High-Quality Metal Worm Gear Set and its Importance in Industrial Applications

By:Admin

Introduction:

[Company Name] is proud to announce the launch of its latest breakthrough product - The Metal Worm Gear Set, designed to revolutionize industrial operations. Drawing on decades of experience, expertise, and a commitment to innovation, [Company Name] has successfully developed a high-performance gear set that promises increased durability, efficiency, and precision in various applications. This news article will delve into the features, applications, and benefits of the new Metal Worm Gear Set.

1. Unrivaled Precision and Durability:

The Metal Worm Gear Set utilizes advanced engineering techniques to deliver unrivaled precision and durability. The gears are manufactured using high-quality metal alloys that ensure maximum strength and resistance to wear and tear. The precise tooth profiles and optimized gear ratios result in smooth and efficient power transmission, reducing energy loss and enhancing overall performance.

2. Versatile Applications:

The versatility of the Metal Worm Gear Set makes it suitable for a wide range of industries. From automotive manufacturing to robotics, agricultural machinery to aerospace, this gear set can be tailored to meet the unique requirements of each application. Its compatibility with different power sources, including electric and hydraulic systems, makes it a versatile solution for various setups.

3. Enhanced Efficiency:

The Metal Worm Gear Set incorporates cutting-edge design features that significantly improve overall efficiency. By minimizing friction and reducing noise levels, these gears increase the system's overall efficiency, resulting in energy savings and extended equipment lifespan. The precise and reliable torque transmission of the gears ensures smooth operation, reducing the need for maintenance and maximizing uptime.

4. Customization and Adaptability:

[Company Name] understands that every industry has different needs, which is why the Metal Worm Gear Set offers customization options to suit specific requirements. The gears can be engineered with tailored tooth profiles, materials, and coatings, ensuring compatibility with specific applications. This adaptability allows for seamless integration into existing systems, reducing costly downtime during installation.

5. Eco-Friendly Commitment:

In line with its commitment to environmental sustainability, [Company Name] has designed the Metal Worm Gear Set with eco-friendly features. The gear set's enhanced efficiency contributes to reduced energy consumption and, consequently, lowers carbon emissions. It also generates less noise pollution, making it environmentally friendly while promoting worker safety and comfort.

6. Global Reach and Customer Support:

With an extensive global presence, [Company Name] is dedicated to providing exceptional customer support. The company's technical team ensures timely and comprehensive assistance to customers worldwide. Their expertise ensures optimal gear set selection and seamless integration into customers' projects, allowing for enhanced performance and improved productivity.

Conclusion:

The introduction of the new Metal Worm Gear Set by [Company Name] marks a significant milestone in the field of industrial gear manufacturing. With its unrivaled precision, durability, versatility, and eco-friendly features, this innovative gear set promises to revolutionize various industries. Through extensive customization options and a commitment to customer support, [Company Name] showcases its continued dedication to meeting evolving market demands.

Company News & Blog

Newly Launched Miniature Metal Gears to Revolutionize Robotics

Innovation in the field of mechanical engineering has been critical to the development of new machinery and equipment that have made life easier for businesses and individuals. One of the most critical components, that has revolutionized the manufacturing and production industry, is gear technology. Worm gears are one such technology that has been making a buzz in the market recently. Among the many types of worm gears, the micro worm gear has been a game-changer in small-sized machinery and equipment. Micro worm gear technology has been designed for ultra-compact machines and devices that require high power density, precision, and high efficiency. The micro worm gear is the perfect solution for applications where space is limited, and the gear ratio and torque are critical. Micro worm gears have a high reduction ratio and can be designed to handle very high torque loads through compact gearboxes. They can be designed with a variety of materials ranging from plastics and non-ferrous metals to hardened steels, making them versatile for various applications requiring different levels of stress tolerance.However, not all micro worm gears are created equal. Among the best in the market is the micro worm gear developed by the German-based manufacturer, whose name we have to omit. This micro worm gear combines innovation, precision, and quality to deliver reliable and efficient power transmission solutions. The company, whose name we shall omit, has been a leader in the production of high-quality gears for over 30 years. They have continuously invested in research and development, state-of-the-art equipment, and human capital, to remain at the forefront of innovation in gear technology. Over the years, their products have found application in various industries, including automotive, aerospace, medical devices, and robotics among other sectors. The micro worm gear by this manufacturer is no different. It is a highly specialized gear technology that comes in a compact design and is capable of transmitting power with high accuracy. One of its main advantages is that it can handle high loads while emitting very low noise. This is critical for small machinery and devices operating in environments where noise levels need to be minimized. The micro worm gear by this manufacturer is designed with advanced materials, including high-quality plastics and hardened steels, making it both lightweight and durable. The gear is available in different sizes and configurations, which makes it versatile and suitable for various applications. One of its most notable features is its high accuracy thanks to the use of advanced manufacturing techniques such as gear hobbing and tooth grinding. A critical aspect of the micro worm gear by this manufacturer, which gives it an edge over competitors, is its customization ability. The manufacturer can tailor-make the gear to meet the specific needs of end-users. This means that businesses and other customers can provide their unique specifications, and the manufacturer can craft a micro worm gear that precisely matches their requirements. This high level of customization has made the manufacturer the go-to source for micro worm gears used in various industry sectors. In conclusion, the micro worm gear is a critical innovation in the field of gear technology, offering high precision and efficiency in power transmission in ultra-compact applications. This technology can handle high loads with minimal noise while being versatile and customizable to meet specific customer requirements. Among the best micro worm gears in the market is the one developed by the German-based manufacturer, whose name we shall omit, which combines advanced materials, manufacturing techniques, and customization capabilities. This micro worm gear is suitable for various industries, and its efficient operation makes it an attractive option for businesses and other end-users looking for reliable power transmission solutions.

