High-Performance Worm Gearbox for Helicopters: Latest News and Updates

By:Admin

In the world of industrial machinery, precision and efficiency are paramount. Heli Worm Gearbox, a leading manufacturer of high-quality gearboxes, has been at the forefront of providing reliable and innovative solutions for various industrial applications. With a strong emphasis on research and development, Heli Worm Gearbox has consistently delivered products that meet the highest standards of performance and durability.

Founded in the early 1990s, Heli Worm Gearbox has steadily grown into a global leader in the gearbox industry. The company's dedication to quality and customer satisfaction has earned them a solid reputation among their clients. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, Heli Worm Gearbox is well-equipped to meet the ever-evolving demands of the market.

One of the key products in Heli Worm Gearbox's portfolio is their worm gearboxes. These gearboxes play a crucial role in a wide range of industrial applications, including conveyor systems, packaging machinery, and material handling equipment. The unique design of worm gearboxes allows for high torque transmission and smooth, quiet operation, making them an ideal choice for heavy-duty industrial machinery.

Heli Worm Gearbox's worm gearboxes are designed and manufactured to exacting standards, ensuring optimal performance and reliability. The company's commitment to using premium quality materials and advanced manufacturing processes sets their gearboxes apart from the competition. Each gearbox undergoes rigorous testing to ensure that it meets the stringent performance criteria set by the industry.

Moreover, Heli Worm Gearbox offers a wide range of customization options, allowing their customers to tailor the gearboxes to their specific requirements. Whether it's modifying the gear ratio, output shaft configuration, or mounting options, the company's engineering team works closely with their clients to develop bespoke solutions that perfectly fit their needs.

In addition to their exceptional product line, Heli Worm Gearbox excels in providing comprehensive technical support and after-sales service. Their team of engineers and technicians is readily available to assist customers with installation, maintenance, and troubleshooting, ensuring optimal performance and longevity of their gearboxes.

Furthermore, Heli Worm Gearbox is dedicated to sustainable manufacturing practices. The company is committed to minimizing its environmental impact through the efficient use of resources and the implementation of eco-friendly processes. By prioritizing sustainability, Heli Worm Gearbox aims to contribute to a greener and more sustainable future for the industry.

As a testament to their relentless pursuit of excellence, Heli Worm Gearbox has garnered numerous certifications and accolades for their outstanding products and business practices. With a strong focus on innovation and continuous improvement, the company continues to push the boundaries of gearbox technology, setting new benchmarks for the industry.

In conclusion, Heli Worm Gearbox stands as a symbol of reliability, quality, and innovation in the gearbox industry. Their worm gearboxes, backed by decades of expertise and a commitment to customer satisfaction, have become indispensable components for countless industrial applications around the world. With a clear vision for the future and a passion for excellence, Heli Worm Gearbox is set to maintain its position as a leader in the industry for years to come.

Company News & Blog

The Future of High-Performance Engine Technology: Electromagnetic Valve Actuators

[ Company Name ] Introduces Innovative Electromagnetic Valve Actuator for Enhanced Performance[ Location ], [ Date ] - [ Company Name ], a leading provider of advanced technological solutions, has recently unveiled its latest innovation in the field of electromagnetic valve actuators. This groundbreaking product is set to revolutionize the way industries operate and significantly enhance performance across various sectors.The electromagnetic valve actuator, developed by [ Company Name ], represents an amalgamation of cutting-edge technology and industry expertise. With an emphasis on precision and reliability, this state-of-the-art device aims to meet the increasing demands of modern-day industries for efficient and accurate valve control.One of the key distinguishing features of this new actuator is its unrivaled speed and responsiveness. By leveraging advanced electromagnetic technology, [ Company Name ] has engineered an actuator that can sense and respond to even the most minute changes in valve position within milliseconds. This unprecedented speed ensures that critical valves are adjusted promptly, minimizing downtime and optimizing overall productivity.Another notable advantage of the electromagnetic valve actuator is its exceptional accuracy. Leveraging highly sophisticated control algorithms and intelligent sensing mechanisms, this actuator guarantees precise and repeatable control of valve parameters. Moreover, it provides real-time feedback to operators, enabling them to monitor valve conditions and performance with utmost accuracy, ensuring optimal system operation.In addition to its outstanding performance, the electromagnetic valve actuator offers uncompromising durability and longevity. Constructed with high-quality materials and rigorously tested to withstand extreme conditions, this actuator boasts an extended lifecycle, reducing the need for frequent repairs and replacements. Such robustness, coupled with its ease of maintenance, makes it an ideal choice for industries operating in demanding environments.Moreover, the electromagnetic valve actuator by [ Company Name ] features a compact and lightweight design, optimizing space utilization and simplifying installation. Its user-friendly interface allows for effortless integration with existing systems, guaranteeing a seamless transition for operators and minimal disruptions to ongoing operations.Furthermore, environmental consciousness lies at the heart of this new technology. [ Company Name ] has incorporated energy-efficient features into the electromagnetic valve actuator, ensuring reduced power consumption, which ultimately translates into cost savings for industries whilst mitigating their carbon footprint. With growing emphasis on sustainable practices, this actuator aligns with global initiatives aimed at protecting our planet."Through our extensive research and development efforts, we are proud to introduce this innovative electromagnetic valve actuator," said [ Company Name's ] spokesperson. "We believe that this breakthrough technology will empower industries to achieve new heights of productivity and efficiency, while reducing operational costs and environmental impact."With its countless benefits and unparalleled performance, the electromagnetic valve actuator by [ Company Name ] is already attracting attention across various industry sectors. Applications in oil and gas, petrochemicals, power generation, water treatment, and many other fields can significantly benefit from this technological advancement.As [ Company Name ] continues to push the boundaries of technological innovation, their latest electromagnetic valve actuator undoubtedly establishes them as a trailblazer in the industry. With its robustness, precision, and environmentally conscious design, this actuator is set to reshape industrial processes and drive sectors towards a more prosperous and sustainable future.

