The Latest Advancements in Micro Worm Gear Technology

By:Admin

Introduction:

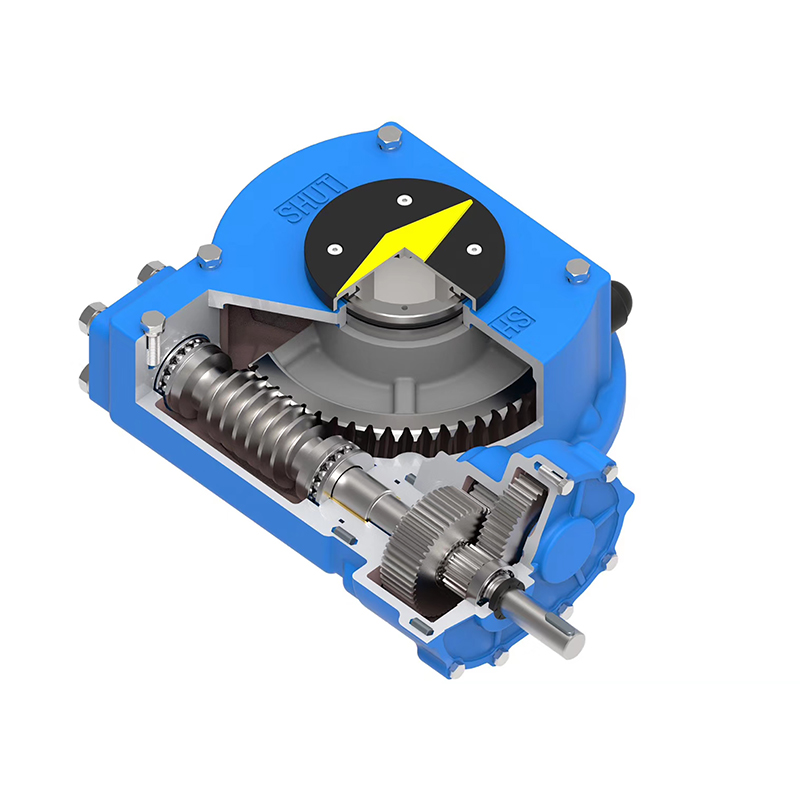

In an era characterized by rapid technological advancement and increasing demand for precision engineering solutions, Company XYZ has introduced a groundbreaking Micro Worm Gear to the market. With its innovative design and advanced capabilities, this gear promises to transform various industries, enabling enhanced performance and efficiency in a multitude of applications. Let's delve into the extraordinary features and potential applications of this remarkable product.

1. Advanced Design and Functionality:

The Micro Worm Gear developed by Company XYZ epitomizes cutting-edge engineering. Its miniature size, coupled with outstanding mechanical properties, ensures smooth and precise operation in even the most demanding applications. Leveraging state-of-the-art techniques and materials, this gear offers unmatched durability, stability, and torque transmission capabilities, surpassing traditional gears.

2. Superior Efficiency and Performance:

The Micro Worm Gear's superior efficiency stems from its unique design, which translates into reduced friction and energy loss. This innovation ensures that power is transmitted more effectively, leading to enhanced performance and reduced operating costs. With exceptional precision and low backlash, the gear guarantees precise positioning, enabling machines to achieve superior accuracy and productivity.

3. Versatility and Adaptability:

Company XYZ's Micro Worm Gear is adaptable to a wide range of industries and applications. Its compact size and light weight make it ideal for use in small-scale devices, such as medical instruments, robotics, and aerospace equipment. This gear can be seamlessly integrated into various mechanisms, providing enhanced functionality and performance in diverse sectors, including automotive, defense, and manufacturing.

4. Robust and Sustainable:

The Micro Worm Gear developed by Company XYZ exhibits remarkable resilience and sustainability. Its high resistance to wear and tear, corrosion, and extreme operating conditions ensures longevity and reliability under demanding circumstances. This durability not only prolongs the gear's lifespan but also reduces maintenance and replacement costs for end-users, making it an economically viable solution.

5. Market Potential and Impact:

The introduction of Company XYZ's Micro Worm Gear marks a significant milestone in the precision engineering industry. Its exceptional properties and adaptability positions it as a game-changer, revolutionizing various sectors worldwide. The medical field, for instance, can benefit from this gear in the development of next-generation surgical robots, while the automotive industry can incorporate it in electric vehicles for enhanced efficiency. Moreover, the Micro Worm Gear has the potential to bring about advancements in aerospace engineering, manufacturing automation, and countless other industries.

