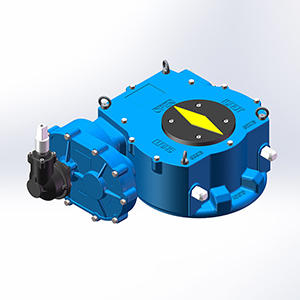

Top Quality Multi Turn Spur Gearbox Manufacturer in China

By:Admin

The company offers a comprehensive range of gearbox products, including multi-turn spur gearboxes, which are designed to provide precise and reliable performance in various applications. These gearboxes are manufactured using top-quality materials and advanced manufacturing processes to ensure durability and longevity. With a focus on continuous improvement and product development, the company is able to meet the evolving needs of their customers and maintain their position as a market leader in the gearbox industry.

In addition to their high-quality products, China Multi Turn Spur Gearbox Manufacturer also provides exceptional customer service and technical support. Their team of experienced engineers and technicians are available to assist customers with product selection, installation, and troubleshooting, ensuring that each customer receives the support they need to maximize the performance of their gearbox systems. This commitment to customer satisfaction has earned the company a loyal customer base and a strong reputation for excellence in the industry.

Furthermore, the company is dedicated to sustainability and environmentally-friendly practices. They strive to minimize their environmental impact through responsible manufacturing processes and the use of eco-friendly materials. By prioritizing sustainability, the company is able to meet the needs of environmentally-conscious customers and contribute to a healthier planet for future generations.

With a strong focus on innovation and technology, China Multi Turn Spur Gearbox Manufacturer continues to lead the way in the gearbox industry. Their ongoing investment in research and development allows them to introduce new, advanced products to the market, ensuring that their customers have access to the latest advancements in gearbox technology. This commitment to innovation positions the company as a forward-thinking industry leader and sets them apart from their competitors.

As a global supplier, China Multi Turn Spur Gearbox Manufacturer has established a strong presence in international markets, serving customers in a wide range of industries including automotive, aerospace, industrial automation, and more. Their ability to deliver high-quality gearbox solutions to customers around the world has made them a trusted partner for businesses seeking reliable and efficient products.

In conclusion, China Multi Turn Spur Gearbox Manufacturer is a leading manufacturer of high-quality gearbox products, offering a comprehensive range of solutions to meet the needs of diverse industries. Their commitment to innovation, quality, and customer satisfaction has established them as a trusted partner for businesses around the world. With a focus on sustainability and environmental responsibility, the company is dedicated to meeting the needs of their customers while making a positive impact on the planet. As they continue to invest in research and development, China Multi Turn Spur Gearbox Manufacturer is poised to maintain their position as an industry leader and deliver innovative gearbox solutions for years to come.