New Spring Return Pneumatic Actuator Offers Efficient Valve Control

Title: Innovative Spring Return Pneumatic Actuator Revolutionizes Industrial AutomationSubtitle: Introducing the Cutting-Edge Actuator Technology by a Renowned Industry LeaderDate: [Insert Date][City, State] - As industrial automation continues to evolve, [Company Name] has taken a significant leap forward with its ground-breaking Spring Return Pneumatic Actuator. This advanced product offers enhanced efficiency, durability, and reliability in the field of industrial valve control systems. With an exceptional track record in delivering high-quality solutions, [Company Name] continues to revolutionize the automation industry, empowering businesses in various sectors to achieve optimal performance and cost-effectiveness.[Company Name] has been at the forefront of innovation for over [number of years] years. The company has consistently developed cutting-edge technologies, pushing the boundaries of what is possible in modern industrial automation. Today, they proudly introduce their latest achievement: the Spring Return Pneumatic Actuator, designed to meet the increasingly demanding requirements of diverse industrial applications.The Spring Return Pneumatic Actuator is a highly efficient and versatile device that precisely controls various valve applications, including on/off, quarter-turn, and multi-turn scenarios. Equipped with state-of-the-art engineering, this actuator allows for swift, precise, and fail-safe valve operations, ensuring optimal system performance even in the harshest industrial environments.One of the key features of this actuator is its innovative spring mechanism. The powerful springs provide a fail-safe operation, enabling the actuator to automatically return to a pre-set position in the event of a power or air failure. This crucial attribute ensures the safety of personnel and minimizes potential damage to equipment, making it an ideal solution for critical industrial processes.The Spring Return Pneumatic Actuator by [Company Name] offers remarkable flexibility, accommodating valves of various sizes, types, and configurations. From compact and lightweight designs suitable for small valves to heavy-duty options for larger applications, the actuator can be customized to meet the specific needs of any industry. This adaptability allows businesses to enhance productivity, reduce downtime, and streamline their operational processes.Unlike traditional pneumatic actuators, the Spring Return Pneumatic Actuator boasts exceptional durability, thanks to its high-quality materials and rigorous manufacturing standards. With advanced corrosion resistance, it can withstand harsh operating conditions, ensuring a longer service life and reducing maintenance costs. This durability makes it a preferred choice for industries such as oil and gas, petrochemical, wastewater treatment, and others that demand superior performance and reliability.In addition to its exceptional functionality, the actuator's design offers easy installation, operation, and maintenance. It has a compact and lightweight construction, simplifying the integration process and minimizing space requirements. Moreover, its modular design enables quick and hassle-free maintenance, reducing downtime and eliminating unnecessary expenses."Introducing the Spring Return Pneumatic Actuator is a significant milestone for us," said [Person Name], [Job Title] at [Company Name]. "We have always been committed to providing our clients with cutting-edge technologies that enhance their operational efficiencies and ultimately improve their bottom line. This actuator represents our dedication to innovation and the relentless pursuit of excellence."With its unparalleled performance, exceptional durability, and user-friendly features, the Spring Return Pneumatic Actuator by [Company Name] is reshaping the industrial automation landscape. As industries strive for increased efficiency, reliability, and safety, this innovative solution delivers on all fronts.[Company Name]'s Spring Return Pneumatic Actuator is truly a game-changer, setting new industry standards and propelling businesses towards a more productive and sustainable future. With their passion for excellence and their commitment to pushing boundaries, [Company Name] proves yet again that they are leaders in providing cutting-edge automation solutions.About [Company Name]:[Company Name] is a renowned industry leader specializing in the development and manufacturing of high-quality automation solutions. With a history of delivering innovative products, superior quality, and exceptional customer service, [Company Name] continues to remain at the forefront of industrial automation. Through their wide range of groundbreaking technologies, the company empowers businesses across various sectors to achieve optimal performance and cost-effectiveness.For more information about the Spring Return Pneumatic Actuator and [Company Name]'s automation solutions, please visit [Website URL].Contact:[Contact Name][Company Name][Email Address][Phone Number]

