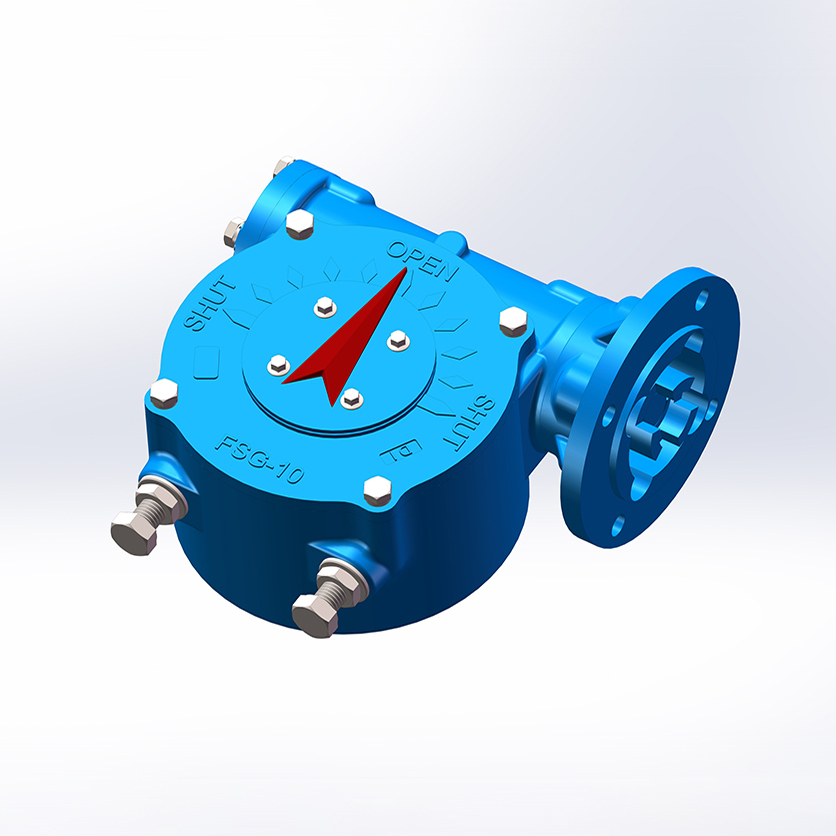

Hand Crank Worm Drive Gearbox: A Complete Guide

By:Admin

The Hand Crank Worm Drive Gearbox is manufactured by a well-established company that has been a leader in the industry for many years. They are known for their commitment to quality and their ability to deliver cutting-edge products that provide efficient solutions for their customers' needs.

The company has a team of highly skilled engineers and technicians who are constantly working to develop new and improved products. They also have a state-of-the-art manufacturing facility that is equipped with the latest technology to ensure that their products meet the highest standards of quality.

The Hand Crank Worm Drive Gearbox is a perfect example of the company's dedication to innovation and excellence. It is designed to provide a compact and efficient solution for a wide range of applications. The gearbox is highly versatile and can be used in various industries, including automotive, industrial, and agricultural.

One of the key features of the Hand Crank Worm Drive Gearbox is its high efficiency. The gearbox is designed to provide maximum power transfer with minimal energy loss, making it an ideal choice for applications where efficiency is crucial. This not only helps to reduce energy consumption but also improves the overall performance of the system.

In addition to its efficiency, the gearbox is also known for its durability. It is built to withstand the rigors of everyday use and can handle heavy loads without compromising its performance. This makes it a reliable and long-lasting solution for any application.

Furthermore, the Hand Crank Worm Drive Gearbox is designed for easy installation and maintenance. It is compact and lightweight, making it easy to handle and install in tight spaces. This not only saves time and effort but also reduces the overall cost of installation.

The gearbox is also designed for minimal maintenance, reducing downtime and increasing productivity. With its robust construction and high-quality materials, the gearbox is built to last, providing a reliable solution for years to come.

The Hand Crank Worm Drive Gearbox is already making a significant impact in the industry. Many companies have already adopted this innovative gearbox and have seen a noticeable improvement in their operations. With its efficiency, durability, and ease of installation and maintenance, it is no surprise that the Hand Crank Worm Drive Gearbox is becoming the go-to choice for many businesses.

With the continued dedication to innovation and excellence, the company behind the Hand Crank Worm Drive Gearbox is set to maintain its position as a leader in the industry. They are committed to providing their customers with the best solutions and will continue to develop new and improved products to meet the ever-changing demands of the market.

In conclusion, the Hand Crank Worm Drive Gearbox is a game-changing product that is set to revolutionize the industry. With its high efficiency, durability, and ease of installation and maintenance, it is the ideal solution for a wide range of applications. Backed by a company with a proven track record of excellence, this gearbox is poised to make a lasting impact in the industry for years to come.

