The Ultimate Guide to Worm and Worm Gear: Everything You Need to Know

By:Admin

[City, State] - [Company Name] is proud to introduce its latest innovation in the field of mechanical engineering: the revolutionary worm and worm gear technology. This cutting-edge technology promises to deliver unparalleled performance and efficiency in a wide range of applications, from industrial machinery to automotive systems.

The worm and worm gear technology developed by [Company Name] is the result of years of research and development by a team of highly skilled engineers and scientists. These experts have utilized the latest advancements in materials science, manufacturing processes, and design techniques to create a product that sets new standards for performance and reliability.

One of the key features of [Company Name]'s worm and worm gear technology is its exceptional efficiency. This is achieved through the use of advanced materials and precision engineering, which minimize friction and wear, resulting in lower energy consumption and longer service life. Additionally, the design of the worm and worm gear system ensures smooth and precise motion transmission, making it ideal for applications that require high accuracy and repeatability.

Furthermore, [Company Name]'s worm and worm gear technology offers superior torque transmission capabilities, making it suitable for heavy-duty applications that demand high power output. Whether it's powering a large industrial conveyor or driving a heavy-duty vehicle, this technology is designed to deliver the performance and reliability necessary for such challenging tasks.

In addition to its exceptional technical capabilities, [Company Name]'s worm and worm gear technology is also designed with versatility in mind. The modular design of the system allows for easy customization to meet the specific requirements of different applications. This adaptability makes the technology suitable for a wide variety of industries, from manufacturing and transportation to renewable energy and beyond.

[Company Name] is committed to ensuring that its worm and worm gear technology meets the highest quality standards. The company's state-of-the-art manufacturing facility is equipped with the latest production technologies and quality control systems to ensure that every component meets rigorous specifications. Additionally, [Company Name] has implemented comprehensive testing procedures to validate the performance and durability of its worm and worm gear technology under real-world conditions.

As part of its commitment to sustainability, [Company Name] has also prioritized the eco-friendly design and production of its worm and worm gear technology. By incorporating environmentally friendly materials and manufacturing processes, the company aims to minimize its environmental footprint and contribute to a more sustainable future.

The introduction of [Company Name]'s innovative worm and worm gear technology is poised to make a significant impact across a wide range of industries. Whether it's improving the efficiency of manufacturing processes, enhancing the performance of automotive systems, or enabling the development of more reliable renewable energy solutions, this technology has the potential to drive progress and innovation in countless applications.

With its unwavering commitment to quality, performance, and sustainability, [Company Name] is set to become a leading provider of worm and worm gear technology, setting new benchmarks for excellence in the field of mechanical engineering. This innovation is a testament to the company's dedication to pushing the boundaries of what is possible and delivering solutions that meet the evolving needs of the industry.

