- Home

- Blog

- Essential Guide to Air Filter Regulators and Lubricators: Maintenance and Functionality Explained

Essential Guide to Air Filter Regulators and Lubricators: Maintenance and Functionality Explained

By:Admin

[Your Position]

[Date]

[Title of the Article]

[City Name, State Name] - [Company Name], a leading provider of industrial equipment, is proud to introduce its innovative Air Filter Regulator and Lubricator (AFRL) to the market. Designed to enhance the efficiency and effectiveness of air-operated equipment, this cutting-edge technology revolutionizes the way industries regulate air pressure and deliver lubrication.

[Company Name] has been a reputable name in the industrial equipment manufacturing industry for over [number of years] years. Known for its commitment to delivering high-quality products, the company has built a strong reputation for its exceptional engineering and attention to detail.

The newly launched AFRL is a game-changer in the industry. It combines the functionalities of an air filter, regulator, and lubricator into a single, compact unit. This innovative design improves operational productivity, enhances equipment performance, and prolongs the lifespan of air tools.

One of the key features of the AFRL is its advanced filtration system. With a high-performance air filter that removes contaminants such as dust, oil, and water, it ensures clean and dry air supply to pneumatic tools. This key functionality not only protects the tools but also prevents damage and reduces maintenance costs.

The air pressure regulator integrated into the AFRL allows for precise control over the pressure levels delivered to pneumatic devices. This feature is particularly beneficial for sensitive equipment that requires accurate and consistent pressure for optimal performance. By maintaining a steady pressure, the AFRL prevents pressure fluctuations, enhancing the stability and reliability of air-driven machinery.

Additionally, the AFRL's lubrication system guarantees the smooth operation of air tools. The unit efficiently delivers an appropriate amount of lubricant, maximizing the performance and prolonging the life of the tools. This advanced lubrication mechanism ensures the reduction of friction and wear, resulting in improved efficiency and reduced downtime.

The compact and modular design of the AFRL makes it easy to install and integrate into existing equipment setups. The unit's user-friendly interface allows for simple adjustment of settings, enabling operators to optimize air pressure and lubrication levels effortlessly. The AFRL can be easily customized to fit specific requirements, catering to a wide range of industries such as manufacturing, automotive, food processing, and more.

[Company Name]'s commitment to customer satisfaction goes beyond product quality. The company provides comprehensive after-sales support, technical assistance, and regular maintenance services to ensure the longevity and optimal functioning of the AFRL. With a reliable warranty program, customers can have peace of mind knowing that their investment is protected.

"We are thrilled to bring this revolutionary AFRL to market," said [Name], [Position] at [Company Name]. "With our innovative design and commitment to delivering exceptional performance, we believe that this product will significantly improve operational efficiency and enhance the overall productivity of various industries."

[Company Name] continues to be an industry leader, constantly striving to innovate and develop new solutions to meet the changing needs of its customers. The introduction of the AFRL further solidifies the company's position as a reliable provider of top-quality industrial equipment.

About [Company Name]:

[Company Name] is a renowned industrial equipment manufacturer, dedicated to delivering exceptional products and services to customers. With a strong focus on innovation and customer satisfaction, the company has consistently achieved recognition for its engineering excellence and commitment to quality. [Company Name]'s diverse product range includes [list some of the main products/services offered by the company].

For press inquiries or more information, please contact:

[Company Name]

[Contact Person]

[Position]

[Phone Number]

[Email Address]

###

Note: The above text is only a sample and should be modified to fit the specific brand and company information.