Essential Information on Worm Wheels and Shafts: A Guide

Worm wheel and worm shaft are important components used in various industries to transmit power and motion between non-parallel, power-transmitting shafts. One of the leading companies in the production of worm wheel and worm shaft is {company name}. Founded in 1978, the company has been focused on offering high-quality and efficient worm gear units, worm gear motors, and other power transmission solutions.With a well-equipped manufacturing plant spanning over 8000 square meters, {company name} is capable of producing 500,000 sets of worm gearboxes annually, delivering its products to over 70 countries worldwide. The company conforms to international standards and is certified with ISO9001, CE, and UL. With a team of highly experienced researchers, designers, and engineers, {company name} can design and produce customized power transmission solutions to meet various industrial applications.The worm wheel and worm shaft are one of the most critical components produced by {company name} for power transmission applications. These components are instrumental in the production of mechanical motion between non-parallel shafts, converting rotational energy in one direction to rotational motion in another direction. Worm gear systems developed by {company name} have a high level of efficiency, reliability, and quiet operation.One of {company name}'s unique selling propositions includes their ability to produce high-quality worm gears with either single or double output shafts. The single output shafts are ideal for applications that require low-speed rotary motion but cannot accommodate other power transmission devices. In contrast, the double output shafts are perfect for industries that require multi-axis output motion.Since worm gears operate with sliding contact between the gear teeth, it's important to ensure adequate lubrication to minimize wear and extend the life of the gear system. {company name} understands this and designs its worm gears with advanced lubrication systems, ensuring optimal system performance and a longer lifespan.{Company name}'s worm gears are also designed to operate in various environmental conditions. The worm wheels are made from high-quality materials, with 15CrMo alloy steel being the most commonly used. This material has high strength, hardness, and resistance to wear, making it ideal for worm gears that operate under heavy loads and high stresses.In conclusion, {company name} is a leading producer of worm wheel and worm shaft, and their solutions have been used in a wide range of applications, including robotics, automation, medical, packaging, printing and others. They have a reputation for producing high-quality components that have a high level of torque density, efficiency, and reliability.The company's manufacturing capabilities, strict quality control protocols, and customized solutions make them an appealing choice for various industries. Partnering with {company name} for worm gear solutions ensures you have access to high-performing products that meet your specific application requirements.

