Revamp Your Machinery with Cutting-Edge Screw Gear Innovations

By:Admin

Innovative Screw Gear Enhances Industry Performance and Precision

[News Intro]

In a groundbreaking development, a leading engineering firm, renowned for its advanced products and cutting-edge technology, has unveiled a revolutionary screw gear system aimed at optimizing industry performance and precision. This groundbreaking invention is set to transform a wide range of sectors, from manufacturing to robotics, by delivering enhanced efficiency, increased stability, and unparalleled accuracy.

[Company Introduction]

{Insert Company Name}, a prominent player in the engineering industry, has gained accolades for its innovative solutions and manufacturing expertise. The company boasts a rich heritage and has consistently pushed the boundaries of technology, aiming to meet industry demands and accelerate progress through systematic advancements. With a dedicated team of experienced researchers and engineers, {Company Name} has become renowned for its commitment to excellence, resulting in a significant market presence and global recognition.

[News Body]

The latest breakthrough from {Company Name}, the newly introduced screw gear technology, is anticipated to revolutionize various sectors that heavily rely on gear systems for precision, efficiency, and performance. By leveraging its expertise and extensive research, {Company Name} has managed to design a screw gear that surpasses traditional models in nearly every aspect.

One of the key advantages presented by this invention is increased operational efficiency. The screw gear's innovative design incorporates a precision helix pattern, ensuring smoother and more streamlined rotations. As a result, it reduces friction, minimizes energy loss, and enhances overall workflow efficiency. Industrial machinery and manufacturing processes utilizing this revolutionary gear system are expected to experience significant gains in productivity and reduced downtime, ultimately leading to improved profitability.

Moreover, the screw gear's unique structural integrity greatly enhances stability and precision. Unlike conventional gear systems that are susceptible to misalignment and vibrations, this revolutionary invention offers superior resistance to these issues. The specially engineered screw gear minimizes disturbances caused by abrupt changes in torque or external forces, ensuring a stable and steady operation. Industries involved in robotics, automation, and critical applications, where accuracy plays a pivotal role, will greatly benefit from this breakthrough invention.

Another notable advantage of the screw gear is its compatibility with diverse industry applications. Designed for versatility, this new gear can be adapted to various systems, including power transmission, conveyors, machine tools, and fluid pumps, among others. Regardless of the industry, the innovative screw gear technology seamlessly integrates with existing systems, providing an easy and cost-effective solution for businesses looking to enhance their equipment's performance.

{Company Name}'s commitment to precision and industry needs is further exemplified by the rigorous testing and quality control processes incorporated into every screw gear system. Before commercial release, this revolutionary gear technology underwent comprehensive tests and evaluations to ensure it met stringent industry standards for reliability, efficiency, and durability. This meticulous approach adopted by {Company Name} underlines their dedication to delivering products that surpass customer expectations.

The introduction of this inventive screw gear system has garnered significant interest and attention within the engineering community. Industry experts and professionals have hailed this game-changing technology as a significant step forward in optimizing performance and precision, anticipating its widespread adoption across various sectors. As {Company Name} continues to raise the bar in advancing engineering excellence, this latest innovation cements their position as a key player in shaping the future of industry.

[Conclusion]

{Company Name}'s revolutionary screw gear technology sets a new standard in the engineering realm, offering enhanced performance, stability, and precision. Its innovative design and robust construction make it an ideal choice for diverse industries seeking to enhance efficiency, reduce downtime, and improve overall productivity. With this pioneering development, {Company Name} reinforces its commitment to innovation and driving progress, solidifying its position as a market leader and paving the way for a transformative future in engineering.

