistance to its customers, ensuring that they get the most out of their automation solutions. Whether it is technical support, training, or maintenance, {Company} is dedicated to helping its customers succeed.

With its robust performance, advanced features, and superior support, {Company}'s Single Acting Pneumatic Actuator is setting a new standard for industrial automation. It is revolutionizing the way industrial companies operate and is paving the way for enhanced efficiency and productivity. As the industry continues to evolve, {Company} remains at the forefront, delivering innovative solutions that meet the needs of its customers.

In conclusion, {Company} is proud to introduce its Single Acting Pneumatic Actuator, a game-changing technology that is revolutionizing industrial automation. With its superior performance, advanced features, and exceptional support, the actuator is setting a new standard for automation solutions. {Company} continues to lead the way in delivering innovative products that help industrial companies achieve their automation goals.

Company News & Blog

Remote Operated Ball Valve: A Revolutionary Solution for Industrial Control

The use of remote operated ball valves has become increasingly popular in various industries due to their ability to control the flow of liquids and gases with precision and efficiency. These advanced valves are revolutionizing the way companies manage their processes, and one company at the forefront of this technology is {Company Name}.{Company Name} is a leading provider of innovative valve solutions, with a strong focus on developing remote operated ball valves that meet the evolving needs of its customers. The company has a rich history of delivering high-quality products and services to a wide range of industries, including oil and gas, petrochemical, power generation, and water treatment.The remote operated ball valves offered by {Company Name} are designed to provide reliable and accurate flow control, allowing operators to remotely monitor and adjust the valves from a central control room. This level of automation not only improves efficiency but also reduces the risk of human error and enhances overall safety.One of the key advantages of {Company Name}'s remote operated ball valves is their ability to integrate seamlessly with digital control systems, enabling real-time data monitoring and analysis. This advanced connectivity allows for quick decision-making and proactive maintenance, leading to minimized downtime and increased productivity.In addition to their impressive technology, {Company Name} also prides itself on its commitment to sustainability and environmental responsibility. The company's remote operated ball valves are designed to minimize energy consumption and reduce emissions, aligning with the growing demand for eco-friendly solutions in today's industrial landscape.Furthermore, {Company Name} places a strong emphasis on customer satisfaction, offering comprehensive support and maintenance services to ensure the long-term performance and reliability of its remote operated ball valves. The company's team of experts is dedicated to understanding each customer's unique needs and providing tailored solutions that deliver maximum value.As the demand for remote operated ball valves continues to grow, {Company Name} remains at the forefront of innovation, constantly refining its products and exploring new possibilities for their application. By staying ahead of the curve and anticipating industry trends, the company is well-positioned to meet the evolving needs of its customers and maintain its leadership in the valve technology sector.In conclusion, {Company Name} is a true pioneer in the development and implementation of remote operated ball valves, offering cutting-edge solutions that are reshaping the way industries manage fluid and gas flow control. With a strong focus on technology, sustainability, and customer satisfaction, the company is poised to continue driving innovation and delivering exceptional value to its clients for years to come.Whether it's maximizing operational efficiency, minimizing environmental impact, or ensuring the highest level of safety, {Company Name}'s remote operated ball valves are a game-changer for industries around the world. With their advanced features and proven reliability, these valves are empowering companies to optimize their processes and achieve new levels of performance. As the industry continues to evolve, {Company Name} will undoubtedly remain a trusted partner for those in search of top-of-the-line valve solutions.