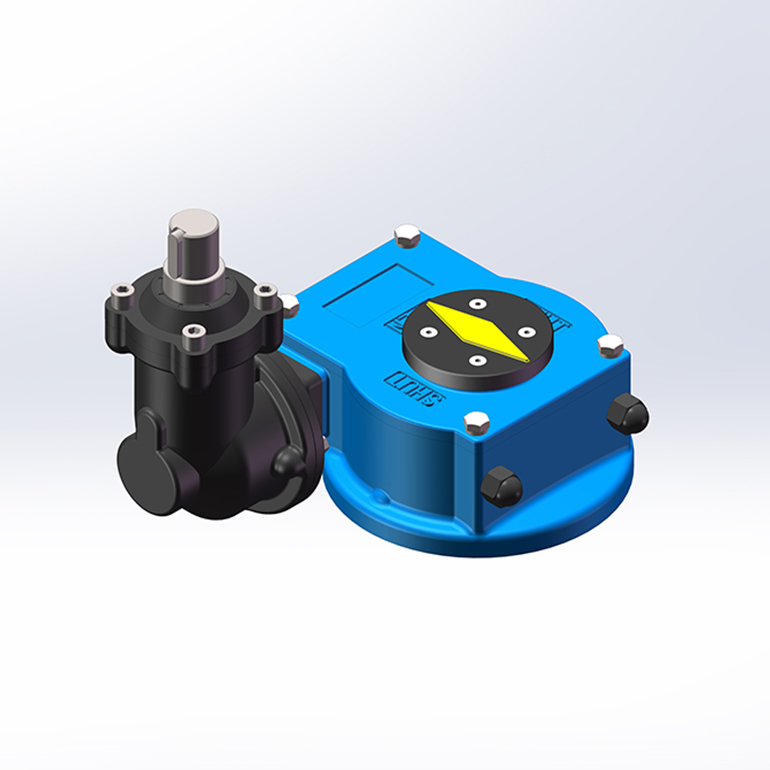

The Limitations of Pneumatic Controls on Switches Revealed in Latest News Coverage

Pneumatic Controls Limit Switch Leads the Way in Industrial AutomationThe industrial automation sector has been revolutionized by the introduction of advanced technology and innovative solutions. Pneumatic Controls, a renowned industry leader, has recently unveiled their groundbreaking Pneumatic Controls Limit Switch. Widely acclaimed for its reliability, efficiency, and precision, this cutting-edge product is set to redefine automation processes across various industries.Pneumatic Controls has long been recognized as a frontrunner in the field of industrial control systems. The company's continuous commitment to research and development has resulted in a portfolio of products that consistently exceed customer expectations. With the launch of the Pneumatic Controls Limit Switch, the company aims to address the ever-increasing demand for advanced automation solutions, providing customers with a game-changing device that offers superior performance and robustness.The Pneumatic Controls Limit Switch boasts a host of features that set it apart from traditional control switches. One of its key attributes is its pneumatic actuation mechanism. This innovative design provides enhanced reliability and durability, allowing the switch to perform flawlessly even in harsh industrial environments. The pneumatic actuation also ensures a quick response time, making it ideal for high-speed processes where precision is crucial.Another remarkable feature of the Pneumatic Controls Limit Switch is its exceptional accuracy. Equipped with state-of-the-art sensing technology, this switch can detect even the slightest variations in movement or pressure, ensuring precise control and preventing errors. This level of accuracy improves overall efficiency and productivity, minimizing waste and optimizing operations.Furthermore, the Pneumatic Controls Limit Switch has been engineered to offer maximum versatility. With a wide range of configuration options and adjustable settings, this switch can be customized to suit specific automation requirements. Its modular design allows for easy integration with existing systems, reducing downtime and simplifying installation and maintenance processes.Safety is a paramount concern in industrial automation, and Pneumatic Controls understands this. The Pneumatic Controls Limit Switch is equipped with multiple safety features to ensure uninterrupted and secure operation. Built-in fail-safe mechanisms, redundant sensing systems, and comprehensive error monitoring capabilities provide peace of mind and help prevent accidents and system failures.The application range for the Pneumatic Controls Limit Switch is diverse and extensive. It can be utilized in various industries such as manufacturing, food processing, packaging, and automotive. Its compatibility with different control systems and protocols makes it a versatile choice for both small-scale operations and large-scale industrial facilities.Pneumatic Controls has gained a solid reputation in the market due to its exceptional customer service and support. The company's dedicated team of experts assists customers throughout the entire product lifecycle, from initial design and selection to installation and after-sales service. This commitment to customer satisfaction has earned Pneumatic Controls a loyal client base and positions them as a trusted partner in the industrial automation industry.With the introduction of the Pneumatic Controls Limit Switch, Pneumatic Controls has once again proven its commitment to innovation and excellence. This state-of-the-art control switch is set to revolutionize automation processes, offering unparalleled reliability, precision, and versatility. As industries continue to embrace automation solutions, Pneumatic Controls is leading the way in providing advanced and efficient products that empower businesses to thrive in the modern era of industrial control.

