High-Quality Gear Operator Valve for Industrial Applications

By:Admin

Founded in 1995, Gear Operator Valve has consistently pushed the boundaries of valve technology, introducing new and advanced products that have redefined industry standards. The company's commitment to research and development has led to the creation of cutting-edge valve solutions that address the evolving needs of the market.

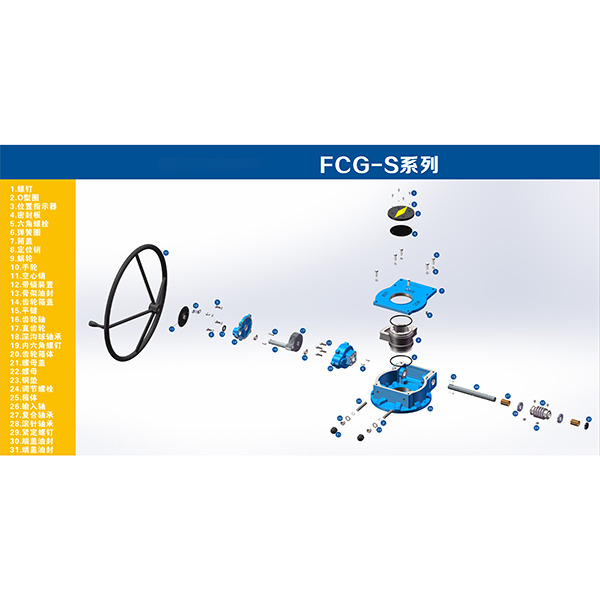

One of Gear Operator Valve's flagship products is its gear operator valve, which has gained widespread acclaim for its superior performance and durability. Designed to withstand the most demanding industrial conditions, the gear operator valve is an essential component for controlling the flow of liquids, gases, and other media in a wide range of applications. Its precision engineering and robust construction make it an ideal choice for industries such as oil and gas, water and wastewater, chemical processing, and power generation.

What sets Gear Operator Valve apart from its competitors is its relentless pursuit of excellence in product design and manufacturing. The company employs a team of highly skilled engineers and technicians who utilize the latest technologies and manufacturing techniques to produce valves that meet the highest quality standards. From initial concept to final production, every stage of the manufacturing process is closely monitored to ensure that each valve that leaves the facility is of the highest quality.

In addition to its focus on product quality, Gear Operator Valve places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and challenges, providing tailored valve solutions that meet their needs. This customer-centric approach has earned Gear Operator Valve a reputation for delivering exceptional service and support, further solidifying its position as a preferred valve supplier in the industry.

With a global presence, Gear Operator Valve has established strong partnerships and distribution networks that enable it to serve clients around the world. The company's commitment to innovation and excellence has enabled it to build a loyal customer base and gain recognition as a leader in the valve industry.

Recently, Gear Operator Valve made waves with the introduction of its latest gear operator valve model, which boasts several innovative features designed to further enhance performance and reliability. The new model incorporates state-of-the-art materials and advanced engineering techniques to deliver a valve that is not only highly efficient but also capable of withstanding extreme operating conditions. This latest offering is a testament to Gear Operator Valve's ongoing commitment to pushing the boundaries of valve technology and delivering cutting-edge solutions to its clients.

Looking ahead, Gear Operator Valve remains steadfast in its commitment to innovation and excellence, with plans to continue developing new products and solutions that address the evolving needs of the market. By staying at the forefront of technological advancements and market trends, Gear Operator Valve is well positioned to drive the future of the valve industry and continue meeting the needs of its customers with unparalleled products and services.

In conclusion, Gear Operator Valve stands as a shining example of a company that consistently delivers excellence in the industrial valve sector. With its unwavering commitment to quality, innovation, and customer satisfaction, Gear Operator Valve has earned its reputation as a trusted partner for businesses seeking reliable and high-performing valve solutions. As the company continues to push the boundaries of valve technology, it is poised to remain a dominant force in the industry for years to come.