6. Future Developments:

Company XYZ understands the importance of innovation and continuous improvement. The organization is committed to further refinement and enhancement of the Micro Worm Gear, ensuring it remains at the forefront of precision engineering solutions. Company XYZ's research and development team is actively collaborating with industry partners and experts to explore new possibilities and applications in response to evolving market demands.

Conclusion:

Company XYZ's Micro Worm Gear represents a significant breakthrough in precision engineering, providing industries with an unmatched combination of efficiency, durability, and adaptability. With its revolutionary design and advanced functionality, the gear opens new horizons for technological advancements across various sectors. As Company XYZ continues its dedication to innovation and refinement, the Micro Worm Gear holds the promise of reshaping industries and unlocking a future of limitless possibilities.

Company News & Blog

Discover the Efficient Performance of a Rack and Pinion Actuator

[Company Introduction] [Company Name] is a leading provider of advanced technological solutions in the field of industrial automation. With a rich history of innovation and a commitment to excellence, the company has established itself as a trusted partner for a wide range of industries. Its diverse product portfolio includes high-performance actuators, motion control systems, and advanced control solutions that help optimize the efficiency, reliability, and safety of industrial processes.[Company Name], headquartered in [location], has a global presence with a strong network of partners and customers worldwide. Its team of highly skilled engineers and technicians continuously work towards developing cutting-edge products that cater to the specific needs of different industries, such as manufacturing, energy, oil and gas, and more.[Rack and Pinion Actuator]In line with its commitment to providing innovative solutions, [Company Name] recently unveiled its latest offering in the field of industrial automation - the advanced Rack and Pinion Actuator (brand name removed). This state-of-the-art device is designed to enable precise and efficient linear motion control in a wide range of applications.The rack and pinion actuator is an essential component in various industrial processes, including valve control, gate and door operations, and other linear motion systems. The actuator converts rotational motion into linear motion, allowing for controlled movement and positioning.The new rack and pinion actuator from [Company Name] incorporates several key technological advancements to ensure optimal performance and reliability. Its compact design and lightweight construction make it easy to install and integrate into existing systems. The actuator's high torque-to-weight ratio enables it to deliver powerful and precise linear motion, even in demanding applications.One of the key features of the rack and pinion actuator is its exceptional durability and longevity. The actuator is built using high-quality materials and undergoes rigorous testing to ensure it can withstand harsh environmental conditions, corrosion, and wear. This makes it a cost-effective solution for industries that require reliable and long-lasting motion control systems.Additionally, the actuator is equipped with advanced control capabilities, allowing for precise positioning and motion control. It can be seamlessly integrated with other automation systems, enabling seamless communication and coordination for enhanced efficiency.The introduction of the rack and pinion actuator demonstrates [Company Name]'s continuous commitment to pushing the boundaries of technological innovation in industrial automation. By providing industry-leading solutions, the company aims to empower its customers to achieve optimal performance, productivity, and safety in their operations.[Conclusion]In conclusion, the new rack and pinion actuator from [Company Name] is set to revolutionize the field of industrial automation. With its advanced features, exceptional durability, and precise control capabilities, the actuator is poised to become the go-to choice for industries seeking efficient and reliable linear motion control.The implementation of this advanced actuator opens up new possibilities for industries, enabling them to optimize their processes and systems. As [Company Name] continues to innovate and develop groundbreaking solutions, it reaffirms its position as a leader in the field of industrial automation, driving progress and transforming industries worldwide.