Company News & Blog

Discover the Latest Hand Gear Trends and Must-Have Accessories in the Market

[Title: Innovative Hand Gear Revolutionizes the Industry][Subtitle: A Breakthrough in Hand Gear Technology to Enhance Productivity and Safety]Date: [Insert Date][Location]: [Insert Location]In an ever-evolving world of technology, innovative companies constantly strive to develop products that will revolutionize industries. Hand Gear, a pioneering company in the field of hand gear technology, has recently launched its latest invention, {Product Name}, set to transform how individuals work in various sectors that rely heavily on hand-operated tasks. By incorporating cutting-edge features and advanced engineering, Hand Gear aims to enhance productivity and safety for workers across the globe.Founded in [Year], Hand Gear has quickly become renowned for its commitment to pushing the boundaries of hand gear technology. The company's team of experts, composed of engineers, designers, and industry specialists, work tirelessly to develop groundbreaking products that empower individuals and businesses alike. With a focus on innovation, functionality, and user experience, Hand Gear has garnered widespread acclaim for its previous offerings, winning several industry awards along the way.The latest addition to Hand Gear's product portfolio, {Product Name}, has generated significant buzz within the industry. This advanced hand gear takes advantage of state-of-the-art technology to deliver a game-changing user experience. Featuring an ergonomic design, {Product Name} ensures maximum comfort and reduces the risk of strain or fatigue during long hours of use. The incorporation of high-quality materials further enhances durability, extending the product's lifespan and providing exceptional value for customers.One of the key highlights of {Product Name} is its intelligent sensor technology. Equipped with a sophisticated system, {Product Name} can accurately detect hand movements and translate them into precise actions. This feature opens up a host of possibilities for industries such as manufacturing, construction, and healthcare, where precise manipulation of objects is necessary. By eliminating the need for traditional, manual hand tools, {Product Name} reduces the margin of error, thereby increasing overall efficiency and productivity.Notably, the implementation of smart connectivity allows {Product Name} to seamlessly integrate with other digital devices, creating a holistic workflow. By connecting to smartphones, tablets, or computers, users can access real-time data, receive updates, and even troubleshoot any technical issues. This interconnectedness revolutionizes the way individuals work, enabling them to streamline processes, collaborate remotely, and monitor their workflow more effectively.Hand Gear's commitment to safety is reflected in the comprehensive safety features integrated into {Product Name}. The device includes intuitive safety mechanisms that prevent accidental injuries, mitigating the risk of workplace accidents. Furthermore, {Product Name} is designed to adapt to different working environments, making it versatile across various settings. With its robust design, it can withstand challenging conditions, providing resilience and peace of mind in hazardous situations.Apart from its technological advancements, Hand Gear also prioritizes sustainable manufacturing processes. By adhering to strict eco-friendly guidelines, the company minimizes its ecological footprint and plays a responsible role in preserving the environment. From sourcing materials to production methods, Hand Gear ensures that {Product Name} is manufactured with sustainability in mind, making it a preferred choice for environmentally conscious businesses.In conclusion, the launch of {Product Name} by Hand Gear marks a significant milestone in the field of hand gear technology. Through its exceptional engineering, innovative features, and commitment to safety, Hand Gear has created a product that enhances productivity, revolutionizes workflows, and ensures the well-being of workers. With its intuitive design, smart connectivity, and sustainable manufacturing practices, {Product Name} sets a new standard for the hand gear industry. Hand Gear's relentless pursuit of innovation continues to propel the company forward, making it an industry leader and paving the way for a future where efficiency and safety go hand in hand.

