High-Quality Electric Wafer Butterfly Valve for Reliable Flow Control

By:Admin

The industrial sector is constantly evolving, with new technologies and innovations shaping the way businesses operate and maintain their systems. One such innovation that is revolutionizing industrial control systems is the Electric Wafer Butterfly Valve. This cutting-edge technology is transforming the way industries control the flow of fluids and gases, offering a more efficient and reliable solution for industrial applications.

The Electric Wafer Butterfly Valve, offered by {}, is a state-of-the-art valve that is designed to provide precise control over the flow of fluids and gases in industrial systems. This valve is equipped with an electric actuator, which allows for remote operation and control, making it an ideal solution for industries looking to streamline their processes and improve overall efficiency.

One of the key features of the Electric Wafer Butterfly Valve is its compact and lightweight design, which makes it easy to install and integrate into existing systems. This valve is also highly durable and can withstand the harsh conditions often found in industrial environments, ensuring reliable performance and minimal maintenance requirements.

The innovative design of the Electric Wafer Butterfly Valve also allows for precise flow control, providing industries with the ability to adjust flow rates with a high degree of accuracy. This level of control is essential for industries that rely on precise flow management, such as chemical processing plants, water treatment facilities, and power generation plants.

In addition to its precision control capabilities, the Electric Wafer Butterfly Valve also offers significant energy savings. By utilizing an electric actuator, this valve can adjust flow rates and monitor system performance to optimize energy usage, helping industries reduce their operational costs and minimize their environmental impact.

Furthermore, the Electric Wafer Butterfly Valve is equipped with advanced diagnostics and monitoring capabilities, allowing industries to proactively identify and address potential issues before they escalate into costly downtime or system failures. This proactive approach to maintenance and monitoring can help industries prevent costly disruptions and ensure the reliable and continuous operation of their systems.

{} is a leading provider of industrial valves and control solutions, with a strong commitment to innovation and quality. Their Electric Wafer Butterfly Valve is a testament to their dedication to providing cutting-edge solutions to their customers, helping them improve their operational efficiency and maintain a competitive edge in the market.

With a focus on reliability, performance, and efficiency, {} is dedicated to meeting the unique needs of industries across a wide range of sectors, including oil and gas, chemical processing, water and wastewater, and power generation. Their Electric Wafer Butterfly Valve is just one of many innovative solutions that they offer to help industries overcome their most pressing challenges and achieve their operational goals.

The introduction of the Electric Wafer Butterfly Valve is a clear example of how technological advancements are shaping the future of industrial control systems. By providing industries with a more efficient, reliable, and precise solution for flow control, this valve is helping businesses improve their operational processes and maintain a competitive edge in today's dynamic market.

As industries continue to evolve and adapt to changing demands and technological advancements, solutions like the Electric Wafer Butterfly Valve will play an increasingly important role in helping businesses optimize their processes, reduce operational costs, and enhance overall performance. With its advanced features and capabilities, this valve is set to become a valuable asset for industries across the globe, as they work to achieve greater efficiency and success in their operations.

Company News & Blog

Leading Turbo Manufacturer in China Offers High-Quality Products in Growing Market