Company News & Blog

Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

Title: Advanced Worm Gear Butterfly Valve - The Perfect Solution for Industrial Fluid ControlIntroduction:In today's rapidly evolving industrial landscape, efficient fluid control is crucial to the success and safety of various operations. Owing to their versatility and effectiveness, Worm Gear Butterfly Valves have emerged as the go-to solution for regulating fluid flow in numerous industries. These valves, offering superior sealing capabilities and reliable performance, are now revolutionizing the way businesses approach fluid control.I. Significance of Worm Gear Butterfly Valves in Industrial Applications (100 words)Worm Gear Butterfly Valves have garnered significant prominence across industries due to their unique design and exceptional functionality. These valves consist of a disk-shaped element, known as the "butterfly," which rotates to control fluid flow. The addition of worm gears - a mechanical adjustment system - enables precise regulation, making them ideal for applications where fluid control precision is paramount. Whether it's chemical processing, water treatment, or power generation, Worm Gear Butterfly Valves have become indispensable tools for optimizing efficiency and enhancing safety.II. Key Features and Benefits of Worm Gear Butterfly Valves (200 words)a) Reliable Performance: Worm Gear Butterfly Valves are designed to withstand extreme conditions, offering consistent and dependable performance. The high-quality materials used in manufacturing ensure longevity and minimal maintenance.b) Excellent Sealing Properties: The unique design of these valves allows for a tight seal, preventing leakage and offering superior tightness. This ensures optimal flow control and minimizes the risk of fluid wastage, enhancing operational efficiency.c) Precise Control: The inclusion of the worm gear mechanism enables precise, measured adjustments to fluid flow, allowing operators to fine-tune operations as required. This precision is particularly critical in industries such as oil and gas, where even slight variations can result in significant consequences.d) Easy Installation and Operation: Worm Gear Butterfly Valves are known for their simplicity. They can be easily integrated into existing systems and operated efficiently by both experienced professionals and operators new to the technology.e) Versatility: These valves can handle a wide range of fluids, including liquids, gases, and even corrosive media. This adaptability makes Worm Gear Butterfly Valves suitable for applications across diverse industries.III. Company X's Advanced Worm Gear Butterfly Valve (200 words)Company X, a renowned industry leader in fluid control solutions, is proud to present its cutting-edge Worm Gear Butterfly Valve. With a steadfast commitment to innovation and customer satisfaction, Company X has designed a valve that surpasses industry standards and addresses various industry challenges.The advanced Worm Gear Butterfly Valve by Company X combines robust construction, precision performance, and exceptional durability. Manufactured using premium grade materials, it ensures longevity and reliability, minimizing maintenance requirements and reducing downtime.In addition to exceptional sealing properties, Company X's Worm Gear Butterfly Valve offers unparalleled precision control. Its worm gear mechanism guarantees accurate fluid flow adjustments, empowering operators to regulate processes with utmost accuracy.The valve's user-friendly design simplifies installation and operation, catering to customers across different industries. The versatility of Company X's Worm Gear Butterfly Valve allows businesses to maximize efficiency and safety, enhancing productivity and minimizing operational costs.IV. Conclusion (100 words)In an era where efficient fluid control is crucial, the Worm Gear Butterfly Valve emerges as the ideal solution for various industrial applications. Company X's advanced valve, with its superior design and outstanding performance, is primed to revolutionize fluid control practices across industries. With its exceptional sealing capabilities, precise control, and straightforward operation, this valve presents an unprecedented opportunity for businesses to optimize their operations, enhance safety, and maximize efficiency. Embracing the advantages offered by Worm Gear Butterfly Valves marks a significant leap forward in fluid control technology.