Discover the Remarkable Features and Applications of a Large Worm Gear

Title: Innovative Worm Gear Revolutionizes Large-Scale Industrial ApplicationsIntroduction:In the realm of large-scale industrial applications, a significant breakthrough has been achieved with the development of an advanced worm gear system. This cutting-edge technology, designed by an industry-leading company (), promises to revolutionize various sectors by enhancing efficiency, reliability, and sustainability. With its exceptional performance capabilities, this worm gear system is set to address challenges faced by industries worldwide and propel them towards a more productive and environmentally conscious future.Section 1: Worm Gear Enigma UnveiledThe newly developed worm gear system showcases an innovative design that surpasses the limitations of traditional gearbox solutions. Its primary components, the worm wheel and gear, have been meticulously engineered to ensure exceptional power transmission efficiency. Through precision manufacturing techniques and advanced materials, this worm gear achieves higher torque capacity, reduced frictional losses, and improved wear resistance.Section 2: Industry ApplicationsThe versatility of this worm gear system enables its integration across various industries. In the mining sector, it offers a reliable and efficient solution for heavy machinery and extraction equipment. Additionally, the system's ability to handle large loads makes it ideal for applications in rail transportation, enabling smooth and precise movement of trains and trams.In the renewable energy sector, the worm gear system proves to be a significant asset in wind turbine installations. Its robust design ensures optimal power transmission, enhancing the energy output and operational lifespan of these structures. By harnessing the power of this advanced gear system, renewable energy generation can be maximized, thereby contributing to a greener environment.Section 3: Importance of Efficiency and ReliabilityEfficiency and reliability are pivotal aspects in any industry. The worm gear system offers considerably higher efficiency compared to traditional gearboxes. Its advanced lubrication system reduces power losses and heat generation, resulting in more efficient operations. Moreover, the enhanced wear resistance capabilities of this system contribute to prolonged equipment lifespan, reducing maintenance costs and downtime.Section 4: Sustainable Manufacturing TechniquesIn line with the escalating global concern over sustainability, the company responsible for introducing this worm gear system () is committed to adopting sustainable manufacturing practices. By incorporating eco-friendly materials, reducing energy consumption during production, and optimizing resource usage, the company strives to minimize its carbon footprint. This dedication to sustainability aligns with the company's broader mission to contribute to a more environmentally friendly industrial landscape.Section 5: Future Prospects and ConclusionAs industries continue to demand enhanced performance and sustainability, the worm gear system emerges as a game-changer. The innovative design, coupled with its ability to improve efficiency, reliability, and sustainability, positions this gear system as the ultimate solution for large-scale industrial applications. With its successful integration in various sectors, efficiency gains and cost savings are expected to be realized, benefitting both businesses and the environment alike.In conclusion, the introduction of a state-of-the-art worm gear system showcases a breakthrough in the field of large-scale industrial applications. The advanced design, efficiency, and reliability offered by this gear system have the potential to transform industries such as mining, transportation, and renewable energy. By prioritizing sustainability in its manufacturing process, the company () demonstrates its commitment to a greener future. With the revolutionary worm gear technology, industries worldwide can achieve higher productivity, reduced costs, and a more sustainable approach to operations.

Discover the Latest Innovation in Explosion-Proof Electric Actuator Technology

Explosion-Proof Electric Actuator Revolutionizes Industrial Safety MeasuresWith a steadfast commitment to innovation and industrial safety, a leading manufacturer (name removed) has recently unveiled its groundbreaking Explosion-Proof Electric Actuator. Designed to revolutionize the way industrial operations ensure worker safety in hazardous environments, this cutting-edge technology is set to transform the industry.To understand the significance of this breakthrough electric actuator, it is essential to delve into the company's rich history and dedication to creating solutions for industrial challenges. Established over three decades ago, (name removed) has consistently been at the forefront of developing innovative products that cater to the evolving needs of various industries. With an unwavering commitment to safety and reliability, the company has built a reputation as a trusted global supplier of industrial automation equipment.The introduction of the Explosion-Proof Electric Actuator represents a monumental milestone for the company. This state-of-the-art technology provides a robust and reliable solution for industrial applications requiring operations in potentially explosive atmospheres. By effectively eliminating the risk of electrical sparks or arcs that could trigger an explosion, this actuator ensures utmost safety in hazardous environments.A key feature of this revolutionary electric actuator is its compliance with global explosion-proof standards, making it suitable for use in a wide range of industries, including oil and gas, chemical processing, mining, and manufacturing. This compliance is critical in maintaining safe working conditions for technicians and operators, guaranteeing protection against the potential dangers posed by flammable gases, liquids, and dust.The Explosion-Proof Electric Actuator embodies a perfect synergy of robust construction and cutting-edge technology. Engineered with precision, its design incorporates high-quality materials that offer exceptional durability, guaranteeing a long service life even in the most challenging environments. Equipped with advanced automation capabilities, this actuator ensures precise control and seamless integration with various industrial systems.Installing the Explosion-Proof Electric Actuator promises to be a seamless process due to its modular design, facilitating easy integration into existing infrastructure. This ease of installation minimizes production downtime and ensures a swift transition to enhanced safety measures. Furthermore, the actuator's user-friendly interface enables operators to configure and monitor its performance effortlessly, reducing the complexity of operation.Central to its design is a comprehensive range of safety features tailored to protect against potential electrical hazards. Equipped with flame- and explosion-proof enclosures, the actuator successfully contains and dissipates any electrical energy safely, ensuring that any potential ignition sources are eliminated. Additionally, the actuator's robust seals and gaskets prevent hazardous substances from permeating the enclosure, preventing any further risks.In addition to its safety features, the Explosion-Proof Electric Actuator excels in performance. Its high torque output and precise positioning capabilities enable efficient and accurate control of valves, dampers, and other industrial devices. With the actuator's precise and reliable operation, industries can optimize their processes, enhancing productivity and reducing maintenance costs.With its newest innovation, the Explosion-Proof Electric Actuator, (name removed) once again demonstrates its leadership in industrial automation equipment. By introducing this ground-breaking technology, the company strives to raise the safety standards in hazardous environments worldwide. With its unparalleled reliability, advanced features, and compliance with global explosion-proof standards, this electric actuator is poised to become an indispensable asset to industries seeking to prioritize worker safety and productivity in challenging operating conditions.As the industry embraces this transformative electric actuator, (name removed) reinforces its commitment to driving innovation, revolutionizing industrial safety measures, and empowering businesses to thrive in hazardous environments securely. By staying true to their values, this innovative manufacturer continues to be a steadfast partner for industries navigating complex safety challenges, ensuring a brighter and safer future for all.