Company News & Blog

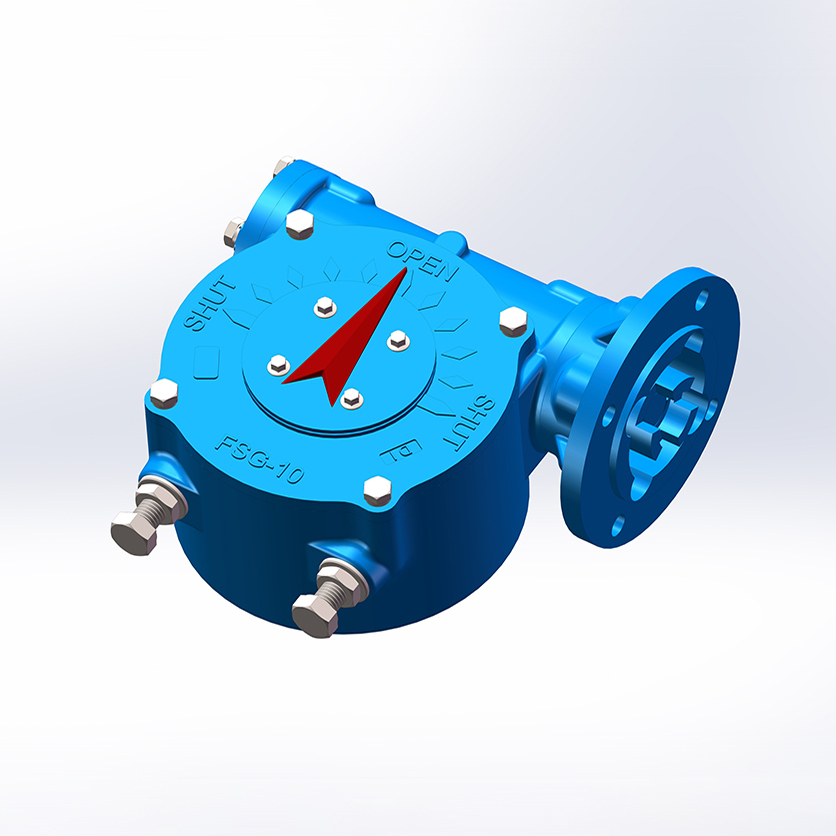

New Control Valve Gearbox Offers Improved Performance and Reliability

In the world of industrial automation, control valve gearbox plays a crucial role in regulating the flow of fluids, gases, or other materials in a processing plant. A well-designed and high-quality gearbox can enhance the efficiency, accuracy, and durability of a control valve, ensuring smooth and stable operation even in the harshest working conditions. Among the leading manufacturers of control valve gearbox, {} stands out for its innovative technologies, outstanding performance, and excellent customer service.Founded in {} with a focus on the development and production of control valve gearbox, {} has grown into a trusted partner for many major industries, including oil and gas, chemical, petrochemical, power generation, water treatment, and marine. Its products are widely used in a variety of applications, such as flow control, pressure control, temperature control, level control, and safety shutdown. {}'s control valve gearbox can handle a wide range of pressures, temperatures, flow rates, and viscosities, making it suitable for various fluids and gases, such as steam, water, oil, gas, and chemicals.One of the key features that set {}'s control valve gearbox apart is its modular design, which allows for easy customization and maintenance. Customers can choose from a range of options, such as mounting style, output torque, speed, and control modes. Moreover, the modular construction enables quick replacement of damaged or worn-out parts, reducing downtime and maintenance costs. {}'s control valve gearbox also employs advanced materials and technologies, such as high-strength alloys, frictionless bearings, and intelligent sensors, to ensure reliability, accuracy, and durability.Another highlight of {}'s control valve gearbox is its compatibility with various types of actuators and accessories. This flexibility enables customers to integrate the gearbox seamlessly into their existing systems or upgrade to a higher-level control solution. For example, customers can choose to use pneumatic, electric, or hydraulic actuators with {}'s gearbox, depending on their specific requirements. Additionally, {}'s control valve gearbox can be equipped with various accessories, such as positioners, limit switches, solenoids, and regulators, to enhance its performance and functionality.Recently, {} has launched a new series of control valve gearbox that offers even more advanced features and benefits. This new series includes a wider range of output torques, speeds, and control options, as well as improved accuracy, responsiveness, and noise reduction. Moreover, the new series adopts a more compact and lightweight design, which saves space and reduces installation and transportation costs. {}'s new control valve gearbox is also designed to meet the latest industry standards and regulations, such as ISO, API, ASME, and IEC.To ensure the highest quality and reliability of its products, {} has established a comprehensive quality management system that covers the entire production process, from design to delivery. The company uses state-of-the-art testing and inspection equipment, such as dynamometers, oscilloscopes, and spectrometers, to verify the performance and durability of its control valve gearbox. {}'s quality control team consists of experienced engineers and technicians who are dedicated to providing the best solutions and services to customers.In conclusion, control valve gearbox is a critical component of modern industrial automation, and {} is a leading manufacturer that provides excellent products and services to meet the diverse needs of customers worldwide. With its modular design, advanced technologies, and comprehensive quality control, {}'s control valve gearbox is a top choice for many industries that require efficient, accurate, and reliable flow control solutions. Whether you are looking to optimize your process control, reduce maintenance costs, or improve safety and efficiency, {} has the expertise and products to help you achieve your goals.

