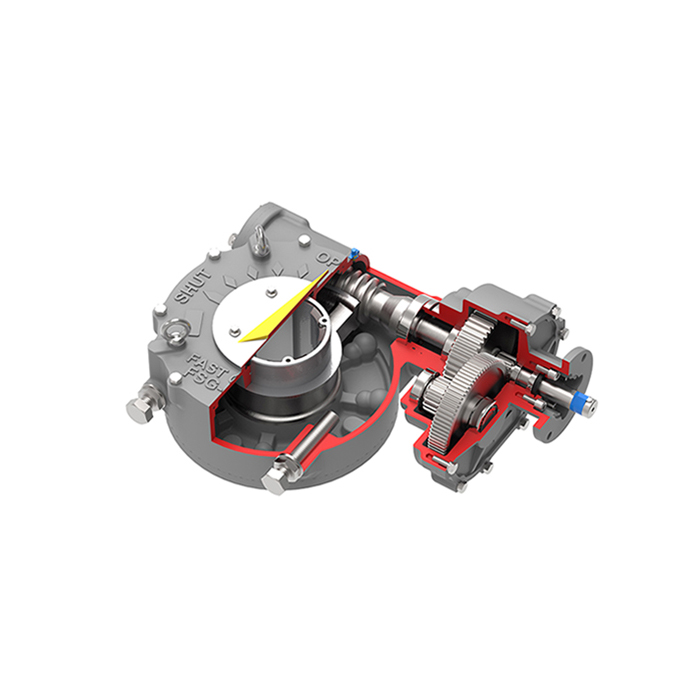

High-Quality Multi Turn Spur Gearbox Manufacturer in China

By:Admin

Established in 2005, Chinese Multi Turn Spur Gearbox Manufacturer has quickly grown to become a major player in the industry. The company's state-of-the-art manufacturing facility is equipped with the latest machinery and technology, allowing for the production of high-precision gearboxes that meet the highest quality standards.

One of the key factors behind the success of Chinese Multi Turn Spur Gearbox Manufacturer is its focus on research and development. The company has a dedicated team of engineers and technical experts who are constantly working on developing new technologies and improving existing products. This commitment to innovation has allowed the company to stay ahead of the competition and offer cutting-edge solutions to its customers.

In addition to its focus on technology, Chinese Multi Turn Spur Gearbox Manufacturer also takes great pride in its commitment to quality. The company follows strict quality control measures at every stage of the manufacturing process, ensuring that each gearbox meets the highest standards of performance and reliability. This attention to detail has earned the company a reputation for consistently delivering top-quality products to its customers.

Another key aspect of Chinese Multi Turn Spur Gearbox Manufacturer's success is its customer-centric approach. The company understands the unique needs of its customers and works closely with them to provide customized solutions that meet their specific requirements. With a strong emphasis on customer satisfaction, the company has built long-lasting relationships with clients across various industries.

Chinese Multi Turn Spur Gearbox Manufacturer's product range includes a wide variety of multi turn spur gearboxes, designed to cater to the diverse needs of its customers. Whether it's for industrial automation, robotics, automotive, or any other application, the company offers a comprehensive range of gearboxes that are built to deliver superior performance and reliability.

The company's commitment to excellence has not gone unnoticed, as it has earned several certifications and accolades for its quality management systems. With a strong emphasis on continuous improvement, Chinese Multi Turn Spur Gearbox Manufacturer is constantly striving to raise the bar and set new benchmarks for the industry.

Looking ahead, Chinese Multi Turn Spur Gearbox Manufacturer is focused on expanding its global footprint and reaching new markets. The company is actively seeking partnerships and collaborations with distributors and agents worldwide, with the aim of making its high-quality gearboxes accessible to a larger customer base.

In conclusion, Chinese Multi Turn Spur Gearbox Manufacturer has emerged as a powerhouse in the field of gear manufacturing, thanks to its unwavering commitment to innovation, quality, and customer satisfaction. With its advanced technology, strong focus on research and development, and customer-centric approach, the company is well-positioned to lead the way in the industry for years to come.