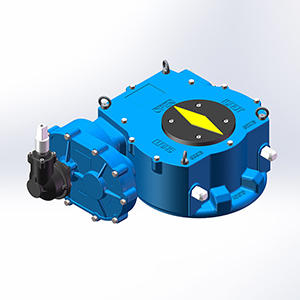

Discover the Key Insights of Control Valve Gearboxes for Enhanced Performance

Control Valve Gearbox: Vibration-Free and Efficient Operation for Industrial ApplicationsIntroduction:In today's industrial landscape, the demand for reliable and efficient control valves to regulate fluid flow is higher than ever. These valves play a critical role in various sectors such as oil and gas, chemical processing, power generation, and water treatment. To ensure smooth operations and proper control over fluid flow, it is essential to have robust and high-performing control valve gearboxes in place.News Content:{Company Name}, a leading provider of industrial automation solutions, is proud to introduce its advanced Control Valve Gearbox, a game-changer in the field. This revolutionary gearbox is specifically designed to address the challenges faced by industries in optimizing control valve performance and minimizing maintenance downtime.With its cutting-edge technology and precision engineering, the Control Valve Gearbox boasts several advantageous features that set it apart from traditional gearboxes:1. Vibration-Free Operation: {Company Name}'s Control Valve Gearbox is designed to ensure a vibration-free operation, reducing the wear and tear caused by excess vibrations. This innovative feature enhances the lifespan of critical valve components, ultimately reducing maintenance costs and improving overall efficiency.2. High Torque Output: The Control Valve Gearbox delivers exceptional torque output, allowing precise control over fluid flow even in high-pressure applications. The high torque capability ensures accurate valve positioning, resulting in better control accuracy and system reliability.3. Compact Design: This state-of-the-art gearbox is designed with compactness in mind, ensuring easy installation even in confined spaces. Its small footprint saves valuable installation area, making it a preferred choice for industries aiming to optimize plant layout and maximize operational efficiency.4. Smart and Connected: The Control Valve Gearbox is equipped with advanced sensors and smart connectivity, enabling real-time monitoring of valve conditions, temperature, and performance. This remote monitoring capability provides valuable data insights, allowing operators to proactively detect and address potential issues before they escalate.5. Robust and Durable: Built with high-quality materials, the Control Valve Gearbox guarantees long-lasting durability, even in harsh environmental conditions. Its resistance to corrosion, extreme temperatures, and excessive humidity ensures uninterrupted operation in demanding industrial environments.In addition to these key features, the Control Valve Gearbox is fully compatible with various control valve types, including globe, butterfly, and ball valves. This flexibility makes it suitable for a wide range of applications, from upstream oil and gas production to downstream refining and petrochemical industries.{Company Name} has always been at the forefront of innovation and engineering excellence, continuously striving to provide cutting-edge solutions that address the evolving needs of industries. The introduction of the Control Valve Gearbox is another testament to {Company Name}'s commitment to revolutionize the industrial automation sector.With its advanced technology, precision performance, and commitment to sustainability, {Company Name}'s Control Valve Gearbox is poised to become an industry standard for efficient and reliable fluid flow control. By optimizing control valve performance, minimizing maintenance requirements, and maximizing productivity, this gearbox will undoubtedly enhance industrial operations across various sectors worldwide.

Newly Launched Miniature Metal Gears to Revolutionize Robotics

Innovation in the field of mechanical engineering has been critical to the development of new machinery and equipment that have made life easier for businesses and individuals. One of the most critical components, that has revolutionized the manufacturing and production industry, is gear technology. Worm gears are one such technology that has been making a buzz in the market recently. Among the many types of worm gears, the micro worm gear has been a game-changer in small-sized machinery and equipment. Micro worm gear technology has been designed for ultra-compact machines and devices that require high power density, precision, and high efficiency. The micro worm gear is the perfect solution for applications where space is limited, and the gear ratio and torque are critical. Micro worm gears have a high reduction ratio and can be designed to handle very high torque loads through compact gearboxes. They can be designed with a variety of materials ranging from plastics and non-ferrous metals to hardened steels, making them versatile for various applications requiring different levels of stress tolerance.However, not all micro worm gears are created equal. Among the best in the market is the micro worm gear developed by the German-based manufacturer, whose name we have to omit. This micro worm gear combines innovation, precision, and quality to deliver reliable and efficient power transmission solutions. The company, whose name we shall omit, has been a leader in the production of high-quality gears for over 30 years. They have continuously invested in research and development, state-of-the-art equipment, and human capital, to remain at the forefront of innovation in gear technology. Over the years, their products have found application in various industries, including automotive, aerospace, medical devices, and robotics among other sectors. The micro worm gear by this manufacturer is no different. It is a highly specialized gear technology that comes in a compact design and is capable of transmitting power with high accuracy. One of its main advantages is that it can handle high loads while emitting very low noise. This is critical for small machinery and devices operating in environments where noise levels need to be minimized. The micro worm gear by this manufacturer is designed with advanced materials, including high-quality plastics and hardened steels, making it both lightweight and durable. The gear is available in different sizes and configurations, which makes it versatile and suitable for various applications. One of its most notable features is its high accuracy thanks to the use of advanced manufacturing techniques such as gear hobbing and tooth grinding. A critical aspect of the micro worm gear by this manufacturer, which gives it an edge over competitors, is its customization ability. The manufacturer can tailor-make the gear to meet the specific needs of end-users. This means that businesses and other customers can provide their unique specifications, and the manufacturer can craft a micro worm gear that precisely matches their requirements. This high level of customization has made the manufacturer the go-to source for micro worm gears used in various industry sectors. In conclusion, the micro worm gear is a critical innovation in the field of gear technology, offering high precision and efficiency in power transmission in ultra-compact applications. This technology can handle high loads with minimal noise while being versatile and customizable to meet specific customer requirements. Among the best micro worm gears in the market is the one developed by the German-based manufacturer, whose name we shall omit, which combines advanced materials, manufacturing techniques, and customization capabilities. This micro worm gear is suitable for various industries, and its efficient operation makes it an attractive option for businesses and other end-users looking for reliable power transmission solutions.