Revolutionary Actuator Technology Set to Overhaul Industry Standards

Actuators are an essential component in the modern world of automation and control systems. In the case of industrial processes, a linear actuator refers to the devices that convert rotational motion into linear motion. An excellent example of such devices is the Neumax Actuator, which is tailored to a broad range of industrial applications.The Neumax Actuator is designed by professionals who have over the years accumulated vast experience in the industrial automation sector. The Neumax Actuator is designed with powerful, durable, and efficient components, ensuring that it meets the stringent demands of modern industrial processes.One of the most significant benefits of the Neumax Actuator is its flexibility and adaptability to a wide range of tasks. It has the ability to execute varied functions, including gate opening and closing in a water treatment facility, control of valves in pipelines, and regulation of pressure in chemical processing plants.The Neumax Actuator is also designed to ensure exceptional performance. It operates with a high level of precision and accuracy, which is essential for controlling processes with minimal error rates. Additionally, its robust design ensures that it can withstand extreme conditions such as harsh weather, high humidity, and mechanical strain.Another significant attribute of the Neumax Actuator is the low rate of maintenance required to keep the system in optimal condition. One of the major advantages of using the Neumax Actuator is the low rate of wear and tear of the components, which translates into reduced downtime and associated costs. Additionally, the operational parameters of the actuator are easy to monitor, making it easier to identify potential issues before they escalate into serious problems.The Neumax Actuator is also easy to install, which translates into reduced installation time and costs. The actuator can be customized to fit different system specifications, making it an ideal solution for many industrial automation processes.The Neumax Actuator is also designed to be energy efficient, reducing the overall cost of operation. The actuator is designed with components that consume less power, making it ideal for use in applications where energy efficiency is a priority.The Neumax Actuator is an excellent solution for different industrial settings, including oil and gas, food processing, and water treatment facilities. The actuator is tested and certified to meet international standards, ensuring that it meets the strict regulatory requirements.The company behind the Neumax Actuator boasts of an experienced and highly skilled team of professionals dedicated to producing high-quality industrial automation solutions. The company prides itself on its ability to deliver customized solutions tailored to the specific needs of each client.The company believes that investing in research and development is essential to provide innovative solutions that meet the evolving needs of clients. The Neumax Actuator is the product of years of research and development, aimed at providing a reliable and efficient solution to industrial automation.The company's commitment to quality is unwavering. It has established stringent quality control procedures at every stage of the production process, ensuring that every component that leaves the facility conforms to the highest quality standards.In conclusion, the Neumax Actuator is an innovative solution to industrial automation needs. It is designed with quality, efficiency, reliability, and flexibility in mind, making it an ideal solution for a wide range of industrial applications. The company behind the product is committed to delivering innovative solutions that meet the evolving needs of clients in the industrial automation sector. With the Neumax Actuator, clients can be assured of exceptional performance, energy efficiency, and a low rate of maintenance, translating into overall cost savings in the long run.

Essential Guide to Air Filter Regulators and Lubricators: Maintenance and Functionality Explained