Title: Leading Chinese Turbo Manufacturer Expands its Reach in Global Markets Introduction:In a bid to strengthen its position in the turbocharger industry, a prominent Chinese turbo manufacturer, known for its expertise in cutting-edge technology and efficient production processes, is successfully expanding its reach in the global market. This strategic move comes as the company aims to meet the growing demand for turbochargers across various industries, including automotive, power generation, and marine applications. With a commitment to delivering high-quality turbochargers and exceptional customer service, the Chinese turbo manufacturer is poised to establish itself as a global leader in the industry.Company Overview:Established in [year], the company has consistently been at the forefront of innovation in turbocharger technology. Armed with state-of-the-art research and development facilities, the company has made significant strides in perfecting their turbocharging solutions. With a focus on energy efficiency, reliability, and performance, their product portfolio caters to a diverse range of customer requirements across different sectors.The company's commitment to quality has been recognized by various domestic and international certifications, including ISO 9001, ISO/TS 16949, and ISO 14001. Adhering to stringent quality control measures, the company ensures that its turbochargers meet the highest industry standards while also adopting eco-friendly manufacturing processes.Expanding Global Reach:In recent years, the Chinese turbo manufacturer has made significant inroads overseas, tapping into new markets worldwide. With an extensive distribution network and a strong presence in regions such as North America, Western Europe, and Asia-Pacific, the company has successfully established strong partnerships with leading original equipment manufacturers (OEMs) and aftermarket dealers in these regions.The company's ability to adapt its offerings to local market requirements has been a key driver of its success. By tailoring their turbochargers to suit specific applications, the manufacturer has been able to meet the diverse demands of different industries. This adaptability, coupled with a strong commitment to customer satisfaction, has resulted in accelerated growth in international markets.Technological Advancements:The Chinese turbo manufacturer's success can be attributed to its continuous investment in research and development. By collaborating with leading industry experts, the company has pushed the boundaries of turbocharging technology. This has led to improved efficiency, reduced emissions, and increased power output in their turbochargers, ensuring optimum performance across various applications.Additionally, the company has embraced the latest advancements in manufacturing processes, including intelligent automation and robotics. By implementing cutting-edge technology, they have achieved higher production capacities, enhanced precision, and improved product consistency. Through automated quality control systems, the company guarantees the reliability and durability of its turbochargers, thereby fostering trust among its customers.Future Growth Prospects:Looking ahead, the Chinese turbo manufacturer intends to further expand its global footprint by exploring emerging markets in Africa, the Middle East, and Latin America. With the rise in demand for energy-efficient and environmentally friendly solutions, these regions present significant growth opportunities for the company.Furthermore, ongoing investments in research and development will pave the way for the development of advanced turbocharging solutions, meeting the evolving needs of industries like electric vehicles and renewable energy. By continuously innovating and staying ahead of market trends, the company remains confident in its ability to meet global demand and maintain its position as a leading turbo manufacturer.Conclusion:As the global demand for turbochargers continues to rise, a reputable Chinese turbo manufacturer is strategically positioning itself as a key player in the industry. Through its unwavering commitment to cutting-edge technology, superior quality, and customer satisfaction, the company has successfully expanded its reach in global markets. With a combination of innovative solutions, adaptable offerings, and a dedication to research and development, the Chinese turbo manufacturer is poised for a promising future in the turbocharging industry.

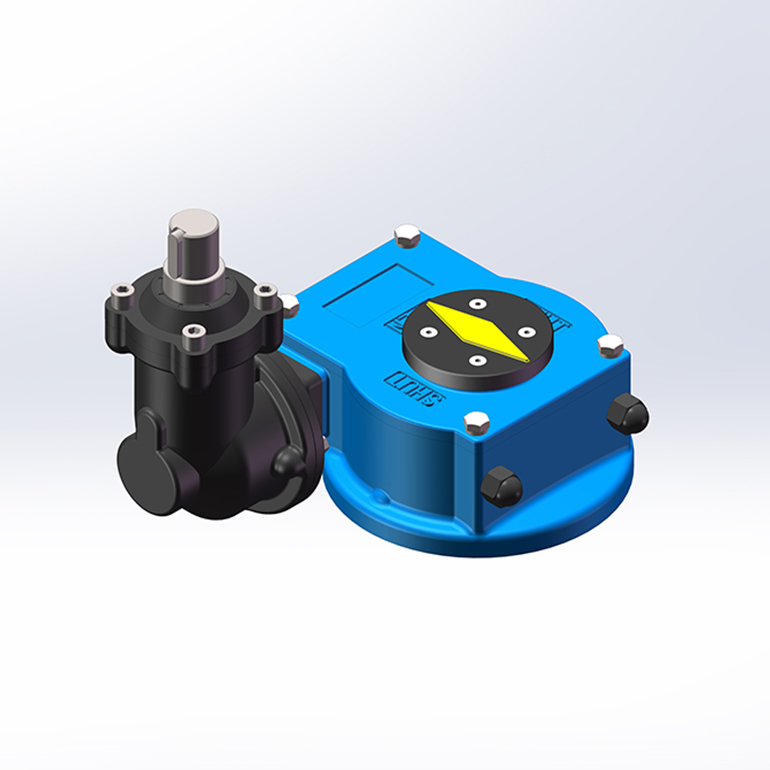

Top Multi-Turn Worm Gearbox Suppliers in China - Get the Best Deals Now!