Revolutionary Actuator Technology Set to Overhaul Industry Standards

Actuators are an essential component in the modern world of automation and control systems. In the case of industrial processes, a linear actuator refers to the devices that convert rotational motion into linear motion. An excellent example of such devices is the Neumax Actuator, which is tailored to a broad range of industrial applications.The Neumax Actuator is designed by professionals who have over the years accumulated vast experience in the industrial automation sector. The Neumax Actuator is designed with powerful, durable, and efficient components, ensuring that it meets the stringent demands of modern industrial processes.One of the most significant benefits of the Neumax Actuator is its flexibility and adaptability to a wide range of tasks. It has the ability to execute varied functions, including gate opening and closing in a water treatment facility, control of valves in pipelines, and regulation of pressure in chemical processing plants.The Neumax Actuator is also designed to ensure exceptional performance. It operates with a high level of precision and accuracy, which is essential for controlling processes with minimal error rates. Additionally, its robust design ensures that it can withstand extreme conditions such as harsh weather, high humidity, and mechanical strain.Another significant attribute of the Neumax Actuator is the low rate of maintenance required to keep the system in optimal condition. One of the major advantages of using the Neumax Actuator is the low rate of wear and tear of the components, which translates into reduced downtime and associated costs. Additionally, the operational parameters of the actuator are easy to monitor, making it easier to identify potential issues before they escalate into serious problems.The Neumax Actuator is also easy to install, which translates into reduced installation time and costs. The actuator can be customized to fit different system specifications, making it an ideal solution for many industrial automation processes.The Neumax Actuator is also designed to be energy efficient, reducing the overall cost of operation. The actuator is designed with components that consume less power, making it ideal for use in applications where energy efficiency is a priority.The Neumax Actuator is an excellent solution for different industrial settings, including oil and gas, food processing, and water treatment facilities. The actuator is tested and certified to meet international standards, ensuring that it meets the strict regulatory requirements.The company behind the Neumax Actuator boasts of an experienced and highly skilled team of professionals dedicated to producing high-quality industrial automation solutions. The company prides itself on its ability to deliver customized solutions tailored to the specific needs of each client.The company believes that investing in research and development is essential to provide innovative solutions that meet the evolving needs of clients. The Neumax Actuator is the product of years of research and development, aimed at providing a reliable and efficient solution to industrial automation.The company's commitment to quality is unwavering. It has established stringent quality control procedures at every stage of the production process, ensuring that every component that leaves the facility conforms to the highest quality standards.In conclusion, the Neumax Actuator is an innovative solution to industrial automation needs. It is designed with quality, efficiency, reliability, and flexibility in mind, making it an ideal solution for a wide range of industrial applications. The company behind the product is committed to delivering innovative solutions that meet the evolving needs of clients in the industrial automation sector. With the Neumax Actuator, clients can be assured of exceptional performance, energy efficiency, and a low rate of maintenance, translating into overall cost savings in the long run.

Enhance Control Valve Functionality with Advanced Limit Switch Technology

Title: Control Valve Limit Switch: Enhancing Efficiency and Safety in Industrial ProcessesIntroduction:In today's highly industrialized world, process automation has become an integral part of numerous industries. One crucial component of process automation is the control valve limit switch. Renowned for its reliable performance, safety features, and unparalleled efficiency, this state-of-the-art technology has revolutionized the way businesses operate. By providing real-time control and monitoring capabilities, the control valve limit switch ensures optimal functioning of industrial processes, minimizing downtime, and maximizing productivity.Company Introduction: [Company name][Company name] is a global leader in the manufacturing and distribution of advanced control system components. With a multi-decade track record of excellence, [Company name] is at the forefront of providing cutting-edge solutions to industries around the world. Committed to quality, innovation, and customer satisfaction, the company boasts a team of highly skilled engineers, technicians, and professionals dedicated to meeting the evolving needs of the automation industry.News Content: Control Valve Limit Switch[Company name], renowned for its expertise in control valve limit switches, has recently introduced its latest range of advanced limit switch solutions. This new product line is set to redefine standards in the automation sector, delivering enhanced efficiency and safety to industrial processes.1. Enhanced Performance and Reliability:Featuring state-of-the-art technology and precision engineering, the new control valve limit switches by [Company name] guarantee optimum performance and reliability. The switches are designed to withstand harsh industrial environments, including extreme temperatures, corrosive substances, and high pressure. Equipped with robust components and advanced features, these limit switches ensure long-term operational reliability, reducing maintenance costs and downtime.2. Real-Time Monitoring:A key highlight of [Company name]'s control valve limit switch range is its real-time monitoring capabilities. These switches provide continuous feedback on valve position, allowing operators to precisely control flow rates and pressure levels. With the ability to monitor critical parameters, industrial processes can be fine-tuned to optimize efficiency and minimize the risk of system failures.3. Enhanced Safety Features:Safety is of paramount importance in industrial processes. [Company name] recognizes this and has integrated several safety features into their control valve limit switches. These include over-travel protection, position indication, and local/manual control options. The switches are designed to ensure fail-safe operation, mitigating potential hazards and reducing the risk of accidents.4. Easy Installation and Integration:[Company name]'s control valve limit switches are designed to be easy to install and integrate into existing automation systems. With a variety of mounting options available, they can be seamlessly integrated into diverse industrial environments. Additionally, the switches are compatible with a range of control systems, enabling quick retrofitting or upgrading of older systems without major modifications.5. Versatility and Customization:Recognizing that different industries have unique requirements, [Company name] offers a wide range of control valve limit switches catering to various industrial applications. Whether it be the oil and gas sector, power generation, chemical processing, or wastewater treatment, their switches can be customized to meet specific needs. This versatility ensures that businesses across sectors can benefit from their advanced automation solutions.Conclusion:The introduction of [Company name]'s latest control valve limit switch range is set to revolutionize industrial automation, enhancing efficiency and safety across multiple industries. With advanced features, robust construction, and real-time monitoring capabilities, these switches are poised to become the go-to solution for businesses aiming to optimize their processes and minimize downtime. [Company name]'s commitment to excellence and customer satisfaction ensures that they will continue to be a global leader in providing cutting-edge control system components for years to come.