Advanced Electric Valve Operator: The Ultimate Guide for Efficient Operations

[Headline]: Innovative Electric Valve Operator Introduces Advanced Solutions for Efficient Automation[Subheading]: Leading Company's Cutting-Edge Electric Valve Operator Revolutionizes Industrial AutomationDate: [Current date][City]: [City name]In an era where efficiency and automation have become the pillars of industrial systems, leading manufacturing company [Company Name] is set to disrupt the market with its groundbreaking Electric Valve Operator. This advanced solution is poised to revolutionize industrial automation, offering improved performance, energy efficiency, and seamless integration into existing systems. Designed to cater to the diverse needs of various industries, the Electric Valve Operator is set to become a game-changer in process automation and control.[Company Name], a global leader in innovative industrial solutions, is renowned for its commitment to quality and technological advancement. The Electric Valve Operator, developed through extensive research and development efforts, embodies the company's dedication to providing cutting-edge solutions that truly meet the needs of its customers.With the advent of industry 4.0 and the increasing demand for efficient production processes, the Electric Valve Operator comes at a crucial time. By effectively automating valve control, this innovative solution optimizes and streamlines complex industrial operations, resulting in enhanced productivity, reduced downtime, and improved overall efficiency. Industries such as oil and gas, water treatment, chemical processing, and power generation are expected to benefit immensely from this revolutionary device.The Electric Valve Operator boasts a range of key features that set it apart from traditional valve control systems. Leveraging advanced technology and a state-of-the-art control system, it offers precise, accurate, and rapid valve positioning. Backed by its intelligent control algorithm, the Electric Valve Operator ensures consistent and reliable operation, while minimizing potential human errors.One of the standout features of this groundbreaking solution is its energy-efficient design. The Electric Valve Operator incorporates intelligent power management, effectively minimizing power consumption without compromising performance. By reducing energy expenditure, industries can significantly cut costs and enhance sustainability efforts.Moreover, this electric valve operator seamlessly integrates with existing infrastructure, facilitating hassle-free installation and compatibility with standardized communication protocols. This flexible integration capability allows for easy incorporation into a wide range of industrial automation systems, ensuring streamlined operations without significant disruptions.In addition to its outstanding technical capabilities, [Company Name] also prioritizes user-friendly interfaces to enhance the overall user experience. The Electric Valve Operator simplifies configuration, monitoring, and troubleshooting through an intuitive graphical user interface (GUI). This user-friendly interface empowers operators to efficiently monitor valve performance, identify potential issues, and make necessary adjustments promptly.Safety also lies at the core of the Electric Valve Operator's design. [Company Name] has prioritized stringent safety measures, ensuring that the Electric Valve Operator meets global safety standards. With built-in fail-safe features, emergency shutdown mechanisms, and comprehensive protection against voltage surges, this solution guarantees the well-being of both personnel and equipment.In conclusion, the Electric Valve Operator from [Company Name] represents a significant step forward in industrial automation. This cutting-edge solution promises to accelerate the pace of innovation across multiple industries, empowering businesses to thrive in an increasingly fast-paced world. With its exceptional performance, energy efficiency, seamless integration, and strong focus on safety, the Electric Valve Operator establishes itself as the go-to solution for industries seeking to optimize their operations and achieve unmatched levels of efficiency.[Company Name]'s commitment to providing top-of-the-line industrial solutions ensures that the Electric Valve Operator is just the beginning of a new era in automation. As industries continue to evolve, [Company Name] is set to spearhead the development of groundbreaking technologies, empowering businesses to embrace automation and maximize their potential.

What Is Worm and Wheel Steering Gear and How Does It Work?