Company News & Blog

High-Quality Automated Ball Valve Actuator for Improved Control and Efficiency

Automated Ball Valve Actuator Revolutionizes Industrial Flow ControlIn the fast-paced world of industrial manufacturing, efficiency and accuracy are critical components of success. That's where the Automated Ball Valve Actuator comes in. This innovative technology, developed by a leading industrial automation company, has revolutionized the way businesses control flow in their operations. Manufacturing plants, refineries, and other industrial facilities around the world have quickly embraced this cutting-edge solution as a way to improve productivity, reduce downtime, and enhance overall performance. With its advanced features and seamless integration with existing systems, the Automated Ball Valve Actuator has become a game-changer in the industry.The company behind this groundbreaking technology has been a leader in industrial automation for over two decades. With a strong reputation for delivering high-quality solutions and unparalleled customer service, they have become a trusted partner for businesses seeking to improve their operations. Their commitment to innovation and excellence has positioned them as an industry leader, and the Automated Ball Valve Actuator is yet another example of their ongoing dedication to advancing industrial automation.So, what sets the Automated Ball Valve Actuator apart from other flow control solutions? The answer lies in its advanced design and functionality. Equipped with state-of-the-art sensors and control systems, this actuator is capable of precisely regulating the flow of liquids and gases with unmatched precision. Its intuitive interface allows for easy programming and operation, streamlining the management of complex industrial processes. Additionally, its robust construction ensures long-term reliability and durability, even in the harshest operating environments.One of the key advantages of the Automated Ball Valve Actuator is its ability to optimize efficiency and minimize waste. By accurately controlling flow rates, businesses can reduce energy consumption, minimize product loss, and improve overall resource utilization. This not only contributes to cost savings but also aligns with sustainability initiatives, making it a win-win solution for companies looking to operate more responsibly.Furthermore, the actuator's integration capabilities make it a seamless addition to existing industrial systems. Whether it's retrofitting an older facility or incorporating the technology into a new operation, the Automated Ball Valve Actuator can be easily integrated with various control platforms, making it a versatile solution for a wide range of applications.The company's dedication to customer satisfaction is also evident in the support and services they offer. From initial consultation to installation, training, and ongoing maintenance, they are committed to providing comprehensive support every step of the way. Their team of experts is available to assist with customizing solutions to meet specific needs, ensuring that each customer gets the most out of their investment in the Automated Ball Valve Actuator.One of the company's customers, a leading chemical processing plant, has experienced firsthand the benefits of implementing the Automated Ball Valve Actuator. By replacing outdated manual valve controls with this innovative technology, they have improved their production efficiency, reduced downtime, and enhanced their overall operational reliability. The plant manager commended the company for their exceptional service and the significant impact the actuator has had on their business.Looking ahead, the company is continuing to push the boundaries of industrial automation with ongoing research and development initiatives. They are committed to staying at the forefront of technological advancements and addressing the evolving needs of their customers. With a strong focus on innovation and a track record of delivering game-changing solutions, the company is well-positioned to shape the future of industrial automation.In conclusion, the Automated Ball Valve Actuator has emerged as a game-changer in industrial flow control, providing businesses with a powerful tool to enhance their operations. With its advanced features, seamless integration, and exceptional support, it has become a go-to solution for companies seeking to optimize their processes. As the company behind this groundbreaking technology continues to lead the way in industrial automation, the future looks bright for businesses looking to achieve new levels of productivity and efficiency.