Worm Wheel Gear: Everything You Need to Know

Worm Wheel Gear, a leading manufacturer in the mechanical engineering industry, has recently made strides in the development of precision worm wheel gears. These innovative gears are revolutionizing the way various industries operate, providing enhanced efficiency and performance in a wide range of machinery and equipment.With a history of over 50 years in the industry, Worm Wheel Gear has built a strong reputation for producing high-quality, reliable products. The company prides itself on its commitment to continuous improvement and innovation, and the development of precision worm wheel gears is a testament to this dedication.Worm wheel gears are a crucial component in many types of machinery, including automotive, aerospace, construction, and industrial equipment. These gears are used to transmit power between two shafts at right angles, and their precision is essential for smooth and efficient operation.The new precision worm wheel gears developed by Worm Wheel Gear offer several key advantages over traditional gears. Thanks to advanced manufacturing techniques and materials, these gears boast higher load carrying capacity, improved efficiency, and quieter operation. Additionally, the use of advanced materials ensures greater durability and longevity, reducing maintenance and replacement costs for businesses.One of the most significant benefits of these precision worm wheel gears is their ability to operate at higher speeds without sacrificing performance. This is especially valuable for industries such as automotive and aerospace, where high-speed machinery is essential for meeting production demands.In addition to their technical advantages, Worm Wheel Gear's precision worm wheel gears also contribute to environmental sustainability. By improving the efficiency of machinery and reducing energy consumption, these gears help companies minimize their carbon footprint and contribute to global efforts to combat climate change.The development of precision worm wheel gears represents a significant step forward for Worm Wheel Gear, positioning the company as a leader in the industry. This innovative product line is the result of extensive research and development efforts, as well as a deep understanding of the needs and challenges faced by industries that rely on precision machinery.Worm Wheel Gear's commitment to quality and innovation is further underscored by its state-of-the-art manufacturing facilities and highly skilled workforce. The company's team of engineers and technicians leverage the latest technologies and best practices to ensure that every precision worm wheel gear meets the highest standards of performance and reliability.As industry demands continue to evolve, Worm Wheel Gear remains at the forefront of innovation, continually seeking new ways to improve its products and services. The development of precision worm wheel gears is just one example of the company's ongoing efforts to provide cutting-edge solutions to its customers.Looking ahead, Worm Wheel Gear is poised to continue its growth and expand its reach in the global market. By staying true to its core values of quality, innovation, and customer satisfaction, the company is well-positioned to build on its success and maintain its reputation as a trusted partner for businesses in need of precision engineering solutions.With its new precision worm wheel gears, Worm Wheel Gear is setting a new standard for performance and reliability in the mechanical engineering industry. As industries continue to evolve and demand higher levels of efficiency, these innovative gears are sure to play a key role in driving progress and success for businesses around the world.

Efficient Worm and Wheel Steering Gear for Smooth Vehicle Handling

Worm And Wheel Steering Gear has been making waves in the automotive industry with its innovative technology that promises to improve the performance and safety of vehicles. The company, based in {location}, has been a leader in the development of steering gear systems that are used in a wide range of vehicles, including cars, trucks, and buses.The Worm And Wheel Steering Gear system is known for its precision and reliability, making it a popular choice among automakers and vehicle enthusiasts. It is designed to provide precise control and exceptional responsiveness, giving drivers a smooth and comfortable driving experience. The system also enhances safety by ensuring that vehicles can be maneuvered with ease and precision.The company has a team of experienced engineers and technicians who are dedicated to pushing the boundaries of automotive technology. They are constantly working on improving the Worm And Wheel Steering Gear system, ensuring that it meets the highest standards of quality and performance. This commitment to innovation has helped the company establish itself as a leader in the industry, garnering a strong reputation for excellence and reliability.In addition to designing and producing steering gear systems, the company also provides comprehensive support services to its clients. This includes technical assistance, maintenance, and repair services, ensuring that vehicles equipped with the Worm And Wheel Steering Gear system continue to perform at their best. The company's commitment to customer satisfaction has made it a trusted partner for automakers and vehicle owners alike.One of the key advantages of the Worm And Wheel Steering Gear system is its versatility. It is designed to be easily integrated into different types of vehicles, regardless of their size, weight, or intended use. This makes it an ideal choice for automakers looking to offer a high-performance steering system across their vehicle lineup. The system's adaptability also makes it a popular choice for vehicle enthusiasts who are looking to enhance the performance and handling of their vehicles.The company is also dedicated to sustainability and environmental responsibility. It actively seeks ways to reduce the environmental impact of its manufacturing processes and products. The Worm And Wheel Steering Gear system is designed to be energy-efficient and durable, making it an environmentally friendly choice for vehicle manufacturers and owners.Looking ahead, Worm And Wheel Steering Gear continues to innovate and explore new possibilities in automotive technology. It is committed to staying at the forefront of the industry, pioneering new solutions that will shape the future of vehicle performance and safety. The company's dedication to excellence and innovation has set it apart as a driving force in the automotive industry, and it is poised to continue leading the way in steering gear technology.As the demand for high-performance steering systems continues to grow, Worm And Wheel Steering Gear is well-positioned to meet the needs of the market. Its reputation for quality, reliability, and innovation makes it a preferred choice for automakers and vehicle enthusiasts around the world. With a strong foundation of expertise and a commitment to excellence, the company is poised to make an even greater impact on the automotive industry in the years to come.