The Worm And Wheel Steering Gear (need remove brand name) has long been one of the most popular devices in the automotive industry, and for good reason. This reliable and durable steering mechanism has been utilized for decades in vehicles of all kinds, from the smallest passenger cars to the largest commercial trucks.When it comes to the Worm And Wheel Steering Gear (need remove brand name), the company behind it is one that has been in business for many years, and has established a reputation for quality and reliability. With a long history of engineering and manufacturing excellence, this company has become a trusted provider of steering gear systems to automotive manufacturers worldwide.According to company officials, the Worm And Wheel Steering Gear (need remove brand name) is designed to provide a smooth, easy-to-operate steering experience for drivers. By utilizing a combination of worm gears and a wheel-shaped gear, this mechanism is able to provide precise, responsive steering in a wide range of driving conditions.One of the key benefits of the Worm And Wheel Steering Gear (need remove brand name) is its durability. Unlike some other steering mechanisms that can wear out or break down over time, this device has been engineered to withstand the rigors of harsh driving conditions and heavy use. This means that drivers can rely on it to provide consistent performance year after year, even under the most demanding circumstances.Another important feature of the Worm And Wheel Steering Gear (need remove brand name) is its versatility. Because it is designed to fit a wide range of vehicles, this mechanism can be used in everything from small passenger cars to large commercial trucks. This makes it an ideal choice for automotive manufacturers looking to streamline their production processes and reduce costs.Of course, one of the key factors driving the popularity of the Worm And Wheel Steering Gear (need remove brand name) is its ease of operation. By providing a smooth, easy-to-use steering experience, this device helps drivers stay in control of their vehicles and maneuver through even the most challenging driving conditions with ease.Overall, there is no doubt that the Worm And Wheel Steering Gear (need remove brand name) is one of the most important components in today's vehicles. Whether you are a driver, an automotive manufacturer, or simply someone interested in the latest automotive technology, this innovative and reliable device is one that is sure to impress. So why not take a closer look today and see what all the fuss is about?

Leading Turbo Manufacturer in China Offers High-Quality Products in Growing Market

Title: Leading Chinese Turbo Manufacturer Expands its Reach in Global Markets Introduction:In a bid to strengthen its position in the turbocharger industry, a prominent Chinese turbo manufacturer, known for its expertise in cutting-edge technology and efficient production processes, is successfully expanding its reach in the global market. This strategic move comes as the company aims to meet the growing demand for turbochargers across various industries, including automotive, power generation, and marine applications. With a commitment to delivering high-quality turbochargers and exceptional customer service, the Chinese turbo manufacturer is poised to establish itself as a global leader in the industry.Company Overview:Established in [year], the company has consistently been at the forefront of innovation in turbocharger technology. Armed with state-of-the-art research and development facilities, the company has made significant strides in perfecting their turbocharging solutions. With a focus on energy efficiency, reliability, and performance, their product portfolio caters to a diverse range of customer requirements across different sectors.The company's commitment to quality has been recognized by various domestic and international certifications, including ISO 9001, ISO/TS 16949, and ISO 14001. Adhering to stringent quality control measures, the company ensures that its turbochargers meet the highest industry standards while also adopting eco-friendly manufacturing processes.Expanding Global Reach:In recent years, the Chinese turbo manufacturer has made significant inroads overseas, tapping into new markets worldwide. With an extensive distribution network and a strong presence in regions such as North America, Western Europe, and Asia-Pacific, the company has successfully established strong partnerships with leading original equipment manufacturers (OEMs) and aftermarket dealers in these regions.The company's ability to adapt its offerings to local market requirements has been a key driver of its success. By tailoring their turbochargers to suit specific applications, the manufacturer has been able to meet the diverse demands of different industries. This adaptability, coupled with a strong commitment to customer satisfaction, has resulted in accelerated growth in international markets.Technological Advancements:The Chinese turbo manufacturer's success can be attributed to its continuous investment in research and development. By collaborating with leading industry experts, the company has pushed the boundaries of turbocharging technology. This has led to improved efficiency, reduced emissions, and increased power output in their turbochargers, ensuring optimum performance across various applications.Additionally, the company has embraced the latest advancements in manufacturing processes, including intelligent automation and robotics. By implementing cutting-edge technology, they have achieved higher production capacities, enhanced precision, and improved product consistency. Through automated quality control systems, the company guarantees the reliability and durability of its turbochargers, thereby fostering trust among its customers.Future Growth Prospects:Looking ahead, the Chinese turbo manufacturer intends to further expand its global footprint by exploring emerging markets in Africa, the Middle East, and Latin America. With the rise in demand for energy-efficient and environmentally friendly solutions, these regions present significant growth opportunities for the company.Furthermore, ongoing investments in research and development will pave the way for the development of advanced turbocharging solutions, meeting the evolving needs of industries like electric vehicles and renewable energy. By continuously innovating and staying ahead of market trends, the company remains confident in its ability to meet global demand and maintain its position as a leading turbo manufacturer.Conclusion:As the global demand for turbochargers continues to rise, a reputable Chinese turbo manufacturer is strategically positioning itself as a key player in the industry. Through its unwavering commitment to cutting-edge technology, superior quality, and customer satisfaction, the company has successfully expanded its reach in global markets. With a combination of innovative solutions, adaptable offerings, and a dedication to research and development, the Chinese turbo manufacturer is poised for a promising future in the turbocharging industry.