[Your Name][Your Position][Date][Title of the Article][City Name, State Name] - [Company Name], a leading provider of industrial equipment, is proud to introduce its innovative Air Filter Regulator and Lubricator (AFRL) to the market. Designed to enhance the efficiency and effectiveness of air-operated equipment, this cutting-edge technology revolutionizes the way industries regulate air pressure and deliver lubrication.[Company Name] has been a reputable name in the industrial equipment manufacturing industry for over [number of years] years. Known for its commitment to delivering high-quality products, the company has built a strong reputation for its exceptional engineering and attention to detail.The newly launched AFRL is a game-changer in the industry. It combines the functionalities of an air filter, regulator, and lubricator into a single, compact unit. This innovative design improves operational productivity, enhances equipment performance, and prolongs the lifespan of air tools.One of the key features of the AFRL is its advanced filtration system. With a high-performance air filter that removes contaminants such as dust, oil, and water, it ensures clean and dry air supply to pneumatic tools. This key functionality not only protects the tools but also prevents damage and reduces maintenance costs.The air pressure regulator integrated into the AFRL allows for precise control over the pressure levels delivered to pneumatic devices. This feature is particularly beneficial for sensitive equipment that requires accurate and consistent pressure for optimal performance. By maintaining a steady pressure, the AFRL prevents pressure fluctuations, enhancing the stability and reliability of air-driven machinery.Additionally, the AFRL's lubrication system guarantees the smooth operation of air tools. The unit efficiently delivers an appropriate amount of lubricant, maximizing the performance and prolonging the life of the tools. This advanced lubrication mechanism ensures the reduction of friction and wear, resulting in improved efficiency and reduced downtime.The compact and modular design of the AFRL makes it easy to install and integrate into existing equipment setups. The unit's user-friendly interface allows for simple adjustment of settings, enabling operators to optimize air pressure and lubrication levels effortlessly. The AFRL can be easily customized to fit specific requirements, catering to a wide range of industries such as manufacturing, automotive, food processing, and more.[Company Name]'s commitment to customer satisfaction goes beyond product quality. The company provides comprehensive after-sales support, technical assistance, and regular maintenance services to ensure the longevity and optimal functioning of the AFRL. With a reliable warranty program, customers can have peace of mind knowing that their investment is protected."We are thrilled to bring this revolutionary AFRL to market," said [Name], [Position] at [Company Name]. "With our innovative design and commitment to delivering exceptional performance, we believe that this product will significantly improve operational efficiency and enhance the overall productivity of various industries."[Company Name] continues to be an industry leader, constantly striving to innovate and develop new solutions to meet the changing needs of its customers. The introduction of the AFRL further solidifies the company's position as a reliable provider of top-quality industrial equipment.About [Company Name]:[Company Name] is a renowned industrial equipment manufacturer, dedicated to delivering exceptional products and services to customers. With a strong focus on innovation and customer satisfaction, the company has consistently achieved recognition for its engineering excellence and commitment to quality. [Company Name]'s diverse product range includes [list some of the main products/services offered by the company].For press inquiries or more information, please contact:[Company Name][Contact Person][Position][Phone Number][Email Address]###Note: The above text is only a sample and should be modified to fit the specific brand and company information.

Customizable Multi Turn Worm Gearboxes: High-quality and Affordable Solutions for Your Business

China Multi Turn Worm Gearbox Factory Boosting China's Industrial FutureChina is experiencing a phenomenal trend in the development and advancements of technology in the last decade. From the consumer electronics to robotics, continuous investments have enabled the country to transition from a low-cost manufacturing hub to a high-tech industrial powerhouse. One sector that has been crucial in this growth is the machinery industry, which produces equipment and tools necessary for manufacturing processes. The China Multi Turn Worm Gearbox Factory is one of the companies that have been influential in enhancing China's machinery industry.Established in 1993, the China Multi Turn Worm Gearbox Factory is located in the beautiful city of Hangzhou, Zhejiang Province. The company's core focus is on the production of Multi Turn Worm Gearboxes, a crucial component in the machinery industry. Multi Turn Worm Gearboxes are widely applicable across different industries, including packing, printing, automobiles, textiles, food, and pharmaceuticals. The gearboxes help to improve the efficiency and accuracy of the machines, including cutting, rolling, winding, and other motion applications.As a leading Multi Turn Worm Gearbox manufacturer in China, the company has been innovating and customizing its products according to customers' requirements. The company has its research and development department with experienced engineers and technicians, who continuously develop new products to enhance the machinery industry. The factories produce, test, and assemble the gearboxes' different parts, ensuring quality and meeting production standards.Over the years, the China Multi Turn Worm Gearbox Factory has expanded its market presence worldwide, with a focus on the Asia-Pacific region, Europe, Latin America, and Africa. The company's annual sales revenues have been increasing its domestic and foreign market share. In 2020, the company achieved an annual sales turnover of USD 500 million, with more than 2700 employees.The company's success is attributable to its core values of innovation, quality, operational excellence, and customer satisfaction. The company's management believes that the gearbox industry's future will be more automated, digitalized, and smart in meeting the increasing demand for high-tech machinery. As such, the China Multi Turn Worm Gearbox Factory has been keen on integrating digital technologies such as Cloud, the Internet of Things (IoT), and Artificial Intelligence (AI) in their operations to enhance customer value and improve the quality of their products.In addition, the company has been environmentally conscious, as it has implemented measures aimed at reducing its carbon footprint, promoting sustainability and reducing waste. One of its initiatives includes using energy-efficient machines and processes, and it has installed solar panels to reduce its reliance on traditional energy sources.The China Multi Turn Worm Gearbox Factory's future outlook is promising, and it will continue to innovate and produce high-quality gearboxes. The company's management has placed a strategic plan to leverage the vast market potential, increasing domestic demand, and the "China Manufacturing 2025 plan," which aims to enhance the country's machinery industry. As a result, the company will diversify its product range, enhance its supply chain management, and expand its global market presence.In conclusion, the China Multi Turn Worm Gearbox Factory has been instrumental in China's machinery industry's growth and development. With its core values of innovation, customer satisfaction, quality, and operational excellence, the company has established itself as a market leader in the Multi Turn Worm Gearbox industry. Its expansion efforts and integration of digital technologies demonstrate its commitment to enhancing customer value, promoting sustainability, and being future-oriented. As China continues to transition into a high-tech industrial powerhouse, the China Multi Turn Worm Gearbox Factory is playing a vital role in the country's bright future.