Newly Launched Miniature Metal Gears to Revolutionize Robotics

Innovation in the field of mechanical engineering has been critical to the development of new machinery and equipment that have made life easier for businesses and individuals. One of the most critical components, that has revolutionized the manufacturing and production industry, is gear technology. Worm gears are one such technology that has been making a buzz in the market recently. Among the many types of worm gears, the micro worm gear has been a game-changer in small-sized machinery and equipment. Micro worm gear technology has been designed for ultra-compact machines and devices that require high power density, precision, and high efficiency. The micro worm gear is the perfect solution for applications where space is limited, and the gear ratio and torque are critical. Micro worm gears have a high reduction ratio and can be designed to handle very high torque loads through compact gearboxes. They can be designed with a variety of materials ranging from plastics and non-ferrous metals to hardened steels, making them versatile for various applications requiring different levels of stress tolerance.However, not all micro worm gears are created equal. Among the best in the market is the micro worm gear developed by the German-based manufacturer, whose name we have to omit. This micro worm gear combines innovation, precision, and quality to deliver reliable and efficient power transmission solutions. The company, whose name we shall omit, has been a leader in the production of high-quality gears for over 30 years. They have continuously invested in research and development, state-of-the-art equipment, and human capital, to remain at the forefront of innovation in gear technology. Over the years, their products have found application in various industries, including automotive, aerospace, medical devices, and robotics among other sectors. The micro worm gear by this manufacturer is no different. It is a highly specialized gear technology that comes in a compact design and is capable of transmitting power with high accuracy. One of its main advantages is that it can handle high loads while emitting very low noise. This is critical for small machinery and devices operating in environments where noise levels need to be minimized. The micro worm gear by this manufacturer is designed with advanced materials, including high-quality plastics and hardened steels, making it both lightweight and durable. The gear is available in different sizes and configurations, which makes it versatile and suitable for various applications. One of its most notable features is its high accuracy thanks to the use of advanced manufacturing techniques such as gear hobbing and tooth grinding. A critical aspect of the micro worm gear by this manufacturer, which gives it an edge over competitors, is its customization ability. The manufacturer can tailor-make the gear to meet the specific needs of end-users. This means that businesses and other customers can provide their unique specifications, and the manufacturer can craft a micro worm gear that precisely matches their requirements. This high level of customization has made the manufacturer the go-to source for micro worm gears used in various industry sectors. In conclusion, the micro worm gear is a critical innovation in the field of gear technology, offering high precision and efficiency in power transmission in ultra-compact applications. This technology can handle high loads with minimal noise while being versatile and customizable to meet specific customer requirements. Among the best micro worm gears in the market is the one developed by the German-based manufacturer, whose name we shall omit, which combines advanced materials, manufacturing techniques, and customization capabilities. This micro worm gear is suitable for various industries, and its efficient operation makes it an attractive option for businesses and other end-users looking for reliable power transmission solutions.

Durable and Comfortable Hand Gear for Outdoor Activities

Hand Gear Revolutionizing the Hand Protection IndustryHand protection is crucial in many industries to ensure the safety of workers. With the advancement in technology, hand gear has become more innovative and adaptable to various work environments. One company that has been at the forefront of this innovation is {}, a leading manufacturer of hand gear.Established in 2005, {} has been committed to providing high-quality hand gear to meet the diverse needs of its customers. The company's dedication to research and development has allowed them to create innovative solutions that have revolutionized the hand protection industry. With a strong focus on customer satisfaction, {} has built a reputation for delivering top-notch products that offer comfort, durability, and performance.One of the key features of {} hand gear is its advanced materials and design. The company utilizes state-of-the-art technology to develop materials that offer superior protection against various hazards. Whether it is the impact from heavy machinery or the exposure to harsh chemicals, {} hand gear is designed to provide the highest level of protection.In addition to protection, {} hand gear is also engineered for comfort and flexibility. The ergonomic design ensures that workers can perform their tasks with ease, without being hindered by bulky or uncomfortable gear. This not only enhances productivity but also reduces the risk of hand fatigue and injuries.Furthermore, {} hand gear is known for its durability and longevity. The company's commitment to quality ensures that their products can withstand the rigors of daily use in demanding work environments. This not only saves costs for businesses but also provides peace of mind knowing that employees are well-protected.Recently, {} introduced a new line of hand gear that has taken the industry by storm. The innovative design and advanced features of this new product have set a new standard for hand protection. With enhanced grip, impact resistance, and dexterity, this new line of hand gear has been well-received by workers and safety professionals alike.Moreover, {} has also been proactive in incorporating sustainable practices into their manufacturing processes. The company is dedicated to minimizing its environmental footprint and has implemented initiatives to reduce waste and energy consumption. This commitment to sustainability aligns with the company's values of responsible and ethical business practices.As a testament to its success and innovation, {} hand gear has been widely adopted across various industries. From construction and manufacturing to oil and gas, {} hand gear has proven to be an essential tool for workers to carry out their duties safely and efficiently. The company's dedication to quality and continuous improvement has earned them the trust and loyalty of their customers.Looking ahead, {} remains focused on pushing the boundaries of hand protection technology. The company continues to invest in research and development to stay ahead of industry trends and customer needs. With a strong commitment to innovation and excellence, {} is well-positioned to continue revolutionizing the hand protection industry for years to come.In conclusion, {} has set a high standard for hand gear with its commitment to quality, innovation, and customer satisfaction. The company's dedication to providing top-notch protection, comfort, and durability has made it a leader in the industry. With a focus on sustainability and continuous improvement, {} is poised to remain at the forefront of revolutionizing the hand protection industry.