How Worm Reduction Gearboxes Can Improve Performance and Efficiency

Worm Reduction Gearbox is an essential component in various industrial applications, and the technology advancements in this field have significantly improved the efficiency and reliability of machinery. One company that has been leading the way in the development and production of high-quality Worm Reduction Gearboxes is the renowned industrial equipment manufacturer.With a rich history dating back to the early 20th century, the company has established itself as a trusted and innovative provider of power transmission solutions. Their commitment to excellence and continuous improvement has enabled them to develop a wide range of gearboxes that meet the diverse needs of industries such as mining, construction, agriculture, and transportation.The Worm Reduction Gearbox, in particular, has been a standout product in their portfolio. This gearbox is designed to provide a reduction in speed and an increase in torque, making it an ideal choice for applications where high precision and heavy-duty performance are required. The company’s Worm Reduction Gearboxes are engineered to deliver reliable and efficient power transmission, ensuring smooth operation and long service life.One of the key features of the company’s Worm Reduction Gearbox is its compact and robust design. This enables easy installation and integration into various types of machinery, saving valuable space and accommodating the specific requirements of different industrial setups. Furthermore, the gearbox is manufactured using high-quality materials and precision engineering techniques, ensuring durability and resistance to wear and tear in demanding operating conditions.The company prides itself on its dedication to research and development, and this has been a driving force behind the continuous enhancement of their Worm Reduction Gearbox. By leveraging the latest technologies and production processes, they have been able to optimize the performance and efficiency of their gearboxes, meeting the evolving needs of modern industries.In addition to the superior technical capabilities of their Worm Reduction Gearbox, the company’s commitment to customer satisfaction is evident in their comprehensive support services. They offer expert technical advice, customization options, and after-sales maintenance and repair services to ensure that their customers achieve maximum value from their gearbox investment.The company’s Worm Reduction Gearbox has gained recognition in the market for its exceptional performance, reliability, and cost-effectiveness. With a focus on meeting and exceeding industry standards, this gearbox has become the preferred choice for many leading companies across different sectors.With a global presence and a strong network of distributors and partners, the company has been successful in delivering their Worm Reduction Gearbox to customers worldwide. Their dedication to quality, reliability, and innovation has earned them a solid reputation and established them as a go-to supplier for power transmission solutions.Looking ahead, the company remains committed to pushing the boundaries of gearbox technology and meeting the ever-evolving demands of industrial applications. With a strong focus on sustainability and efficiency, they are continuously investing in research and development to further enhance their Worm Reduction Gearbox and ensure that it remains at the forefront of industry standards.In conclusion, the company’s Worm Reduction Gearbox stands as a testament to their expertise in power transmission solutions. With a combination of cutting-edge technology, superior quality, and unwavering customer support, they have set a benchmark for gearbox performance and reliability in the global market. As industries continue to evolve, the company remains poised to lead the way in providing innovative and efficient solutions for power transmission needs.