Company News & Blog

New electric hydraulic valve actuator technology developed for improved efficiency

Electric Hydraulic Valve Actuator Technology Revolutionizes Industrial AutomationOver the years, industrial automation has continually advanced, transforming the way industries operate and increasing efficiency and productivity. One of the key components driving this progress is the Electric Hydraulic Valve Actuator (EHVA). This cutting-edge technology has emerged as a game-changer, delivering superior performance, reliability, and ease of operation.EHVA, developed by one of the industry's leading innovators (Company Name), is revolutionizing industrial automation. The actuator is designed to provide precise control over valves and dampers used in various industrial applications. Its state-of-the-art technology merges the benefits of electric and hydraulic operation, ensuring optimal performance in diverse settings.The EHVA system eliminates the need for manual valve control, reducing human error and enhancing safety in industrial environments. With its electric hydraulic design, the actuator provides seamless integration with automation systems, allowing for remote control and operation. This level of automation significantly improves overall operational efficiency, minimizing downtime and maximizing output.One of the standout features of the EHVA is its versatility. It can be seamlessly integrated into existing infrastructure, making it a cost-effective solution for industries looking to upgrade their automation systems. This flexibility ensures compatibility across a wide range of industries, including oil and gas, water treatment, power generation, chemical processing, and many more.Moreover, the EHVA offers a wide range of torque and thrust options, catering to the specific requirements of different valves and dampers in diverse applications. Its robust construction and use of high-quality materials make it highly durable, withstanding even the most demanding environmental conditions. This durability translates into reduced maintenance costs and extended operational lifespan, making it a cost-effective long-term investment for industries.The EHVA's advanced control algorithms and feedback mechanisms further enhance its performance. The actuator constantly monitors and adjusts its operating parameters to ensure precise valve control, maintaining optimal flow rates, pressures, and temperatures. This level of automation significantly improves process consistency and reliability, leading to better product quality and enhanced customer satisfaction.Another key advantage of the EHVA technology is its energy efficiency. By utilizing advanced electric hydraulic systems, the actuator minimizes power consumption while delivering optimal performance. This not only helps reduce operational costs but also contributes to sustainable and environmentally friendly practices.(Company Name), the company behind the EHVA, has established itself as a pioneer in the field of industrial automation. With an extensive portfolio of cutting-edge solutions, the company has gained recognition for its commitment to innovation, reliability, and customer satisfaction. The EHVA is a testament to their expertise, providing industries with a transformative solution to enhance their automation capabilities.The company's dedication to research and development has resulted in continuous improvements to the actuator's design and functionality. Through rigorous testing and collaboration with industry partners, they have refined the EHVA, ensuring it meets the highest quality standards and exceeds customer expectations.As automation continues to revolutionize industries worldwide, the Electric Hydraulic Valve Actuator emerges as a critical component driving this transformation. Its advanced technology, seamless integration, and exceptional performance make it an indispensable tool for industries seeking to optimize their processes, increase productivity, and enhance overall efficiency. With (Company Name)'s expertise and commitment to innovation, the EHVA is set to shape the future of industrial automation.