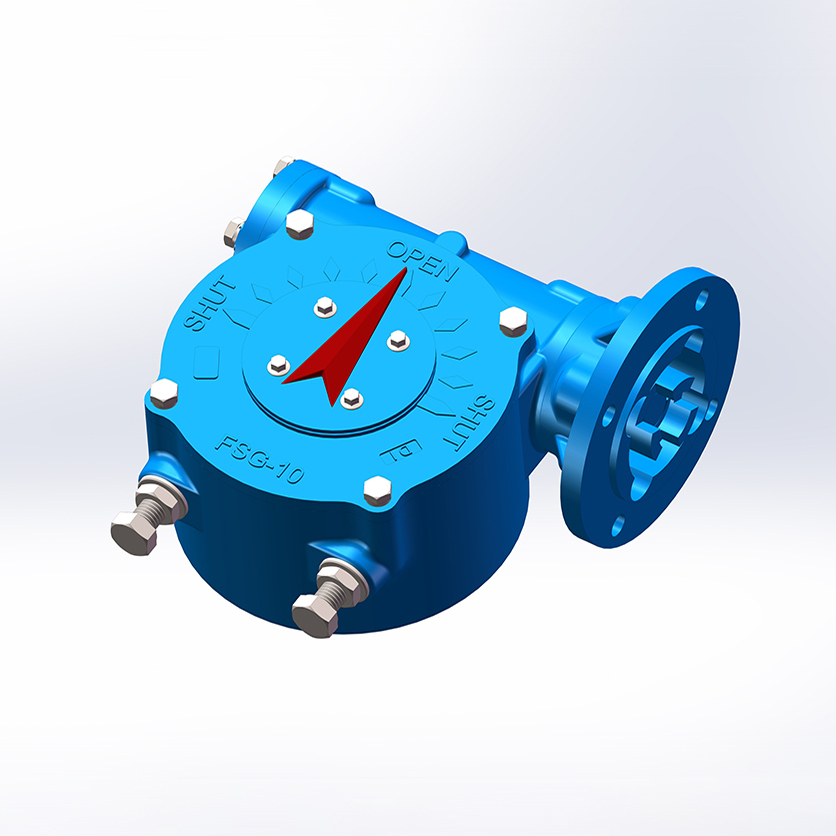

Enhancing Performance and Control: Gearbox for Gate Valves Revealed in Latest News