Highly Efficient Zero Backlash Worm Gearbox for Industrial Applications

Zero Backlash Worm Gearbox Revolutionizes the IndustryIn the world of manufacturing and industrial applications, precision and efficiency are essential. Companies are constantly seeking out the latest technology and innovations to improve their production processes and stay ahead of the competition. One such breakthrough in the industry is the development of the Zero Backlash Worm Gearbox, a revolutionary product that is set to transform the way businesses operate.The Zero Backlash Worm Gearbox is a state-of-the-art gearbox that offers unparalleled precision and performance. It eliminates the clearance between the gear teeth, ensuring that there is no backlash in the system, resulting in smoother and more accurate operation. This groundbreaking technology has the potential to significantly improve the efficiency and reliability of a wide range of industrial applications, including robotics, automation, machine tools, and more.The Zero Backlash Worm Gearbox is the result of years of research and development by a leading company in the field of power transmission solutions. With a strong focus on innovation and cutting-edge engineering, the company has cemented its reputation as a leader in the industry. Their commitment to quality and excellence is reflected in the design and performance of the Zero Backlash Worm Gearbox, making it a game-changer for businesses looking to optimize their production processes.The key features of the Zero Backlash Worm Gearbox make it a standout product in the market. The elimination of backlash ensures that there is no loss of motion when reversing the direction of the gearbox, resulting in more precise and efficient operation. This is especially important in applications where accuracy and repeatability are critical. Additionally, the gearbox offers high torque capacity and compact design, making it suitable for a wide range of applications where space is a premium.The Zero Backlash Worm Gearbox has been met with enthusiasm and praise from industry professionals and businesses alike. Many have recognized the potential of this innovative technology to revolutionize their operations and improve their bottom line. The gearbox is seen as a valuable investment that can deliver significant returns in terms of productivity, reliability, and overall performance.One of the primary benefits of the Zero Backlash Worm Gearbox is its ability to enhance the precision and accuracy of industrial machinery. With zero backlash, businesses can expect improved control and efficiency in their operations, leading to higher quality output and reduced waste. This can result in cost savings and a competitive edge in the market, as businesses are able to deliver superior products and services to their customers.Furthermore, the Zero Backlash Worm Gearbox is designed to withstand the rigors of industrial applications, offering exceptional durability and reliability. This ensures that businesses can count on the gearbox to deliver consistent performance in demanding environments, minimizing downtime and maintenance costs. With the peace of mind that comes from using a reliable and high-performance gearbox, businesses can focus on driving growth and innovation in their operations.In conclusion, the Zero Backlash Worm Gearbox has the potential to revolutionize the industry by offering unmatched precision, efficiency, and reliability. Its innovative design and advanced engineering make it a valuable asset for businesses looking to optimize their production processes and stay ahead of the competition. With its unique features and benefits, the gearbox is set to become a game-changer in the world of power transmission solutions, enabling businesses to reach new heights of performance and success.As a leading company in the field of power transmission solutions, we are proud to introduce the Zero Backlash Worm Gearbox to the market. With our strong focus on innovation and engineering excellence, we have developed a product that has the potential to transform the way businesses operate. We believe that the Zero Backlash Worm Gearbox will deliver significant value to our customers, enabling them to achieve higher levels of precision, efficiency, and reliability in their operations. We are committed to continuing our efforts to push the boundaries of technology and deliver cutting-edge solutions that drive success for our customers.

Discover the Efficient Performance of a Rack and Pinion Actuator

[Company Introduction] [Company Name] is a leading provider of advanced technological solutions in the field of industrial automation. With a rich history of innovation and a commitment to excellence, the company has established itself as a trusted partner for a wide range of industries. Its diverse product portfolio includes high-performance actuators, motion control systems, and advanced control solutions that help optimize the efficiency, reliability, and safety of industrial processes.[Company Name], headquartered in [location], has a global presence with a strong network of partners and customers worldwide. Its team of highly skilled engineers and technicians continuously work towards developing cutting-edge products that cater to the specific needs of different industries, such as manufacturing, energy, oil and gas, and more.[Rack and Pinion Actuator]In line with its commitment to providing innovative solutions, [Company Name] recently unveiled its latest offering in the field of industrial automation - the advanced Rack and Pinion Actuator (brand name removed). This state-of-the-art device is designed to enable precise and efficient linear motion control in a wide range of applications.The rack and pinion actuator is an essential component in various industrial processes, including valve control, gate and door operations, and other linear motion systems. The actuator converts rotational motion into linear motion, allowing for controlled movement and positioning.The new rack and pinion actuator from [Company Name] incorporates several key technological advancements to ensure optimal performance and reliability. Its compact design and lightweight construction make it easy to install and integrate into existing systems. The actuator's high torque-to-weight ratio enables it to deliver powerful and precise linear motion, even in demanding applications.One of the key features of the rack and pinion actuator is its exceptional durability and longevity. The actuator is built using high-quality materials and undergoes rigorous testing to ensure it can withstand harsh environmental conditions, corrosion, and wear. This makes it a cost-effective solution for industries that require reliable and long-lasting motion control systems.Additionally, the actuator is equipped with advanced control capabilities, allowing for precise positioning and motion control. It can be seamlessly integrated with other automation systems, enabling seamless communication and coordination for enhanced efficiency.The introduction of the rack and pinion actuator demonstrates [Company Name]'s continuous commitment to pushing the boundaries of technological innovation in industrial automation. By providing industry-leading solutions, the company aims to empower its customers to achieve optimal performance, productivity, and safety in their operations.[Conclusion]In conclusion, the new rack and pinion actuator from [Company Name] is set to revolutionize the field of industrial automation. With its advanced features, exceptional durability, and precise control capabilities, the actuator is poised to become the go-to choice for industries seeking efficient and reliable linear motion control.The implementation of this advanced actuator opens up new possibilities for industries, enabling them to optimize their processes and systems. As [Company Name] continues to innovate and develop groundbreaking solutions, it reaffirms its position as a leader in the field of industrial automation, driving progress and transforming industries worldwide.