Company News & Blog

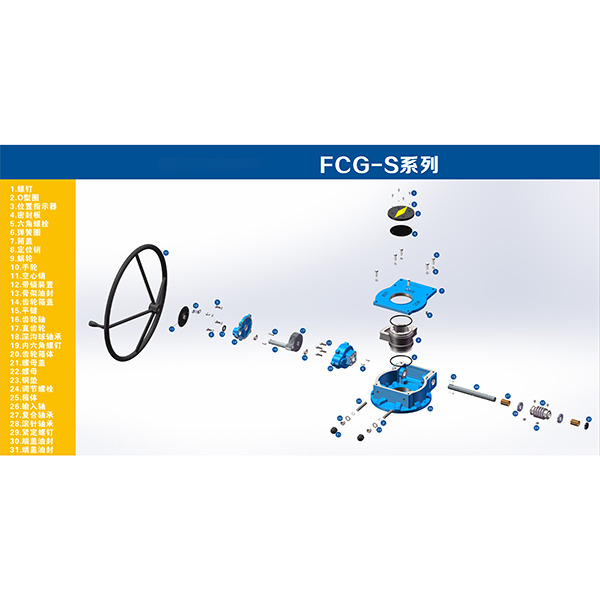

New Handwheel Gear Operator Launched to Improve Industrial Operations

[Headline]: Innovative Handwheel Gear Operator Revolutionizes Industrial Operations[Subheading]: Introducing a Groundbreaking solution to Efficient and Reliable Machinery Control[Date][City], [State] - In a bid to enhance the efficiency and precision of machinery control, a leading industrial automation company unveils its latest product - the Handwheel Gear Operator. Designed to optimize operations across various industries, this cutting-edge innovation is set to revolutionize the way industrial processes are carried out.[Company Name], a global leader in industrial automation solutions, has developed the Handwheel Gear Operator as a result of extensive research and development. Combining state-of-the-art technology with a user-friendly interface, this revolutionary device simplifies machinery control and ensures improved productivity.The Handwheel Gear Operator serves as a compact and versatile tool, suitable for a wide range of applications. From heavy industrial machinery to delicate precision instruments, this device provides operators with enhanced control and maneuverability. Its ergonomic design ensures comfortable operation, reducing fatigue and increasing efficiency in the workplace.One of the key features of the Handwheel Gear Operator is its seamless integration with existing machinery. This device can easily be retrofitted onto various equipment, making it a cost-effective and hassle-free solution for businesses looking to optimize their machinery control systems. The Handwheel Gear Operator also boasts compatibility with a range of industrial protocols, allowing for seamless communication and integration with existing control systems.Enhanced precision is another aspect that sets the Handwheel Gear Operator apart. Equipped with advanced digital technology, this device offers operators a high degree of accuracy in controlling speed, torque, and direction. This not only reduces the chances of human error but also enables smoother and more precise operations, resulting in improved product quality, reduced downtime, and increased overall productivity.Moreover, the Handwheel Gear Operator boasts advanced safety features, ensuring optimal worker protection. With its high-level fault detection mechanism and emergency shutdown capabilities, this device guarantees a safe operating environment for workers. By minimizing the risk of accidents and equipment damage, businesses can prioritize the well-being of their employees while maintaining continuous operations with minimal interruptions.To further enhance user experience, the Handwheel Gear Operator is equipped with a user-friendly interface. Its intuitive controls and digital display provide operators with real-time feedback, allowing for swift adjustments and monitoring of key parameters. Additionally, the device's modular design ensures easy maintenance and reduces downtime, further optimizing the overall operational efficiency."We are thrilled to introduce the Handwheel Gear Operator to the market," says [Company Name] spokesperson. "With its cutting-edge technology and extensive compatibility, we believe this device will transform the way industries operate, increasing productivity and ensuring a safer working environment for all."As industries continue to evolve and embrace automation and digitalization, the Handwheel Gear Operator offers a reliable and efficient solution to meet the growing demands of modern industrial processes. By integrating this innovative device into their operations, businesses can streamline their machinery control processes, reduce costs, and maximize productivity.About [Company Name]:[Company Name] is a leading global provider of industrial automation solutions, specializing in the design and manufacture of innovative devices to optimize industrial processes. With a strong commitment to quality and customer satisfaction, [Company Name] continues to revolutionize the industrial automation sector through cutting-edge technologies. For more information, please visit the company's website at [website URL].[Note: Please replace the [Company Name] placeholders with the actual name of the company.]