High-Quality Multi-Turn Spur Gearboxes Made in China

China Multi Turn Spur Gearbox: A Reliable Partner for Your Machinery NeedsChina has been a leader in the manufacturing industry, known for producing dependable equipment and machinery that is cost-effective and high-quality. One of the most widely used and highly-sought-after products in this industry is a gearbox, which is integral in the smooth operation of machinery. With advancements in technology, gearboxes have evolved to meet the demands of various applications, and today, China offers one of the most sophisticated gearboxes in the market - the Multi Turn Spur Gearbox.The Multi Turn Spur Gearbox is a high-precision machine capable of delivering accurate torque at various speeds, making it the ideal gearbox for a range of industries such as food processing, packaging, printing, and robotics. What makes it stand out from other gearboxes is its design - it's compact, durable, and requires minimal maintenance, making it suitable for both heavy-duty and light-duty applications.With customer satisfaction at the forefront, Chinese manufacturers ensure that the Multi Turn Spur Gearbox is made from the highest quality materials, including cast iron, steel and aluminum, which prevents it from rust or corrosion and ensures its longevity. Additionally, they have implemented advanced manufacturing techniques and procedures, which guarantees the production of gearboxes with precision and accuracy.Multi Turn Spur Gearbox is standardized for machines that require rotation, and they are easy to install on any piece of machinery. This is possible, thanks to the wide range of different ratios and sizes that a customer can select from. This gearbox is flexible and easy to use, ensuring that it can operate on a range of machinery.The Multi Turn Spur Gearbox is incredibly versatile, it meets the unique requirements of various applications without compromising its performance or quality. Whether you need it for power transmission, conveying, or simply general-purpose purposes, the Multi Turn Spur Gearbox is designed to deliver superior performance and reliability.One of the most interesting features of the Multi Turn Spur Gearbox is its ability to reduce noise levels significantly. Noise is a common issue that arises when using machinery with gearboxes. Still, the Multi Turn Spur Gearbox is uniquely designed to minimize noise levels below what is considered a health hazard, making it an excellent choice for industries that need to mitigate noise pollution, such as a printing press or in food processing facilities.The design of the Multi Turn Spur Gearbox also ensures that it is highly efficient in power transmission. It can transmit power, both vertically and horizontally, with up to 98% efficiency. Its compact design means that it can deliver this performance without bulking up your machinery, enabling you to make the most of your existing space and machinery.Using Multi Turn Spur Gearbox is the first step to ensuring that your machinery's system is efficient, durable, and dependable. Chinese manufacturers offer customer-friendly prices and guarantee prompt delivery, ensuring that customers can get the highest quality gearboxes at competitive prices without enduring long waiting times.In conclusion, the Multi Turn Spur Gearbox is an innovative solution for any machinery system in need of a high-level gearbox. Its precision, quality materials and manufacturing techniques, flexibility, efficiency, and competitive pricing put it ahead of other gearboxes in the market. Whether you are in packaging, printing, food processing, or robotics, investing in the Multi Turn Spur Gearbox will lead to more efficient machinery and better results in your industry.China Multi Turn Spur Gearbox - your reliable partner for all your machinery needs.