The Future of High-Performance Engine Technology: Electromagnetic Valve Actuators

[ Company Name ] Introduces Innovative Electromagnetic Valve Actuator for Enhanced Performance[ Location ], [ Date ] - [ Company Name ], a leading provider of advanced technological solutions, has recently unveiled its latest innovation in the field of electromagnetic valve actuators. This groundbreaking product is set to revolutionize the way industries operate and significantly enhance performance across various sectors.The electromagnetic valve actuator, developed by [ Company Name ], represents an amalgamation of cutting-edge technology and industry expertise. With an emphasis on precision and reliability, this state-of-the-art device aims to meet the increasing demands of modern-day industries for efficient and accurate valve control.One of the key distinguishing features of this new actuator is its unrivaled speed and responsiveness. By leveraging advanced electromagnetic technology, [ Company Name ] has engineered an actuator that can sense and respond to even the most minute changes in valve position within milliseconds. This unprecedented speed ensures that critical valves are adjusted promptly, minimizing downtime and optimizing overall productivity.Another notable advantage of the electromagnetic valve actuator is its exceptional accuracy. Leveraging highly sophisticated control algorithms and intelligent sensing mechanisms, this actuator guarantees precise and repeatable control of valve parameters. Moreover, it provides real-time feedback to operators, enabling them to monitor valve conditions and performance with utmost accuracy, ensuring optimal system operation.In addition to its outstanding performance, the electromagnetic valve actuator offers uncompromising durability and longevity. Constructed with high-quality materials and rigorously tested to withstand extreme conditions, this actuator boasts an extended lifecycle, reducing the need for frequent repairs and replacements. Such robustness, coupled with its ease of maintenance, makes it an ideal choice for industries operating in demanding environments.Moreover, the electromagnetic valve actuator by [ Company Name ] features a compact and lightweight design, optimizing space utilization and simplifying installation. Its user-friendly interface allows for effortless integration with existing systems, guaranteeing a seamless transition for operators and minimal disruptions to ongoing operations.Furthermore, environmental consciousness lies at the heart of this new technology. [ Company Name ] has incorporated energy-efficient features into the electromagnetic valve actuator, ensuring reduced power consumption, which ultimately translates into cost savings for industries whilst mitigating their carbon footprint. With growing emphasis on sustainable practices, this actuator aligns with global initiatives aimed at protecting our planet."Through our extensive research and development efforts, we are proud to introduce this innovative electromagnetic valve actuator," said [ Company Name's ] spokesperson. "We believe that this breakthrough technology will empower industries to achieve new heights of productivity and efficiency, while reducing operational costs and environmental impact."With its countless benefits and unparalleled performance, the electromagnetic valve actuator by [ Company Name ] is already attracting attention across various industry sectors. Applications in oil and gas, petrochemicals, power generation, water treatment, and many other fields can significantly benefit from this technological advancement.As [ Company Name ] continues to push the boundaries of technological innovation, their latest electromagnetic valve actuator undoubtedly establishes them as a trailblazer in the industry. With its robustness, precision, and environmentally conscious design, this actuator is set to reshape industrial processes and drive sectors towards a more prosperous and sustainable future.