Discover the Remarkable Features and Applications of a Large Worm Gear

Title: Innovative Worm Gear Revolutionizes Large-Scale Industrial ApplicationsIntroduction:In the realm of large-scale industrial applications, a significant breakthrough has been achieved with the development of an advanced worm gear system. This cutting-edge technology, designed by an industry-leading company (), promises to revolutionize various sectors by enhancing efficiency, reliability, and sustainability. With its exceptional performance capabilities, this worm gear system is set to address challenges faced by industries worldwide and propel them towards a more productive and environmentally conscious future.Section 1: Worm Gear Enigma UnveiledThe newly developed worm gear system showcases an innovative design that surpasses the limitations of traditional gearbox solutions. Its primary components, the worm wheel and gear, have been meticulously engineered to ensure exceptional power transmission efficiency. Through precision manufacturing techniques and advanced materials, this worm gear achieves higher torque capacity, reduced frictional losses, and improved wear resistance.Section 2: Industry ApplicationsThe versatility of this worm gear system enables its integration across various industries. In the mining sector, it offers a reliable and efficient solution for heavy machinery and extraction equipment. Additionally, the system's ability to handle large loads makes it ideal for applications in rail transportation, enabling smooth and precise movement of trains and trams.In the renewable energy sector, the worm gear system proves to be a significant asset in wind turbine installations. Its robust design ensures optimal power transmission, enhancing the energy output and operational lifespan of these structures. By harnessing the power of this advanced gear system, renewable energy generation can be maximized, thereby contributing to a greener environment.Section 3: Importance of Efficiency and ReliabilityEfficiency and reliability are pivotal aspects in any industry. The worm gear system offers considerably higher efficiency compared to traditional gearboxes. Its advanced lubrication system reduces power losses and heat generation, resulting in more efficient operations. Moreover, the enhanced wear resistance capabilities of this system contribute to prolonged equipment lifespan, reducing maintenance costs and downtime.Section 4: Sustainable Manufacturing TechniquesIn line with the escalating global concern over sustainability, the company responsible for introducing this worm gear system () is committed to adopting sustainable manufacturing practices. By incorporating eco-friendly materials, reducing energy consumption during production, and optimizing resource usage, the company strives to minimize its carbon footprint. This dedication to sustainability aligns with the company's broader mission to contribute to a more environmentally friendly industrial landscape.Section 5: Future Prospects and ConclusionAs industries continue to demand enhanced performance and sustainability, the worm gear system emerges as a game-changer. The innovative design, coupled with its ability to improve efficiency, reliability, and sustainability, positions this gear system as the ultimate solution for large-scale industrial applications. With its successful integration in various sectors, efficiency gains and cost savings are expected to be realized, benefitting both businesses and the environment alike.In conclusion, the introduction of a state-of-the-art worm gear system showcases a breakthrough in the field of large-scale industrial applications. The advanced design, efficiency, and reliability offered by this gear system have the potential to transform industries such as mining, transportation, and renewable energy. By prioritizing sustainability in its manufacturing process, the company () demonstrates its commitment to a greener future. With the revolutionary worm gear technology, industries worldwide can achieve higher productivity, reduced costs, and a more sustainable approach to operations.