Enhance Your Machinery with High-Quality Electric Actuators for Maximum Efficiency

Title: Groundbreaking Electric Actuator Revolutionizes Industrial AutomationIntroduction:In today's rapidly evolving industrial landscape, technological advancements continue to redefine efficiency and productivity. The latest innovation making waves in the automation sector is the cutting-edge Electric Actuator developed by a pioneering company (remove brand name), offering unprecedented precision and control. With applications ranging across diverse industries such as manufacturing, energy, and transportation, this revolutionary actuator is poised to transform industrial automation processes, optimizing productivity while reducing costs and environmental impact.Electric Actuator: Unleashing a New Era of Precision and ControlThe Electric Actuator, developed by (remove brand name), is an advanced electromechanical device designed to replace conventional pneumatic and hydraulic actuators, offering significantly improved precision, control, and reliability. With its compact and lightweight design, it is adaptable to a wide range of industrial operations, from valve control to material handling, robotics, and even 3D printing.Enhanced Precision and Control:Owing to its high-precision servo motor drive system, this Electric Actuator can deliver unparalleled positional accuracy and repeatability. By eliminating the traditional drawbacks associated with pneumatic and hydraulic systems, such as air leaks, pressure loss, and unpredictable performance, it ensures enhanced control over critical operations. Industrial processes dependent on precise movement, alignment, and positioning will greatly benefit from the increased accuracy and repeatability offered by this groundbreaking technology.Efficiency and Energy Savings:The Electric Actuator boasts remarkable energy efficiency, providing substantial cost savings to industries grappling with rising energy costs and environmental concerns. Its variable speed control, along with minimal energy loss during operation, leads to a significant reduction in energy consumption, ultimately resulting in a greener and more sustainable manufacturing environment. Moreover, the elimination of costly and maintenance-intensive hydraulic or pneumatic systems brings about substantial cost-cutting benefits, enhancing the overall cost-effectiveness of industrial operations.Remote Monitoring and Control:The incorporation of cutting-edge digital technology enables the Electric Actuator to be seamlessly integrated into Internet of Things (IoT) platforms. This empowers industries to monitor and control their operations remotely, even from a centralized control room. Real-time data feedback, preventive maintenance diagnostics, and predictive failure analysis capabilities prevent unexpected downtime, boosting operational efficiency and reducing production losses.Adaptability and Customization:Recognizing the diverse needs of different industries, the Electric Actuator offers a flexible framework that can be easily customized to suit specific application requirements. The actuator's operating parameters, force range, speed, stroke length, and various control interfaces can all be tailored to match the industrial processes, ensuring optimal performance and compatibility.Safety and Reliability:Reliability is a crucial aspect of any industrial automation technology, and the Electric Actuator meets the highest safety and durability standards. Equipped with advanced safety features such as overload protection and emergency stop functionality, it ensures worker safety while preventing costly accidents and equipment damage. Additionally, the Electric Actuator exhibits exceptional resistance to harsh environmental conditions, guaranteeing a long lifespan and minimal maintenance requirements.Future Outlook:As industries across the globe grapple with the challenges of increasing productivity while reducing environmental impact, the Electric Actuator developed by (remove brand name) offers a game-changing solution that addresses these concerns head-on. With its unparalleled precision, control, efficiency, and adaptability, this innovative technology holds immense potential for revolutionizing industrial automation across a wide range of sectors. By enabling industries to optimize their operations, streamline processes, and reduce costs, the Electric Actuator is poised to lead the next generation of industrial automation.