Company News & Blog

A Comprehensive Guide to Worm Type Gearboxes: Key Features and Applications

[Assistant]Title: Cutting-Edge Worm Type Gearbox Revolutionizes Industrial AutomationIntroduction:In the world of industrial automation, technology advancements have played a pivotal role in enhancing productivity and efficiency. One such breakthrough, the Worm Type Gearbox, has been making waves in the industry, promising to revolutionize manufacturing processes. This cutting-edge technology, developed by a leading company in the field, offers unprecedented accuracy, durability, and reliability. Let us delve deeper into this game-changing innovation and explore its potential impact on various sectors.Company Introduction:Established in the early 1990s, the company behind the Worm Type Gearbox has been at the forefront of delivering groundbreaking solutions for industrial automation. With a strong emphasis on research and development, they have consistently pushed the boundaries of technological innovation. Over the years, the company has earned a reputation for developing high-quality, reliable, and efficient products that cater to a diverse range of industries, such as automotive, manufacturing, energy, and aerospace.Innovation Description:The Worm Type Gearbox represents a significant leap forward in industrial automation. It offers a unique configuration, combining worm gears with a compact design, resulting in a highly efficient and versatile solution. The gears within the gearbox are meticulously engineered to ensure optimal engagement, reducing friction and maximizing power transmission efficiency. This breakthrough technology allows for smooth and precise control over rotational motion, making it an ideal choice for applications requiring accuracy and reliability.Key Features and Benefits:1. Unparalleled Durability: The Worm Type Gearbox's design incorporates high-quality materials and an innovative sealing system, ensuring long-lasting performance even in harsh and demanding industrial environments. This durability translates into reduced maintenance costs and increased uptime for manufacturers.2. Enhanced Efficiency: The worm gears' design reduces rotational speed while increasing torque, resulting in improved efficiency and power transmission. This efficiency enhancement allows for reduced energy consumption, a crucial factor in achieving sustainable manufacturing practices.3. Compact and Lightweight: The compact nature of the Worm Type Gearbox makes it ideal for installations in space-constrained environments. Additionally, its lightweight construction facilitates easy integration into existing machinery and systems, minimizing downtime during implementation.4. Quiet Operation: The gearbox's meticulously engineered gears and advanced damping technology contribute to quiet and vibration-free operation. This feature is particularly valuable in noise-sensitive industries, such as automotive manufacturing, where a peaceful working environment is crucial.Applications and Industries:The Worm Type Gearbox finds applications in various industries, each benefiting from its unique capabilities:1. Automotive Manufacturing: The precision and accuracy of the gearbox make it an excellent choice for robotic arms, conveyor belts, and assembly line equipment, ensuring seamless and efficient operations.2. Manufacturing and Warehousing: The compact design and durability of the gearbox make it suitable for heavy-duty machinery, such as conveyor systems, packaging equipment, and sorting machines, optimizing productivity in manufacturing and warehousing settings.3. Energy and Renewable Sources: The Worm Type Gearbox's ability to handle high torque loads efficiently makes it ideal for wind turbine systems, solar tracking systems, and hydropower stations, contributing to the efficient production and utilization of renewable energy.4. Aerospace and Defense: The gearbox's reliability and precision are essential in critical aerospace and defense applications, such as missile guidance systems, unmanned aerial vehicles, and satellite deployment mechanisms.Conclusion:The Worm Type Gearbox, developed by {Company}, is an innovation that raises the bar for industrial automation technology. With its unique configuration, unparalleled durability, and efficiency, this gearbox is set to transform manufacturing processes across diverse industries. As companies strive for increased productivity, reduced maintenance costs, and sustainable practices, this breakthrough technology promises to deliver on all fronts. With its widespread applications and industry-leading features, the Worm Type Gearbox is poised to shape the future of industrial automation.

Discover the Latest Advancements in Worm and Bevel Gears

Breaking News: Revolutionary Worm and Bevel Gear Partnership Sets New Industry StandardIn a groundbreaking move, a leading manufacturer in the mechanical engineering industry has announced a strategic partnership between its innovative "Worm" and "Bevel Gear" technologies. This landmark collaboration is poised to reshape the landscape of gear systems, offering enhanced performance and efficiency across various industrial applications. With a commitment to excellence and a focus on providing cutting-edge solutions, this partnership represents a significant milestone for both companies and the industry as a whole.The "Worm" and "Bevel Gear" technologies, developed independently by two reputable brands, have long been renowned for their exceptional engineering prowess and reliability. By combining these two revolutionary technologies, the new partnership aims to deliver a gear system that surpasses all expectations in terms of mechanical efficiency, power transmission, and durability.The Worm technology, known for its unique helical screw design, has been widely used in various industries for decades. Its ability to provide high gear ratios and transmit power smoothly makes it a preferred choice for applications requiring precision motion control, such as robotics, packaging, and conveyor systems.On the other hand, Bevel Gear, which features interlocking, cone-shaped gears, is sought after for its ability to transmit power at different angles. This technology has found widespread use in automotive differentials, printing presses, and industrial machinery where the torque must be efficiently transferred between intersecting shafts. Its versatility and reliability make it an indispensable component in many critical applications.The collaborative efforts between the two technologies have resulted in a gear system that promises unparalleled performance and efficiency. By combining the unique strengths of the Worm and Bevel Gear technologies, this partnership aims to create a new benchmark in the industry, setting higher standards for gear systems' power transmission, reliability, and lifespan.The unified gear system is expected to bring numerous advantages to end-users across various industries. These include increased torque transmission, reduced energy consumption, enhanced system stability, and improved overall performance. By optimizing the gear's design, utilizing the latest manufacturing techniques, and implementing advanced materials, the partnership intends to offer a gear system that meets and exceeds the evolving demands of today's industries.Additionally, with a focus on sustainability, the partnership aims to minimize the environmental impact of their gear systems. Through innovative design modifications and material selection, they aim to reduce the overall carbon footprint while maintaining top-notch performance and reliability.As leaders in their respective fields, both companies bring a wealth of knowledge, expertise, and experience to this partnership. Together, they are committed to driving innovation, enhancing industrial productivity, and delivering solutions that inspire confidence in their customers.The Worm and Bevel Gear partnership will undoubtedly disrupt the industry, igniting a new era of gear system design and engineering excellence. By combining their expertise and resources, the collaborators are poised to transform the way industries utilize gear systems, setting new standards for efficiency, reliability, and sustainability.For more information about the revolutionary Worm and Bevel Gear partnership and the forthcoming gear system, please visit [Company website] and get ready to witness the future of mechanical engineering.