High-Quality Multi-Turn Spur Gearboxes Made in China

China Multi Turn Spur Gearbox: A Reliable Partner for Your Machinery NeedsChina has been a leader in the manufacturing industry, known for producing dependable equipment and machinery that is cost-effective and high-quality. One of the most widely used and highly-sought-after products in this industry is a gearbox, which is integral in the smooth operation of machinery. With advancements in technology, gearboxes have evolved to meet the demands of various applications, and today, China offers one of the most sophisticated gearboxes in the market - the Multi Turn Spur Gearbox.The Multi Turn Spur Gearbox is a high-precision machine capable of delivering accurate torque at various speeds, making it the ideal gearbox for a range of industries such as food processing, packaging, printing, and robotics. What makes it stand out from other gearboxes is its design - it's compact, durable, and requires minimal maintenance, making it suitable for both heavy-duty and light-duty applications.With customer satisfaction at the forefront, Chinese manufacturers ensure that the Multi Turn Spur Gearbox is made from the highest quality materials, including cast iron, steel and aluminum, which prevents it from rust or corrosion and ensures its longevity. Additionally, they have implemented advanced manufacturing techniques and procedures, which guarantees the production of gearboxes with precision and accuracy.Multi Turn Spur Gearbox is standardized for machines that require rotation, and they are easy to install on any piece of machinery. This is possible, thanks to the wide range of different ratios and sizes that a customer can select from. This gearbox is flexible and easy to use, ensuring that it can operate on a range of machinery.The Multi Turn Spur Gearbox is incredibly versatile, it meets the unique requirements of various applications without compromising its performance or quality. Whether you need it for power transmission, conveying, or simply general-purpose purposes, the Multi Turn Spur Gearbox is designed to deliver superior performance and reliability.One of the most interesting features of the Multi Turn Spur Gearbox is its ability to reduce noise levels significantly. Noise is a common issue that arises when using machinery with gearboxes. Still, the Multi Turn Spur Gearbox is uniquely designed to minimize noise levels below what is considered a health hazard, making it an excellent choice for industries that need to mitigate noise pollution, such as a printing press or in food processing facilities.The design of the Multi Turn Spur Gearbox also ensures that it is highly efficient in power transmission. It can transmit power, both vertically and horizontally, with up to 98% efficiency. Its compact design means that it can deliver this performance without bulking up your machinery, enabling you to make the most of your existing space and machinery.Using Multi Turn Spur Gearbox is the first step to ensuring that your machinery's system is efficient, durable, and dependable. Chinese manufacturers offer customer-friendly prices and guarantee prompt delivery, ensuring that customers can get the highest quality gearboxes at competitive prices without enduring long waiting times.In conclusion, the Multi Turn Spur Gearbox is an innovative solution for any machinery system in need of a high-level gearbox. Its precision, quality materials and manufacturing techniques, flexibility, efficiency, and competitive pricing put it ahead of other gearboxes in the market. Whether you are in packaging, printing, food processing, or robotics, investing in the Multi Turn Spur Gearbox will lead to more efficient machinery and better results in your industry.China Multi Turn Spur Gearbox - your reliable partner for all your machinery needs.

Discover the Power and Potential of Large Worm Gears

Title: Innovations in Worm Gear Technology Revolutionize IndustriesIntroduction:In today's rapidly evolving industrial landscape, it is essential for companies to continuously innovate and adapt to remain competitive. One such groundbreaking innovation is the large worm gear developed by a leading company in the industry. [Omitting brand name] has revolutionized the sector with its cutting-edge technology and highly efficient worm gears. This news article delves into the transformative potential of this gear technology, exploring its impact on various industries and highlighting the key features that differentiate it from traditional systems.1. The Rise of Large Worm Gears:The introduction of large worm gears by [Omitting brand name] has opened up new avenues for industries such as automotive, machinery, and manufacturing, where the demand for high torque and precise motion control is paramount. These large worm gears are specially designed for heavy-duty applications and offer enhanced power transmission capabilities, making them ideal for large-scale machinery and mechanical systems. Thanks to their unique design, they have the ability to efficiently transfer rotational motion between intersecting shafts while handling high loads and minimizing backlash.2. Enhancements in Efficiency and Durability:[Omitting brand name]'s large worm gears incorporate state-of-the-art materials and manufacturing processes, resulting in gears that exhibit exceptional strength, durability, and wear resistance. The use of advanced lubrication techniques in these gears also reduces friction, ensuring smooth and efficient operation over extended periods. Moreover, the precision engineering employed in their design contributes to increased efficiency, enabling industries to enhance their productivity while reducing energy consumption.3. Precision and Accuracy:The large worm gears developed by [Omitting brand name] offer superior levels of precision and accuracy, making them ideal for applications that require exact positioning and predictable motion control. The gear teeth are precisely machined to ensure consistent contact, resulting in reliable and accurate transmission of motion. This level of precision is crucial in industries such as robotics, aerospace, and medical devices, where any deviation can have serious consequences.4. Versatility and Adaptability:One of the key strengths of [Omitting brand name]'s large worm gears lies in their versatility and adaptability. These gears can be customized and optimized to suit varying customer requirements, allowing for seamless integration into existing systems. Furthermore, their compact design ensures easy installation and integration with other components, providing immense flexibility to manufacturers across different industries.The versatile nature of these gears also enables them to be used in a wide range of applications, including conveyor systems, cranes, excavators, and rotary tables. This adaptability is reflected in the extraordinary growth and adoption that [Omitting brand name]'s large worm gears have witnessed across industries.Conclusion:The advent of large worm gears by [Omitting brand name] has significantly disrupted traditional gear systems, bringing about a paradigm shift in industries that rely on high torque, precision, and efficiency. The innovative features incorporated into these gears, such as enhanced durability, precision engineering, and adaptability, have earned them recognition and preference among a diverse range of sectors.As large worm gears continue to evolve and overcome technical challenges, their applications are likely to expand even further, opening up new possibilities in industries striving for the highest standards of performance and reliability. [Omitting brand name] remains at the forefront of this transformation, continuously pushing boundaries and striving to create gear systems that redefine industry standards.