New Electric Motor Valve Actuator Revolutionizes Industrial Automation

Electric Motor Valve Actuator (EMVA) Brings Innovation to the IndustryIn today's fast-paced world, technology and innovation are constantly reshaping our industries. This is particularly true for the industrial automation sector, where companies are always on the lookout for new and improved solutions to optimize their processes.One such innovation that has been making waves in the industry is the Electric Motor Valve Actuator (EMVA). This cutting-edge technology has been gaining popularity due to its efficiency, reliability, and versatility. EMVA is revolutionizing the way industries control valves and optimize their operations.The EMVA is a sophisticated device that is designed to control the opening and closing of valves in various industrial applications. It operates using an electric motor, which provides precise and reliable control over the valve's position. This technology is particularly beneficial in industries such as oil and gas, chemical processing, water treatment, and power generation, where the accurate control of valves is crucial for maintaining safety and efficiency.One of the leading companies at the forefront of EMVA technology is [Company Name]. With a strong commitment to innovation and excellence, [Company Name] has been delivering high-quality electric motor valve actuators to its clients worldwide. The company takes pride in its ability to provide custom solutions that meet the unique needs of each industry it serves.[Company Name] has a proven track record of delivering reliable and durable EMVA products that are capable of withstanding the harsh conditions of industrial environments. The company's products are designed to offer precise control, fast response times, and long-term reliability, making them the ideal choice for a wide range of industrial applications.Moreover, [Company Name] offers a comprehensive range of electric motor valve actuators, including quarter-turn and multi-turn actuators, as well as linear actuators. These options allow customers to find the perfect solution for their specific valve control needs.As a global leader in industrial automation, [Company Name] is dedicated to providing its clients with top-of-the-line products and unparalleled customer service. This commitment to excellence has earned the company a strong reputation in the industry, making it a trusted partner for businesses around the world.With a team of experienced engineers and industry experts, [Company Name] continues to push the boundaries of what is possible in industrial automation. The company's relentless pursuit of innovation has led to the development of advanced EMVA technology that sets new standards for efficiency and performance.In addition to its cutting-edge products, [Company Name] also offers comprehensive support and maintenance services for its electric motor valve actuators. This ensures that its clients can maximize the lifespan and performance of their EMVA systems, thereby minimizing downtime and ensuring the smooth operation of their facilities.The growing demand for electric motor valve actuators reflects the increasing need for advanced automation solutions in the industrial sector. As industries continue to evolve and adopt new technologies, the role of EMVA in optimizing processes and enhancing efficiency will only become more significant.In conclusion, the Electric Motor Valve Actuator is a game-changing technology that is revolutionizing the industrial automation sector. With [Company Name] leading the way in developing and delivering top-quality EMVA solutions, the industry is set to experience new levels of efficiency, reliability, and performance. As the demand for advanced automation solutions continues to grow, the EMVA will undoubtedly play a crucial role in shaping the future of industrial processes.

Ball Valve Position Indicator: A Guide to Manual Operation

Ball Valve Position Indicator Enhances Efficiency and Safety in Industrial OperationsIn the world of industrial operations, efficiency and safety are two of the most crucial factors that must be carefully considered. Companies are continuously seeking innovative solutions to enhance their operational processes and ensure the well-being of their employees. This is where the {Company Name} comes into the picture with their advanced ball valve position indicator, which is designed to streamline operations and provide accuracy in valve positioning.The {Company Name}, a leading provider of industrial automation and control products, has recently introduced their state-of-the-art ball valve position indicator, which is set to revolutionize the way industrial operations are carried out. The new product is equipped with advanced technology that allows for precise and reliable monitoring of valve positions, ultimately leading to improved efficiency and safety in industrial settings.One of the key features of the ball valve position indicator is its ability to provide real-time feedback on the position of the valve, allowing operators to have full visibility and control over the valve's operation. This is particularly beneficial in situations where quick and accurate adjustments are necessary to maintain the integrity of the industrial processes. Additionally, the indicator is designed to withstand harsh industrial environments, ensuring its durability and reliability in various operating conditions.The installation of the ball valve position indicator is also a straightforward process, thanks to its user-friendly design and compatibility with a wide range of industrial valves. This means that companies can easily integrate the indicator into their existing systems without the need for extensive modifications or downtime, thereby minimizing disruptions to their operations.The {Company Name} takes pride in its commitment to delivering high-quality products that not only enhance operational efficiency but also prioritize the safety of personnel. The ball valve position indicator is a testament to this commitment, as it is designed to minimize the risk of human error by providing accurate and immediate feedback on valve positions. This ultimately reduces the likelihood of potential accidents and ensures the well-being of workers in industrial facilities.Furthermore, the ball valve position indicator is a cost-effective solution for companies looking to optimize their operational processes. Its ability to facilitate precise valve positioning can lead to reduced energy consumption and maintenance costs, ultimately contributing to overall cost savings for industrial operations. This makes it an attractive investment for companies looking to enhance their efficiency while maintaining a competitive edge in the industry.The {Company Name} is dedicated to providing comprehensive support and guidance to its customers, ensuring that they can fully maximize the benefits of the ball valve position indicator. With a team of experienced professionals, the company offers technical assistance and expertise to help customers seamlessly integrate the indicator into their operations.In conclusion, the introduction of the ball valve position indicator by the {Company Name} marks a significant milestone in the advancement of industrial automation and control products. Its cutting-edge technology, ease of installation, and focus on safety and efficiency make it a valuable addition to any industrial operation. As companies continue to prioritize the optimization of their processes, the ball valve position indicator stands out as a reliable solution that can make a tangible impact on the overall performance and safety of industrial facilities.