New Handwheel Gear Operator Launched to Improve Industrial Operations

[Headline]: Innovative Handwheel Gear Operator Revolutionizes Industrial Operations[Subheading]: Introducing a Groundbreaking solution to Efficient and Reliable Machinery Control[Date][City], [State] - In a bid to enhance the efficiency and precision of machinery control, a leading industrial automation company unveils its latest product - the Handwheel Gear Operator. Designed to optimize operations across various industries, this cutting-edge innovation is set to revolutionize the way industrial processes are carried out.[Company Name], a global leader in industrial automation solutions, has developed the Handwheel Gear Operator as a result of extensive research and development. Combining state-of-the-art technology with a user-friendly interface, this revolutionary device simplifies machinery control and ensures improved productivity.The Handwheel Gear Operator serves as a compact and versatile tool, suitable for a wide range of applications. From heavy industrial machinery to delicate precision instruments, this device provides operators with enhanced control and maneuverability. Its ergonomic design ensures comfortable operation, reducing fatigue and increasing efficiency in the workplace.One of the key features of the Handwheel Gear Operator is its seamless integration with existing machinery. This device can easily be retrofitted onto various equipment, making it a cost-effective and hassle-free solution for businesses looking to optimize their machinery control systems. The Handwheel Gear Operator also boasts compatibility with a range of industrial protocols, allowing for seamless communication and integration with existing control systems.Enhanced precision is another aspect that sets the Handwheel Gear Operator apart. Equipped with advanced digital technology, this device offers operators a high degree of accuracy in controlling speed, torque, and direction. This not only reduces the chances of human error but also enables smoother and more precise operations, resulting in improved product quality, reduced downtime, and increased overall productivity.Moreover, the Handwheel Gear Operator boasts advanced safety features, ensuring optimal worker protection. With its high-level fault detection mechanism and emergency shutdown capabilities, this device guarantees a safe operating environment for workers. By minimizing the risk of accidents and equipment damage, businesses can prioritize the well-being of their employees while maintaining continuous operations with minimal interruptions.To further enhance user experience, the Handwheel Gear Operator is equipped with a user-friendly interface. Its intuitive controls and digital display provide operators with real-time feedback, allowing for swift adjustments and monitoring of key parameters. Additionally, the device's modular design ensures easy maintenance and reduces downtime, further optimizing the overall operational efficiency."We are thrilled to introduce the Handwheel Gear Operator to the market," says [Company Name] spokesperson. "With its cutting-edge technology and extensive compatibility, we believe this device will transform the way industries operate, increasing productivity and ensuring a safer working environment for all."As industries continue to evolve and embrace automation and digitalization, the Handwheel Gear Operator offers a reliable and efficient solution to meet the growing demands of modern industrial processes. By integrating this innovative device into their operations, businesses can streamline their machinery control processes, reduce costs, and maximize productivity.About [Company Name]:[Company Name] is a leading global provider of industrial automation solutions, specializing in the design and manufacture of innovative devices to optimize industrial processes. With a strong commitment to quality and customer satisfaction, [Company Name] continues to revolutionize the industrial automation sector through cutting-edge technologies. For more information, please visit the company's website at [website URL].[Note: Please replace the [Company Name] placeholders with the actual name of the company.]

Revolutionary Actuator Technology Set to Overhaul Industry Standards

Actuators are an essential component in the modern world of automation and control systems. In the case of industrial processes, a linear actuator refers to the devices that convert rotational motion into linear motion. An excellent example of such devices is the Neumax Actuator, which is tailored to a broad range of industrial applications.The Neumax Actuator is designed by professionals who have over the years accumulated vast experience in the industrial automation sector. The Neumax Actuator is designed with powerful, durable, and efficient components, ensuring that it meets the stringent demands of modern industrial processes.One of the most significant benefits of the Neumax Actuator is its flexibility and adaptability to a wide range of tasks. It has the ability to execute varied functions, including gate opening and closing in a water treatment facility, control of valves in pipelines, and regulation of pressure in chemical processing plants.The Neumax Actuator is also designed to ensure exceptional performance. It operates with a high level of precision and accuracy, which is essential for controlling processes with minimal error rates. Additionally, its robust design ensures that it can withstand extreme conditions such as harsh weather, high humidity, and mechanical strain.Another significant attribute of the Neumax Actuator is the low rate of maintenance required to keep the system in optimal condition. One of the major advantages of using the Neumax Actuator is the low rate of wear and tear of the components, which translates into reduced downtime and associated costs. Additionally, the operational parameters of the actuator are easy to monitor, making it easier to identify potential issues before they escalate into serious problems.The Neumax Actuator is also easy to install, which translates into reduced installation time and costs. The actuator can be customized to fit different system specifications, making it an ideal solution for many industrial automation processes.The Neumax Actuator is also designed to be energy efficient, reducing the overall cost of operation. The actuator is designed with components that consume less power, making it ideal for use in applications where energy efficiency is a priority.The Neumax Actuator is an excellent solution for different industrial settings, including oil and gas, food processing, and water treatment facilities. The actuator is tested and certified to meet international standards, ensuring that it meets the strict regulatory requirements.The company behind the Neumax Actuator boasts of an experienced and highly skilled team of professionals dedicated to producing high-quality industrial automation solutions. The company prides itself on its ability to deliver customized solutions tailored to the specific needs of each client.The company believes that investing in research and development is essential to provide innovative solutions that meet the evolving needs of clients. The Neumax Actuator is the product of years of research and development, aimed at providing a reliable and efficient solution to industrial automation.The company's commitment to quality is unwavering. It has established stringent quality control procedures at every stage of the production process, ensuring that every component that leaves the facility conforms to the highest quality standards.In conclusion, the Neumax Actuator is an innovative solution to industrial automation needs. It is designed with quality, efficiency, reliability, and flexibility in mind, making it an ideal solution for a wide range of industrial applications. The company behind the product is committed to delivering innovative solutions that meet the evolving needs of clients in the industrial automation sector. With the Neumax Actuator, clients can be assured of exceptional performance, energy efficiency, and a low rate of maintenance, translating into overall cost savings in the long run.