Top Providers of Traditional Chinese Scrolls for Art Lovers Worldwide

Title: Chinese Scroll Suppliers: Preserving Traditional Art through Exquisite CraftsmanshipIntroductionDate:Location:In the bustling realm of traditional Chinese art, a group of dedicated scroll suppliers has emerged, diligently safeguarding and promoting the essence of this ancient art form. Combining years of expertise with a commitment to preserving cultural heritage, Chinese Scroll Suppliers, a leading company in the industry, has been instrumental in showcasing the intricacy and beauty of Chinese scroll paintings to both domestic and international art enthusiasts.Company OverviewWith a rich history dating back centuries, scroll paintings have long been cherished as a quintessential representation of Chinese culture. Chinese Scroll Suppliers, a renowned name in the field, embraces this heritage by offering a wide range of high-quality, authentic, and handcrafted scrolls. Their collection includes traditional landscapes, calligraphy scrolls, flower and bird paintings, and other classic themes, created by skilled artisans who have inherited the techniques passed down through generations.Allied with a deep appreciation for the cultural significance of scrolls, Chinese Scroll Suppliers consistently strives to enhance the aesthetic value of their offerings. Using the finest materials, such as silk, rice paper, and exquisite ink pigments, the company adheres to strict quality standards to deliver artworks that exemplify the mastery of traditional Chinese painting techniques.Reviving the Art of Chinese ScrollsIn recent years, Chinese Scroll Suppliers has actively participated in preserving and reviving the diminishing art of Chinese scrolls. Recognizing the importance of promoting this cultural legacy, the company collaborates with renowned artists, calligraphers, and scholars who are devoted to preserving and developing the art form.Through extensive research, Chinese Scroll Suppliers has successfully sought out talented emerging artists and supported them in showcasing their skills to a broader audience. By providing a platform for these budding artists, the company ensures that the art of Chinese scrolls continues to thrive and evolve in the modern era.Furthermore, Chinese Scroll Suppliers frequently organizes exhibitions, workshops, and seminars to increase public awareness and appreciation of scroll painting techniques. These events not only allow art enthusiasts to have a firsthand experience of the creative process but also serve as an educational platform, imparting knowledge about the history and cultural significance of Chinese scrolls.International Reach and RecognitionChinese Scroll Suppliers has gained widespread acclaim for its commitment to promoting Chinese scroll artistry on the global stage. Through meticulous curation and thoughtful collaborations, the company has successfully exported Chinese scrolls to various corners of the world, introducing international art lovers to the distinctive beauty of traditional Chinese painting.To cater to diverse tastes and preferences, Chinese Scroll Suppliers constantly innovates while staying true to the essence of traditional Chinese art. Their collection features a fusion of traditional and contemporary styles, showcasing the versatility of Chinese scrolls to a worldwide audience.ConclusionChinese Scroll Suppliers has firmly established itself as a beacon of excellence in the realm of traditional Chinese scroll artistry. Through tireless dedication, the company continues to preserve, promote, and revitalize this treasured cultural embodiment. By bridging the gap between past and present, Chinese Scroll Suppliers serves as a catalyst for the preservation and international recognition of this exceptional art form.As the art world evolves, the commitment of Chinese Scroll Suppliers exemplifies the enduring allure and importance of traditional Chinese scrolls, ensuring that future generations will appreciate and cherish this extraordinary cultural heritage.