China Multi-Turn Worm Gearbox Suppliers,In the world of manufacturing and machinery, there is great demand for high-quality, reliable gearboxes. These essential components are critical to the function of a wide range of industrial equipment, from conveyor belts to water treatment plants. As such, it is crucial for companies to have access to reputable suppliers that can provide them with top-of-the-line products.One such supplier is based in China and specializes in the production of multi-turn worm gearboxes. This company has gained a stellar reputation in the industry for its commitment to quality, innovation, and customer satisfaction. With a long history of successful partnerships with businesses around the world, the company has established itself as a leading player in the global gearbox market.The company's multi-turn worm gearboxes are highly regarded for their exceptional performance, durability, and versatility. These gearboxes are designed to provide precision control and high torque in a wide range of industrial applications. They are built to withstand the harshest operating conditions, making them the ideal choice for heavy-duty machinery.What sets this company apart from its competitors is its unwavering dedication to excellence. Its state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing for the production of gearboxes that meet the highest standards of quality and reliability. Additionally, the company has a team of highly skilled engineers and technicians who are constantly working to improve and innovate its products.In addition to its commitment to quality, the company places a strong emphasis on customer satisfaction. It works closely with its clients to understand their specific needs and requirements, and then develops tailored solutions that meet or exceed their expectations. The company's customer-centric approach has earned it a loyal and satisfied customer base, who consistently rely on the company for all their gearbox needs.Furthermore, the company is dedicated to maintaining a sustainable and environmentally friendly operation. It adheres to strict environmental standards and regulations, and is constantly seeking ways to reduce its carbon footprint and minimize waste. This commitment to sustainability has not only garnered the company praise from environmental advocates, but has also positioned it as a responsible and reliable partner for businesses around the world.Looking ahead, the company has ambitious plans for the future. It is continuously investing in research and development to stay ahead of the curve and remain at the forefront of gearbox technology. It is also exploring new market opportunities and expanding its global reach, with the goal of solidifying its position as a leading supplier of multi-turn worm gearboxes.In conclusion, China Multi-Turn Worm Gearbox Suppliers, is a company that has earned its reputation as a top-tier supplier of high-quality gearboxes. With its unwavering commitment to excellence, customer satisfaction, and sustainability, the company is well-positioned to continue its success and make a lasting impact on the global gearbox market. Businesses in need of reliable, high-performance gearboxes need look no further than this esteemed company.

Discover the Advantages and Applications of Bevel Worm Gears

[Company Name] Introduces Innovative Bevel Worm Gear Technology for Enhanced Productivity and Efficiency[City, State], [Month, Day, Year] - [Company Name], a leading provider of advanced industrial solutions, proudly announces the launch of their latest technological innovation - the Bevel Worm Gear. This cutting-edge gear mechanism is poised to revolutionize various industries by offering increased productivity, superior efficiency, and enhanced performance.The Bevel Worm Gear technology is a result of several years of intensive research and development efforts by [Company Name]'s team of highly skilled engineers and scientists. This advanced gear mechanism combines the best features of bevel gears and worm gears, resulting in a highly versatile solution suitable for a wide range of applications.The bevel gear aspect of this technology ensures smooth and efficient power transmission between intersecting shafts. By utilizing specially designed teeth, the gear effectively transfers power at various angles, allowing for enhanced flexibility in machinery design. This enables engineers to create more compact and efficient systems, reducing the overall footprint of machinery without compromising performance.Simultaneously, the worm gear component brings unparalleled efficiency and precision to the table. The worm gear is known for its high gear ratio and self-locking capabilities, which prevent components from moving when not in use. This feature is particularly advantageous in industries that require precision control and safety, as it prevents accidental movement and potential damage to machinery.In addition to its compact design and power transmission capabilities, the Bevel Worm Gear technology offers substantial torque output. This makes it ideal for heavy-duty machinery applications that demand high power and accuracy, such as industrial manufacturing, mining, and construction.Furthermore, [Company Name] has subjected the Bevel Worm Gear technology to rigorous testing to ensure its durability and longevity. The gear mechanism is constructed with premium-grade materials, ensuring resistance to wear, fatigue, and excessive friction. This robust build ensures that machinery equipped with Bevel Worm Gear technology can withstand harsh operating conditions, guaranteeing increased longevity and reduced maintenance costs.With the launch of this game-changing technology, [Company Name] revolutionizes various industries, providing them with a solution that significantly enhances productivity, efficiency, and performance. Manufacturers worldwide can expect increased throughput, reduced downtime, and improved overall operational efficiency, leading to significant cost savings and an enhanced competitive edge."Introducing the Bevel Worm Gear technology is a significant milestone for us," stated [Company Name]'s CEO. "We believe that this innovation will redefine industrial manufacturing processes and enable companies to push the boundaries of what they can achieve. Our team has worked diligently to develop a gear mechanism that seamlessly combines the best features of bevel and worm gears, and we are excited to witness the transformative impact it will have on diverse industries."The Bevel Worm Gear technology is anticipated to disrupt various industries, including automotive, aerospace, energy, and marine. Its versatility and efficiency make it well-suited for numerous applications, ranging from conveyor systems and material handling equipment to robotics and heavy machinery.[Company Name] plans to collaborate with leading manufacturers in different sectors to integrate the Bevel Worm Gear technology into their machinery and enhance their offerings. By joining forces with industry leaders, [Company Name] aims to accelerate the adoption of this revolutionary technology and foster a new era of productivity, efficiency, and innovation.As a key player in the industrial solutions landscape, [Company Name]'s introduction of the Bevel Worm Gear technology establishes the company as a forward-thinking innovator committed to driving progress and enabling industries to thrive in a rapidly evolving world. With this new development, manufacturers can anticipate increased operational capabilities and the ability to overcome complex challenges efficiently and effectively.