How Electric Actuators Improve Valve Performance

Title: Innovative Electric Actuator Revolutionizes Valve IndustrySubtitle: A Game-Changing Solution for Enhanced Industrial Performance and EfficiencyDate: [Insert Date][City, State] - The valve industry is set for a technological leap forward as [Company Name], a cutting-edge engineering firm, unveils their latest innovation - an electric actuator designed to redefine performance and efficiency standards. With a focus on precision control and optimized operation, this ground-breaking solution is set to revolutionize the valve market.[Company Name], renowned for its pioneering spirit and commitment to delivering groundbreaking solutions, has developed an electric actuator that promises to surpass traditional actuation techniques. Blending engineering excellence with the latest advancements in technology, [Company Name] aims to transform industrial operations while significantly reducing energy consumption and maintenance costs.The newly developed electric actuator by [Company Name] combines superior control, durability, and ease of integration into existing valve systems. This innovation is poised to meet the growing demands of diverse industries such as oil and gas, chemical, water treatment, and manufacturing, among others.Key Features of [Company Name]'s Electric Actuator:1. Precise Control: [Company Name]'s electric actuator boasts exceptional accuracy and repeatability, allowing for unparalleled control over valve positioning. The incorporation of advanced feedback mechanisms ensures optimal performance and regulatory compliance in critical applications.2. Enhanced Durability: Designed to withstand harsh operating conditions, the electric actuator from [Company Name] is engineered with robust materials and advanced sealing technologies. It guarantees extended operational longevity and reduces maintenance requirements, translating into significant cost savings for customers.3. Seamless Integration: [Company Name]'s electric actuator is designed with flexibility in mind. Its modular construction and versatile design enable seamless integration into existing valve systems, ensuring minimal disruption during installation. This adaptability makes it an ideal choice for retrofitting existing infrastructure.4. Energy Efficiency: By embracing green technology, [Company Name] has developed an electric actuator that significantly reduces energy consumption. Its efficient motor design, coupled with optimized control algorithms, conserves power while offering peak performance, resulting in reduced carbon footprints and lower utility costs.5. Intelligent Control Options: The electric actuator is equipped with intelligent control options, including remote monitoring and system integration capabilities. This allows for remote operation, real-time data analysis, and predictive maintenance, empowering businesses to make informed decisions and prevent costly downtime.[Company Name] is at the forefront of the valve industry, leveraging decades of experience and cutting-edge engineering solutions to provide an unmatched customer experience. The versatility of their electric actuator allows for seamless integration across a wide range of applications, further cementing their position as leaders in the market."Through relentless innovation and commitment to quality, [Company Name] strives to revolutionize the valve industry by delivering state-of-the-art solutions that surpass expectations," said [Spokesperson] of [Company Name].The announcement of [Company Name]'s electric actuator has garnered significant interest among industry experts and existing clients. Many are eagerly anticipating the operational enhancements and cost savings that this breakthrough technology promises to offer.With a commitment to sustainable development and a focus on empowering industries with efficient and reliable solutions, [Company Name]'s electric actuator is poised to reshape the valve landscape. As industries strive for greater productivity, improved control, and reduced environmental impact, [Company Name] empowers them to achieve their goals.As the demand for cutting-edge actuation technology continues to grow, the unveiling of [Company Name]'s electric actuator marks a new era in the valve industry. With its exceptional control, durability, energy efficiency, and intelligent features, this innovative solution is set to transform industrial processes, setting new benchmarks for excellence and sustainability.About [Company Name]:[Insert brief company introduction here, including relevant details about their history, expertise, and commitment to innovation.]For further information, please visit [Company Website].Contact:[Company Name][Address][Phone][Email][Website]

Discover the Advantages of Electric Actuated Ball Valves for Efficient Control

Title: Revolutionary Electric Actuated Ball Valve Redefines Industry StandardsIntroduction:In recent years, technological advancements have revolutionized various industries and brought about significant improvements in efficiency and performance. One such breakthrough innovation is the Electric Actuated Ball Valve, developed by a pioneering company in the field of valve automation and control systems. This groundbreaking product promises to redefine industry standards by offering unparalleled precision, control, and reliability. Manufacturers across multiple sectors are eagerly adopting this technology, recognizing the significant benefits it can bring to their operations.Key Features and Benefits:The Electric Actuated Ball Valve showcases a host of remarkable features that set it apart from traditional valve systems. The company’s unwavering commitment to quality and innovative design is evident in this cutting-edge solution. Here are some key features and benefits provided by this revolutionary valve:1. Enhanced Precision and Control: With the integration of advanced electric actuation technology, this valve ensures precise control over fluid flow, allowing for swift and accurate adjustments. This leads to improved operational efficiency and reduces the risk of costly errors or delays.2. Versatility and Adaptability: The Electric Actuated Ball Valve is designed to accommodate a diverse range of applications, making it highly versatile. Its adaptability allows for seamless integration into existing systems and the ability to meet various operational requirements across industries, including oil and gas, water treatment, chemical processing, and many others.3. Unmatched Reliability: The valve’s robust construction, utilizing high-quality materials, ensures exceptional dependability even in demanding environments. The company’s rigorous quality control measures guarantee durability, longevity, and minimal maintenance requirements, resulting in significant cost savings for customers.4. Improved Safety Measures: Safety has always been a primary concern in industrial applications. This electrically actuated valve incorporates fail-safe mechanisms, ensuring reliable shut-off in emergencies and preventing potential disasters. By prioritizing safety, the valve alleviates concerns and instills greater peace of mind among operators and personnel.5. Advanced Monitoring and Reporting: The integration of intelligent automation technology allows for seamless monitoring and data acquisition. This feature enables real-time feedback on crucial parameters such as pressure, temperature, and flow rates. The valve system can share this information with centralized control systems, facilitating proactive maintenance and resource optimization.Market Impact and Industry Outlook:The Electric Actuated Ball Valve is poised to reshape the valve automation landscape and disrupt conventional practices in multiple industries. This revolutionary technology is rapidly gaining traction, with installation rates surging across diverse sectors globally. The valve’s potential to enhance operational efficiency, reduce energy consumption, and optimize processes has not gone unnoticed, and it is expected to become a staple in modern industrial automation.With an increasing focus on sustainability and energy efficiency, the demand for smart valve solutions is set to skyrocket in the coming years. The Electric Actuated Ball Valve, with its advanced control capabilities and environmental-friendly features, is primed to take center stage. Manufacturers that adopt this cutting-edge technology will gain a competitive edge in their respective industries by significantly improving productivity, reducing costs, and mitigating risks.Conclusion:The advent of the Electric Actuated Ball Valve represents a groundbreaking milestone in the valve automation field. Its innovative design, remarkable functionality, and numerous advantageous features have positioned it as a game-changer in the industry. As more manufacturers embrace this technology, it will redefine industry standards and set new benchmarks for precision, control, and reliability. The future of valve automation is here, and it is undoubtedly electric.