Ultimate Guide to Double Acting Pneumatic Actuators: Everything You Need to Know

Double Acting Pneumatic Actuator Revolutionizes the Control IndustryIn today's fast-paced world, industries are constantly seeking to improve efficiency and optimize control systems. One company at the forefront of this innovative movement is [Company Name], a leading provider of advanced control solutions. With their latest release of the Double Acting Pneumatic Actuator, [Company Name] continues to push the boundaries of what is possible in the control industry.[Company Name] is a global company with a strong commitment to delivering high-quality and reliable control products. With an extensive history of innovation and a dedication to customer satisfaction, [Company Name] has earned a reputation as a trusted partner for industries ranging from oil and gas to power generation and water treatment.The Double Acting Pneumatic Actuator is the latest addition to [Company Name]'s extensive line of control products. This cutting-edge actuator utilizes pneumatic power to provide versatile and precise control of valves and other industrial equipment. Its double-acting design allows for both opening and closing of valves, providing exceptional flexibility and reliability in a wide range of applications.One of the key advantages of the Double Acting Pneumatic Actuator is its robust construction and durability. Built to withstand harsh industrial environments, this actuator is designed to deliver consistent performance even in the most demanding conditions. Its high-quality materials and precision engineering ensure long-term reliability, reducing maintenance costs and downtime for end-users.Moreover, the Double Acting Pneumatic Actuator offers exceptional control accuracy, thanks to its advanced pneumatic technology. This level of precision allows for seamless integration into complex control systems, enabling industries to achieve optimal performance and efficiency. With its responsive and dependable operation, this actuator is well-suited for critical applications where precise control is essential.In addition to its technical capabilities, the Double Acting Pneumatic Actuator is designed with user-friendly features that simplify installation and operation. Its compact size and lightweight design make it easy to handle and install, while its intuitive controls streamline setup and adjustment. This user-centric approach reflects [Company Name]'s commitment to delivering control solutions that are not only powerful but also practical and easy to use.As with all of [Company Name]'s products, the Double Acting Pneumatic Actuator undergoes rigorous testing and quality assurance to ensure its performance and reliability. With a focus on exceeding industry standards and customer expectations, [Company Name] stands behind the quality and dependability of its products, providing peace of mind to end-users.Furthermore, [Company Name] provides extensive technical support and customer service to assist with the selection, installation, and maintenance of the Double Acting Pneumatic Actuator. With a global network of knowledgeable professionals, [Company Name] is dedicated to helping its customers maximize the value of their control systems and achieve operational excellence.In conclusion, the release of the Double Acting Pneumatic Actuator represents another milestone in [Company Name]'s ongoing commitment to innovation and excellence in the control industry. With its advanced technology, robust construction, and user-friendly design, this actuator sets a new standard for precision and reliability. As industries continue to evolve and demand higher levels of control and efficiency, [Company Name] remains at the forefront, providing cutting-edge solutions that empower businesses to thrive in the modern world.