Different Types and Uses of Worm Wheel Gears Explained

The Worm Wheel Gear (WWG) is a unique and advanced technology that is revolutionizing the manufacturing industry. The WWG works by transmitting rotational motion at a right angle with the help of worm gear and wheel. This innovative design has made the WWG the go-to choice for companies that desire precision, efficiency and cost savings in their manufacturing processes.WWG is a product of German ingenuity and has been in existence for over 100 years. Today, it is widely used in the automotive industry, pharmaceuticals, food, and beverage, as well as numerous other industrial applications. The technology behind the WWG has been fine-tuned over the years to deliver maximum results with minimal human intervention.One of the greatest advantages of WWG is that it offers high torque capacity, making it ideal for applications requiring low speed, high torque requirements. Additionally, the WWG is less prone to damage from shock loading and can tolerate misalignment between the worm gear and the wheel. This has led to improved performance and durability and a decrease in downtime due to mechanical failures.The WWG is manufactured with high-quality materials and precision engineering, ensuring reliability and longevity. WWG manufacturers are consistently upgrading their technology to meet the industries’ ever-changing demands. For example, many producers have incorporated computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to increase accuracy, reduce waste, and decrease production time.As a responsible corporate citizen, a reputable company has ventured into the production of WWG with an eye on environmental sustainability. A select range of environmentally-friendly gear oils was introduced to work with the WWG to maintain superior performance while reducing environmental impact.Moreover, the production process of Worm Wheel Gears has been honed to reduce environmental damage from waste. The manufacturing waste such as trimmings and filings is recycled into raw material for the production of new WWGs. Because of this, the company's production process is zero-waste. Additionally, the energy used for production is generated wholly from renewable energy sources, thereby reducing the carbon footprint.The success of WWG has continued to grow since its inception, with more and more companies understanding its benefits, building their machines around it. The technology serves large corporations and small to medium enterprises (SME); it boasts of reducing operation costs, increasing productivity, and providing the highest-quality products for manufacturing companies.In conclusion, the WWG is a revolutionary technology that is shaking up the manufacturing industry. The benefits of its use are numerous, including precision, efficiency, durability, cost savings, and environmental sustainability. WWG has become the preferred choice for many companies worldwide, and its growth is predicted to continue as more businesses understand its advantages. Companies that adopt WWG in their production processes will undoubtedly experience a significant improvement, both in their efficiency and output.