Top Multi-Turn Worm Gearbox Suppliers in China Unveiled

Title: China's Multi-Turn Worm Gearbox Suppliers: Delivering Excellence in Precision EngineeringIntroduction:China's manufacturing industry has made monumental strides over the years, solidifying its position as a global leader in providing high-quality industrial products. In particular, the multi-turn worm gearbox sector has witnessed remarkable growth, largely thanks to a cohort of dependable suppliers implementing advanced precision engineering techniques. This article delves into the thriving market of multi-turn worm gearbox suppliers in China, shedding light on the prowess of these companies in delivering excellence in precision engineering.1. A Booming Market for Multi-Turn Worm Gearbox Suppliers in China:China's industrial landscape has expanded rapidly, paving the way for significant advancements in various sectors. One such sector gaining prominence is the production and distribution of multi-turn worm gearbox, an essential mechanical component extensively used in diverse fields such as automation, robotics, and industrial machinery. To meet the surging demand for precision-driven products, a multitude of suppliers have emerged across China, offering cutting-edge solutions to both domestic and international markets.2. Emphasizing Precision Engineering:Precision engineering lies at the core of successful multi-turn worm gearbox production, ensuring durability, efficiency, and accuracy. To address this essential aspect, suppliers in China are utilizing state-of-the-art technology and employing highly skilled engineers and technicians. By leveraging advanced machinery and adhering to stringent quality control measures, Chinese suppliers are consistently delivering stellar products that meet and exceed international standards.3. Commitment to Research and Development:China's multi-turn worm gearbox suppliers comprehend the significance of relentless innovation and understand that staying at the forefront of technological advancements is crucial for sustained growth. Companies are investing substantial resources in research and development, striving to improve the functional capabilities of their gearboxes while simultaneously enhancing energy efficiency, reducing noise levels, and expanding load-bearing capacities.4. Tailored Solutions for Diverse Industries:The versatility of multi-turn worm gearboxes is one of their primary advantages, making them suitable for a wide range of industries. Recognizing this, Chinese suppliers are dedicated to designing and manufacturing gearboxes that cater specifically to each industry's unique requirements. Whether it is for industrial automation, agriculture, or renewable energy applications, China's suppliers can customize their gearboxes to enhance system performance, adaptability, and overall productivity.5. Quality Assurance: Certifications and Standards:Chinese multi-turn worm gearbox suppliers understand the significance of quality assurance in gaining the confidence of global markets. Reliable suppliers comply with international quality management systems, often holding certifications such as ISO 9001, ISO 14001, and OHSAS 18001. Adhering to these rigorous standards ensures that customers receive products that adhere to global benchmarks of quality, reliability, and safety.6. Steadfast Commitment to Customer Satisfaction:Drawing upon the rich tradition of excellent customer service, Chinese multi-turn worm gearbox suppliers prioritize client satisfaction as paramount. By nurturing long-standing partnerships with their customers, suppliers in China establish trust and foster open communication channels throughout the entire procurement process. This commitment to customer-centricity further solidifies China's position as a preferred source for multi-turn worm gearbox solutions worldwide.Conclusion:As China's manufacturing industry continues to grow, the country's multi-turn worm gearbox suppliers stand out as reliable and technologically advanced contributors to the global precision engineering market. With a focus on quality, innovation, and customer satisfaction, these Chinese suppliers are seamlessly integrating cutting-edge technology into their products, enabling industries across the globe to optimize their operations and precision machinery. As the sector continues to flourish, the world can expect China's multi-turn worm gearbox suppliers to maintain their path of excellence, spreading their wings and conquering new horizons.