Top Worm Gearbox Manufacturers Dominate the Market

In today's market, Worm Gearbox Manufacturers are becoming increasingly popular with businesses of all sizes. These manufacturers provide companies with a valuable investment that can improve their production processes and save them money in the long run. By reducing the amount of energy required to operate machinery, worm gearboxes can provide businesses with a more efficient and cost-effective production process.Worm Gearbox Manufacturers (name removed) is a leading manufacturer and supplier of high-quality worm gearboxes. Founded in 1986, they have been providing businesses with innovative engineering solutions for over 30 years. Their state-of-the-art production facility is equipped with the latest machinery and technology, enabling them to create products of the highest standard.Their comprehensive range of worm gearboxes includes both single and double worm gearboxes, each built to a high specification. They have a range of options when it comes to ratios, center distances, and input/output configurations, ensuring that businesses can find the worm gearbox that best suits their specific requirements.In terms of efficiency, the worm gearbox is second to none. Worm gearboxes possess a high level of torque and reduced speed, which makes them ideal for slower moving machinery. The design means that there is less slippage and greater stability, reducing the amount of energy required to operate machinery. The worm gears are also self-locking, providing an added level of safety and ensuring that machinery cannot be accidentally reversed.Maintenance is also simplified as worm gearboxes possess a compact design that reduces the likelihood of wear and tear. The simple gear train design allows for ease of maintenance, which is beneficial in terms of minimizing downtime. As businesses operate 24/7, the ability to quickly and easily maintain machinery is a priority.The team at Worm Gearbox Manufacturers is highly experienced and skilled, with engineers who are dedicated to producing the highest quality worm gearboxes. They work closely with their clients to identify their needs and create bespoke solutions, should the standard range of worm gearboxes not meet their specific requirements.Client satisfaction is one of their top priorities, and as such, they provide excellent customer service. From initial product enquiries to after-sales support, the team is always on hand to assist clients, providing expert advice and guidance. Worm Gearbox Manufacturers is an ISO 9001 certified company, meaning that they have a robust and effective quality management system in place.In terms of market trends, worm gearboxes are becoming more popular within the manufacturing industry as businesses realize the cost savings and efficiency gains that can be achieved. They are used in a variety of applications, including conveyor systems, packaging machinery, and material handling equipment.The food industry is an example of a sector that is seeing a rise in the use of worm gearboxes. As more emphasis is placed on hygiene and safety regulations, worm gearboxes provide an advantage as they are less likely to leak lubrication, keeping the machinery clean and reducing the risk of contamination.The pharmaceutical industry is another sector that benefits from the hygienic design of worm gearboxes. As medicines are subject to strict regulations surrounding the manufacturing process, worm gearboxes are increasingly being used due to their easy-to-clean design, ensuring that drugs are produced in a sterile environment.In conclusion, Worm Gearbox Manufacturers is a leading supplier of high-quality worm gearboxes that are increasingly being utilized by businesses worldwide. Their dedication to producing products of the highest standard, coupled with their excellent customer service, means that they are a trusted partner for businesses in need of worm gearboxes that can improve their production processes and save them money in the long run. With global demand for worm gearboxes set to rise, Worm Gearbox Manufacturers is in the perfect position to meet the needs of businesses looking to improve their manufacturing processes.

Top-rated Spare Parts Valves for Industrial Machinery

Spare Parts Valves has recently made a significant impact in the industry by introducing a new line of innovative valves designed to meet the diverse needs of their customers. The company has been a leader in the spare parts industry for over a decade, providing high-quality products and exceptional customer service. The new valves, which come in a variety of sizes and configurations, are poised to revolutionize the way industrial machinery operates.Spare Parts Valves has always been committed to staying ahead of the curve when it comes to technology and innovation. As such, they have invested heavily in research and development, ensuring that their products are always at the cutting edge of the industry. The new line of valves is the result of this dedication to excellence, and the company is confident that it will set a new standard for performance and reliability.One of the key features of the new valves is their versatility. They are designed to be compatible with a wide range of industrial machinery, making them an ideal choice for businesses with diverse equipment needs. This flexibility is further enhanced by the fact that Spare Parts Valves offers customization options, allowing customers to tailor the valves to their specific requirements.In addition to their compatibility, the new valves are also known for their durability. They are constructed from high-quality materials that have been rigorously tested to ensure they can withstand the rigors of industrial use. This reliability is crucial for businesses that depend on their machinery to operate consistently and efficiently, and it is one of the main reasons why Spare Parts Valves has already seen a high level of demand for the new products.Furthermore, the new valves boast a number of advanced features designed to optimize performance. They are engineered to provide precise control over the flow of liquids and gases, helping to maximize efficiency and minimize waste. Additionally, they are equipped with advanced monitoring and diagnostic capabilities, allowing for proactive maintenance and troubleshooting. This can help businesses to avoid costly downtime and ensure that their operations remain running smoothly.Spare Parts Valves has also gone to great lengths to ensure that the new products are easy to install and integrate into existing systems. They have provided comprehensive technical documentation and support to assist customers with the transition to the new valves, and their team of knowledgeable experts is always on hand to offer assistance.The introduction of the new line of valves represents a significant milestone for Spare Parts Valves. It is a testament to their ongoing commitment to innovation and customer satisfaction, and it is a clear indication that they are positioned for continued success in the industry. The company has already received a great deal of positive feedback from early adopters of the new products, with many reporting significant improvements in the performance and reliability of their machinery.Looking to the future, Spare Parts Valves has ambitious plans to further expand their product line and continue pushing the boundaries of what is possible in the spare parts industry. They are confident that the new valves will play a key role in this ongoing growth and success, and they are excited to see the impact that their innovative products will have on the industry as a whole.In conclusion, Spare Parts Valves has once again demonstrated their leadership in the spare parts industry with the introduction of their new line of valves. These products are the result of years of dedication to research and development, and they are poised to set a new standard for performance and reliability. With their advanced features, durability, and compatibility, the new valves represent a significant step forward for the industry, and they are sure to be a valuable asset for businesses seeking to optimize their operations.