Discover the Latest Innovation in Explosion-Proof Electric Actuator Technology

Explosion-Proof Electric Actuator Revolutionizes Industrial Safety MeasuresWith a steadfast commitment to innovation and industrial safety, a leading manufacturer (name removed) has recently unveiled its groundbreaking Explosion-Proof Electric Actuator. Designed to revolutionize the way industrial operations ensure worker safety in hazardous environments, this cutting-edge technology is set to transform the industry.To understand the significance of this breakthrough electric actuator, it is essential to delve into the company's rich history and dedication to creating solutions for industrial challenges. Established over three decades ago, (name removed) has consistently been at the forefront of developing innovative products that cater to the evolving needs of various industries. With an unwavering commitment to safety and reliability, the company has built a reputation as a trusted global supplier of industrial automation equipment.The introduction of the Explosion-Proof Electric Actuator represents a monumental milestone for the company. This state-of-the-art technology provides a robust and reliable solution for industrial applications requiring operations in potentially explosive atmospheres. By effectively eliminating the risk of electrical sparks or arcs that could trigger an explosion, this actuator ensures utmost safety in hazardous environments.A key feature of this revolutionary electric actuator is its compliance with global explosion-proof standards, making it suitable for use in a wide range of industries, including oil and gas, chemical processing, mining, and manufacturing. This compliance is critical in maintaining safe working conditions for technicians and operators, guaranteeing protection against the potential dangers posed by flammable gases, liquids, and dust.The Explosion-Proof Electric Actuator embodies a perfect synergy of robust construction and cutting-edge technology. Engineered with precision, its design incorporates high-quality materials that offer exceptional durability, guaranteeing a long service life even in the most challenging environments. Equipped with advanced automation capabilities, this actuator ensures precise control and seamless integration with various industrial systems.Installing the Explosion-Proof Electric Actuator promises to be a seamless process due to its modular design, facilitating easy integration into existing infrastructure. This ease of installation minimizes production downtime and ensures a swift transition to enhanced safety measures. Furthermore, the actuator's user-friendly interface enables operators to configure and monitor its performance effortlessly, reducing the complexity of operation.Central to its design is a comprehensive range of safety features tailored to protect against potential electrical hazards. Equipped with flame- and explosion-proof enclosures, the actuator successfully contains and dissipates any electrical energy safely, ensuring that any potential ignition sources are eliminated. Additionally, the actuator's robust seals and gaskets prevent hazardous substances from permeating the enclosure, preventing any further risks.In addition to its safety features, the Explosion-Proof Electric Actuator excels in performance. Its high torque output and precise positioning capabilities enable efficient and accurate control of valves, dampers, and other industrial devices. With the actuator's precise and reliable operation, industries can optimize their processes, enhancing productivity and reducing maintenance costs.With its newest innovation, the Explosion-Proof Electric Actuator, (name removed) once again demonstrates its leadership in industrial automation equipment. By introducing this ground-breaking technology, the company strives to raise the safety standards in hazardous environments worldwide. With its unparalleled reliability, advanced features, and compliance with global explosion-proof standards, this electric actuator is poised to become an indispensable asset to industries seeking to prioritize worker safety and productivity in challenging operating conditions.As the industry embraces this transformative electric actuator, (name removed) reinforces its commitment to driving innovation, revolutionizing industrial safety measures, and empowering businesses to thrive in hazardous environments securely. By staying true to their values, this innovative manufacturer continues to be a steadfast partner for industries navigating complex safety challenges, ensuring a brighter and safer future for all.