Worm and Wheel Gearboxes: A Guide to Understanding Their Function and Benefits

Worm And Wheel Type Gearbox: The Future of Power Transmission Power transmission is a crucial aspect of modern machinery and equipment, and the gearbox is one of the most critical components for this purpose. A gearbox helps convert the rotational speed and torque generated by a prime mover (e.g., motor, engine) into more usable forms for various applications. Among the many types of gearboxes available, the Worm and Wheel type gearbox stands out for its efficiency, reliability, and versatility. The Worm and Wheel type gearbox is a type of semi-reduction gearbox that uses a worm gear meshed with a worm wheel to transmit power between two shafts. The worm gear is a helical gear with one or more teeth that wrap around the worm wheel, which is usually a spur gear. The worm gear's helix angle causes the worm wheel to rotate at a reduced speed and increased torque relative to the worm gear's input. This gear set can provide a high gear reduction ratio in a compact form factor and is suitable for high-torque, low-speed applications. The Worm and Wheel type gearbox finds widespread use in various industries, including material handling, packaging, food processing, automotive, and robotics. Some typical applications of this gearbox include conveyor systems, mixers, elevators, winches, cranes, and robots. These applications demand high torque, smooth motion control, and low noise, which the Worm and Wheel type gearbox can provide with ease. The Worm and Wheel type gearbox's benefits include efficiency, reliability, and low maintenance. It can achieve a gear reduction ratio of up to 100:1 in a single stage, which reduces the number of gear sets required for a given application. This, in turn, reduces the gearbox's weight, size, and cost, making it a cost-effective solution for many applications. Additionally, the worm gear's self-locking feature can prevent back-driving and hold a load in place, making it suitable for vertical applications. The Worm and Wheel type gearbox's compact design also makes it easy to integrate into a machine or equipment. One of the leading manufacturers of Worm and Wheel type gearbox is {Removed brand name}. It has been providing cutting-edge solutions in power transmission for over 30 years and has established itself as a leader in the industry. The company's Worm and Wheel type gearbox product line includes over 100 models with various reduction ratios, input speeds, and output torques. These gearboxes are made of high-quality materials such as aluminum, steel, and cast iron, and come in various sizes and configurations to suit different applications. {Removed brand name} Worm and Wheel type gearbox products are known for their exceptional performance, durability, and low maintenance requirements. The company uses advanced manufacturing processes and quality control measures to ensure that each gearbox meets the highest standards of quality and reliability. Its research and development team continually strives to improve the gearbox's design and performance and come up with innovative solutions to meet the evolving needs of the market. Apart from Worm and Wheel type gearbox, {Removed brand name} offers a wide range of power transmission solutions, including planetary gearboxes, helical gearboxes, bevel gearboxes, and coupling devices. The company's expertise in this field has earned it a reputation as a trusted supplier of high-quality power transmission products. In conclusion, the Worm and Wheel type gearbox is an excellent option for applications that require high torque, low speed, and smooth motion control. {Removed brand name} Worm and Wheel type gearbox products offer exceptional performance, durability, and cost-effectiveness, making them an ideal choice for various industries' power transmission needs. As the demand for efficient and reliable power transmission systems grows, the Worm and Wheel type gearbox's role is set to become even more critical in shaping the future of modern machinery and equipment.