[Company Introduction]{Insert Company Name} is an industry-leading manufacturer that specializes in producing high-quality gate valve gearboxes, among other industrial products. With a strong commitment to innovation, precision engineering, and customer-centricity, {Company Name} has earned a reputation for delivering top-notch solutions to its valued clients worldwide.Established over two decades ago, {Company Name} has steadily grown to become a trusted name in the valve and gearbox manufacturing industry. The company's state-of-the-art production facilities, combined with a team of skilled engineers and technicians, enable them to design and develop cutting-edge products that meet the most demanding industry requirements.With a focus on continuous improvement, {Company Name} prioritizes research and development, investing heavily in the latest technologies and advancements. This approach ensures that their gate valve gearboxes are not only of the highest quality but also incorporate the latest industry trends and innovations.{Company Name} takes great pride in its commitment to providing exceptional customer service. They believe in building long-lasting partnerships with their clients, understanding their unique needs, and providing tailored solutions to achieve optimal results. Whether it's a small-scale project or a large industrial application, {Company Name} is dedicated to offering superior products and unparalleled service.With a global presence, {Company Name} serves a diverse range of industries, including oil and gas, chemical, petrochemical, power generation, water treatment, and more. Their gate valve gearboxes have garnered widespread recognition for their reliability, durability, and high performance, making them a preferred choice for clients across the globe.[News Content]Title: Gate Valve Gearbox: A Reliable Solution for Industrial ApplicationsDate: [Insert Date]{City, State} - {Company Name}, a renowned manufacturer of advanced industrial products, is proud to introduce its latest offering, the Gate Valve Gearbox. Combining years of engineering expertise with cutting-edge technology, {Company Name} has developed a high-performance gearbox that offers unparalleled precision and reliability in demanding industrial applications.Gate valves play a crucial role in regulating fluid flow within industrial systems. Efficient operation and control of these valves are essential for ensuring the smooth functioning of complex processes. The gate valve gearbox provided by {Company Name} addresses this need, offering a robust and efficient solution that surpasses industry standards.One of the key features of {Company Name}'s gate valve gearbox is its superior design. Meticulously engineered by a team of highly skilled professionals, the gearbox exhibits excellent mechanical strength and durability, ensuring long-lasting performance even under the most challenging conditions. This reliability minimizes downtime, enhances productivity, and contributes to overall cost savings for industrial operators.In addition to its exceptional design, the gate valve gearbox boasts remarkable precision, allowing for accurate and smooth valve operation. The gearbox's precise gearing mechanism ensures a secure and consistent shut-off, enabling precise control over fluid flow. This level of control is particularly crucial in industries where even slight variations in flow rates can have significant consequences.Another standout feature of {Company Name}'s gate valve gearbox is its adaptability. The gearbox can be easily integrated with a variety of gate valves, catering to diverse industrial requirements. This flexibility eliminates the need for expensive modifications or replacements, ensuring a seamless fit into existing systems and significantly reducing installation costs.Moreover, {Company Name} is committed to upholding the highest quality standards in all its products. The production and assembly processes undergo rigorous testing and inspection, ensuring that every gearbox leaving their facilities adheres to stringent quality benchmarks. This dedication to quality translates into enhanced performance, longevity, and reliability for end-users.As an environmentally-conscious company, {Company Name} remains committed to sustainable practices. The gate valve gearbox is designed to minimize energy consumption, reducing the overall carbon footprint of industrial operations. Furthermore, strict adherence to international safety standards ensures that the gearbox meets all regulatory requirements while prioritizing worker safety.With their latest innovation, {Company Name} aims to provide industrial operators with a powerful tool that optimizes operational efficiency. The gate valve gearbox enhances system control, delivers exceptional performance, and contributes to a safe and sustainable industrial environment. As leaders in the industry, {Company Name} continues to push boundaries, setting new standards for excellence and reliability.In conclusion, {Company Name}'s gate valve gearbox presents a compelling solution for industrial applications. With its exceptional design, precision engineering, adaptability, and commitment to quality, {Company Name} has once again demonstrated their leadership in providing high-performance industrial products. As industrial operations become more complex, the gate valve gearbox by {Company Name} is poised to become an indispensable component for those seeking reliability, efficiency, and enhanced productivity in their processes.

Revolutionary Actuator Technology Set to Overhaul Industry Standards

Actuators are an essential component in the modern world of automation and control systems. In the case of industrial processes, a linear actuator refers to the devices that convert rotational motion into linear motion. An excellent example of such devices is the Neumax Actuator, which is tailored to a broad range of industrial applications.The Neumax Actuator is designed by professionals who have over the years accumulated vast experience in the industrial automation sector. The Neumax Actuator is designed with powerful, durable, and efficient components, ensuring that it meets the stringent demands of modern industrial processes.One of the most significant benefits of the Neumax Actuator is its flexibility and adaptability to a wide range of tasks. It has the ability to execute varied functions, including gate opening and closing in a water treatment facility, control of valves in pipelines, and regulation of pressure in chemical processing plants.The Neumax Actuator is also designed to ensure exceptional performance. It operates with a high level of precision and accuracy, which is essential for controlling processes with minimal error rates. Additionally, its robust design ensures that it can withstand extreme conditions such as harsh weather, high humidity, and mechanical strain.Another significant attribute of the Neumax Actuator is the low rate of maintenance required to keep the system in optimal condition. One of the major advantages of using the Neumax Actuator is the low rate of wear and tear of the components, which translates into reduced downtime and associated costs. Additionally, the operational parameters of the actuator are easy to monitor, making it easier to identify potential issues before they escalate into serious problems.The Neumax Actuator is also easy to install, which translates into reduced installation time and costs. The actuator can be customized to fit different system specifications, making it an ideal solution for many industrial automation processes.The Neumax Actuator is also designed to be energy efficient, reducing the overall cost of operation. The actuator is designed with components that consume less power, making it ideal for use in applications where energy efficiency is a priority.The Neumax Actuator is an excellent solution for different industrial settings, including oil and gas, food processing, and water treatment facilities. The actuator is tested and certified to meet international standards, ensuring that it meets the strict regulatory requirements.The company behind the Neumax Actuator boasts of an experienced and highly skilled team of professionals dedicated to producing high-quality industrial automation solutions. The company prides itself on its ability to deliver customized solutions tailored to the specific needs of each client.The company believes that investing in research and development is essential to provide innovative solutions that meet the evolving needs of clients. The Neumax Actuator is the product of years of research and development, aimed at providing a reliable and efficient solution to industrial automation.The company's commitment to quality is unwavering. It has established stringent quality control procedures at every stage of the production process, ensuring that every component that leaves the facility conforms to the highest quality standards.In conclusion, the Neumax Actuator is an innovative solution to industrial automation needs. It is designed with quality, efficiency, reliability, and flexibility in mind, making it an ideal solution for a wide range of industrial applications. The company behind the product is committed to delivering innovative solutions that meet the evolving needs of clients in the industrial automation sector. With the Neumax Actuator, clients can be assured of exceptional performance, energy efficiency, and a low rate of maintenance, translating into overall cost savings in the long run.