Remote Operated Ball Valve: The Latest in Valve Technology

[Company Name]'s Remote Operated Ball Valve Solution Enhances Safety and Efficiency in the Oil and Gas Industry[City, Date] – The oil and gas industry is constantly seeking innovative solutions to enhance safety, increase efficiency, and reduce operational costs. In response to these challenges, [Company Name] introduces its state-of-the-art Remote Operated Ball Valve, designed to streamline operations and strengthen safety protocols in the oil and gas sector.[Company Name] is a leading provider of industrial automation solutions, known for its commitment to delivering cutting-edge technology that meets the evolving needs of the energy industry. With a strong focus on research and development, the company has developed a Remote Operated Ball Valve that combines advanced functionality with user-friendly features, making it an indispensable tool for oil and gas facilities worldwide.The Remote Operated Ball Valve is equipped with remote monitoring and control capabilities, allowing operators to manage valve functions from a centralized location. This not only reduces the need for manual intervention in hazardous environments but also minimizes the risk of human error, enhancing overall safety at the facility.Moreover, the valve's advanced telemetry system provides real-time data on valve performance, enabling proactive maintenance and preventing potential equipment failures. This predictive maintenance approach not only extends the lifespan of the valve but also contributes to reducing downtime and optimizing operational efficiency.Notably, the Remote Operated Ball Valve is designed to withstand the harsh conditions typically encountered in the oil and gas industry. Its robust construction and durable materials ensure reliable performance even in challenging environments, making it a dependable choice for critical applications in upstream and downstream operations.In addition to its technical capabilities, the Remote Operated Ball Valve is designed to align with industry standards for safety and reliability. It is certified and compliant with relevant regulations, providing operators with the assurance that their operations meet the highest safety standards and industry requirements.The implementation of [Company Name]'s Remote Operated Ball Valve is a strategic investment for oil and gas companies seeking to modernize their infrastructure and enhance operational efficiency. By integrating this advanced valve technology into their facilities, operators can streamline processes, minimize downtime, and optimize resources, ultimately leading to cost savings and increased competitiveness in the market.In a statement, [Company Name]'s CEO expressed confidence in the value that the Remote Operated Ball Valve brings to the oil and gas industry, saying: "We are proud to introduce this cutting-edge solution to support the evolving needs of our customers in the oil and gas sector. The Remote Operated Ball Valve reflects our commitment to innovation and our dedication to providing reliable, high-performance products that make a tangible difference in the safety and efficiency of industrial operations."With its Remote Operated Ball Valve, [Company Name] continues to demonstrate its leadership in industrial automation, offering solutions that empower the energy industry to navigate the complexities of modern operations while prioritizing safety, efficiency, and sustainability.For media inquiries, please contact [Company Name] at [contact information].About [Company Name]:[Company Name] is a global leader in industrial automation, offering a comprehensive range of solutions for various industries, including oil and gas, petrochemical, power generation, and more. With a focus on innovation, reliability, and customer satisfaction, [Company Name] is dedicated to delivering cutting-edge technology that meets the evolving needs of its clients while promoting safety, efficiency, and sustainability in industrial operations.