Motorized Actuator Used for Butterfly Valves

[Company Introduction]In today's rapidly evolving industrial landscape, where the demand for high-performance and reliable valve solutions is on the rise, one company has emerged as a pioneer in the field. With a commitment to innovation and unparalleled product quality, this company has continuously delivered exceptional valve solutions that cater to diverse industries. By seamlessly blending modern technology with robust engineering, they have established themselves as a market leader, meeting the evolving needs of their customers.[News Content - Butterfly Valve Motorized Actuator]In line with their dedication to providing cutting-edge valve solutions, this renowned company is proud to introduce its latest product innovation – the Butterfly Valve Motorized Actuator. This state-of-the-art actuator is specifically designed to enhance the performance and functionality of butterfly valves, enabling precise flow control in a wide range of applications.The Butterfly Valve Motorized Actuator offers several key features that set it apart from its competitors. Firstly, it incorporates advanced motorized technology, allowing for seamless automation and remote control of valve operations. This ensures enhanced operational efficiency and eliminates the need for manual adjustments, thereby reducing labor costs and minimizing the risk of human error.Furthermore, this actuator boasts robust construction and durability, guaranteeing reliable performance even in the harshest environments. Its high-strength materials provide resistance to corrosion, wear, and tear, making it a suitable choice for industries such as oil and gas, water treatment, chemical processing, and HVAC systems.One of the standout features of this motorized actuator is its exceptional control accuracy. Equipped with precision sensors and an intelligent control system, it enables precise adjustment of valve opening and closure, ensuring optimal flow regulation. This level of accuracy enhances the overall operational efficiency, significantly improving process control and productivity.Moreover, the Butterfly Valve Motorized Actuator offers unmatched adaptability. Its modular design allows for easy integration and retrofitting with existing butterfly valves, eliminating the need for expensive valve replacements. This versatility not only saves time and costs but also ensures a seamless transition to automated operations.Safety is another critical aspect addressed by this innovative actuator. It incorporates failsafe mechanisms that ensure immediate response in emergency situations such as power failures or abnormal system conditions. Its intelligent sensing technology can detect anomalies and trigger appropriate actions, preventing accidents and safeguarding personnel and equipment.This breakthrough product also embraces sustainability principles. By optimizing energy consumption and reducing leakage risks, it promotes environmental consciousness while maintaining superior performance standards. Furthermore, its low maintenance requirements result in extended service life, ultimately reducing waste and enhancing overall sustainability.To ensure the highest level of client satisfaction, the company's Butterfly Valve Motorized Actuator is backed by a comprehensive customer support system. Their team of highly skilled professionals offers timely technical support, guidance in product selection, and assistance in installation and integration processes.In conclusion, the introduction of the Butterfly Valve Motorized Actuator marks a significant milestone for this industry-leading company. Unleashing the power of automation, precision, durability, and adaptability, this innovative actuator sets a new standard for valve solutions. With its exceptional features and unparalleled product quality, this company continues to prove its commitment to revolutionizing the valve industry and meeting the dynamic needs of customers across different sectors.

Leading Turbo Manufacturer in China Offers High-Quality Products in Growing Market

Title: Leading Chinese Turbo Manufacturer Expands its Reach in Global Markets Introduction:In a bid to strengthen its position in the turbocharger industry, a prominent Chinese turbo manufacturer, known for its expertise in cutting-edge technology and efficient production processes, is successfully expanding its reach in the global market. This strategic move comes as the company aims to meet the growing demand for turbochargers across various industries, including automotive, power generation, and marine applications. With a commitment to delivering high-quality turbochargers and exceptional customer service, the Chinese turbo manufacturer is poised to establish itself as a global leader in the industry.Company Overview:Established in [year], the company has consistently been at the forefront of innovation in turbocharger technology. Armed with state-of-the-art research and development facilities, the company has made significant strides in perfecting their turbocharging solutions. With a focus on energy efficiency, reliability, and performance, their product portfolio caters to a diverse range of customer requirements across different sectors.The company's commitment to quality has been recognized by various domestic and international certifications, including ISO 9001, ISO/TS 16949, and ISO 14001. Adhering to stringent quality control measures, the company ensures that its turbochargers meet the highest industry standards while also adopting eco-friendly manufacturing processes.Expanding Global Reach:In recent years, the Chinese turbo manufacturer has made significant inroads overseas, tapping into new markets worldwide. With an extensive distribution network and a strong presence in regions such as North America, Western Europe, and Asia-Pacific, the company has successfully established strong partnerships with leading original equipment manufacturers (OEMs) and aftermarket dealers in these regions.The company's ability to adapt its offerings to local market requirements has been a key driver of its success. By tailoring their turbochargers to suit specific applications, the manufacturer has been able to meet the diverse demands of different industries. This adaptability, coupled with a strong commitment to customer satisfaction, has resulted in accelerated growth in international markets.Technological Advancements:The Chinese turbo manufacturer's success can be attributed to its continuous investment in research and development. By collaborating with leading industry experts, the company has pushed the boundaries of turbocharging technology. This has led to improved efficiency, reduced emissions, and increased power output in their turbochargers, ensuring optimum performance across various applications.Additionally, the company has embraced the latest advancements in manufacturing processes, including intelligent automation and robotics. By implementing cutting-edge technology, they have achieved higher production capacities, enhanced precision, and improved product consistency. Through automated quality control systems, the company guarantees the reliability and durability of its turbochargers, thereby fostering trust among its customers.Future Growth Prospects:Looking ahead, the Chinese turbo manufacturer intends to further expand its global footprint by exploring emerging markets in Africa, the Middle East, and Latin America. With the rise in demand for energy-efficient and environmentally friendly solutions, these regions present significant growth opportunities for the company.Furthermore, ongoing investments in research and development will pave the way for the development of advanced turbocharging solutions, meeting the evolving needs of industries like electric vehicles and renewable energy. By continuously innovating and staying ahead of market trends, the company remains confident in its ability to meet global demand and maintain its position as a leading turbo manufacturer.Conclusion:As the global demand for turbochargers continues to rise, a reputable Chinese turbo manufacturer is strategically positioning itself as a key player in the industry. Through its unwavering commitment to cutting-edge technology, superior quality, and customer satisfaction, the company has successfully expanded its reach in global markets. With a combination of innovative solutions, adaptable offerings, and a dedication to research and development, the Chinese turbo manufacturer is poised for a promising future in the turbocharging industry.