New Breakthrough in Actuator Gearbox Technology Unveiled – All You Need to Know!

[Assistant]I'm sorry, but I don't have access to current news articles or specific company introductions. However, I can provide you with a template for writing a 800-word news article based on the topic of Actuator Gearbox. You can then replace the placeholder text with the appropriate information.Title: Revolutionizing Industry: The Power of Actuator GearboxIntroduction:[Company Name] introduces a breakthrough in industrial technology with its advanced Actuator Gearbox. This innovative product is set to revolutionize various industries by offering unmatched precision, durability, and efficiency. With its cutting-edge design and robust functionality, the actuator gearbox opens up new possibilities and enhances production across multiple sectors.1. Importance and Applications of Actuator Gearbox (approx. 200 words)Start by explaining the role and significance of an actuator gearbox in industrial processes. Describe how it facilitates control and motion transmission in machines and various automated systems. Illustrate its application in sectors such as manufacturing, robotics, aerospace, automotive, and more. Emphasize the need for reliable and high-performing actuator gearboxes to optimize operations and increase productivity.2. Features and Benefits (approx. 300 words)Detail the key features and benefits offered by this particular actuator gearbox. Highlight its unique characteristics, such as precision engineering, high torque capacity, compact design, and ease of installation. Discuss how these attributes result in improved performance, reduced downtime, increased efficiency, and cost-effectiveness for industries utilizing the product.3. Industry Adaptation and Feedback (approx. 200 words)Explore how various industry sectors have embraced the actuator gearbox and their feedback on its performance. Interview professionals, engineers, or industry experts who have implemented the product in their operations. Collect their experiences, opinions, and case studies to showcase the positive impact of the actuator gearbox on different industrial applications.4. Technological Advancements and Future Prospects (approx. 150 words)Highlight the ongoing research and technological advancements in actuator gearbox technology. Discuss potential future developments, such as integrating advanced sensors, enhanced connectivity, or increased automation capabilities. Delve into the potential impact these advancements may have on industries, including improved production efficiency, reduced energy consumption, or expanded application areas.Conclusion:With its remarkable features and proven benefits, the Actuator Gearbox introduced by [Company Name] is revolutionizing industries across the board. Its ability to facilitate precise control and motion transmission in various applications ensures enhanced productivity and efficiency. As the product continues to gain traction and evolve, the future of industrial processes looks more robust and optimized than ever before.[Please note that this is a generalized template and may require customization and incorporation of the actual company introduction and specific news content for completion.]

Essential Guide to Air Filter Regulators and Lubricators: Maintenance and Functionality Explained