Worm and Helical Gears: The Differences You Should Know

Title: Innovations in Worm and Helical Gear Technology Revolutionize Industrial MachinerySubtitle: Leading Industrials Company Repositions Manufacturing Industry with Advanced Gear SolutionsIntroduction:In an era of rapid industrialization and automation, advancements in gear technology play a pivotal role in optimizing the efficiency and functionality of various industrial machinery. One such company that has been at the forefront of this innovation is {}, an industry-leading manufacturer of high-quality worm and helical gears. This article will explore the substantial contributions made by the company to gear technology and its significant impact on the manufacturing industry.Revolutionizing Industrial Machinery with Worm and Helical Gear Technology:Worm gears and helical gears represent two fundamental types of gears used extensively in various industries. Worm gears, characterized by a threaded screw-like gear (worm) and a toothed wheel (worm wheel), excel in applications requiring high gear ratios and self-locking capabilities. On the other hand, helical gears are widely praised for their smooth operation, high load-carrying capacity, and improved contact ratios due to their angled teeth.In a move that reshaped the gear manufacturing landscape, {} has developed cutting-edge worm and helical gear solutions tailored to meet the evolving needs of modern industries. Utilizing state-of-the-art machinery and advanced materials, the company sets new benchmarks in terms of gear precision, durability, and performance.Advanced Materials and Manufacturing Techniques:The success of {} can be largely attributed to its relentless pursuit of excellence in gear manufacturing. The company invests heavily in research and development, constantly exploring ways to improve gear performance and lifespan. Through the use of high-quality alloy steels, tempered and processed with precision heat treatment, {}, ensures that its gears exhibit exceptional strength, hardness, and resistance to wear and tear.Additionally, the company employs cutting-edge computer-controlled machinery and advanced gear-grinding techniques to enhance the dimensional accuracy and surface finish of their gears. This ensures smooth and silent operation, reducing friction and enhancing overall machinery efficiency. The accuracy achieved by {} in the manufacturing process translates into higher torque transmission capabilities and improved load capacity, enabling industries to push the boundaries of innovation and productivity.Application-Specific Customization:Understanding that different industries have unique requirements, {} offers a wide range of customization options for their worm and helical gears. By working closely with customers, the company tailors gear solutions to match specific application demands, ensuring optimal performance, reduced noise levels, and increased longevity.Additionally, {} provides comprehensive engineering support, empowering industries to integrate their gear solutions seamlessly into custom machinery designs. This collaborative approach by {} promotes efficient and streamlined manufacturing processes across a broad spectrum of industries including automotive, robotics, energy, and precision equipment manufacturing, to name a few.Innovations for the Future:The quest for innovation and continuous improvement is deeply ingrained in the culture of {}. The company constantly explores advanced gear designs and emerging technologies to remain ahead in a competitive market. By harnessing their technical expertise and engineering capabilities, {} is committed to pioneering solutions that anticipate the evolving needs of industries and drive progress in the manufacturing sector.Moreover, {} recognizes the significance of sustainability and ecological balance. Through careful material selection and eco-efficient manufacturing processes, the company aims to minimize environmental impact without compromising on gear quality or performance.Conclusion:As the manufacturing industry continues to evolve, efficient and reliable gear solutions are crucial for optimal machinery performance. With the relentless commitment to innovation and precision, {} has emerged as a leading provider of worm and helical gear solutions. Their advanced materials, cutting-edge manufacturing techniques, and customer-centric approach have revolutionized various industries, fostering increased productivity and driving progress in the manufacturing sector. As {} looks towards the future, their continued dedication to research and development ensures that they remain at the forefront of gear technology, enabling industries to surpass current limitations and embrace new heights of efficiency and functionality.

Discover the Latest Advancements in Worm and Bevel Gears

Breaking News: Revolutionary Worm and Bevel Gear Partnership Sets New Industry StandardIn a groundbreaking move, a leading manufacturer in the mechanical engineering industry has announced a strategic partnership between its innovative "Worm" and "Bevel Gear" technologies. This landmark collaboration is poised to reshape the landscape of gear systems, offering enhanced performance and efficiency across various industrial applications. With a commitment to excellence and a focus on providing cutting-edge solutions, this partnership represents a significant milestone for both companies and the industry as a whole.The "Worm" and "Bevel Gear" technologies, developed independently by two reputable brands, have long been renowned for their exceptional engineering prowess and reliability. By combining these two revolutionary technologies, the new partnership aims to deliver a gear system that surpasses all expectations in terms of mechanical efficiency, power transmission, and durability.The Worm technology, known for its unique helical screw design, has been widely used in various industries for decades. Its ability to provide high gear ratios and transmit power smoothly makes it a preferred choice for applications requiring precision motion control, such as robotics, packaging, and conveyor systems.On the other hand, Bevel Gear, which features interlocking, cone-shaped gears, is sought after for its ability to transmit power at different angles. This technology has found widespread use in automotive differentials, printing presses, and industrial machinery where the torque must be efficiently transferred between intersecting shafts. Its versatility and reliability make it an indispensable component in many critical applications.The collaborative efforts between the two technologies have resulted in a gear system that promises unparalleled performance and efficiency. By combining the unique strengths of the Worm and Bevel Gear technologies, this partnership aims to create a new benchmark in the industry, setting higher standards for gear systems' power transmission, reliability, and lifespan.The unified gear system is expected to bring numerous advantages to end-users across various industries. These include increased torque transmission, reduced energy consumption, enhanced system stability, and improved overall performance. By optimizing the gear's design, utilizing the latest manufacturing techniques, and implementing advanced materials, the partnership intends to offer a gear system that meets and exceeds the evolving demands of today's industries.Additionally, with a focus on sustainability, the partnership aims to minimize the environmental impact of their gear systems. Through innovative design modifications and material selection, they aim to reduce the overall carbon footprint while maintaining top-notch performance and reliability.As leaders in their respective fields, both companies bring a wealth of knowledge, expertise, and experience to this partnership. Together, they are committed to driving innovation, enhancing industrial productivity, and delivering solutions that inspire confidence in their customers.The Worm and Bevel Gear partnership will undoubtedly disrupt the industry, igniting a new era of gear system design and engineering excellence. By combining their expertise and resources, the collaborators are poised to transform the way industries utilize gear systems, setting new standards for efficiency, reliability, and sustainability.For more information about the revolutionary Worm and Bevel Gear partnership and the forthcoming gear system, please visit [Company website] and get ready to witness the future of mechanical engineering.