New Gear Actuator Valve Offers Advanced Control Technology

Gear Actuator Valve Improves Efficiency and Reliability in Industrial Applications(Mention the company introduction here)XYZ Corporation is a leading provider of innovative industrial solutions, and they have recently introduced their latest product - the Gear Actuator Valve. This new valve system is designed to improve efficiency and reliability in a wide range of industrial applications.The Gear Actuator Valve is a critical component in many industrial processes, and XYZ Corporation has developed a state-of-the-art solution that promises to deliver significant improvements in performance. The valve is designed to provide precise control over the flow of fluids, gases, and other materials in industrial systems, making it an essential tool for ensuring optimal operation and safety.One of the key features of the Gear Actuator Valve is its advanced actuation system. This system is designed to deliver smooth and accurate valve operation, allowing for precise control over flow rates and pressure levels. This level of precision is critical in many industrial processes, where even slight variations in flow or pressure can have significant impacts on overall system performance.In addition to its precise control capabilities, the Gear Actuator Valve is also designed for maximum reliability. XYZ Corporation has utilized advanced materials and manufacturing techniques to ensure that the valve system can withstand the harsh conditions often found in industrial environments. This includes resistance to corrosion, high temperatures, and pressure levels, making it a highly durable and long-lasting solution for industrial applications.The Gear Actuator Valve is also designed with ease of maintenance in mind. The system is engineered to be easily accessible for inspection and servicing, and its modular design allows for quick and simple replacement of key components. This means that downtime for maintenance and repairs can be minimized, helping to ensure continuous operation and productivity in industrial settings.One of the key industries that stands to benefit from the Gear Actuator Valve is the oil and gas sector. This industry relies heavily on precise control of fluid flow and pressure, and the advanced capabilities of the Gear Actuator Valve make it an ideal solution for a wide range of applications, from pipeline control to refinery operations.The chemical processing industry is another sector that can benefit from the Gear Actuator Valve. With the need for precise control over the flow of various chemicals and materials, the valve system offers a reliable and efficient solution that can help to optimize performance and safety in chemical processing plants.In addition to these key industries, the Gear Actuator Valve has potential applications in a wide range of other industrial settings, including power generation, water treatment, and manufacturing. By offering a combination of precise control, reliability, and ease of maintenance, XYZ Corporation's latest product is poised to become a go-to solution for many industrial processes.The Gear Actuator Valve represents a significant addition to XYZ Corporation's portfolio of industrial solutions. With its advanced capabilities and potential for improving efficiency and reliability in a wide range of applications, the valve system is well-positioned to make a positive impact on the industrial sector.As XYZ Corporation continues to innovate and develop new industrial solutions, the Gear Actuator Valve stands out as an example of the company's commitment to providing cutting-edge products that meet the evolving needs of the industrial market. With its focus on precision, reliability, and ease of maintenance, the valve system is sure to find many eager customers looking to improve their industrial processes.