[Your Name][Your Position][Date][Title of the Article][City Name, State Name] - [Company Name], a leading provider of industrial equipment, is proud to introduce its innovative Air Filter Regulator and Lubricator (AFRL) to the market. Designed to enhance the efficiency and effectiveness of air-operated equipment, this cutting-edge technology revolutionizes the way industries regulate air pressure and deliver lubrication.[Company Name] has been a reputable name in the industrial equipment manufacturing industry for over [number of years] years. Known for its commitment to delivering high-quality products, the company has built a strong reputation for its exceptional engineering and attention to detail.The newly launched AFRL is a game-changer in the industry. It combines the functionalities of an air filter, regulator, and lubricator into a single, compact unit. This innovative design improves operational productivity, enhances equipment performance, and prolongs the lifespan of air tools.One of the key features of the AFRL is its advanced filtration system. With a high-performance air filter that removes contaminants such as dust, oil, and water, it ensures clean and dry air supply to pneumatic tools. This key functionality not only protects the tools but also prevents damage and reduces maintenance costs.The air pressure regulator integrated into the AFRL allows for precise control over the pressure levels delivered to pneumatic devices. This feature is particularly beneficial for sensitive equipment that requires accurate and consistent pressure for optimal performance. By maintaining a steady pressure, the AFRL prevents pressure fluctuations, enhancing the stability and reliability of air-driven machinery.Additionally, the AFRL's lubrication system guarantees the smooth operation of air tools. The unit efficiently delivers an appropriate amount of lubricant, maximizing the performance and prolonging the life of the tools. This advanced lubrication mechanism ensures the reduction of friction and wear, resulting in improved efficiency and reduced downtime.The compact and modular design of the AFRL makes it easy to install and integrate into existing equipment setups. The unit's user-friendly interface allows for simple adjustment of settings, enabling operators to optimize air pressure and lubrication levels effortlessly. The AFRL can be easily customized to fit specific requirements, catering to a wide range of industries such as manufacturing, automotive, food processing, and more.[Company Name]'s commitment to customer satisfaction goes beyond product quality. The company provides comprehensive after-sales support, technical assistance, and regular maintenance services to ensure the longevity and optimal functioning of the AFRL. With a reliable warranty program, customers can have peace of mind knowing that their investment is protected."We are thrilled to bring this revolutionary AFRL to market," said [Name], [Position] at [Company Name]. "With our innovative design and commitment to delivering exceptional performance, we believe that this product will significantly improve operational efficiency and enhance the overall productivity of various industries."[Company Name] continues to be an industry leader, constantly striving to innovate and develop new solutions to meet the changing needs of its customers. The introduction of the AFRL further solidifies the company's position as a reliable provider of top-quality industrial equipment.About [Company Name]:[Company Name] is a renowned industrial equipment manufacturer, dedicated to delivering exceptional products and services to customers. With a strong focus on innovation and customer satisfaction, the company has consistently achieved recognition for its engineering excellence and commitment to quality. [Company Name]'s diverse product range includes [list some of the main products/services offered by the company].For press inquiries or more information, please contact:[Company Name][Contact Person][Position][Phone Number][Email Address]###Note: The above text is only a sample and should be modified to fit the specific brand and company information.

Enhance Control Valve Functionality with Advanced Limit Switch Technology

Title: Control Valve Limit Switch: Enhancing Efficiency and Safety in Industrial ProcessesIntroduction:In today's highly industrialized world, process automation has become an integral part of numerous industries. One crucial component of process automation is the control valve limit switch. Renowned for its reliable performance, safety features, and unparalleled efficiency, this state-of-the-art technology has revolutionized the way businesses operate. By providing real-time control and monitoring capabilities, the control valve limit switch ensures optimal functioning of industrial processes, minimizing downtime, and maximizing productivity.Company Introduction: [Company name][Company name] is a global leader in the manufacturing and distribution of advanced control system components. With a multi-decade track record of excellence, [Company name] is at the forefront of providing cutting-edge solutions to industries around the world. Committed to quality, innovation, and customer satisfaction, the company boasts a team of highly skilled engineers, technicians, and professionals dedicated to meeting the evolving needs of the automation industry.News Content: Control Valve Limit Switch[Company name], renowned for its expertise in control valve limit switches, has recently introduced its latest range of advanced limit switch solutions. This new product line is set to redefine standards in the automation sector, delivering enhanced efficiency and safety to industrial processes.1. Enhanced Performance and Reliability:Featuring state-of-the-art technology and precision engineering, the new control valve limit switches by [Company name] guarantee optimum performance and reliability. The switches are designed to withstand harsh industrial environments, including extreme temperatures, corrosive substances, and high pressure. Equipped with robust components and advanced features, these limit switches ensure long-term operational reliability, reducing maintenance costs and downtime.2. Real-Time Monitoring:A key highlight of [Company name]'s control valve limit switch range is its real-time monitoring capabilities. These switches provide continuous feedback on valve position, allowing operators to precisely control flow rates and pressure levels. With the ability to monitor critical parameters, industrial processes can be fine-tuned to optimize efficiency and minimize the risk of system failures.3. Enhanced Safety Features:Safety is of paramount importance in industrial processes. [Company name] recognizes this and has integrated several safety features into their control valve limit switches. These include over-travel protection, position indication, and local/manual control options. The switches are designed to ensure fail-safe operation, mitigating potential hazards and reducing the risk of accidents.4. Easy Installation and Integration:[Company name]'s control valve limit switches are designed to be easy to install and integrate into existing automation systems. With a variety of mounting options available, they can be seamlessly integrated into diverse industrial environments. Additionally, the switches are compatible with a range of control systems, enabling quick retrofitting or upgrading of older systems without major modifications.5. Versatility and Customization:Recognizing that different industries have unique requirements, [Company name] offers a wide range of control valve limit switches catering to various industrial applications. Whether it be the oil and gas sector, power generation, chemical processing, or wastewater treatment, their switches can be customized to meet specific needs. This versatility ensures that businesses across sectors can benefit from their advanced automation solutions.Conclusion:The introduction of [Company name]'s latest control valve limit switch range is set to revolutionize industrial automation, enhancing efficiency and safety across multiple industries. With advanced features, robust construction, and real-time monitoring capabilities, these switches are poised to become the go-to solution for businesses aiming to optimize their processes and minimize downtime. [Company name]'s commitment to excellence and customer satisfaction ensures that they will continue to be a global leader in providing cutting-edge control system components for years to come.