Revamp Your Machinery with Cutting-Edge Screw Gear Innovations

[News Headline]Innovative Screw Gear Enhances Industry Performance and Precision[News Intro]In a groundbreaking development, a leading engineering firm, renowned for its advanced products and cutting-edge technology, has unveiled a revolutionary screw gear system aimed at optimizing industry performance and precision. This groundbreaking invention is set to transform a wide range of sectors, from manufacturing to robotics, by delivering enhanced efficiency, increased stability, and unparalleled accuracy.[Company Introduction]{Insert Company Name}, a prominent player in the engineering industry, has gained accolades for its innovative solutions and manufacturing expertise. The company boasts a rich heritage and has consistently pushed the boundaries of technology, aiming to meet industry demands and accelerate progress through systematic advancements. With a dedicated team of experienced researchers and engineers, {Company Name} has become renowned for its commitment to excellence, resulting in a significant market presence and global recognition.[News Body]The latest breakthrough from {Company Name}, the newly introduced screw gear technology, is anticipated to revolutionize various sectors that heavily rely on gear systems for precision, efficiency, and performance. By leveraging its expertise and extensive research, {Company Name} has managed to design a screw gear that surpasses traditional models in nearly every aspect.One of the key advantages presented by this invention is increased operational efficiency. The screw gear's innovative design incorporates a precision helix pattern, ensuring smoother and more streamlined rotations. As a result, it reduces friction, minimizes energy loss, and enhances overall workflow efficiency. Industrial machinery and manufacturing processes utilizing this revolutionary gear system are expected to experience significant gains in productivity and reduced downtime, ultimately leading to improved profitability.Moreover, the screw gear's unique structural integrity greatly enhances stability and precision. Unlike conventional gear systems that are susceptible to misalignment and vibrations, this revolutionary invention offers superior resistance to these issues. The specially engineered screw gear minimizes disturbances caused by abrupt changes in torque or external forces, ensuring a stable and steady operation. Industries involved in robotics, automation, and critical applications, where accuracy plays a pivotal role, will greatly benefit from this breakthrough invention.Another notable advantage of the screw gear is its compatibility with diverse industry applications. Designed for versatility, this new gear can be adapted to various systems, including power transmission, conveyors, machine tools, and fluid pumps, among others. Regardless of the industry, the innovative screw gear technology seamlessly integrates with existing systems, providing an easy and cost-effective solution for businesses looking to enhance their equipment's performance.{Company Name}'s commitment to precision and industry needs is further exemplified by the rigorous testing and quality control processes incorporated into every screw gear system. Before commercial release, this revolutionary gear technology underwent comprehensive tests and evaluations to ensure it met stringent industry standards for reliability, efficiency, and durability. This meticulous approach adopted by {Company Name} underlines their dedication to delivering products that surpass customer expectations.The introduction of this inventive screw gear system has garnered significant interest and attention within the engineering community. Industry experts and professionals have hailed this game-changing technology as a significant step forward in optimizing performance and precision, anticipating its widespread adoption across various sectors. As {Company Name} continues to raise the bar in advancing engineering excellence, this latest innovation cements their position as a key player in shaping the future of industry.[Conclusion]{Company Name}'s revolutionary screw gear technology sets a new standard in the engineering realm, offering enhanced performance, stability, and precision. Its innovative design and robust construction make it an ideal choice for diverse industries seeking to enhance efficiency, reduce downtime, and improve overall productivity. With this pioneering development, {Company Name} reinforces its commitment to innovation and driving progress, solidifying its position as a market leader and paving the way for a transformative future in engineering.