Discover the Advantages and Applications of Bevel Worm Gears

[Company Name] Introduces Innovative Bevel Worm Gear Technology for Enhanced Productivity and Efficiency[City, State], [Month, Day, Year] - [Company Name], a leading provider of advanced industrial solutions, proudly announces the launch of their latest technological innovation - the Bevel Worm Gear. This cutting-edge gear mechanism is poised to revolutionize various industries by offering increased productivity, superior efficiency, and enhanced performance.The Bevel Worm Gear technology is a result of several years of intensive research and development efforts by [Company Name]'s team of highly skilled engineers and scientists. This advanced gear mechanism combines the best features of bevel gears and worm gears, resulting in a highly versatile solution suitable for a wide range of applications.The bevel gear aspect of this technology ensures smooth and efficient power transmission between intersecting shafts. By utilizing specially designed teeth, the gear effectively transfers power at various angles, allowing for enhanced flexibility in machinery design. This enables engineers to create more compact and efficient systems, reducing the overall footprint of machinery without compromising performance.Simultaneously, the worm gear component brings unparalleled efficiency and precision to the table. The worm gear is known for its high gear ratio and self-locking capabilities, which prevent components from moving when not in use. This feature is particularly advantageous in industries that require precision control and safety, as it prevents accidental movement and potential damage to machinery.In addition to its compact design and power transmission capabilities, the Bevel Worm Gear technology offers substantial torque output. This makes it ideal for heavy-duty machinery applications that demand high power and accuracy, such as industrial manufacturing, mining, and construction.Furthermore, [Company Name] has subjected the Bevel Worm Gear technology to rigorous testing to ensure its durability and longevity. The gear mechanism is constructed with premium-grade materials, ensuring resistance to wear, fatigue, and excessive friction. This robust build ensures that machinery equipped with Bevel Worm Gear technology can withstand harsh operating conditions, guaranteeing increased longevity and reduced maintenance costs.With the launch of this game-changing technology, [Company Name] revolutionizes various industries, providing them with a solution that significantly enhances productivity, efficiency, and performance. Manufacturers worldwide can expect increased throughput, reduced downtime, and improved overall operational efficiency, leading to significant cost savings and an enhanced competitive edge."Introducing the Bevel Worm Gear technology is a significant milestone for us," stated [Company Name]'s CEO. "We believe that this innovation will redefine industrial manufacturing processes and enable companies to push the boundaries of what they can achieve. Our team has worked diligently to develop a gear mechanism that seamlessly combines the best features of bevel and worm gears, and we are excited to witness the transformative impact it will have on diverse industries."The Bevel Worm Gear technology is anticipated to disrupt various industries, including automotive, aerospace, energy, and marine. Its versatility and efficiency make it well-suited for numerous applications, ranging from conveyor systems and material handling equipment to robotics and heavy machinery.[Company Name] plans to collaborate with leading manufacturers in different sectors to integrate the Bevel Worm Gear technology into their machinery and enhance their offerings. By joining forces with industry leaders, [Company Name] aims to accelerate the adoption of this revolutionary technology and foster a new era of productivity, efficiency, and innovation.As a key player in the industrial solutions landscape, [Company Name]'s introduction of the Bevel Worm Gear technology establishes the company as a forward-thinking innovator committed to driving progress and enabling industries to thrive in a rapidly evolving world. With this new development, manufacturers can anticipate increased operational capabilities and the ability to overcome complex challenges efficiently and effectively.