Essential Information on Worm Wheels and Shafts: A Guide

Worm wheel and worm shaft are important components used in various industries to transmit power and motion between non-parallel, power-transmitting shafts. One of the leading companies in the production of worm wheel and worm shaft is {company name}. Founded in 1978, the company has been focused on offering high-quality and efficient worm gear units, worm gear motors, and other power transmission solutions.With a well-equipped manufacturing plant spanning over 8000 square meters, {company name} is capable of producing 500,000 sets of worm gearboxes annually, delivering its products to over 70 countries worldwide. The company conforms to international standards and is certified with ISO9001, CE, and UL. With a team of highly experienced researchers, designers, and engineers, {company name} can design and produce customized power transmission solutions to meet various industrial applications.The worm wheel and worm shaft are one of the most critical components produced by {company name} for power transmission applications. These components are instrumental in the production of mechanical motion between non-parallel shafts, converting rotational energy in one direction to rotational motion in another direction. Worm gear systems developed by {company name} have a high level of efficiency, reliability, and quiet operation.One of {company name}'s unique selling propositions includes their ability to produce high-quality worm gears with either single or double output shafts. The single output shafts are ideal for applications that require low-speed rotary motion but cannot accommodate other power transmission devices. In contrast, the double output shafts are perfect for industries that require multi-axis output motion.Since worm gears operate with sliding contact between the gear teeth, it's important to ensure adequate lubrication to minimize wear and extend the life of the gear system. {company name} understands this and designs its worm gears with advanced lubrication systems, ensuring optimal system performance and a longer lifespan.{Company name}'s worm gears are also designed to operate in various environmental conditions. The worm wheels are made from high-quality materials, with 15CrMo alloy steel being the most commonly used. This material has high strength, hardness, and resistance to wear, making it ideal for worm gears that operate under heavy loads and high stresses.In conclusion, {company name} is a leading producer of worm wheel and worm shaft, and their solutions have been used in a wide range of applications, including robotics, automation, medical, packaging, printing and others. They have a reputation for producing high-quality components that have a high level of torque density, efficiency, and reliability.The company's manufacturing capabilities, strict quality control protocols, and customized solutions make them an appealing choice for various industries. Partnering with {company name} for worm gear solutions ensures you have access to high-performing products that meet your specific application requirements.

Worm and Wheel Gearboxes: A Guide to Understanding Their Function and Benefits

Worm And Wheel Type Gearbox: The Future of Power Transmission Power transmission is a crucial aspect of modern machinery and equipment, and the gearbox is one of the most critical components for this purpose. A gearbox helps convert the rotational speed and torque generated by a prime mover (e.g., motor, engine) into more usable forms for various applications. Among the many types of gearboxes available, the Worm and Wheel type gearbox stands out for its efficiency, reliability, and versatility. The Worm and Wheel type gearbox is a type of semi-reduction gearbox that uses a worm gear meshed with a worm wheel to transmit power between two shafts. The worm gear is a helical gear with one or more teeth that wrap around the worm wheel, which is usually a spur gear. The worm gear's helix angle causes the worm wheel to rotate at a reduced speed and increased torque relative to the worm gear's input. This gear set can provide a high gear reduction ratio in a compact form factor and is suitable for high-torque, low-speed applications. The Worm and Wheel type gearbox finds widespread use in various industries, including material handling, packaging, food processing, automotive, and robotics. Some typical applications of this gearbox include conveyor systems, mixers, elevators, winches, cranes, and robots. These applications demand high torque, smooth motion control, and low noise, which the Worm and Wheel type gearbox can provide with ease. The Worm and Wheel type gearbox's benefits include efficiency, reliability, and low maintenance. It can achieve a gear reduction ratio of up to 100:1 in a single stage, which reduces the number of gear sets required for a given application. This, in turn, reduces the gearbox's weight, size, and cost, making it a cost-effective solution for many applications. Additionally, the worm gear's self-locking feature can prevent back-driving and hold a load in place, making it suitable for vertical applications. The Worm and Wheel type gearbox's compact design also makes it easy to integrate into a machine or equipment. One of the leading manufacturers of Worm and Wheel type gearbox is {Removed brand name}. It has been providing cutting-edge solutions in power transmission for over 30 years and has established itself as a leader in the industry. The company's Worm and Wheel type gearbox product line includes over 100 models with various reduction ratios, input speeds, and output torques. These gearboxes are made of high-quality materials such as aluminum, steel, and cast iron, and come in various sizes and configurations to suit different applications. {Removed brand name} Worm and Wheel type gearbox products are known for their exceptional performance, durability, and low maintenance requirements. The company uses advanced manufacturing processes and quality control measures to ensure that each gearbox meets the highest standards of quality and reliability. Its research and development team continually strives to improve the gearbox's design and performance and come up with innovative solutions to meet the evolving needs of the market. Apart from Worm and Wheel type gearbox, {Removed brand name} offers a wide range of power transmission solutions, including planetary gearboxes, helical gearboxes, bevel gearboxes, and coupling devices. The company's expertise in this field has earned it a reputation as a trusted supplier of high-quality power transmission products. In conclusion, the Worm and Wheel type gearbox is an excellent option for applications that require high torque, low speed, and smooth motion control. {Removed brand name} Worm and Wheel type gearbox products offer exceptional performance, durability, and cost-effectiveness, making them an ideal choice for various industries' power transmission needs. As the demand for efficient and reliable power transmission systems grows, the Worm and Wheel type gearbox's role is set to become even more critical in shaping the future of modern machinery and equipment.