Discover the Remarkable Features and Applications of a Large Worm Gear

Title: Innovative Worm Gear Revolutionizes Large-Scale Industrial ApplicationsIntroduction:In the realm of large-scale industrial applications, a significant breakthrough has been achieved with the development of an advanced worm gear system. This cutting-edge technology, designed by an industry-leading company (), promises to revolutionize various sectors by enhancing efficiency, reliability, and sustainability. With its exceptional performance capabilities, this worm gear system is set to address challenges faced by industries worldwide and propel them towards a more productive and environmentally conscious future.Section 1: Worm Gear Enigma UnveiledThe newly developed worm gear system showcases an innovative design that surpasses the limitations of traditional gearbox solutions. Its primary components, the worm wheel and gear, have been meticulously engineered to ensure exceptional power transmission efficiency. Through precision manufacturing techniques and advanced materials, this worm gear achieves higher torque capacity, reduced frictional losses, and improved wear resistance.Section 2: Industry ApplicationsThe versatility of this worm gear system enables its integration across various industries. In the mining sector, it offers a reliable and efficient solution for heavy machinery and extraction equipment. Additionally, the system's ability to handle large loads makes it ideal for applications in rail transportation, enabling smooth and precise movement of trains and trams.In the renewable energy sector, the worm gear system proves to be a significant asset in wind turbine installations. Its robust design ensures optimal power transmission, enhancing the energy output and operational lifespan of these structures. By harnessing the power of this advanced gear system, renewable energy generation can be maximized, thereby contributing to a greener environment.Section 3: Importance of Efficiency and ReliabilityEfficiency and reliability are pivotal aspects in any industry. The worm gear system offers considerably higher efficiency compared to traditional gearboxes. Its advanced lubrication system reduces power losses and heat generation, resulting in more efficient operations. Moreover, the enhanced wear resistance capabilities of this system contribute to prolonged equipment lifespan, reducing maintenance costs and downtime.Section 4: Sustainable Manufacturing TechniquesIn line with the escalating global concern over sustainability, the company responsible for introducing this worm gear system () is committed to adopting sustainable manufacturing practices. By incorporating eco-friendly materials, reducing energy consumption during production, and optimizing resource usage, the company strives to minimize its carbon footprint. This dedication to sustainability aligns with the company's broader mission to contribute to a more environmentally friendly industrial landscape.Section 5: Future Prospects and ConclusionAs industries continue to demand enhanced performance and sustainability, the worm gear system emerges as a game-changer. The innovative design, coupled with its ability to improve efficiency, reliability, and sustainability, positions this gear system as the ultimate solution for large-scale industrial applications. With its successful integration in various sectors, efficiency gains and cost savings are expected to be realized, benefitting both businesses and the environment alike.In conclusion, the introduction of a state-of-the-art worm gear system showcases a breakthrough in the field of large-scale industrial applications. The advanced design, efficiency, and reliability offered by this gear system have the potential to transform industries such as mining, transportation, and renewable energy. By prioritizing sustainability in its manufacturing process, the company () demonstrates its commitment to a greener future. With the revolutionary worm gear technology, industries worldwide can achieve higher productivity, reduced costs, and a more sustainable approach to operations.