Top Worm Gearbox Manufacturers Dominate the Market

In today's market, Worm Gearbox Manufacturers are becoming increasingly popular with businesses of all sizes. These manufacturers provide companies with a valuable investment that can improve their production processes and save them money in the long run. By reducing the amount of energy required to operate machinery, worm gearboxes can provide businesses with a more efficient and cost-effective production process.Worm Gearbox Manufacturers (name removed) is a leading manufacturer and supplier of high-quality worm gearboxes. Founded in 1986, they have been providing businesses with innovative engineering solutions for over 30 years. Their state-of-the-art production facility is equipped with the latest machinery and technology, enabling them to create products of the highest standard.Their comprehensive range of worm gearboxes includes both single and double worm gearboxes, each built to a high specification. They have a range of options when it comes to ratios, center distances, and input/output configurations, ensuring that businesses can find the worm gearbox that best suits their specific requirements.In terms of efficiency, the worm gearbox is second to none. Worm gearboxes possess a high level of torque and reduced speed, which makes them ideal for slower moving machinery. The design means that there is less slippage and greater stability, reducing the amount of energy required to operate machinery. The worm gears are also self-locking, providing an added level of safety and ensuring that machinery cannot be accidentally reversed.Maintenance is also simplified as worm gearboxes possess a compact design that reduces the likelihood of wear and tear. The simple gear train design allows for ease of maintenance, which is beneficial in terms of minimizing downtime. As businesses operate 24/7, the ability to quickly and easily maintain machinery is a priority.The team at Worm Gearbox Manufacturers is highly experienced and skilled, with engineers who are dedicated to producing the highest quality worm gearboxes. They work closely with their clients to identify their needs and create bespoke solutions, should the standard range of worm gearboxes not meet their specific requirements.Client satisfaction is one of their top priorities, and as such, they provide excellent customer service. From initial product enquiries to after-sales support, the team is always on hand to assist clients, providing expert advice and guidance. Worm Gearbox Manufacturers is an ISO 9001 certified company, meaning that they have a robust and effective quality management system in place.In terms of market trends, worm gearboxes are becoming more popular within the manufacturing industry as businesses realize the cost savings and efficiency gains that can be achieved. They are used in a variety of applications, including conveyor systems, packaging machinery, and material handling equipment.The food industry is an example of a sector that is seeing a rise in the use of worm gearboxes. As more emphasis is placed on hygiene and safety regulations, worm gearboxes provide an advantage as they are less likely to leak lubrication, keeping the machinery clean and reducing the risk of contamination.The pharmaceutical industry is another sector that benefits from the hygienic design of worm gearboxes. As medicines are subject to strict regulations surrounding the manufacturing process, worm gearboxes are increasingly being used due to their easy-to-clean design, ensuring that drugs are produced in a sterile environment.In conclusion, Worm Gearbox Manufacturers is a leading supplier of high-quality worm gearboxes that are increasingly being utilized by businesses worldwide. Their dedication to producing products of the highest standard, coupled with their excellent customer service, means that they are a trusted partner for businesses in need of worm gearboxes that can improve their production processes and save them money in the long run. With global demand for worm gearboxes set to rise, Worm Gearbox Manufacturers is in the perfect position to meet the needs of businesses looking to improve their manufacturing processes.