Ultimate Guide to Double Acting Pneumatic Actuators: Everything You Need to Know

Double Acting Pneumatic Actuator Revolutionizes the Control IndustryIn today's fast-paced world, industries are constantly seeking to improve efficiency and optimize control systems. One company at the forefront of this innovative movement is [Company Name], a leading provider of advanced control solutions. With their latest release of the Double Acting Pneumatic Actuator, [Company Name] continues to push the boundaries of what is possible in the control industry.[Company Name] is a global company with a strong commitment to delivering high-quality and reliable control products. With an extensive history of innovation and a dedication to customer satisfaction, [Company Name] has earned a reputation as a trusted partner for industries ranging from oil and gas to power generation and water treatment.The Double Acting Pneumatic Actuator is the latest addition to [Company Name]'s extensive line of control products. This cutting-edge actuator utilizes pneumatic power to provide versatile and precise control of valves and other industrial equipment. Its double-acting design allows for both opening and closing of valves, providing exceptional flexibility and reliability in a wide range of applications.One of the key advantages of the Double Acting Pneumatic Actuator is its robust construction and durability. Built to withstand harsh industrial environments, this actuator is designed to deliver consistent performance even in the most demanding conditions. Its high-quality materials and precision engineering ensure long-term reliability, reducing maintenance costs and downtime for end-users.Moreover, the Double Acting Pneumatic Actuator offers exceptional control accuracy, thanks to its advanced pneumatic technology. This level of precision allows for seamless integration into complex control systems, enabling industries to achieve optimal performance and efficiency. With its responsive and dependable operation, this actuator is well-suited for critical applications where precise control is essential.In addition to its technical capabilities, the Double Acting Pneumatic Actuator is designed with user-friendly features that simplify installation and operation. Its compact size and lightweight design make it easy to handle and install, while its intuitive controls streamline setup and adjustment. This user-centric approach reflects [Company Name]'s commitment to delivering control solutions that are not only powerful but also practical and easy to use.As with all of [Company Name]'s products, the Double Acting Pneumatic Actuator undergoes rigorous testing and quality assurance to ensure its performance and reliability. With a focus on exceeding industry standards and customer expectations, [Company Name] stands behind the quality and dependability of its products, providing peace of mind to end-users.Furthermore, [Company Name] provides extensive technical support and customer service to assist with the selection, installation, and maintenance of the Double Acting Pneumatic Actuator. With a global network of knowledgeable professionals, [Company Name] is dedicated to helping its customers maximize the value of their control systems and achieve operational excellence.In conclusion, the release of the Double Acting Pneumatic Actuator represents another milestone in [Company Name]'s ongoing commitment to innovation and excellence in the control industry. With its advanced technology, robust construction, and user-friendly design, this actuator sets a new standard for precision and reliability. As industries continue to evolve and demand higher levels of control and efficiency, [Company Name] remains at the forefront, providing cutting-edge solutions that empower businesses to thrive in the modern world.