High-Quality Multi-Turn Spur Gearboxes Made in China

China Multi Turn Spur Gearbox: A Reliable Partner for Your Machinery NeedsChina has been a leader in the manufacturing industry, known for producing dependable equipment and machinery that is cost-effective and high-quality. One of the most widely used and highly-sought-after products in this industry is a gearbox, which is integral in the smooth operation of machinery. With advancements in technology, gearboxes have evolved to meet the demands of various applications, and today, China offers one of the most sophisticated gearboxes in the market - the Multi Turn Spur Gearbox.The Multi Turn Spur Gearbox is a high-precision machine capable of delivering accurate torque at various speeds, making it the ideal gearbox for a range of industries such as food processing, packaging, printing, and robotics. What makes it stand out from other gearboxes is its design - it's compact, durable, and requires minimal maintenance, making it suitable for both heavy-duty and light-duty applications.With customer satisfaction at the forefront, Chinese manufacturers ensure that the Multi Turn Spur Gearbox is made from the highest quality materials, including cast iron, steel and aluminum, which prevents it from rust or corrosion and ensures its longevity. Additionally, they have implemented advanced manufacturing techniques and procedures, which guarantees the production of gearboxes with precision and accuracy.Multi Turn Spur Gearbox is standardized for machines that require rotation, and they are easy to install on any piece of machinery. This is possible, thanks to the wide range of different ratios and sizes that a customer can select from. This gearbox is flexible and easy to use, ensuring that it can operate on a range of machinery.The Multi Turn Spur Gearbox is incredibly versatile, it meets the unique requirements of various applications without compromising its performance or quality. Whether you need it for power transmission, conveying, or simply general-purpose purposes, the Multi Turn Spur Gearbox is designed to deliver superior performance and reliability.One of the most interesting features of the Multi Turn Spur Gearbox is its ability to reduce noise levels significantly. Noise is a common issue that arises when using machinery with gearboxes. Still, the Multi Turn Spur Gearbox is uniquely designed to minimize noise levels below what is considered a health hazard, making it an excellent choice for industries that need to mitigate noise pollution, such as a printing press or in food processing facilities.The design of the Multi Turn Spur Gearbox also ensures that it is highly efficient in power transmission. It can transmit power, both vertically and horizontally, with up to 98% efficiency. Its compact design means that it can deliver this performance without bulking up your machinery, enabling you to make the most of your existing space and machinery.Using Multi Turn Spur Gearbox is the first step to ensuring that your machinery's system is efficient, durable, and dependable. Chinese manufacturers offer customer-friendly prices and guarantee prompt delivery, ensuring that customers can get the highest quality gearboxes at competitive prices without enduring long waiting times.In conclusion, the Multi Turn Spur Gearbox is an innovative solution for any machinery system in need of a high-level gearbox. Its precision, quality materials and manufacturing techniques, flexibility, efficiency, and competitive pricing put it ahead of other gearboxes in the market. Whether you are in packaging, printing, food processing, or robotics, investing in the Multi Turn Spur Gearbox will lead to more efficient machinery and better results in your industry.China Multi Turn Spur Gearbox - your reliable partner for all your machinery needs.

Discover the Advantages of Worm and Wheel Gears in Mechanical Applications

Title: Innovative Gear Technology Revolutionizes Industry: The Advancement of Worm and Wheel GearSubtitle: A Promising Breakthrough Takes Industrial Efficiency to New HeightsIntroduction:In the ever-evolving landscape of industrial technology, one breakthrough has captured the attention of manufacturers around the world: the revolutionary Worm and Wheel Gear. This cutting-edge gear technology, heralded for its unparalleled strength, precision, and efficiency, is poised to revolutionize various industries and has already garnered significant attention from businesses seeking to enhance their operations. This article aims to explore the exceptional attributes of the Worm and Wheel Gear, its potential applications across industries, and its role in driving future advancements.Unlocking the Power of Worm and Wheel Gear:Worm and Wheel Gear, a groundbreaking innovation in gear technology, combines sophisticated design principles with state-of-the-art materials to achieve unmatched performance. Utilizing a helical gear (the worm) meshed with a cylindrical gear (the wheel), this gear system facilitates smooth yet robust power transmission. The design ensures a self-locking mechanism, preventing the system from reverse motion, providing enhanced safety and stability in various applications.The Benefits of Worm and Wheel Gear:1. Enhanced Power Transmission Efficiency: Worm and Wheel Gear boasts outstanding efficiency due to minimal friction and incredible contact ratio. With the ability to transmit power from various angles, this technology reduces energy losses and allows for more precise control.2. Increased Load Capacity: The Worm and Wheel Gear configuration effectively distributes load over multiple teeth, leading to improved load-carrying capabilities. It ensures smooth operation, even under heavy loads, making it ideal for applications requiring high torque.3. Unmatched Precision: Its helix angle and high gear teeth engagement provide exceptional accuracy, offering further advantages in applications demanding precise positioning, such as robotics, automotive steering systems, and medical devices.4. Reduced Noise and Vibration: The Worm and Wheel Gear's advanced design minimizes noise and vibrations, enhancing overall operation comfort and promoting a quieter working environment.5. Versatile Applications: This revolutionary gear system finds applications across numerous industries, including but not limited to robotics, automotive, aerospace, medical equipment, and heavy machinery. It offers precise control and endurance in environments that demand high torque, accuracy, and safety.Commercial Implications:The advent of Worm and Wheel Gear technology has sparked a revolution in the manufacturing industry. Commercial ventures around the world are eagerly integrating this advanced gear system into their designs to optimize efficiency and productivity. Manufacturers of industrial machinery, such as robotics and automation technology providers, are increasingly embracing this gear technology to create more reliable and high-performance equipment.In the automotive sector, the Worm and Wheel Gear system is rapidly gaining traction due to its ability to enhance steering accuracy, leading to improved vehicle safety and stability. Additionally, the aerospace and heavy machinery industries are leveraging this technology to achieve higher torque capabilities, allowing for safer and more efficient operations in challenging environments.Looking Ahead:As businesses and industries become increasingly reliant on technology, the need for innovative gear solutions is greater than ever before. Worm and Wheel Gear, with its unmatched power transmission efficiency, enhanced load capacity, and versatility, is poised to shape the future of industrial machinery and automation.Furthermore, ongoing research and development in gear technology are expected to unlock new capabilities and expand the Worm and Wheel Gear's potential applications even further. The gear's durability, precision, and ability to handle heavy loads under challenging conditions make it an invaluable asset for the industries of today and tomorrow.Conclusion:The emergence of Worm and Wheel Gear technology marks a milestone in gear engineering and industrial efficiency. With its exceptional power transmission efficiency, load-carrying capacity, precision, and versatility, this innovative gear system has the potential to transform industries ranging from robotics to heavy machinery. As businesses leverage this extraordinary breakthrough to optimize their operations, we can look forward to a future driven by the incredible possibilities offered by the Worm and Wheel Gear.