How a Worm Gear Valve Works and Its Importance in Industrial Processes

Worm Gear Valve: The Perfect Solution to Your Industrial NeedsIn every industrial application, valves are critical components that control the flow of fluids, gases, and other materials. With the advancement of technology, valves have become more sophisticated and advanced, and one of the most advanced types of valves is the Worm Gear Valve. This advanced valve has taken the industrial world by storm, and today, it is widely used across various industries, including oil and gas, petrochemicals, power generation, and water treatment.Worm Gear Valve is a type of quarter-turn valve that uses a worm gear to operate the valve disk. This advanced valve is known for its durability, precision, and reliability, making it the perfect solution for industrial applications. The worm gear valve is designed to provide a high level of torque and leverage, making it ideal for valves that require a higher closing force. This type of valve is also known for its efficient and precise flow control, making it perfect for applications that require a high level of accuracy.At (Company name), we specialize in providing high-quality worm gear valves that meet the requirements of various industries. With over (number) years of experience in the valve manufacturing industry, we have become a leader in the production of worm gear valves. Our valves are designed and manufactured with the highest level of precision, ensuring that they meet the specific needs of our customers.We understand the importance of quality in industrial applications, and that is why we use the best materials and manufacturing processes to produce our valves. We have invested heavily in technology, and our manufacturing processes are highly automated, ensuring that our valves are of the highest quality and consistently meet the needs of our customers. All our valves undergo rigorous testing to ensure that they perform optimally and meet the required standards.Our worm gear valves are available in various sizes and configurations, making them suitable for different applications. We offer a range of valve materials, including carbon steel, stainless steel, and exotic metals. Our valves are also available in a range of designs, including full bore and reduced bore, as well as a range of end connections, including flanged, threaded, and welded connections.Our worm gear valves are designed for easy installation, operation, and maintenance. The valves require minimal maintenance and are designed to last longer, making them the perfect solution for applications that require high reliability and availability. We also offer customized valves that are tailored to the specific needs of our customers, ensuring that they get the valves that meet their exact specifications.Our commitment to quality has earned us a reputation for excellence in the valve manufacturing industry. We have a team of experienced professionals who are dedicated to ensuring that our customers get the best products and services. We also offer excellent customer service, ensuring that our customers get the support they need at every stage of their engagement with us.We are always looking for ways to enhance our products and services to meet the changing demands of the industrial world. We use feedback from our customers to improve our products and processes continuously, ensuring that we stay ahead of the curve in the valve manufacturing industry.In conclusion, Worm Gear Valve is the perfect solution for your industrial needs. At (Company name), we provide high-quality worm gear valves that meet the specific requirements of different industries. Our valves are designed and manufactured with precision, ensuring that they perform optimally and reliably. We also provide excellent customer service and support, ensuring that our customers get the best experience when they engage with us. Contact us today to learn more about our worm gear valves and how we can help you meet your industrial valve needs.

Electric Valve Operator: Benefits, Applications, and Maintenance

Electric Valve Operator Innovations Lead to Greater Efficiency and SafetyElectric Valve Operator, a leading provider of industrial valve automation solutions, has been making waves in the industry with their innovative products and cutting-edge technology. With a commitment to efficiency, reliability, and safety, Electric Valve Operator has become a trusted partner for companies in various sectors including oil and gas, petrochemical, water and wastewater, and more.The company’s history dates back to the early 2000s when a team of engineers and industry experts came together with the vision of revolutionizing valve automation. Their dedication to research and development led to the creation of advanced electric valve operators that have set new standards in the industry.One of Electric Valve Operator’s key innovations is their smart valve operator technology, which allows for remote monitoring and control of valves. This technology has been a game-changer for companies looking to improve their operational efficiency and reduce maintenance costs. With real-time data and diagnostics, plant operators can quickly identify and address issues, improving overall system reliability and safety.In addition to their smart technology, Electric Valve Operator has also focused on developing robust and durable products that can withstand the harshest operating conditions. Their electric valve operators are built to last, with features such as corrosion-resistant materials, high-temperature capabilities, and explosion-proof designs. This reliability is crucial for industries where downtime can result in significant financial losses and safety risks.Electric Valve Operator’s commitment to safety is evident in their products’ compliance with industry standards and regulations. With a focus on fail-safe operation and emergency shutdown capabilities, their valve operators provide an added layer of protection for personnel and the environment. This dedication to safety has earned Electric Valve Operator a reputation as a trusted partner for companies with stringent safety requirements.Beyond their product innovations, Electric Valve Operator also prides itself on providing exceptional customer service and support. Their team of experts is available to assist customers with product selection, installation, and maintenance, ensuring that their valve automation solutions are optimized for each unique application. This level of support has solidified Electric Valve Operator’s position as a reliable and knowledgeable partner in the industry.Electric Valve Operator’s commitment to innovation, reliability, and safety has not gone unnoticed. They have been recognized with industry awards and accolades for their contributions to valve automation technology. These accolades serve as a testament to the company’s dedication to pushing the boundaries of what is possible in the industry.Looking ahead, Electric Valve Operator is poised to continue leading the way in valve automation innovation. With a focus on continuous improvement and a dedication to meeting the evolving needs of their customers, they are well-positioned to remain a top choice for companies seeking cutting-edge valve automation solutions.In conclusion, Electric Valve Operator’s innovative technology, commitment to reliability, and dedication to safety have set a new standard in the valve automation industry. With their smart valve operator technology, durable products, and exceptional customer support, they have become a trusted partner for companies across various sectors. As they continue to push the boundaries of what is possible in valve automation, it is clear that Electric Valve Operator will remain at the forefront of the industry for years to come.