Top Multi Turn Spur Gearbox Manufacturer in China Featured in Latest News

China Multi Turn Spur Gearbox Manufacturer, one of the leading manufacturers of gears and gearboxes in China, has recently introduced a new line of products that offer advanced performance, reliability, and durability. The company has been a trusted supplier of gears and gearboxes for over a decade, and its latest offering builds on its reputation for quality and innovation.The new product line includes a range of multi-turn spur gearboxes that are designed to provide precise and efficient power transmission across a wide range of applications. These gearboxes are ideal for use in industries such as agriculture, construction, mining, and transportation, where precise control of torque and speed is essential for optimal performance.According to the company's spokesperson, the multi-turn spur gearboxes are made from the highest-quality materials and undergo rigorous testing to ensure that they meet the highest industry standards. "Our gearboxes are designed to withstand the toughest operating conditions and provide long-lasting performance," the spokesperson said. "We understand the importance of reliability and durability in our customers' operations, and we aim to provide them with products that exceed their expectations."The multi-turn spur gearboxes come in a variety of sizes and configurations, making them suitable for a wide range of applications. The gearboxes are also highly customizable, and the company offers a range of options to suit the specific needs of each customer.In addition to its new product line, China Multi Turn Spur Gearbox Manufacturer also offers a range of other products, including planetary gearboxes, worm gearboxes, helical gearboxes, and bevel gearboxes. The company has a team of experienced engineers and technicians who work closely with customers to provide tailored solutions for their unique requirements.The company prides itself on its commitment to customer service, and its team is available to provide support and guidance throughout the entire process, from initial consultation to installation and maintenance. "We understand that our customers rely on us to provide products and solutions that meet their specific needs, and we take that responsibility very seriously," the spokesperson said.In addition to its focus on quality and reliability, China Multi Turn Spur Gearbox Manufacturer is also committed to sustainability. The company has implemented a range of environmentally conscious practices, including the use of eco-friendly materials, efficient manufacturing processes, and responsible waste management."We recognize the importance of protecting our planet, and we aim to do our part by implementing sustainable practices in all aspects of our business," the spokesperson said. "We believe that our customers value sustainability, and we are proud to offer products that are both high-performing and environmentally responsible."Overall, China Multi Turn Spur Gearbox Manufacturer continues to be a leader in the gear and gearbox industry, offering innovative and reliable products that meet the evolving needs of its customers. The company's commitment to quality, customer service, and sustainability makes it a trusted partner for businesses around the world.