Worm and Helical Gears: The Differences You Should Know

Title: Innovations in Worm and Helical Gear Technology Revolutionize Industrial MachinerySubtitle: Leading Industrials Company Repositions Manufacturing Industry with Advanced Gear SolutionsIntroduction:In an era of rapid industrialization and automation, advancements in gear technology play a pivotal role in optimizing the efficiency and functionality of various industrial machinery. One such company that has been at the forefront of this innovation is {}, an industry-leading manufacturer of high-quality worm and helical gears. This article will explore the substantial contributions made by the company to gear technology and its significant impact on the manufacturing industry.Revolutionizing Industrial Machinery with Worm and Helical Gear Technology:Worm gears and helical gears represent two fundamental types of gears used extensively in various industries. Worm gears, characterized by a threaded screw-like gear (worm) and a toothed wheel (worm wheel), excel in applications requiring high gear ratios and self-locking capabilities. On the other hand, helical gears are widely praised for their smooth operation, high load-carrying capacity, and improved contact ratios due to their angled teeth.In a move that reshaped the gear manufacturing landscape, {} has developed cutting-edge worm and helical gear solutions tailored to meet the evolving needs of modern industries. Utilizing state-of-the-art machinery and advanced materials, the company sets new benchmarks in terms of gear precision, durability, and performance.Advanced Materials and Manufacturing Techniques:The success of {} can be largely attributed to its relentless pursuit of excellence in gear manufacturing. The company invests heavily in research and development, constantly exploring ways to improve gear performance and lifespan. Through the use of high-quality alloy steels, tempered and processed with precision heat treatment, {}, ensures that its gears exhibit exceptional strength, hardness, and resistance to wear and tear.Additionally, the company employs cutting-edge computer-controlled machinery and advanced gear-grinding techniques to enhance the dimensional accuracy and surface finish of their gears. This ensures smooth and silent operation, reducing friction and enhancing overall machinery efficiency. The accuracy achieved by {} in the manufacturing process translates into higher torque transmission capabilities and improved load capacity, enabling industries to push the boundaries of innovation and productivity.Application-Specific Customization:Understanding that different industries have unique requirements, {} offers a wide range of customization options for their worm and helical gears. By working closely with customers, the company tailors gear solutions to match specific application demands, ensuring optimal performance, reduced noise levels, and increased longevity.Additionally, {} provides comprehensive engineering support, empowering industries to integrate their gear solutions seamlessly into custom machinery designs. This collaborative approach by {} promotes efficient and streamlined manufacturing processes across a broad spectrum of industries including automotive, robotics, energy, and precision equipment manufacturing, to name a few.Innovations for the Future:The quest for innovation and continuous improvement is deeply ingrained in the culture of {}. The company constantly explores advanced gear designs and emerging technologies to remain ahead in a competitive market. By harnessing their technical expertise and engineering capabilities, {} is committed to pioneering solutions that anticipate the evolving needs of industries and drive progress in the manufacturing sector.Moreover, {} recognizes the significance of sustainability and ecological balance. Through careful material selection and eco-efficient manufacturing processes, the company aims to minimize environmental impact without compromising on gear quality or performance.Conclusion:As the manufacturing industry continues to evolve, efficient and reliable gear solutions are crucial for optimal machinery performance. With the relentless commitment to innovation and precision, {} has emerged as a leading provider of worm and helical gear solutions. Their advanced materials, cutting-edge manufacturing techniques, and customer-centric approach have revolutionized various industries, fostering increased productivity and driving progress in the manufacturing sector. As {} looks towards the future, their continued dedication to research and development ensures that they remain at the forefront of gear technology, enabling industries to surpass current limitations and embrace new heights of efficiency and functionality.

Worm and Wheel Gearbox: Understanding its Function and Importance

Worm And Wheel Gearbox, a crucial component used in various industrial machines, has been making waves in the manufacturing industry for its exceptional performance and reliability. This innovative gearbox has been gaining widespread recognition for its ability to provide smooth and precise motion control in a wide range of applications, from automotive assembly lines to packaging equipment.With an impressive track record of delivering high-quality products and outstanding customer service, {} has been at the forefront of providing top-of-the-line Worm And Wheel Gearbox solutions to businesses worldwide. The company prides itself on its commitment to excellence and continuous innovation, which has established its position as a trusted leader in the industry.The Worm And Wheel Gearbox, also known as a worm gear set, is a type of gear arrangement that consists of a worm (a screw-like gear) and a wheel (a cylindrical gear). This unique design allows for high torque output with a smooth and quiet operation, making it ideal for applications that require precise and reliable motion control. The gearbox is widely used in various industries, including manufacturing, robotics, aerospace, and automotive, where its durability and efficiency are highly valued.One of the key advantages of the Worm And Wheel Gearbox is its ability to provide a high gear ratio in a compact and lightweight package. This makes it an ideal choice for space-constrained applications where size and weight are critical considerations. Additionally, the gearbox's design also allows for high efficiency and minimal maintenance, reducing overall operating costs for businesses.{} has been at the forefront of developing and producing advanced Worm And Wheel Gearbox solutions that meet the diverse needs of its customers. The company's team of skilled engineers and technicians work tirelessly to design and manufacture gearboxes that exceed industry standards and deliver exceptional performance in real-world applications.Furthermore, {} offers a wide range of customization options to tailor Worm And Wheel Gearbox solutions to specific customer requirements. This flexibility allows businesses to integrate the gearbox seamlessly into their existing systems, optimizing performance and productivity. With a strong focus on customer satisfaction, the company ensures that each gearbox is rigorously tested and meticulously inspected to guarantee top-quality and reliability.In addition to its dedication to providing superior products, {} is also committed to environmental sustainability and ethical business practices. The company's manufacturing processes adhere to strict environmental regulations, and it actively seeks out opportunities to reduce waste and minimize its carbon footprint. Furthermore, {} prioritizes ethical sourcing and fair labor practices, ensuring that its supply chain upholds the highest standards of integrity and responsibility.As the demand for reliable motion control solutions continues to grow across various industries, Worm And Wheel Gearbox is expected to play a pivotal role in driving operational efficiency and innovation. With {}'s unwavering dedication to excellence and its proven track record of delivering top-quality gearboxes, the company is well-positioned to meet the evolving needs of its customers and contribute to the advancement of the manufacturing industry.In conclusion, the Worm And Wheel Gearbox has emerged as a game-changing technology in the world of motion control, providing businesses with a highly efficient and reliable solution for a wide range of applications. With {} leading the charge in developing and manufacturing advanced gearboxes, businesses can expect to benefit from cutting-edge solutions that elevate their performance and productivity. As the industry continues to evolve, {} remains steadfast in its commitment to innovation, excellence, and sustainability, ensuring that its Worm And Wheel Gearbox solutions exceed expectations and set new standards for the industry.