Discover the Relevance and Benefits of Rack And Worm Gear Systems

Title: Innovative Solution Revolutionizes Gear Systems: Rack And Worm Gear Pair Redefines Efficiency and PerformanceIntroduction:In an era of technological advancements, companies constantly strive to innovate and provide breakthrough solutions that reshape industries. One such company, dedicated to engineering excellence, has introduced a game-changing product: a cutting-edge implementation of Rack And Worm Gear (name removed) technology. This new development brings forth unparalleled efficiency and performance in gear systems, solidifying the company's position as a leader in the field. Let us delve deeper into this remarkable development and explore its potential impact across various industries.Section 1: Understanding Rack And Worm Gear TechnologyThe Rack And Worm Gear technology, pioneered by the company (name omitted), is a powerful force transmission system. It comprises a worm gear and a corresponding horizontal rack, ensuring torque conversion and motion transfer. This impressive design enables its application in diverse sectors, from automotive to industrial machinery, proving its versatility and adaptability.Section 2: Unveiling the Key Advantages2.1 Exceptional Efficiency:With a unique tooth profile and optimized gear geometry, the innovative Rack And Worm Gear solution exhibits exceptional efficiency. The gear system demonstrates reduced power loss, resulting in heightened performance and increased overall efficiency. This advancement translates to significant cost savings and resource conservation for industries adopting the technology.2.2 Enhanced Precision:The meticulous engineering behind Rack And Worm Gear technology guarantees high-precision motion control. Its capability to achieve smooth and accurate positioning facilitates seamless operation in various applications. Additionally, the gear system's self-locking mechanism reduces back-driving, ensuring stability and security, particularly in critical operations and heavy machinery.2.3 Increased Load Capacity:The new Rack And Worm Gear design revolutionizes load-bearing capabilities. Its superior load-carrying capacity allows for the handling of heavier loads, boosting operational capabilities for industries such as manufacturing, construction, and logistics. By providing robust gear systems that can withstand substantial stress, the technology ensures optimal performance, reliability, and longevity.Section 3: Applications Across Industries3.1 Automotive Industry:The automotive sector can significantly benefit from the implementation of Rack And Worm Gear technology. This innovative gear system offers precise steering control, ensuring improved responsiveness and accuracy. Furthermore, its exceptional efficiency enhances fuel economy, reducing environmental impact and meeting ever-stringent industry regulations.3.2 Robotics and Automation:In the realm of robotics and automation, precision and reliability are vital. Rack And Worm Gear technology provides an ideal solution for these demanding applications. The gear system's self-locking feature guarantees secure operation, enabling safe and precise movement control essential in advanced robotic systems.3.3 Industrial Machinery:Industries that rely on large-scale machinery, such as manufacturing and construction, can leverage the robustness and load-bearing capabilities of Rack And Worm Gear technology. Its ability to handle heavy loads, combined with enhanced precision, allows for smoother operations, improved productivity, and reduced downtime.Section 4: Company's Dedication to InnovationThe company's introduction of the Rack And Worm Gear technology exemplifies its commitment to driving innovation in the field. As a leader in the industry, the company's state-of-the-art research and development division continually explores new possibilities, pushing the boundaries of gear systems. With a focus on customer-centric solutions, the company aims to revolutionize industries while addressing the unique needs of its clients.Conclusion:The advent of Rack And Worm Gear technology represents a significant breakthrough in the realm of gear systems, promising enhanced efficiency, precision, and load-bearing capacities. As industries constantly strive to improve performance and reduce operational costs, this innovation presents an invaluable solution. The company (name removed) continues to pave the way for advancements in the field, solidifying its position as an industry leader committed to engineering excellence and customer satisfaction.