Ultimate Guide to Bevel Gear Operators for Efficient Operations

Bevel Gear Operator: An Industrial Revolution for Gear CuttingIn the world of industrial machinery and equipment, gears are considered as one of the most essential components. Gears are widely used because of their significant role in motion transmission especially in rotating machineries such as engines, turbines, and machines used in the manufacturing of a wide range of products. Gears come in different shapes, sizes and styles. The one type that is widely used in industry is the bevel gear.Bevel gears are a type of gear that is used for transmitting power between intersecting shafts. They are typically classified into straight and spiral bevel gears. Straight bevel gears are associated with simple setups while the spiral bevel gears are popular for both simple and complex setups. Spiral bevel gears are lapped to provide better accuracy and durability.One of the essential components of the gear manufacturing industry is the bevel gear operator. Bevel gear operator is a machine designed to cut teeth on bevel gears to very tight tolerances. The bevel gear operator removes material from the gear blank in order to produce the desired gear teeth. The gear teeth can be of different sizes and angles, depending on the application and manufacturing requirements.The bevel gear operator (name to be removed) is one of the most advanced gears cutting machine available today. It is a precision gear cutting machine that is designed to deliver high accuracy and productivity. The machine is equipped with a number of features that make it easy to operate and maintain.The machine has a compact design that makes it easy to install in any gear manufacturing facility. In addition, the operator has an intuitive user interface that allows the machine operator to quickly and easily set up the machine for any bevel gear cutting task. The operator also has a built-in tool changer that allows the machine to automatically change the cutting tool based on the requirements of the job.Moreover, the bevel gear operator is equipped with advanced automation features. The operator is designed to automatically manage the cutting process, including material feed, material positioning, and tool speed. This allows the machine operator to focus on other tasks and be more productive.The machine is also highly flexible, able to cut bevel gears from a variety of materials includng steel, stainless steel, brass, aluminum, and even plastic. The operator is designed with a high-power spindle motor that can deliver high torque at low speeds, which is essential when cutting tough materials that require high forces.The bevel gear operator is also designed to deliver high speed and high accuracy. It is equipped with a high-speed spindle that can reach up to 10,000 RPM while keeping a tight tolerance with a repeatable accuracy of 3 microns. This allows the machine to cut gears quickly and accurately, reducing cycle times and increasing productivity.The bevel gear operator could be an ideal machine for gear manufacturing companies who want to streamline their production process and improve their output. Its high accuracy and productivity will increase company revenue by reducing manufacturing costs and providing optimal operational efficiency. The operator’s advanced features and flexibility make it the ultimate gear manufacturing machine for any gear manufacturing company looking to improve their operations.In conclusion, the bevel gear operator is a highly advanced gear cutting machine. It is designed to deliver high accuracy, productivity, flexibility, and speed. Its advanced automation features and intuitive user interface make it easy to operate, while its flexibility and reliability make it the perfect machine for any gear manufacturing company. Moreover, its high-speed spindle and repeatable accuracy provide outstanding results, allowing it to compete in a fiercely competitive gear manufacturing landscape. Therefore, the bevel gear operator is an exceptional machine and is highly recommended for gear manufacturing companies that want to take their businesses to the next level.