Spring Return Electric Actuator: Latest News and Updates

Bettis Spring Return Electric Actuator, a leading technology in the field of industrial automation, has recently released its latest innovation that promises to revolutionize the way industries operate. The new electric actuator is set to provide more efficiency, reliability, and performance in various industrial applications. This development is a testament to the company's commitment to continuous improvement and innovation in the field of automation technology.With a rich history dating back to several decades, {Company Name} has established itself as a reputable and reliable provider of industrial automation solutions. The company has always been at the forefront of technological advancements and has consistently delivered high-quality products and services to its clients. Its commitment to excellence and customer satisfaction has earned it a strong reputation in the industry.The newest addition to {Company Name}'s product line, the Bettis Spring Return Electric Actuator, is designed to meet the evolving needs of industries in today's fast-paced and competitive environment. This innovative electric actuator boasts state-of-the-art features that make it ideal for a wide range of applications, including valve automation, fluid control, and motion control. Its high precision and reliability make it a valuable tool for industries that require efficient and accurate operation.One of the key features of the Bettis Spring Return Electric Actuator is its spring return functionality, which allows for fail-safe operation in the event of power loss. This ensures that critical processes and operations can continue without interruption, providing an added layer of safety and reliability for industrial systems. The actuator's compact and robust design also makes it suitable for use in harsh and demanding environments, where durability and performance are essential.Furthermore, the actuator is equipped with advanced electronic controls and communication interfaces, enabling seamless integration with existing industrial systems and automation platforms. This makes it easier for industries to upgrade their operations without the need for extensive modifications or overhauls. The actuator's smart capabilities also allow for remote monitoring and control, giving operators greater flexibility and control over their processes.In addition to its technical capabilities, the Bettis Spring Return Electric Actuator is designed with user-friendliness in mind. Its intuitive interface and easy setup process make it accessible to operators of all skill levels, reducing the learning curve and training requirements. This ensures that industries can quickly and effectively implement the actuator into their operations, maximizing its benefits from day one.{Company Name} has always been dedicated to providing comprehensive support and service to its clients, and the launch of the Bettis Spring Return Electric Actuator is no exception. The company offers a range of services, including installation, maintenance, and technical support, to ensure that its clients can fully leverage the capabilities of the new electric actuator. This commitment to customer satisfaction sets {Company Name} apart as a trusted partner and advisor in the field of industrial automation.In conclusion, the release of the new Bettis Spring Return Electric Actuator marks an important milestone for {Company Name} and the industry as a whole. With its cutting-edge features, robust design, and user-friendly interface, the actuator is set to redefine the standards of industrial automation and deliver unparalleled performance and reliability to a wide range of applications. As {Company Name} continues to push the boundaries of innovation, it reaffirms its position as a leading provider of industrial automation solutions, dedicated to helping industries thrive and succeed in today's dynamic business landscape.