Discover all you need to know about high-quality gearboxes for gate valves

[News - 800 words]Title: Introducing the Revolutionary Gate Valve Gearbox: A Milestone in Industrial Equipment InnovationIntroduction:In today's rapidly evolving industrial landscape, there is an ever-increasing demand for reliable and efficient equipment that can enhance operational efficiency and streamline processes. Responding to this need, {Company Name} is proud to introduce its revolutionary Gate Valve Gearbox - a groundbreaking development set to transform various industries with its cutting-edge technology and exceptional performance.Company Introduction:Founded in {Year}, {Company Name} has emerged as a global leader in the manufacturing and distribution of industrial equipment. With a strong commitment to innovation and customer satisfaction, the company has built a solid reputation for delivering superior-quality products that meet the industry's highest standards.With state-of-the-art manufacturing facilities and a dedicated team of experts, {Company Name} has consistently pushed the boundaries of technological advancement. Their relentless pursuit of excellence has culminated in the development of the Gate Valve Gearbox - a game-changer that promises to revolutionize the way industries operate.Gate Valve Gearbox: A Technological Marvel:The Gate Valve Gearbox, with its supreme efficiency and precise control, raises the bar for industrial equipment. Equipped with cutting-edge technology, this gearbox is designed to ensure optimal performance in the most demanding environments. Whether it's in the oil and gas industry, water treatment plants, or power generation facilities, the Gate Valve Gearbox promises unparalleled reliability and durability.The gearbox boasts several key features that set it apart from conventional alternatives. First and foremost, its intelligent control system allows for real-time monitoring and seamless automation. This ensures that the gearbox can withstand even the most extreme conditions and adjust its operations accordingly, mitigating the risks of equipment failure and costly downtime.Additionally, the Gate Valve Gearbox is constructed using state-of-the-art, high-grade materials that enhance its longevity. Its robust design guarantees years of reliable service, reducing the need for frequent maintenance and replacements. This not only saves valuable time but also significantly reduces operational costs, making it a cost-effective choice for industries worldwide.Environmental Impact and Sustainability:{Company Name} not only recognizes the importance of performance but also prioritizes environmental sustainability. The Gate Valve Gearbox is engineered to be eco-friendly, designed with a focus on energy conservation. It reduces power consumption and minimizes greenhouse gas emissions, making it an ideal choice for companies striving to reduce their carbon footprint and meet stringent environmental regulations.In addition to its energy efficiency, the Gate Valve Gearbox also incorporates advanced sealing technology. This innovation ensures minimal leakage, preventing the loss of valuable resources, such as water or gas. By promoting efficient resource utilization, {Company Name}'s gearbox contributes to sustainability efforts and fosters a more responsible approach to industrial operations.Market Impact and Future Prospects:The introduction of the Gate Valve Gearbox by {Company Name} is anticipated to have a substantial impact on the market. With its exceptional performance and numerous advantages, this revolutionary gearbox is set to become the preferred choice for industries around the globe.Furthermore, {Company Name} aims to continually refine and enhance the Gate Valve Gearbox to suit evolving industry needs. Research and development efforts are focused on integrating smart technologies, making the gearbox even more intelligent and versatile. By embracing the digital age and the Industrial Internet of Things (IIoT), {Company Name} strives to empower industries with advanced control and automation capabilities.Conclusion:The Gate Valve Gearbox from {Company Name} holds significant promise for industries worldwide, delivering unmatched reliability, efficiency, and sustainability. This groundbreaking development illustrates the company's long-standing commitment to pushing the boundaries of technological innovation, providing customers with cutting-edge solutions for their industrial needs. As {Company Name} continues to revolutionize the industrial landscape, the Gate Valve Gearbox serves as a testament to their passion for excellence and dedication to shaping a brighter future.