New Gear Actuator Valve Offers Advanced Control Technology

Gear Actuator Valve Improves Efficiency and Reliability in Industrial Applications(Mention the company introduction here)XYZ Corporation is a leading provider of innovative industrial solutions, and they have recently introduced their latest product - the Gear Actuator Valve. This new valve system is designed to improve efficiency and reliability in a wide range of industrial applications.The Gear Actuator Valve is a critical component in many industrial processes, and XYZ Corporation has developed a state-of-the-art solution that promises to deliver significant improvements in performance. The valve is designed to provide precise control over the flow of fluids, gases, and other materials in industrial systems, making it an essential tool for ensuring optimal operation and safety.One of the key features of the Gear Actuator Valve is its advanced actuation system. This system is designed to deliver smooth and accurate valve operation, allowing for precise control over flow rates and pressure levels. This level of precision is critical in many industrial processes, where even slight variations in flow or pressure can have significant impacts on overall system performance.In addition to its precise control capabilities, the Gear Actuator Valve is also designed for maximum reliability. XYZ Corporation has utilized advanced materials and manufacturing techniques to ensure that the valve system can withstand the harsh conditions often found in industrial environments. This includes resistance to corrosion, high temperatures, and pressure levels, making it a highly durable and long-lasting solution for industrial applications.The Gear Actuator Valve is also designed with ease of maintenance in mind. The system is engineered to be easily accessible for inspection and servicing, and its modular design allows for quick and simple replacement of key components. This means that downtime for maintenance and repairs can be minimized, helping to ensure continuous operation and productivity in industrial settings.One of the key industries that stands to benefit from the Gear Actuator Valve is the oil and gas sector. This industry relies heavily on precise control of fluid flow and pressure, and the advanced capabilities of the Gear Actuator Valve make it an ideal solution for a wide range of applications, from pipeline control to refinery operations.The chemical processing industry is another sector that can benefit from the Gear Actuator Valve. With the need for precise control over the flow of various chemicals and materials, the valve system offers a reliable and efficient solution that can help to optimize performance and safety in chemical processing plants.In addition to these key industries, the Gear Actuator Valve has potential applications in a wide range of other industrial settings, including power generation, water treatment, and manufacturing. By offering a combination of precise control, reliability, and ease of maintenance, XYZ Corporation's latest product is poised to become a go-to solution for many industrial processes.The Gear Actuator Valve represents a significant addition to XYZ Corporation's portfolio of industrial solutions. With its advanced capabilities and potential for improving efficiency and reliability in a wide range of applications, the valve system is well-positioned to make a positive impact on the industrial sector.As XYZ Corporation continues to innovate and develop new industrial solutions, the Gear Actuator Valve stands out as an example of the company's commitment to providing cutting-edge products that meet the evolving needs of the industrial market. With its focus on precision, reliability, and ease of maintenance, the valve system is sure to find many eager customers looking to improve their industrial processes.

Efficient Worm and Wheel Steering Gear for Smooth Vehicle Handling

Worm And Wheel Steering Gear has been making waves in the automotive industry with its innovative technology that promises to improve the performance and safety of vehicles. The company, based in {location}, has been a leader in the development of steering gear systems that are used in a wide range of vehicles, including cars, trucks, and buses.The Worm And Wheel Steering Gear system is known for its precision and reliability, making it a popular choice among automakers and vehicle enthusiasts. It is designed to provide precise control and exceptional responsiveness, giving drivers a smooth and comfortable driving experience. The system also enhances safety by ensuring that vehicles can be maneuvered with ease and precision.The company has a team of experienced engineers and technicians who are dedicated to pushing the boundaries of automotive technology. They are constantly working on improving the Worm And Wheel Steering Gear system, ensuring that it meets the highest standards of quality and performance. This commitment to innovation has helped the company establish itself as a leader in the industry, garnering a strong reputation for excellence and reliability.In addition to designing and producing steering gear systems, the company also provides comprehensive support services to its clients. This includes technical assistance, maintenance, and repair services, ensuring that vehicles equipped with the Worm And Wheel Steering Gear system continue to perform at their best. The company's commitment to customer satisfaction has made it a trusted partner for automakers and vehicle owners alike.One of the key advantages of the Worm And Wheel Steering Gear system is its versatility. It is designed to be easily integrated into different types of vehicles, regardless of their size, weight, or intended use. This makes it an ideal choice for automakers looking to offer a high-performance steering system across their vehicle lineup. The system's adaptability also makes it a popular choice for vehicle enthusiasts who are looking to enhance the performance and handling of their vehicles.The company is also dedicated to sustainability and environmental responsibility. It actively seeks ways to reduce the environmental impact of its manufacturing processes and products. The Worm And Wheel Steering Gear system is designed to be energy-efficient and durable, making it an environmentally friendly choice for vehicle manufacturers and owners.Looking ahead, Worm And Wheel Steering Gear continues to innovate and explore new possibilities in automotive technology. It is committed to staying at the forefront of the industry, pioneering new solutions that will shape the future of vehicle performance and safety. The company's dedication to excellence and innovation has set it apart as a driving force in the automotive industry, and it is poised to continue leading the way in steering gear technology.As the demand for high-performance steering systems continues to grow, Worm And Wheel Steering Gear is well-positioned to meet the needs of the market. Its reputation for quality, reliability, and innovation makes it a preferred choice for automakers and vehicle enthusiasts around the world. With a strong foundation of expertise and a commitment to excellence, the company is poised to make an even greater impact on the automotive industry in the years to come.