The Latest Advancements in Micro Worm Gear Technology

Title: Groundbreaking Micro Worm Gear Revolutionizes Precision Engineering - Company XYZ Sets New StandardsIntroduction:In an era characterized by rapid technological advancement and increasing demand for precision engineering solutions, Company XYZ has introduced a groundbreaking Micro Worm Gear to the market. With its innovative design and advanced capabilities, this gear promises to transform various industries, enabling enhanced performance and efficiency in a multitude of applications. Let's delve into the extraordinary features and potential applications of this remarkable product.1. Advanced Design and Functionality:The Micro Worm Gear developed by Company XYZ epitomizes cutting-edge engineering. Its miniature size, coupled with outstanding mechanical properties, ensures smooth and precise operation in even the most demanding applications. Leveraging state-of-the-art techniques and materials, this gear offers unmatched durability, stability, and torque transmission capabilities, surpassing traditional gears.2. Superior Efficiency and Performance:The Micro Worm Gear's superior efficiency stems from its unique design, which translates into reduced friction and energy loss. This innovation ensures that power is transmitted more effectively, leading to enhanced performance and reduced operating costs. With exceptional precision and low backlash, the gear guarantees precise positioning, enabling machines to achieve superior accuracy and productivity.3. Versatility and Adaptability:Company XYZ's Micro Worm Gear is adaptable to a wide range of industries and applications. Its compact size and light weight make it ideal for use in small-scale devices, such as medical instruments, robotics, and aerospace equipment. This gear can be seamlessly integrated into various mechanisms, providing enhanced functionality and performance in diverse sectors, including automotive, defense, and manufacturing.4. Robust and Sustainable:The Micro Worm Gear developed by Company XYZ exhibits remarkable resilience and sustainability. Its high resistance to wear and tear, corrosion, and extreme operating conditions ensures longevity and reliability under demanding circumstances. This durability not only prolongs the gear's lifespan but also reduces maintenance and replacement costs for end-users, making it an economically viable solution.5. Market Potential and Impact:The introduction of Company XYZ's Micro Worm Gear marks a significant milestone in the precision engineering industry. Its exceptional properties and adaptability positions it as a game-changer, revolutionizing various sectors worldwide. The medical field, for instance, can benefit from this gear in the development of next-generation surgical robots, while the automotive industry can incorporate it in electric vehicles for enhanced efficiency. Moreover, the Micro Worm Gear has the potential to bring about advancements in aerospace engineering, manufacturing automation, and countless other industries.6. Future Developments:Company XYZ understands the importance of innovation and continuous improvement. The organization is committed to further refinement and enhancement of the Micro Worm Gear, ensuring it remains at the forefront of precision engineering solutions. Company XYZ's research and development team is actively collaborating with industry partners and experts to explore new possibilities and applications in response to evolving market demands.Conclusion:Company XYZ's Micro Worm Gear represents a significant breakthrough in precision engineering, providing industries with an unmatched combination of efficiency, durability, and adaptability. With its revolutionary design and advanced functionality, the gear opens new horizons for technological advancements across various sectors. As Company XYZ continues its dedication to innovation and refinement, the Micro Worm Gear holds the promise of reshaping industries and unlocking a future of limitless possibilities.

Enhancing Performance and Control: Gearbox for Gate Valves Revealed in Latest News