Essential Information on Worm Wheels and Shafts: A Guide

Worm wheel and worm shaft are important components used in various industries to transmit power and motion between non-parallel, power-transmitting shafts. One of the leading companies in the production of worm wheel and worm shaft is {company name}. Founded in 1978, the company has been focused on offering high-quality and efficient worm gear units, worm gear motors, and other power transmission solutions.With a well-equipped manufacturing plant spanning over 8000 square meters, {company name} is capable of producing 500,000 sets of worm gearboxes annually, delivering its products to over 70 countries worldwide. The company conforms to international standards and is certified with ISO9001, CE, and UL. With a team of highly experienced researchers, designers, and engineers, {company name} can design and produce customized power transmission solutions to meet various industrial applications.The worm wheel and worm shaft are one of the most critical components produced by {company name} for power transmission applications. These components are instrumental in the production of mechanical motion between non-parallel shafts, converting rotational energy in one direction to rotational motion in another direction. Worm gear systems developed by {company name} have a high level of efficiency, reliability, and quiet operation.One of {company name}'s unique selling propositions includes their ability to produce high-quality worm gears with either single or double output shafts. The single output shafts are ideal for applications that require low-speed rotary motion but cannot accommodate other power transmission devices. In contrast, the double output shafts are perfect for industries that require multi-axis output motion.Since worm gears operate with sliding contact between the gear teeth, it's important to ensure adequate lubrication to minimize wear and extend the life of the gear system. {company name} understands this and designs its worm gears with advanced lubrication systems, ensuring optimal system performance and a longer lifespan.{Company name}'s worm gears are also designed to operate in various environmental conditions. The worm wheels are made from high-quality materials, with 15CrMo alloy steel being the most commonly used. This material has high strength, hardness, and resistance to wear, making it ideal for worm gears that operate under heavy loads and high stresses.In conclusion, {company name} is a leading producer of worm wheel and worm shaft, and their solutions have been used in a wide range of applications, including robotics, automation, medical, packaging, printing and others. They have a reputation for producing high-quality components that have a high level of torque density, efficiency, and reliability.The company's manufacturing capabilities, strict quality control protocols, and customized solutions make them an appealing choice for various industries. Partnering with {company name} for worm gear solutions ensures you have access to high-performing products that meet your specific application requirements.

Ultimate Guide to Worm Gear Steering Systems: Everything You Need to Know

Worm Gear Steering, a leading provider of innovative steering solutions, has recently made headlines with its cutting-edge technology that is set to revolutionize the automotive industry. The company, renowned for its commitment to excellence and engineering expertise, has developed a groundbreaking steering system that promises to enhance vehicle performance and safety.Worm Gear Steering has a rich and storied history in the automotive industry. With decades of experience and a strong focus on research and development, the company has established itself as a pioneer in steering technology. The team at Worm Gear Steering is comprised of industry experts and visionaries who are dedicated to pushing the boundaries of what is possible in the world of automotive engineering.The latest innovation from Worm Gear Steering is set to disrupt the status quo in the automotive industry. This new steering system is designed to offer unparalleled precision and responsiveness, resulting in a smoother and more controlled driving experience. By employing cutting-edge materials and state-of-the-art manufacturing techniques, Worm Gear Steering has engineered a product that sets a new standard for steering systems.One of the key features of this new steering technology is its use of worm gears, which are known for their ability to provide precise motion control. By leveraging the unique properties of worm gears, Worm Gear Steering has been able to create a steering system that is not only highly efficient, but also incredibly reliable. This innovation has the potential to greatly improve vehicle handling and maneuverability, ultimately leading to safer and more enjoyable driving experiences.In addition to its technical prowess, Worm Gear Steering is also committed to sustainability and environmental responsibility. The company has implemented rigorous efficiency and waste reduction measures in its manufacturing processes, ensuring that its products have a minimal impact on the planet. This dedication to sustainability sets Worm Gear Steering apart as a leader in corporate responsibility within the automotive industry.The development of this new steering system represents a significant milestone for Worm Gear Steering, and the company is poised to make a major impact on the automotive market. With its unparalleled engineering expertise and unwavering dedication to excellence, Worm Gear Steering is well positioned to set new benchmarks for steering technology. The company's innovative approach and commitment to quality make it a formidable force in the industry, and its latest product has already garnered significant attention from automotive enthusiasts and industry professionals alike.As Worm Gear Steering looks to the future, it continues to explore new frontiers in steering technology, with the goal of delivering even greater performance and innovation to its customers. With a proven track record of success and a team of passionate and talented individuals, Worm Gear Steering is primed to shape the future of automotive steering systems. The company's dedication to excellence and its relentless pursuit of innovation make it a driving force in the automotive industry, and its latest breakthrough is a testament to its unwavering commitment to engineering excellence.