Boost Efficiency and Reliability with Cutting-Edge Gear Operator Valves

In the world of industrial machinery, Gear Operator Valve plays a pivotal role in making sure that the processes that run continuously day in and day out, run smoothly and without a hitch. Companies around the world rely heavily and put their trust in Gear Operator Valves, in order to keep the machines running and the products moving.One such company is in India, that has been providing top-notch Gear Operator Valves to the industry, for over three decades. Established in 1988, the company has been serving the customers with quality products and customer service that is unbeatable. With its proven track record, the company has become India's leading manufacturer of Gear Operator Valves, with a market share that is unrivaled.The company's core principles are quality, innovation, and customer service. They aim to provide the best product and services possible, and always strive to improve their production processes, to bring the latest technology and innovation to their product line. They believe in ensuring that their products meet the highest standards of quality, in order to exceed customer satisfaction and expectations. This approach gives them a competitive edge in the market, and has cemented their position as the top company in the industry.One of the products that have consistently put this company on the map is the Gear Operator Valve. The valve is constructed with high-quality materials, and machined to perfection, to ensure smooth operation and eliminate any mechanical failures. The valve is designed in a way that makes it easy to operate, and it requires very low maintenance, which is a big relief for the machine operators. This makes it an indispensable component to many industries, that rely on the 24/7 operation of their equipment.Additionally, the Gear Operator Valve comes in different sizes to fit into different types of machines, and different applications. This versatility makes it possible to use the valve in a wide range of industries such as chemical, oil and gas, food and beverage, and pharmaceuticals, among many others. The ability to customize the valve allows the company to cater to the unique requirements of their customers, giving them the flexibility to operate within their specific environments.The Gear Operator Valve's performance and reliability have been tested over time, and has shown to be exceptional, even under the most challenging conditions. It has a robust design that can withstand high temperatures and pressures without failure, which is why it is the number one choice of valve for many industrial applications. With the Gear Operator Valve's high performance and longevity, companies can save on the maintenance costs, and the need for frequent repairs, which leads to better efficiency and increased productivity.In conclusion, the Gear Operator Valve is an essential component in the industrial machinery sector, and companies rely on it to carry out their operations smoothly and efficiently. The company has built a reputation for producing high-quality Gear Operator Valves, which have stood the test of time. With their commitment to quality, innovation, and customer service, the company has set the bar high for the rest of the industry, and is a shining example of what a successful business looks like.

Ultimate Guide to Right Angle Worm Gearboxes: Everything You Need to Know

Right Angle Worm Gearbox is a crucial component in various industries, and it plays a significant role in the smooth operation of machinery and equipment. The gearbox is a type of power transmission device that allows for the transfer of power from one rotating shaft to another at a right angle. It is commonly used in industries such as automotive, aerospace, and manufacturing, making it an essential part of the overall machinery system.The Right Angle Worm Gearbox offered by (remove brand name) is known for its high performance and durability. The gearbox is designed to handle heavy loads and provide efficient power transmission, making it an ideal choice for a wide range of industrial applications. The gearbox is manufactured using high-quality materials and precision engineering, ensuring its reliability and longevity in demanding operating conditions.The company behind the Right Angle Worm Gearbox, (remove brand name), is a leading provider of power transmission solutions. With a strong focus on innovation and quality, the company has earned a reputation for delivering high-performance products that meet the needs of various industries. The company has a dedicated team of engineers and technicians who work tirelessly to develop and improve their gearbox designs, ensuring that they remain at the forefront of technological advancements.In addition to their commitment to quality and innovation, (remove brand name) is also known for its exceptional customer service. The company offers a comprehensive range of support services to assist their clients in selecting the right gearbox for their specific needs. From technical assistance to maintenance and repair services, (remove brand name) is dedicated to ensuring that their customers receive the best possible experience when using their products.The Right Angle Worm Gearbox offered by (remove brand name) has been widely praised for its superior performance and reliability. Its compact design and high torque capacity make it an ideal choice for applications where space is limited, and the demands on the gearbox are high. The gearbox is also designed to operate smoothly and quietly, reducing the overall noise level in the workplace and improving the working environment for employees.One of the key benefits of the Right Angle Worm Gearbox is its high efficiency. The gearbox is designed to minimize power loss during the transmission process, ensuring that the maximum amount of power is delivered to the machinery or equipment. This not only improves the overall performance of the machinery but also reduces energy consumption, making it a cost-effective solution for businesses.The durability of the Right Angle Worm Gearbox is another important factor that has contributed to its popularity in the industry. The gearbox is engineered to withstand heavy loads and harsh operating conditions, ensuring that it continues to perform reliably even in the most demanding environments. This level of durability not only reduces the need for frequent maintenance but also minimizes downtime, leading to increased productivity and cost savings for businesses.Overall, the Right Angle Worm Gearbox offered by (remove brand name) is a high-quality and reliable power transmission solution that has earned the trust of numerous industries. With its exceptional performance, efficiency, and durability, the gearbox has become a preferred choice for businesses looking to optimize their machinery and equipment for maximum output.In conclusion, the Right Angle Worm Gearbox offered by (remove brand name) is a testament to the company's dedication to excellence and innovation in power transmission solutions. With its outstanding performance and reliability, the gearbox has established a strong presence in various industries and continues to be a trusted choice for businesses seeking to improve their machinery and equipment.