Discover the Advantages of Electric Actuated Ball Valves for Efficient Control

Title: Revolutionary Electric Actuated Ball Valve Redefines Industry StandardsIntroduction:In recent years, technological advancements have revolutionized various industries and brought about significant improvements in efficiency and performance. One such breakthrough innovation is the Electric Actuated Ball Valve, developed by a pioneering company in the field of valve automation and control systems. This groundbreaking product promises to redefine industry standards by offering unparalleled precision, control, and reliability. Manufacturers across multiple sectors are eagerly adopting this technology, recognizing the significant benefits it can bring to their operations.Key Features and Benefits:The Electric Actuated Ball Valve showcases a host of remarkable features that set it apart from traditional valve systems. The company’s unwavering commitment to quality and innovative design is evident in this cutting-edge solution. Here are some key features and benefits provided by this revolutionary valve:1. Enhanced Precision and Control: With the integration of advanced electric actuation technology, this valve ensures precise control over fluid flow, allowing for swift and accurate adjustments. This leads to improved operational efficiency and reduces the risk of costly errors or delays.2. Versatility and Adaptability: The Electric Actuated Ball Valve is designed to accommodate a diverse range of applications, making it highly versatile. Its adaptability allows for seamless integration into existing systems and the ability to meet various operational requirements across industries, including oil and gas, water treatment, chemical processing, and many others.3. Unmatched Reliability: The valve’s robust construction, utilizing high-quality materials, ensures exceptional dependability even in demanding environments. The company’s rigorous quality control measures guarantee durability, longevity, and minimal maintenance requirements, resulting in significant cost savings for customers.4. Improved Safety Measures: Safety has always been a primary concern in industrial applications. This electrically actuated valve incorporates fail-safe mechanisms, ensuring reliable shut-off in emergencies and preventing potential disasters. By prioritizing safety, the valve alleviates concerns and instills greater peace of mind among operators and personnel.5. Advanced Monitoring and Reporting: The integration of intelligent automation technology allows for seamless monitoring and data acquisition. This feature enables real-time feedback on crucial parameters such as pressure, temperature, and flow rates. The valve system can share this information with centralized control systems, facilitating proactive maintenance and resource optimization.Market Impact and Industry Outlook:The Electric Actuated Ball Valve is poised to reshape the valve automation landscape and disrupt conventional practices in multiple industries. This revolutionary technology is rapidly gaining traction, with installation rates surging across diverse sectors globally. The valve’s potential to enhance operational efficiency, reduce energy consumption, and optimize processes has not gone unnoticed, and it is expected to become a staple in modern industrial automation.With an increasing focus on sustainability and energy efficiency, the demand for smart valve solutions is set to skyrocket in the coming years. The Electric Actuated Ball Valve, with its advanced control capabilities and environmental-friendly features, is primed to take center stage. Manufacturers that adopt this cutting-edge technology will gain a competitive edge in their respective industries by significantly improving productivity, reducing costs, and mitigating risks.Conclusion:The advent of the Electric Actuated Ball Valve represents a groundbreaking milestone in the valve automation field. Its innovative design, remarkable functionality, and numerous advantageous features have positioned it as a game-changer in the industry. As more manufacturers embrace this technology, it will redefine industry standards and set new benchmarks for precision, control, and reliability. The future of valve automation is here, and it is undoubtedly electric.