The Limitations of Pneumatic Controls on Switches Revealed in Latest News Coverage

Pneumatic Controls Limit Switch Leads the Way in Industrial AutomationThe industrial automation sector has been revolutionized by the introduction of advanced technology and innovative solutions. Pneumatic Controls, a renowned industry leader, has recently unveiled their groundbreaking Pneumatic Controls Limit Switch. Widely acclaimed for its reliability, efficiency, and precision, this cutting-edge product is set to redefine automation processes across various industries.Pneumatic Controls has long been recognized as a frontrunner in the field of industrial control systems. The company's continuous commitment to research and development has resulted in a portfolio of products that consistently exceed customer expectations. With the launch of the Pneumatic Controls Limit Switch, the company aims to address the ever-increasing demand for advanced automation solutions, providing customers with a game-changing device that offers superior performance and robustness.The Pneumatic Controls Limit Switch boasts a host of features that set it apart from traditional control switches. One of its key attributes is its pneumatic actuation mechanism. This innovative design provides enhanced reliability and durability, allowing the switch to perform flawlessly even in harsh industrial environments. The pneumatic actuation also ensures a quick response time, making it ideal for high-speed processes where precision is crucial.Another remarkable feature of the Pneumatic Controls Limit Switch is its exceptional accuracy. Equipped with state-of-the-art sensing technology, this switch can detect even the slightest variations in movement or pressure, ensuring precise control and preventing errors. This level of accuracy improves overall efficiency and productivity, minimizing waste and optimizing operations.Furthermore, the Pneumatic Controls Limit Switch has been engineered to offer maximum versatility. With a wide range of configuration options and adjustable settings, this switch can be customized to suit specific automation requirements. Its modular design allows for easy integration with existing systems, reducing downtime and simplifying installation and maintenance processes.Safety is a paramount concern in industrial automation, and Pneumatic Controls understands this. The Pneumatic Controls Limit Switch is equipped with multiple safety features to ensure uninterrupted and secure operation. Built-in fail-safe mechanisms, redundant sensing systems, and comprehensive error monitoring capabilities provide peace of mind and help prevent accidents and system failures.The application range for the Pneumatic Controls Limit Switch is diverse and extensive. It can be utilized in various industries such as manufacturing, food processing, packaging, and automotive. Its compatibility with different control systems and protocols makes it a versatile choice for both small-scale operations and large-scale industrial facilities.Pneumatic Controls has gained a solid reputation in the market due to its exceptional customer service and support. The company's dedicated team of experts assists customers throughout the entire product lifecycle, from initial design and selection to installation and after-sales service. This commitment to customer satisfaction has earned Pneumatic Controls a loyal client base and positions them as a trusted partner in the industrial automation industry.With the introduction of the Pneumatic Controls Limit Switch, Pneumatic Controls has once again proven its commitment to innovation and excellence. This state-of-the-art control switch is set to revolutionize automation processes, offering unparalleled reliability, precision, and versatility. As industries continue to embrace automation solutions, Pneumatic Controls is leading the way in providing advanced and efficient products that empower businesses to thrive in the modern era of industrial control.