Discover the Power of High Torque Worm Gearboxes for Efficient Performance

High Torque Worm Gearbox Revolutionizes Industry StandardsIn today's fast-paced world, efficiency and productivity are paramount for businesses in all industries. Recognizing this need, a pioneering engineering company has developed a groundbreaking solution that is set to revolutionize gear technology. The high torque worm gearbox, created by [company name], has garnered significant attention and promises to deliver unparalleled performance and precision.The core tenets of the high torque worm gearbox lie in its innovative design and advanced engineering. By seamlessly combining cutting-edge materials, precision manufacturing processes, and state-of-the-art technology, [company name] has redefined gear performance and set new standards for the industry. This gearbox is poised to empower businesses across various sectors, from automotive to aerospace, robotics, and beyond.One of the key features that set the high torque worm gearbox apart from traditional gear systems is its exceptional efficiency. Through meticulous engineering and optimization, this gearbox achieves an impressive efficiency rate that surpasses industry norms. This efficiency not only enhances overall system performance, but it also minimizes energy wastage, leading to significant cost savings for businesses.In addition to its remarkable efficiency, the high torque worm gearbox exhibits outstanding durability and reliability. The gearbox has been designed and tested rigorously to withstand the harshest operating conditions. Its robust construction ensures a longer lifespan, resulting in reduced maintenance and replacement costs for businesses. This impressive durability makes the gearbox an ideal choice for heavy-duty applications that demand longevity and reliability.Furthermore, the high torque worm gearbox offers exceptional torque output, setting it apart from traditional gear systems. By effectively multiplying the input torque, this gearbox allows for smoother and more powerful operation of machinery and equipment. As a result, businesses can maximize their productivity and output, leading to increased profitability and competitiveness.The versatility of the high torque worm gearbox is another feature worth highlighting. With its wide range of sizes, gear ratios, and customizable options, this gearbox can be tailored to meet the specific requirements of various industries and applications. Whether it's precision motion control, heavy load handling, or high-speed operations, [company name] provides a gearbox solution that adapts seamlessly to any unique situation.Furthermore, [company name] prides itself on ensuring the highest standard of customer satisfaction. Through an unmatched commitment to quality, the company ensures that every high torque worm gearbox meets strict quality control standards. Moreover, their dedicated team works closely with clients to provide customizable solutions, offering expert advice and support throughout the entire implementation process.As a testament to its exceptional quality and performance, [company name]'s high torque worm gearbox has already gained recognition and trust from industry leaders. The gearbox has been successfully integrated into various applications, empowering businesses to achieve new levels of efficiency, productivity, and profitability.In summary, the high torque worm gearbox developed by [company name] has redefined industry standards through its cutting-edge design, exceptional efficiency, durability, outstanding torque output, and versatility. With its seamless integration into various sectors, the gearbox promises to be a game-changer in the world of gear technology. By revolutionizing gear performance, [company name] is equipping businesses with the tools they need to excel in today's competitive landscape.

What Is Worm and Wheel Steering Gear and How Does It Work?