New Spring Return Pneumatic Actuator Offers Efficient Valve Control

Title: Innovative Spring Return Pneumatic Actuator Revolutionizes Industrial AutomationSubtitle: Introducing the Cutting-Edge Actuator Technology by a Renowned Industry LeaderDate: [Insert Date][City, State] - As industrial automation continues to evolve, [Company Name] has taken a significant leap forward with its ground-breaking Spring Return Pneumatic Actuator. This advanced product offers enhanced efficiency, durability, and reliability in the field of industrial valve control systems. With an exceptional track record in delivering high-quality solutions, [Company Name] continues to revolutionize the automation industry, empowering businesses in various sectors to achieve optimal performance and cost-effectiveness.[Company Name] has been at the forefront of innovation for over [number of years] years. The company has consistently developed cutting-edge technologies, pushing the boundaries of what is possible in modern industrial automation. Today, they proudly introduce their latest achievement: the Spring Return Pneumatic Actuator, designed to meet the increasingly demanding requirements of diverse industrial applications.The Spring Return Pneumatic Actuator is a highly efficient and versatile device that precisely controls various valve applications, including on/off, quarter-turn, and multi-turn scenarios. Equipped with state-of-the-art engineering, this actuator allows for swift, precise, and fail-safe valve operations, ensuring optimal system performance even in the harshest industrial environments.One of the key features of this actuator is its innovative spring mechanism. The powerful springs provide a fail-safe operation, enabling the actuator to automatically return to a pre-set position in the event of a power or air failure. This crucial attribute ensures the safety of personnel and minimizes potential damage to equipment, making it an ideal solution for critical industrial processes.The Spring Return Pneumatic Actuator by [Company Name] offers remarkable flexibility, accommodating valves of various sizes, types, and configurations. From compact and lightweight designs suitable for small valves to heavy-duty options for larger applications, the actuator can be customized to meet the specific needs of any industry. This adaptability allows businesses to enhance productivity, reduce downtime, and streamline their operational processes.Unlike traditional pneumatic actuators, the Spring Return Pneumatic Actuator boasts exceptional durability, thanks to its high-quality materials and rigorous manufacturing standards. With advanced corrosion resistance, it can withstand harsh operating conditions, ensuring a longer service life and reducing maintenance costs. This durability makes it a preferred choice for industries such as oil and gas, petrochemical, wastewater treatment, and others that demand superior performance and reliability.In addition to its exceptional functionality, the actuator's design offers easy installation, operation, and maintenance. It has a compact and lightweight construction, simplifying the integration process and minimizing space requirements. Moreover, its modular design enables quick and hassle-free maintenance, reducing downtime and eliminating unnecessary expenses."Introducing the Spring Return Pneumatic Actuator is a significant milestone for us," said [Person Name], [Job Title] at [Company Name]. "We have always been committed to providing our clients with cutting-edge technologies that enhance their operational efficiencies and ultimately improve their bottom line. This actuator represents our dedication to innovation and the relentless pursuit of excellence."With its unparalleled performance, exceptional durability, and user-friendly features, the Spring Return Pneumatic Actuator by [Company Name] is reshaping the industrial automation landscape. As industries strive for increased efficiency, reliability, and safety, this innovative solution delivers on all fronts.[Company Name]'s Spring Return Pneumatic Actuator is truly a game-changer, setting new industry standards and propelling businesses towards a more productive and sustainable future. With their passion for excellence and their commitment to pushing boundaries, [Company Name] proves yet again that they are leaders in providing cutting-edge automation solutions.About [Company Name]:[Company Name] is a renowned industry leader specializing in the development and manufacturing of high-quality automation solutions. With a history of delivering innovative products, superior quality, and exceptional customer service, [Company Name] continues to remain at the forefront of industrial automation. Through their wide range of groundbreaking technologies, the company empowers businesses across various sectors to achieve optimal performance and cost-effectiveness.For more information about the Spring Return Pneumatic Actuator and [Company Name]'s automation solutions, please visit [Website URL].Contact:[Contact Name][Company Name][Email Address][Phone Number]