Exploring the Importance and Functionality of Worm Gear Valves

Worm Gear Valve: Revolutionizing Fluid Control in Industrial Applications[date]In today's rapidly evolving industrial landscape, efficient fluid control systems are paramount to ensure smooth operations and the longevity of machineries. Companies operating in various sectors have adapted to the ever-increasing demand for reliable and precise fluid control solutions. One such ground-breaking innovation transforming the way industrial fluid control is being executed is the Worm Gear Valve.Worm Gear Valve, designed and manufactured by [Company Name], is making waves in the industry for its exceptional performance, durability, and unparalleled precision. Its cutting-edge engineering, coupled with state-of-the-art materials, has positioned it as a game-changer in fluid control applications across a wide range of industries.The Worm Gear Valve possesses a number of unique features that set it apart from conventional valves currently available in the market. One of its key distinguishing attributes is its worm gear mechanism, which allows for precise control and adjustment of fluid flow, making it an ideal choice for applications that require accuracy and reliability. This mechanism offers a smooth and easy operation, enabling operators to finely tune the fluid flow to suit their specific requirements, ultimately resulting in optimal system performance.Furthermore, the Worm Gear Valve's robust construction ensures longevity and durability, making it suitable for demanding industrial environments. Crafted from high-quality materials, such as stainless steel and reinforced polymers, this valve can withstand harsh conditions, increase service life, and minimize maintenance costs. With its exceptional resistance to corrosion, erosion, and wear, the Worm Gear Valve continues to deliver consistent performance even under the harshest operating conditions.[Company Name], a prominent leader in industrial fluid control solutions, has been successfully supplying the Worm Gear Valve to customers worldwide. The company's extensive expertise and dedicated research and development team have played a crucial role in developing this ground-breaking valve technology. With a commitment to innovation, quality, and customer satisfaction, [Company Name] has become a trusted partner for industries requiring precise fluid control solutions.One of the key aspects of [Company Name] is its customer-centric approach. The company believes in working closely with customers to understand their unique challenges and requirements. This collaborative engagement enables [Company Name] to provide tailored solutions that address specific fluid control needs efficiently and effectively.Another crucial strength of [Company Name] lies in its comprehensive after-sales service and support. Recognizing the importance of uninterrupted operations, the company ensures that their team of highly skilled technicians is readily available to provide on-site assistance and timely maintenance services. [Company Name] aims to build long-lasting relationships with their customers, extending their support beyond the initial purchase to ensure continued satisfaction and reliability.Since its introduction, the Worm Gear Valve has made a significant impact in a wide range of industries, including oil and gas, chemical manufacturing, water treatment, and power generation. Its application extends from industrial processing plants to critical utilities, where precision control is essential for both safety and operational excellence. A valve that can address the varied demands of these industries is a testament to its versatility and adaptability.In conclusion, the Worm Gear Valve from [Company Name] emerges as a groundbreaking innovation revolutionizing fluid control across numerous industrial sectors. With its precise control, robust construction, and exceptional reliability, this valve is rapidly becoming the preferred choice for industries that demand optimal performance, operational efficiency, and extended service life. As [Company Name] continues to lead the way in innovative fluid control solutions, the industry can expect continuous advancements that will shape the future of industrial fluid control systems.