Revolutionary Innovation in the World of Turbine Wheels Discovered by Experts

Title: Revolutionary Turbine Wheel Redefines Renewable Energy Production Introduction:In a groundbreaking development in the field of renewable energy, a cutting-edge turbine wheel has been unveiled, promising to revolutionize power generation around the world. Developed by an innovative company specializing in energy solutions, this turbine wheel harnesses the power of wind and converts it into clean and sustainable electricity. With its unprecedented efficiency and design, this new technology offers a shining beacon of hope for a greener future.[Provide a brief description of the company, highlighting its specialization in energy solutions and commitment to sustainable development. Emphasize their dedication to research and innovation in order to bring about positive changes in the global energy landscape.]Body:1. Turbine Wheel Unveiled - A New Era for Renewable Energy:The new turbine wheel, developed by the pioneering energy solutions company, marks a significant milestone in renewable energy technology. Designed to capitalize on wind energy, this innovative turbine wheel has been engineered to maximize efficiency and output, setting it apart from conventional wind turbines.2. Unleashing the Power of the Wind:The turbine wheel boasts state-of-the-art aerodynamic features that enable it to harness a greater amount of energy from even the slightest breeze. Its unique design enhances wind capture, enabling a more consistent and reliable power generation. Harnessing wind energy has never been more efficient or reliable than with this groundbreaking turbine wheel.3. Increased Efficiency Revolutionizes Energy Production:With its advanced technology, the turbine wheel surpasses its predecessors in terms of energy production. Through meticulous engineering, the company has vastly improved the turbine's ability to convert wind energy into electricity, significantly increasing its overall efficiency. This leap in efficiency is a significant step towards the widespread adoption of renewable energy solutions.4. Versatile Applications Open New Horizons:Efforts have been made to make this revolutionary turbine wheel applicable to a myriad of environments. By adapting and customizing the wheel design, it can be effectively utilized in various locations with different wind conditions. This versatility opens up new possibilities for renewable energy production, making it accessible for regions previously deemed unsuitable for wind-power generation.5. Paving the Way for Sustainable Future:By harnessing the immense power of the wind, this turbine wheel contributes directly to minimizing CO2 emissions and reducing reliance on fossil fuels. The implementation of this advanced technology will accelerate the transition towards a cleaner and more sustainable energy future. The turbine wheel is a testament to the company's commitment to combating climate change and mitigating its environmental impact.6. Overcoming Challenges and Ensuring Reliability:One of the key challenges faced in the renewable energy sector is intermittency. To combat this issue, the turbine wheel is equipped with mechanisms that ensure uninterrupted power supply regardless of wind variations. This innovative feature guarantees a more stable electricity generation, promoting grid reliability and minimizing any fluctuations in energy supply.7. Economic Benefits and Job Creation:The widespread adoption of this turbine wheel technology has the potential to stimulate economic growth. Investments in renewable energy projects using this groundbreaking technology would not only drive down energy costs over time but also create a significant number of sustainable jobs, boosting local economies in the process.8. Collaborative Efforts and Future Prospects:To maximize the impact of this revolutionary turbine wheel technology, the energy solutions company is actively engaging in partnerships and collaborations with governments, businesses, and scientific institutions. By fostering a cooperative spirit and sharing knowledge, they aim to facilitate the integration of this innovative technology into existing energy infrastructures worldwide, accelerating the global transition towards sustainable power generation.Conclusion:The unveiling of this groundbreaking turbine wheel represents a significant milestone in the renewable energy sector. With enhanced efficiency, reliability, and versatility, this technology promises to revolutionize wind energy generation and pave the way for a cleaner and greener future. By harnessing the power of the wind, the turbine wheel offers hope for a sustainable world, advancing the global fight against climate change and fostering economic growth through job creation. The energy solutions company has proven its commitment to innovation and sustainable development, solidifying its position as a leading force in the renewable energy revolution.