[Company Introduction]{Insert Company Name} is an industry-leading manufacturer that specializes in producing high-quality gate valve gearboxes, among other industrial products. With a strong commitment to innovation, precision engineering, and customer-centricity, {Company Name} has earned a reputation for delivering top-notch solutions to its valued clients worldwide.Established over two decades ago, {Company Name} has steadily grown to become a trusted name in the valve and gearbox manufacturing industry. The company's state-of-the-art production facilities, combined with a team of skilled engineers and technicians, enable them to design and develop cutting-edge products that meet the most demanding industry requirements.With a focus on continuous improvement, {Company Name} prioritizes research and development, investing heavily in the latest technologies and advancements. This approach ensures that their gate valve gearboxes are not only of the highest quality but also incorporate the latest industry trends and innovations.{Company Name} takes great pride in its commitment to providing exceptional customer service. They believe in building long-lasting partnerships with their clients, understanding their unique needs, and providing tailored solutions to achieve optimal results. Whether it's a small-scale project or a large industrial application, {Company Name} is dedicated to offering superior products and unparalleled service.With a global presence, {Company Name} serves a diverse range of industries, including oil and gas, chemical, petrochemical, power generation, water treatment, and more. Their gate valve gearboxes have garnered widespread recognition for their reliability, durability, and high performance, making them a preferred choice for clients across the globe.[News Content]Title: Gate Valve Gearbox: A Reliable Solution for Industrial ApplicationsDate: [Insert Date]{City, State} - {Company Name}, a renowned manufacturer of advanced industrial products, is proud to introduce its latest offering, the Gate Valve Gearbox. Combining years of engineering expertise with cutting-edge technology, {Company Name} has developed a high-performance gearbox that offers unparalleled precision and reliability in demanding industrial applications.Gate valves play a crucial role in regulating fluid flow within industrial systems. Efficient operation and control of these valves are essential for ensuring the smooth functioning of complex processes. The gate valve gearbox provided by {Company Name} addresses this need, offering a robust and efficient solution that surpasses industry standards.One of the key features of {Company Name}'s gate valve gearbox is its superior design. Meticulously engineered by a team of highly skilled professionals, the gearbox exhibits excellent mechanical strength and durability, ensuring long-lasting performance even under the most challenging conditions. This reliability minimizes downtime, enhances productivity, and contributes to overall cost savings for industrial operators.In addition to its exceptional design, the gate valve gearbox boasts remarkable precision, allowing for accurate and smooth valve operation. The gearbox's precise gearing mechanism ensures a secure and consistent shut-off, enabling precise control over fluid flow. This level of control is particularly crucial in industries where even slight variations in flow rates can have significant consequences.Another standout feature of {Company Name}'s gate valve gearbox is its adaptability. The gearbox can be easily integrated with a variety of gate valves, catering to diverse industrial requirements. This flexibility eliminates the need for expensive modifications or replacements, ensuring a seamless fit into existing systems and significantly reducing installation costs.Moreover, {Company Name} is committed to upholding the highest quality standards in all its products. The production and assembly processes undergo rigorous testing and inspection, ensuring that every gearbox leaving their facilities adheres to stringent quality benchmarks. This dedication to quality translates into enhanced performance, longevity, and reliability for end-users.As an environmentally-conscious company, {Company Name} remains committed to sustainable practices. The gate valve gearbox is designed to minimize energy consumption, reducing the overall carbon footprint of industrial operations. Furthermore, strict adherence to international safety standards ensures that the gearbox meets all regulatory requirements while prioritizing worker safety.With their latest innovation, {Company Name} aims to provide industrial operators with a powerful tool that optimizes operational efficiency. The gate valve gearbox enhances system control, delivers exceptional performance, and contributes to a safe and sustainable industrial environment. As leaders in the industry, {Company Name} continues to push boundaries, setting new standards for excellence and reliability.In conclusion, {Company Name}'s gate valve gearbox presents a compelling solution for industrial applications. With its exceptional design, precision engineering, adaptability, and commitment to quality, {Company Name} has once again demonstrated their leadership in providing high-performance industrial products. As industrial operations become more complex, the gate valve gearbox by {Company Name} is poised to become an indispensable component for those seeking reliability, efficiency, and enhanced productivity in their processes.

Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

Title: Advanced Worm Gear Butterfly Valve - The Perfect Solution for Industrial Fluid ControlIntroduction:In today's rapidly evolving industrial landscape, efficient fluid control is crucial to the success and safety of various operations. Owing to their versatility and effectiveness, Worm Gear Butterfly Valves have emerged as the go-to solution for regulating fluid flow in numerous industries. These valves, offering superior sealing capabilities and reliable performance, are now revolutionizing the way businesses approach fluid control.I. Significance of Worm Gear Butterfly Valves in Industrial Applications (100 words)Worm Gear Butterfly Valves have garnered significant prominence across industries due to their unique design and exceptional functionality. These valves consist of a disk-shaped element, known as the "butterfly," which rotates to control fluid flow. The addition of worm gears - a mechanical adjustment system - enables precise regulation, making them ideal for applications where fluid control precision is paramount. Whether it's chemical processing, water treatment, or power generation, Worm Gear Butterfly Valves have become indispensable tools for optimizing efficiency and enhancing safety.II. Key Features and Benefits of Worm Gear Butterfly Valves (200 words)a) Reliable Performance: Worm Gear Butterfly Valves are designed to withstand extreme conditions, offering consistent and dependable performance. The high-quality materials used in manufacturing ensure longevity and minimal maintenance.b) Excellent Sealing Properties: The unique design of these valves allows for a tight seal, preventing leakage and offering superior tightness. This ensures optimal flow control and minimizes the risk of fluid wastage, enhancing operational efficiency.c) Precise Control: The inclusion of the worm gear mechanism enables precise, measured adjustments to fluid flow, allowing operators to fine-tune operations as required. This precision is particularly critical in industries such as oil and gas, where even slight variations can result in significant consequences.d) Easy Installation and Operation: Worm Gear Butterfly Valves are known for their simplicity. They can be easily integrated into existing systems and operated efficiently by both experienced professionals and operators new to the technology.e) Versatility: These valves can handle a wide range of fluids, including liquids, gases, and even corrosive media. This adaptability makes Worm Gear Butterfly Valves suitable for applications across diverse industries.III. Company X's Advanced Worm Gear Butterfly Valve (200 words)Company X, a renowned industry leader in fluid control solutions, is proud to present its cutting-edge Worm Gear Butterfly Valve. With a steadfast commitment to innovation and customer satisfaction, Company X has designed a valve that surpasses industry standards and addresses various industry challenges.The advanced Worm Gear Butterfly Valve by Company X combines robust construction, precision performance, and exceptional durability. Manufactured using premium grade materials, it ensures longevity and reliability, minimizing maintenance requirements and reducing downtime.In addition to exceptional sealing properties, Company X's Worm Gear Butterfly Valve offers unparalleled precision control. Its worm gear mechanism guarantees accurate fluid flow adjustments, empowering operators to regulate processes with utmost accuracy.The valve's user-friendly design simplifies installation and operation, catering to customers across different industries. The versatility of Company X's Worm Gear Butterfly Valve allows businesses to maximize efficiency and safety, enhancing productivity and minimizing operational costs.IV. Conclusion (100 words)In an era where efficient fluid control is crucial, the Worm Gear Butterfly Valve emerges as the ideal solution for various industrial applications. Company X's advanced valve, with its superior design and outstanding performance, is primed to revolutionize fluid control practices across industries. With its exceptional sealing capabilities, precise control, and straightforward operation, this valve presents an unprecedented opportunity for businesses to optimize their operations, enhance safety, and maximize efficiency. Embracing the advantages offered by Worm Gear Butterfly Valves marks a significant leap forward in fluid control technology.