Essential Information on Worm Wheels and Shafts: A Guide

Worm wheel and worm shaft are important components used in various industries to transmit power and motion between non-parallel, power-transmitting shafts. One of the leading companies in the production of worm wheel and worm shaft is {company name}. Founded in 1978, the company has been focused on offering high-quality and efficient worm gear units, worm gear motors, and other power transmission solutions.With a well-equipped manufacturing plant spanning over 8000 square meters, {company name} is capable of producing 500,000 sets of worm gearboxes annually, delivering its products to over 70 countries worldwide. The company conforms to international standards and is certified with ISO9001, CE, and UL. With a team of highly experienced researchers, designers, and engineers, {company name} can design and produce customized power transmission solutions to meet various industrial applications.The worm wheel and worm shaft are one of the most critical components produced by {company name} for power transmission applications. These components are instrumental in the production of mechanical motion between non-parallel shafts, converting rotational energy in one direction to rotational motion in another direction. Worm gear systems developed by {company name} have a high level of efficiency, reliability, and quiet operation.One of {company name}'s unique selling propositions includes their ability to produce high-quality worm gears with either single or double output shafts. The single output shafts are ideal for applications that require low-speed rotary motion but cannot accommodate other power transmission devices. In contrast, the double output shafts are perfect for industries that require multi-axis output motion.Since worm gears operate with sliding contact between the gear teeth, it's important to ensure adequate lubrication to minimize wear and extend the life of the gear system. {company name} understands this and designs its worm gears with advanced lubrication systems, ensuring optimal system performance and a longer lifespan.{Company name}'s worm gears are also designed to operate in various environmental conditions. The worm wheels are made from high-quality materials, with 15CrMo alloy steel being the most commonly used. This material has high strength, hardness, and resistance to wear, making it ideal for worm gears that operate under heavy loads and high stresses.In conclusion, {company name} is a leading producer of worm wheel and worm shaft, and their solutions have been used in a wide range of applications, including robotics, automation, medical, packaging, printing and others. They have a reputation for producing high-quality components that have a high level of torque density, efficiency, and reliability.The company's manufacturing capabilities, strict quality control protocols, and customized solutions make them an appealing choice for various industries. Partnering with {company name} for worm gear solutions ensures you have access to high-performing products that meet your specific application requirements.

High-Quality Worm and Gear Set for Efficient Power Transmission

Worm And Gear Set: The Backbone of Precision EngineeringPrecision engineering is integral to a wide range of industries, from automotive to aerospace, and everything in between. At the heart of this precision are often worm and gear sets, intricate and reliable mechanisms that make possible the smooth operation of many machines and devices.One company that has been at the forefront of producing high-quality worm and gear sets for over three decades is {}. With a strong commitment to innovation, quality, and customer satisfaction, they have become a trusted name in the world of precision engineering.Established in the late 1980s, {} has grown to become a leading manufacturer of worm and gear sets, serving a diverse range of industries including automotive, agriculture, and robotics. Their state-of-the-art manufacturing facilities, combined with a team of experienced engineers and technicians, enable them to produce worm and gear sets that meet the most stringent quality standards and technical requirements.The worm and gear set is a type of power transmission mechanism that is used to transfer motion and power between two shafts at right angles to each other. The worm, which is a screw-like gear, meshes with the gear (sometimes referred to as a worm wheel), and when the worm is turned, it drives the gear. This results in a smooth and efficient transfer of power, making worm and gear sets ideal for applications where precision and reliability are crucial.{}'s worm and gear sets are designed and manufactured with precision in mind. Using the latest CAD/CAM software and CNC machining technology, they are able to ensure that each component of the worm and gear set meets the exact specifications required for optimal performance. This attention to detail is what sets {} apart from its competitors, and has earned them a reputation for delivering worm and gear sets of the highest quality.In addition to their standard range of worm and gear sets, {} also offers custom design and manufacturing services, allowing them to meet the specific needs of their customers. Whether it's a unique gear ratio, a special material, or a particular size requirement, {} has the capability to design and produce worm and gear sets that are tailored to individual customer specifications.With a focus on continuous improvement and innovation, {} is constantly investing in research and development to stay ahead of the curve in the precision engineering industry. Their team of engineers is always looking for new ways to improve the performance and efficiency of their worm and gear sets, ensuring that they remain at the forefront of technological advancements in the field.Looking to the future, {} is poised to continue its success as a leading manufacturer of worm and gear sets. With a strong commitment to quality, innovation, and customer satisfaction, they are well-positioned to meet the evolving needs of the precision engineering industry, and to continue providing their customers with the high-quality worm and gear sets that have become synonymous with the {} name.In conclusion, worm and gear sets are an essential component of many machines and devices, and {} has established itself as a trusted manufacturer of these precision engineering components. With a focus on quality, innovation, and customer satisfaction, they continue to lead the way in the industry, delivering worm and gear sets that meet the most stringent technical requirements and provide reliable performance across a wide range of applications.