Discover the Remarkable Features and Applications of a Large Worm Gear

Title: Innovative Worm Gear Revolutionizes Large-Scale Industrial ApplicationsIntroduction:In the realm of large-scale industrial applications, a significant breakthrough has been achieved with the development of an advanced worm gear system. This cutting-edge technology, designed by an industry-leading company (), promises to revolutionize various sectors by enhancing efficiency, reliability, and sustainability. With its exceptional performance capabilities, this worm gear system is set to address challenges faced by industries worldwide and propel them towards a more productive and environmentally conscious future.Section 1: Worm Gear Enigma UnveiledThe newly developed worm gear system showcases an innovative design that surpasses the limitations of traditional gearbox solutions. Its primary components, the worm wheel and gear, have been meticulously engineered to ensure exceptional power transmission efficiency. Through precision manufacturing techniques and advanced materials, this worm gear achieves higher torque capacity, reduced frictional losses, and improved wear resistance.Section 2: Industry ApplicationsThe versatility of this worm gear system enables its integration across various industries. In the mining sector, it offers a reliable and efficient solution for heavy machinery and extraction equipment. Additionally, the system's ability to handle large loads makes it ideal for applications in rail transportation, enabling smooth and precise movement of trains and trams.In the renewable energy sector, the worm gear system proves to be a significant asset in wind turbine installations. Its robust design ensures optimal power transmission, enhancing the energy output and operational lifespan of these structures. By harnessing the power of this advanced gear system, renewable energy generation can be maximized, thereby contributing to a greener environment.Section 3: Importance of Efficiency and ReliabilityEfficiency and reliability are pivotal aspects in any industry. The worm gear system offers considerably higher efficiency compared to traditional gearboxes. Its advanced lubrication system reduces power losses and heat generation, resulting in more efficient operations. Moreover, the enhanced wear resistance capabilities of this system contribute to prolonged equipment lifespan, reducing maintenance costs and downtime.Section 4: Sustainable Manufacturing TechniquesIn line with the escalating global concern over sustainability, the company responsible for introducing this worm gear system () is committed to adopting sustainable manufacturing practices. By incorporating eco-friendly materials, reducing energy consumption during production, and optimizing resource usage, the company strives to minimize its carbon footprint. This dedication to sustainability aligns with the company's broader mission to contribute to a more environmentally friendly industrial landscape.Section 5: Future Prospects and ConclusionAs industries continue to demand enhanced performance and sustainability, the worm gear system emerges as a game-changer. The innovative design, coupled with its ability to improve efficiency, reliability, and sustainability, positions this gear system as the ultimate solution for large-scale industrial applications. With its successful integration in various sectors, efficiency gains and cost savings are expected to be realized, benefitting both businesses and the environment alike.In conclusion, the introduction of a state-of-the-art worm gear system showcases a breakthrough in the field of large-scale industrial applications. The advanced design, efficiency, and reliability offered by this gear system have the potential to transform industries such as mining, transportation, and renewable energy. By prioritizing sustainability in its manufacturing process, the company () demonstrates its commitment to a greener future. With the revolutionary worm gear technology, industries worldwide can achieve higher productivity, reduced costs, and a more sustainable approach to operations.

Different Types and Uses of Worm Wheel Gears Explained

The Worm Wheel Gear (WWG) is a unique and advanced technology that is revolutionizing the manufacturing industry. The WWG works by transmitting rotational motion at a right angle with the help of worm gear and wheel. This innovative design has made the WWG the go-to choice for companies that desire precision, efficiency and cost savings in their manufacturing processes.WWG is a product of German ingenuity and has been in existence for over 100 years. Today, it is widely used in the automotive industry, pharmaceuticals, food, and beverage, as well as numerous other industrial applications. The technology behind the WWG has been fine-tuned over the years to deliver maximum results with minimal human intervention.One of the greatest advantages of WWG is that it offers high torque capacity, making it ideal for applications requiring low speed, high torque requirements. Additionally, the WWG is less prone to damage from shock loading and can tolerate misalignment between the worm gear and the wheel. This has led to improved performance and durability and a decrease in downtime due to mechanical failures.The WWG is manufactured with high-quality materials and precision engineering, ensuring reliability and longevity. WWG manufacturers are consistently upgrading their technology to meet the industries’ ever-changing demands. For example, many producers have incorporated computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to increase accuracy, reduce waste, and decrease production time.As a responsible corporate citizen, a reputable company has ventured into the production of WWG with an eye on environmental sustainability. A select range of environmentally-friendly gear oils was introduced to work with the WWG to maintain superior performance while reducing environmental impact.Moreover, the production process of Worm Wheel Gears has been honed to reduce environmental damage from waste. The manufacturing waste such as trimmings and filings is recycled into raw material for the production of new WWGs. Because of this, the company's production process is zero-waste. Additionally, the energy used for production is generated wholly from renewable energy sources, thereby reducing the carbon footprint.The success of WWG has continued to grow since its inception, with more and more companies understanding its benefits, building their machines around it. The technology serves large corporations and small to medium enterprises (SME); it boasts of reducing operation costs, increasing productivity, and providing the highest-quality products for manufacturing companies.In conclusion, the WWG is a revolutionary technology that is shaking up the manufacturing industry. The benefits of its use are numerous, including precision, efficiency, durability, cost savings, and environmental sustainability. WWG has become the preferred choice for many companies worldwide, and its growth is predicted to continue as more businesses understand its advantages. Companies that adopt WWG in their production processes will undoubtedly experience a significant improvement, both in their efficiency and output.