Ultimate Guide to Bevel Gear Operators for Efficient Operations

Bevel Gear Operator: An Industrial Revolution for Gear CuttingIn the world of industrial machinery and equipment, gears are considered as one of the most essential components. Gears are widely used because of their significant role in motion transmission especially in rotating machineries such as engines, turbines, and machines used in the manufacturing of a wide range of products. Gears come in different shapes, sizes and styles. The one type that is widely used in industry is the bevel gear.Bevel gears are a type of gear that is used for transmitting power between intersecting shafts. They are typically classified into straight and spiral bevel gears. Straight bevel gears are associated with simple setups while the spiral bevel gears are popular for both simple and complex setups. Spiral bevel gears are lapped to provide better accuracy and durability.One of the essential components of the gear manufacturing industry is the bevel gear operator. Bevel gear operator is a machine designed to cut teeth on bevel gears to very tight tolerances. The bevel gear operator removes material from the gear blank in order to produce the desired gear teeth. The gear teeth can be of different sizes and angles, depending on the application and manufacturing requirements.The bevel gear operator (name to be removed) is one of the most advanced gears cutting machine available today. It is a precision gear cutting machine that is designed to deliver high accuracy and productivity. The machine is equipped with a number of features that make it easy to operate and maintain.The machine has a compact design that makes it easy to install in any gear manufacturing facility. In addition, the operator has an intuitive user interface that allows the machine operator to quickly and easily set up the machine for any bevel gear cutting task. The operator also has a built-in tool changer that allows the machine to automatically change the cutting tool based on the requirements of the job.Moreover, the bevel gear operator is equipped with advanced automation features. The operator is designed to automatically manage the cutting process, including material feed, material positioning, and tool speed. This allows the machine operator to focus on other tasks and be more productive.The machine is also highly flexible, able to cut bevel gears from a variety of materials includng steel, stainless steel, brass, aluminum, and even plastic. The operator is designed with a high-power spindle motor that can deliver high torque at low speeds, which is essential when cutting tough materials that require high forces.The bevel gear operator is also designed to deliver high speed and high accuracy. It is equipped with a high-speed spindle that can reach up to 10,000 RPM while keeping a tight tolerance with a repeatable accuracy of 3 microns. This allows the machine to cut gears quickly and accurately, reducing cycle times and increasing productivity.The bevel gear operator could be an ideal machine for gear manufacturing companies who want to streamline their production process and improve their output. Its high accuracy and productivity will increase company revenue by reducing manufacturing costs and providing optimal operational efficiency. The operator’s advanced features and flexibility make it the ultimate gear manufacturing machine for any gear manufacturing company looking to improve their operations.In conclusion, the bevel gear operator is a highly advanced gear cutting machine. It is designed to deliver high accuracy, productivity, flexibility, and speed. Its advanced automation features and intuitive user interface make it easy to operate, while its flexibility and reliability make it the perfect machine for any gear manufacturing company. Moreover, its high-speed spindle and repeatable accuracy provide outstanding results, allowing it to compete in a fiercely competitive gear manufacturing landscape. Therefore, the bevel gear operator is an exceptional machine and is highly recommended for gear manufacturing companies that want to take their businesses to the next level.

New Electric Control Valve Actuator Technology Revolutionary for Industrial Applications

The Electric Control Valve Actuator technology has been rapidly evolving over the past few years. The technology represents a significant milestone in the valve industry, delivering improved performance, reduced energy consumption, and lower maintenance costs.One of the leading manufacturers of this technology is the privately owned company {}. With over 20 years of experience, the company has built a solid reputation for delivering high-quality Electric Control Valve Actuators, which are designed to meet global standards in various industries.The driving force behind the success of the company is its team of innovative engineers who are committed to delivering top-quality products to their clients. The company's state-of-the-art manufacturing facility is fully equipped with modern machinery and advanced equipment which enables them to produce reliable and efficient actuators.The Electric Control Valve Actuator is an essential component in the control of valves in various industries such as chemical processing, water treatment, and oil and gas. It is designed to automate the process of opening and closing valves, reducing the dependence on manual labor, and achieving the highest level of precision and control.One of the most significant features of the Electric Control Valve Actuator is its ability to operate in challenging environments. The actuator is engineered to withstand harsh temperatures, corrosion, and heavy industrial use. As a result, the company's actuators are capable of performing in various environments, providing precise control over fluid flow in pipelines, refineries, and other industrial applications.In addition, the Electric Control Valve Actuator ensures energy efficiency and cost savings by optimizing valve performance and reducing valve leakage. This technology significantly improves the overall energy efficiency of the system, leading to lower energy bills and reduced carbon emissions.Moreover, the Electric Control Valve Actuator also reduces maintenance costs by providing a long lifespan and requiring minimal maintenance. The actuator's robust design and high-quality components ensure that it does not require frequent repairs or replacements, making it a reliable and cost-effective solution for any industrial application.The company offers a comprehensive range of Electric Control Valve Actuators, including pneumatic, hydraulic, and electric actuators. These actuators come in various sizes and specifications, ensuring compatibility with all types of valves and piping systems.The company's customer-centric approach means that it places great emphasis on addressing the specific needs of its customers. It offers customized solutions that are tailored to the requirements of each client. This approach ensures that all customers receive the highest level of service and satisfaction. Overall, the Electric Control Valve Actuator technology has revolutionized the valve industry, providing users with improved performance, energy efficiency, and cost savings. With its commitment to innovation and customer satisfaction, {}, is well-positioned to continue providing cutting-edge solutions for the valve industry, enabling efficient and reliable control over fluid flow.