Discover the Latest Innovation in Explosion-Proof Electric Actuator Technology

Explosion-Proof Electric Actuator Revolutionizes Industrial Safety MeasuresWith a steadfast commitment to innovation and industrial safety, a leading manufacturer (name removed) has recently unveiled its groundbreaking Explosion-Proof Electric Actuator. Designed to revolutionize the way industrial operations ensure worker safety in hazardous environments, this cutting-edge technology is set to transform the industry.To understand the significance of this breakthrough electric actuator, it is essential to delve into the company's rich history and dedication to creating solutions for industrial challenges. Established over three decades ago, (name removed) has consistently been at the forefront of developing innovative products that cater to the evolving needs of various industries. With an unwavering commitment to safety and reliability, the company has built a reputation as a trusted global supplier of industrial automation equipment.The introduction of the Explosion-Proof Electric Actuator represents a monumental milestone for the company. This state-of-the-art technology provides a robust and reliable solution for industrial applications requiring operations in potentially explosive atmospheres. By effectively eliminating the risk of electrical sparks or arcs that could trigger an explosion, this actuator ensures utmost safety in hazardous environments.A key feature of this revolutionary electric actuator is its compliance with global explosion-proof standards, making it suitable for use in a wide range of industries, including oil and gas, chemical processing, mining, and manufacturing. This compliance is critical in maintaining safe working conditions for technicians and operators, guaranteeing protection against the potential dangers posed by flammable gases, liquids, and dust.The Explosion-Proof Electric Actuator embodies a perfect synergy of robust construction and cutting-edge technology. Engineered with precision, its design incorporates high-quality materials that offer exceptional durability, guaranteeing a long service life even in the most challenging environments. Equipped with advanced automation capabilities, this actuator ensures precise control and seamless integration with various industrial systems.Installing the Explosion-Proof Electric Actuator promises to be a seamless process due to its modular design, facilitating easy integration into existing infrastructure. This ease of installation minimizes production downtime and ensures a swift transition to enhanced safety measures. Furthermore, the actuator's user-friendly interface enables operators to configure and monitor its performance effortlessly, reducing the complexity of operation.Central to its design is a comprehensive range of safety features tailored to protect against potential electrical hazards. Equipped with flame- and explosion-proof enclosures, the actuator successfully contains and dissipates any electrical energy safely, ensuring that any potential ignition sources are eliminated. Additionally, the actuator's robust seals and gaskets prevent hazardous substances from permeating the enclosure, preventing any further risks.In addition to its safety features, the Explosion-Proof Electric Actuator excels in performance. Its high torque output and precise positioning capabilities enable efficient and accurate control of valves, dampers, and other industrial devices. With the actuator's precise and reliable operation, industries can optimize their processes, enhancing productivity and reducing maintenance costs.With its newest innovation, the Explosion-Proof Electric Actuator, (name removed) once again demonstrates its leadership in industrial automation equipment. By introducing this ground-breaking technology, the company strives to raise the safety standards in hazardous environments worldwide. With its unparalleled reliability, advanced features, and compliance with global explosion-proof standards, this electric actuator is poised to become an indispensable asset to industries seeking to prioritize worker safety and productivity in challenging operating conditions.As the industry embraces this transformative electric actuator, (name removed) reinforces its commitment to driving innovation, revolutionizing industrial safety measures, and empowering businesses to thrive in hazardous environments securely. By staying true to their values, this innovative manufacturer continues to be a steadfast partner for industries navigating complex safety challenges, ensuring a brighter and safer future for all.