Discover the Power of High Torque Worm Gearboxes for Efficient Performance

High Torque Worm Gearbox Revolutionizes Industry StandardsIn today's fast-paced world, efficiency and productivity are paramount for businesses in all industries. Recognizing this need, a pioneering engineering company has developed a groundbreaking solution that is set to revolutionize gear technology. The high torque worm gearbox, created by [company name], has garnered significant attention and promises to deliver unparalleled performance and precision.The core tenets of the high torque worm gearbox lie in its innovative design and advanced engineering. By seamlessly combining cutting-edge materials, precision manufacturing processes, and state-of-the-art technology, [company name] has redefined gear performance and set new standards for the industry. This gearbox is poised to empower businesses across various sectors, from automotive to aerospace, robotics, and beyond.One of the key features that set the high torque worm gearbox apart from traditional gear systems is its exceptional efficiency. Through meticulous engineering and optimization, this gearbox achieves an impressive efficiency rate that surpasses industry norms. This efficiency not only enhances overall system performance, but it also minimizes energy wastage, leading to significant cost savings for businesses.In addition to its remarkable efficiency, the high torque worm gearbox exhibits outstanding durability and reliability. The gearbox has been designed and tested rigorously to withstand the harshest operating conditions. Its robust construction ensures a longer lifespan, resulting in reduced maintenance and replacement costs for businesses. This impressive durability makes the gearbox an ideal choice for heavy-duty applications that demand longevity and reliability.Furthermore, the high torque worm gearbox offers exceptional torque output, setting it apart from traditional gear systems. By effectively multiplying the input torque, this gearbox allows for smoother and more powerful operation of machinery and equipment. As a result, businesses can maximize their productivity and output, leading to increased profitability and competitiveness.The versatility of the high torque worm gearbox is another feature worth highlighting. With its wide range of sizes, gear ratios, and customizable options, this gearbox can be tailored to meet the specific requirements of various industries and applications. Whether it's precision motion control, heavy load handling, or high-speed operations, [company name] provides a gearbox solution that adapts seamlessly to any unique situation.Furthermore, [company name] prides itself on ensuring the highest standard of customer satisfaction. Through an unmatched commitment to quality, the company ensures that every high torque worm gearbox meets strict quality control standards. Moreover, their dedicated team works closely with clients to provide customizable solutions, offering expert advice and support throughout the entire implementation process.As a testament to its exceptional quality and performance, [company name]'s high torque worm gearbox has already gained recognition and trust from industry leaders. The gearbox has been successfully integrated into various applications, empowering businesses to achieve new levels of efficiency, productivity, and profitability.In summary, the high torque worm gearbox developed by [company name] has redefined industry standards through its cutting-edge design, exceptional efficiency, durability, outstanding torque output, and versatility. With its seamless integration into various sectors, the gearbox promises to be a game-changer in the world of gear technology. By revolutionizing gear performance, [company name] is equipping businesses with the tools they need to excel in today's competitive landscape.