The Worm And Wheel Steering Gear (need remove brand name) has long been one of the most popular devices in the automotive industry, and for good reason. This reliable and durable steering mechanism has been utilized for decades in vehicles of all kinds, from the smallest passenger cars to the largest commercial trucks.When it comes to the Worm And Wheel Steering Gear (need remove brand name), the company behind it is one that has been in business for many years, and has established a reputation for quality and reliability. With a long history of engineering and manufacturing excellence, this company has become a trusted provider of steering gear systems to automotive manufacturers worldwide.According to company officials, the Worm And Wheel Steering Gear (need remove brand name) is designed to provide a smooth, easy-to-operate steering experience for drivers. By utilizing a combination of worm gears and a wheel-shaped gear, this mechanism is able to provide precise, responsive steering in a wide range of driving conditions.One of the key benefits of the Worm And Wheel Steering Gear (need remove brand name) is its durability. Unlike some other steering mechanisms that can wear out or break down over time, this device has been engineered to withstand the rigors of harsh driving conditions and heavy use. This means that drivers can rely on it to provide consistent performance year after year, even under the most demanding circumstances.Another important feature of the Worm And Wheel Steering Gear (need remove brand name) is its versatility. Because it is designed to fit a wide range of vehicles, this mechanism can be used in everything from small passenger cars to large commercial trucks. This makes it an ideal choice for automotive manufacturers looking to streamline their production processes and reduce costs.Of course, one of the key factors driving the popularity of the Worm And Wheel Steering Gear (need remove brand name) is its ease of operation. By providing a smooth, easy-to-use steering experience, this device helps drivers stay in control of their vehicles and maneuver through even the most challenging driving conditions with ease.Overall, there is no doubt that the Worm And Wheel Steering Gear (need remove brand name) is one of the most important components in today's vehicles. Whether you are a driver, an automotive manufacturer, or simply someone interested in the latest automotive technology, this innovative and reliable device is one that is sure to impress. So why not take a closer look today and see what all the fuss is about?

Discover the Latest Advancements in Worm and Bevel Gears

Breaking News: Revolutionary Worm and Bevel Gear Partnership Sets New Industry StandardIn a groundbreaking move, a leading manufacturer in the mechanical engineering industry has announced a strategic partnership between its innovative "Worm" and "Bevel Gear" technologies. This landmark collaboration is poised to reshape the landscape of gear systems, offering enhanced performance and efficiency across various industrial applications. With a commitment to excellence and a focus on providing cutting-edge solutions, this partnership represents a significant milestone for both companies and the industry as a whole.The "Worm" and "Bevel Gear" technologies, developed independently by two reputable brands, have long been renowned for their exceptional engineering prowess and reliability. By combining these two revolutionary technologies, the new partnership aims to deliver a gear system that surpasses all expectations in terms of mechanical efficiency, power transmission, and durability.The Worm technology, known for its unique helical screw design, has been widely used in various industries for decades. Its ability to provide high gear ratios and transmit power smoothly makes it a preferred choice for applications requiring precision motion control, such as robotics, packaging, and conveyor systems.On the other hand, Bevel Gear, which features interlocking, cone-shaped gears, is sought after for its ability to transmit power at different angles. This technology has found widespread use in automotive differentials, printing presses, and industrial machinery where the torque must be efficiently transferred between intersecting shafts. Its versatility and reliability make it an indispensable component in many critical applications.The collaborative efforts between the two technologies have resulted in a gear system that promises unparalleled performance and efficiency. By combining the unique strengths of the Worm and Bevel Gear technologies, this partnership aims to create a new benchmark in the industry, setting higher standards for gear systems' power transmission, reliability, and lifespan.The unified gear system is expected to bring numerous advantages to end-users across various industries. These include increased torque transmission, reduced energy consumption, enhanced system stability, and improved overall performance. By optimizing the gear's design, utilizing the latest manufacturing techniques, and implementing advanced materials, the partnership intends to offer a gear system that meets and exceeds the evolving demands of today's industries.Additionally, with a focus on sustainability, the partnership aims to minimize the environmental impact of their gear systems. Through innovative design modifications and material selection, they aim to reduce the overall carbon footprint while maintaining top-notch performance and reliability.As leaders in their respective fields, both companies bring a wealth of knowledge, expertise, and experience to this partnership. Together, they are committed to driving innovation, enhancing industrial productivity, and delivering solutions that inspire confidence in their customers.The Worm and Bevel Gear partnership will undoubtedly disrupt the industry, igniting a new era of gear system design and engineering excellence. By combining their expertise and resources, the collaborators are poised to transform the way industries utilize gear systems, setting new standards for efficiency, reliability, and sustainability.For more information about the revolutionary Worm and Bevel Gear partnership and the forthcoming gear system, please visit [Company website] and get ready to witness the future of mechanical engineering.