The Limitations of Pneumatic Controls on Switches Revealed in Latest News Coverage

Pneumatic Controls Limit Switch Leads the Way in Industrial AutomationThe industrial automation sector has been revolutionized by the introduction of advanced technology and innovative solutions. Pneumatic Controls, a renowned industry leader, has recently unveiled their groundbreaking Pneumatic Controls Limit Switch. Widely acclaimed for its reliability, efficiency, and precision, this cutting-edge product is set to redefine automation processes across various industries.Pneumatic Controls has long been recognized as a frontrunner in the field of industrial control systems. The company's continuous commitment to research and development has resulted in a portfolio of products that consistently exceed customer expectations. With the launch of the Pneumatic Controls Limit Switch, the company aims to address the ever-increasing demand for advanced automation solutions, providing customers with a game-changing device that offers superior performance and robustness.The Pneumatic Controls Limit Switch boasts a host of features that set it apart from traditional control switches. One of its key attributes is its pneumatic actuation mechanism. This innovative design provides enhanced reliability and durability, allowing the switch to perform flawlessly even in harsh industrial environments. The pneumatic actuation also ensures a quick response time, making it ideal for high-speed processes where precision is crucial.Another remarkable feature of the Pneumatic Controls Limit Switch is its exceptional accuracy. Equipped with state-of-the-art sensing technology, this switch can detect even the slightest variations in movement or pressure, ensuring precise control and preventing errors. This level of accuracy improves overall efficiency and productivity, minimizing waste and optimizing operations.Furthermore, the Pneumatic Controls Limit Switch has been engineered to offer maximum versatility. With a wide range of configuration options and adjustable settings, this switch can be customized to suit specific automation requirements. Its modular design allows for easy integration with existing systems, reducing downtime and simplifying installation and maintenance processes.Safety is a paramount concern in industrial automation, and Pneumatic Controls understands this. The Pneumatic Controls Limit Switch is equipped with multiple safety features to ensure uninterrupted and secure operation. Built-in fail-safe mechanisms, redundant sensing systems, and comprehensive error monitoring capabilities provide peace of mind and help prevent accidents and system failures.The application range for the Pneumatic Controls Limit Switch is diverse and extensive. It can be utilized in various industries such as manufacturing, food processing, packaging, and automotive. Its compatibility with different control systems and protocols makes it a versatile choice for both small-scale operations and large-scale industrial facilities.Pneumatic Controls has gained a solid reputation in the market due to its exceptional customer service and support. The company's dedicated team of experts assists customers throughout the entire product lifecycle, from initial design and selection to installation and after-sales service. This commitment to customer satisfaction has earned Pneumatic Controls a loyal client base and positions them as a trusted partner in the industrial automation industry.With the introduction of the Pneumatic Controls Limit Switch, Pneumatic Controls has once again proven its commitment to innovation and excellence. This state-of-the-art control switch is set to revolutionize automation processes, offering unparalleled reliability, precision, and versatility. As industries continue to embrace automation solutions, Pneumatic Controls is leading the way in providing advanced and efficient products that empower businesses to thrive in the modern era of industrial control.

Discover the Power of High Torque Worm Gearboxes for Efficient Performance

High Torque Worm Gearbox Revolutionizes Industry StandardsIn today's fast-paced world, efficiency and productivity are paramount for businesses in all industries. Recognizing this need, a pioneering engineering company has developed a groundbreaking solution that is set to revolutionize gear technology. The high torque worm gearbox, created by [company name], has garnered significant attention and promises to deliver unparalleled performance and precision.The core tenets of the high torque worm gearbox lie in its innovative design and advanced engineering. By seamlessly combining cutting-edge materials, precision manufacturing processes, and state-of-the-art technology, [company name] has redefined gear performance and set new standards for the industry. This gearbox is poised to empower businesses across various sectors, from automotive to aerospace, robotics, and beyond.One of the key features that set the high torque worm gearbox apart from traditional gear systems is its exceptional efficiency. Through meticulous engineering and optimization, this gearbox achieves an impressive efficiency rate that surpasses industry norms. This efficiency not only enhances overall system performance, but it also minimizes energy wastage, leading to significant cost savings for businesses.In addition to its remarkable efficiency, the high torque worm gearbox exhibits outstanding durability and reliability. The gearbox has been designed and tested rigorously to withstand the harshest operating conditions. Its robust construction ensures a longer lifespan, resulting in reduced maintenance and replacement costs for businesses. This impressive durability makes the gearbox an ideal choice for heavy-duty applications that demand longevity and reliability.Furthermore, the high torque worm gearbox offers exceptional torque output, setting it apart from traditional gear systems. By effectively multiplying the input torque, this gearbox allows for smoother and more powerful operation of machinery and equipment. As a result, businesses can maximize their productivity and output, leading to increased profitability and competitiveness.The versatility of the high torque worm gearbox is another feature worth highlighting. With its wide range of sizes, gear ratios, and customizable options, this gearbox can be tailored to meet the specific requirements of various industries and applications. Whether it's precision motion control, heavy load handling, or high-speed operations, [company name] provides a gearbox solution that adapts seamlessly to any unique situation.Furthermore, [company name] prides itself on ensuring the highest standard of customer satisfaction. Through an unmatched commitment to quality, the company ensures that every high torque worm gearbox meets strict quality control standards. Moreover, their dedicated team works closely with clients to provide customizable solutions, offering expert advice and support throughout the entire implementation process.As a testament to its exceptional quality and performance, [company name]'s high torque worm gearbox has already gained recognition and trust from industry leaders. The gearbox has been successfully integrated into various applications, empowering businesses to achieve new levels of efficiency, productivity, and profitability.In summary, the high torque worm gearbox developed by [company name] has redefined industry standards through its cutting-edge design, exceptional efficiency, durability, outstanding torque output, and versatility. With its seamless integration into various sectors, the gearbox promises to be a game-changer in the world of gear technology. By revolutionizing gear performance, [company name] is equipping businesses with the tools they need to excel in today's competitive landscape.

Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

Title: Advanced Worm Gear Butterfly Valve - The Perfect Solution for Industrial Fluid ControlIntroduction:In today's rapidly evolving industrial landscape, efficient fluid control is crucial to the success and safety of various operations. Owing to their versatility and effectiveness, Worm Gear Butterfly Valves have emerged as the go-to solution for regulating fluid flow in numerous industries. These valves, offering superior sealing capabilities and reliable performance, are now revolutionizing the way businesses approach fluid control.I. Significance of Worm Gear Butterfly Valves in Industrial Applications (100 words)Worm Gear Butterfly Valves have garnered significant prominence across industries due to their unique design and exceptional functionality. These valves consist of a disk-shaped element, known as the "butterfly," which rotates to control fluid flow. The addition of worm gears - a mechanical adjustment system - enables precise regulation, making them ideal for applications where fluid control precision is paramount. Whether it's chemical processing, water treatment, or power generation, Worm Gear Butterfly Valves have become indispensable tools for optimizing efficiency and enhancing safety.II. Key Features and Benefits of Worm Gear Butterfly Valves (200 words)a) Reliable Performance: Worm Gear Butterfly Valves are designed to withstand extreme conditions, offering consistent and dependable performance. The high-quality materials used in manufacturing ensure longevity and minimal maintenance.b) Excellent Sealing Properties: The unique design of these valves allows for a tight seal, preventing leakage and offering superior tightness. This ensures optimal flow control and minimizes the risk of fluid wastage, enhancing operational efficiency.c) Precise Control: The inclusion of the worm gear mechanism enables precise, measured adjustments to fluid flow, allowing operators to fine-tune operations as required. This precision is particularly critical in industries such as oil and gas, where even slight variations can result in significant consequences.d) Easy Installation and Operation: Worm Gear Butterfly Valves are known for their simplicity. They can be easily integrated into existing systems and operated efficiently by both experienced professionals and operators new to the technology.e) Versatility: These valves can handle a wide range of fluids, including liquids, gases, and even corrosive media. This adaptability makes Worm Gear Butterfly Valves suitable for applications across diverse industries.III. Company X's Advanced Worm Gear Butterfly Valve (200 words)Company X, a renowned industry leader in fluid control solutions, is proud to present its cutting-edge Worm Gear Butterfly Valve. With a steadfast commitment to innovation and customer satisfaction, Company X has designed a valve that surpasses industry standards and addresses various industry challenges.The advanced Worm Gear Butterfly Valve by Company X combines robust construction, precision performance, and exceptional durability. Manufactured using premium grade materials, it ensures longevity and reliability, minimizing maintenance requirements and reducing downtime.In addition to exceptional sealing properties, Company X's Worm Gear Butterfly Valve offers unparalleled precision control. Its worm gear mechanism guarantees accurate fluid flow adjustments, empowering operators to regulate processes with utmost accuracy.The valve's user-friendly design simplifies installation and operation, catering to customers across different industries. The versatility of Company X's Worm Gear Butterfly Valve allows businesses to maximize efficiency and safety, enhancing productivity and minimizing operational costs.IV. Conclusion (100 words)In an era where efficient fluid control is crucial, the Worm Gear Butterfly Valve emerges as the ideal solution for various industrial applications. Company X's advanced valve, with its superior design and outstanding performance, is primed to revolutionize fluid control practices across industries. With its exceptional sealing capabilities, precise control, and straightforward operation, this valve presents an unprecedented opportunity for businesses to optimize their operations, enhance safety, and maximize efficiency. Embracing the advantages offered by Worm Gear Butterfly Valves marks a significant leap forward in fluid control technology.