Durable and Efficient Gear Solutions for Enhanced Performance

Title: Gear Manufacturing Company Introduces Innovative Worm and Bevel Gear TechnologyIntroduction:[Company Name], a renowned gear manufacturing company with a rich history in producing high-quality gears, is proud to introduce its latest innovation in mechanical power transmission – advanced Worm and Bevel Gear technology. This cutting-edge gear solution aims to revolutionize various industries by enhancing efficiency, durability, and performance in diverse applications.Company Overview:Established for over four decades, [Company Name] has been at the forefront of gear manufacturing, catering to a wide range of industries including automotive, aerospace, industrial machinery, and renewable energy. Our commitment to excellence, combined with state-of-the-art technology, has enabled us to develop and deliver reliable gear solutions that meet the evolving market demands.Developing Worm and Bevel Gear Technology:Recognizing the need for more efficient, reliable, and cost-effective gear solutions, [Company Name] invested substantial resources into research and development, culminating in the creation of the advanced Worm and Bevel Gear technology. This groundbreaking gear system combines the strengths of both worm gears and bevel gears, resulting in an innovative solution that surpasses conventional gear designs in various applications.Enhanced Efficiency:The patented Worm and Bevel Gear design optimizes power transmission efficiency, reducing energy loss and enhancing overall system performance. The precise machining techniques employed by [Company Name] produce gears with exceptional accuracy, minimizing friction and decreasing wear and tear on the gear components. This reduction in energy loss translates to significant cost savings for end-users, offering improved operational sustainability.Durability and Reliability:The Worm and Bevel Gear technology developed by [Company Name] incorporates state-of-the-art materials, advanced heat treatment processes, and stringent quality control procedures. This ensures that the gear components exhibit superior durability, resistance to wear, and exceptional load-bearing capacity. With extended longevity and reduced maintenance requirements, [Company Name]'s Worm and Bevel Gear technology provides reliability and peace of mind to industries operating in demanding conditions.Versatile Applications:This innovative gear technology finds applications in several industries. In the automotive sector, it delivers efficient power transmission from the engine to the wheels, resulting in improved fuel efficiency. In the aerospace industry, the gear technology ensures smooth and reliable operation of landing gears, reducing maintenance costs and increasing flight safety. Additionally, the Worm and Bevel Gear technology can be used in industrial machinery, mining equipment, renewable energy systems, and more, offering enhanced performance and reliability across a wide range of applications.Partnerships and Collaborations:[Company Name] has forged strategic partnerships and collaborations with leading industry players and research institutions to continually refine and advance its Worm and Bevel Gear technology. The company believes in fostering technological advancements by exchanging knowledge, skills, and expertise. Leveraging these collaborative efforts, [Company Name] endeavors to push the boundaries of gear innovation and reinforce its position as a global leader in gear manufacturing.Conclusion:[Company Name]'s introduction of its advanced Worm and Bevel Gear technology reflects its commitment to shaping the future of mechanical power transmission. With increased efficiency, durability, and reliability, this innovative gear solution holds immense potential to transform various industries, ensuring seamless power transmission and optimizing overall system performance. As [Company Name] continues to focus on delivering cutting-edge gear solutions, the company remains poised to revolutionize the gear manufacturing industry and propel it towards a more advanced and sustainable future.