Enhance Your Machinery with High-Quality Electric Actuators for Maximum Efficiency

Title: Groundbreaking Electric Actuator Revolutionizes Industrial AutomationIntroduction:In today's rapidly evolving industrial landscape, technological advancements continue to redefine efficiency and productivity. The latest innovation making waves in the automation sector is the cutting-edge Electric Actuator developed by a pioneering company (remove brand name), offering unprecedented precision and control. With applications ranging across diverse industries such as manufacturing, energy, and transportation, this revolutionary actuator is poised to transform industrial automation processes, optimizing productivity while reducing costs and environmental impact.Electric Actuator: Unleashing a New Era of Precision and ControlThe Electric Actuator, developed by (remove brand name), is an advanced electromechanical device designed to replace conventional pneumatic and hydraulic actuators, offering significantly improved precision, control, and reliability. With its compact and lightweight design, it is adaptable to a wide range of industrial operations, from valve control to material handling, robotics, and even 3D printing.Enhanced Precision and Control:Owing to its high-precision servo motor drive system, this Electric Actuator can deliver unparalleled positional accuracy and repeatability. By eliminating the traditional drawbacks associated with pneumatic and hydraulic systems, such as air leaks, pressure loss, and unpredictable performance, it ensures enhanced control over critical operations. Industrial processes dependent on precise movement, alignment, and positioning will greatly benefit from the increased accuracy and repeatability offered by this groundbreaking technology.Efficiency and Energy Savings:The Electric Actuator boasts remarkable energy efficiency, providing substantial cost savings to industries grappling with rising energy costs and environmental concerns. Its variable speed control, along with minimal energy loss during operation, leads to a significant reduction in energy consumption, ultimately resulting in a greener and more sustainable manufacturing environment. Moreover, the elimination of costly and maintenance-intensive hydraulic or pneumatic systems brings about substantial cost-cutting benefits, enhancing the overall cost-effectiveness of industrial operations.Remote Monitoring and Control:The incorporation of cutting-edge digital technology enables the Electric Actuator to be seamlessly integrated into Internet of Things (IoT) platforms. This empowers industries to monitor and control their operations remotely, even from a centralized control room. Real-time data feedback, preventive maintenance diagnostics, and predictive failure analysis capabilities prevent unexpected downtime, boosting operational efficiency and reducing production losses.Adaptability and Customization:Recognizing the diverse needs of different industries, the Electric Actuator offers a flexible framework that can be easily customized to suit specific application requirements. The actuator's operating parameters, force range, speed, stroke length, and various control interfaces can all be tailored to match the industrial processes, ensuring optimal performance and compatibility.Safety and Reliability:Reliability is a crucial aspect of any industrial automation technology, and the Electric Actuator meets the highest safety and durability standards. Equipped with advanced safety features such as overload protection and emergency stop functionality, it ensures worker safety while preventing costly accidents and equipment damage. Additionally, the Electric Actuator exhibits exceptional resistance to harsh environmental conditions, guaranteeing a long lifespan and minimal maintenance requirements.Future Outlook:As industries across the globe grapple with the challenges of increasing productivity while reducing environmental impact, the Electric Actuator developed by (remove brand name) offers a game-changing solution that addresses these concerns head-on. With its unparalleled precision, control, efficiency, and adaptability, this innovative technology holds immense potential for revolutionizing industrial automation across a wide range of sectors. By enabling industries to optimize their operations, streamline processes, and reduce costs, the Electric Actuator is poised to lead the next generation of industrial automation.

Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

Title: Advanced Worm Gear Butterfly Valve - The Perfect Solution for Industrial Fluid ControlIntroduction:In today's rapidly evolving industrial landscape, efficient fluid control is crucial to the success and safety of various operations. Owing to their versatility and effectiveness, Worm Gear Butterfly Valves have emerged as the go-to solution for regulating fluid flow in numerous industries. These valves, offering superior sealing capabilities and reliable performance, are now revolutionizing the way businesses approach fluid control.I. Significance of Worm Gear Butterfly Valves in Industrial Applications (100 words)Worm Gear Butterfly Valves have garnered significant prominence across industries due to their unique design and exceptional functionality. These valves consist of a disk-shaped element, known as the "butterfly," which rotates to control fluid flow. The addition of worm gears - a mechanical adjustment system - enables precise regulation, making them ideal for applications where fluid control precision is paramount. Whether it's chemical processing, water treatment, or power generation, Worm Gear Butterfly Valves have become indispensable tools for optimizing efficiency and enhancing safety.II. Key Features and Benefits of Worm Gear Butterfly Valves (200 words)a) Reliable Performance: Worm Gear Butterfly Valves are designed to withstand extreme conditions, offering consistent and dependable performance. The high-quality materials used in manufacturing ensure longevity and minimal maintenance.b) Excellent Sealing Properties: The unique design of these valves allows for a tight seal, preventing leakage and offering superior tightness. This ensures optimal flow control and minimizes the risk of fluid wastage, enhancing operational efficiency.c) Precise Control: The inclusion of the worm gear mechanism enables precise, measured adjustments to fluid flow, allowing operators to fine-tune operations as required. This precision is particularly critical in industries such as oil and gas, where even slight variations can result in significant consequences.d) Easy Installation and Operation: Worm Gear Butterfly Valves are known for their simplicity. They can be easily integrated into existing systems and operated efficiently by both experienced professionals and operators new to the technology.e) Versatility: These valves can handle a wide range of fluids, including liquids, gases, and even corrosive media. This adaptability makes Worm Gear Butterfly Valves suitable for applications across diverse industries.III. Company X's Advanced Worm Gear Butterfly Valve (200 words)Company X, a renowned industry leader in fluid control solutions, is proud to present its cutting-edge Worm Gear Butterfly Valve. With a steadfast commitment to innovation and customer satisfaction, Company X has designed a valve that surpasses industry standards and addresses various industry challenges.The advanced Worm Gear Butterfly Valve by Company X combines robust construction, precision performance, and exceptional durability. Manufactured using premium grade materials, it ensures longevity and reliability, minimizing maintenance requirements and reducing downtime.In addition to exceptional sealing properties, Company X's Worm Gear Butterfly Valve offers unparalleled precision control. Its worm gear mechanism guarantees accurate fluid flow adjustments, empowering operators to regulate processes with utmost accuracy.The valve's user-friendly design simplifies installation and operation, catering to customers across different industries. The versatility of Company X's Worm Gear Butterfly Valve allows businesses to maximize efficiency and safety, enhancing productivity and minimizing operational costs.IV. Conclusion (100 words)In an era where efficient fluid control is crucial, the Worm Gear Butterfly Valve emerges as the ideal solution for various industrial applications. Company X's advanced valve, with its superior design and outstanding performance, is primed to revolutionize fluid control practices across industries. With its exceptional sealing capabilities, precise control, and straightforward operation, this valve presents an unprecedented opportunity for businesses to optimize their operations, enhance safety, and maximize efficiency. Embracing the advantages offered by Worm Gear Butterfly Valves marks a significant leap forward in fluid control technology.

Revolutionary Innovation in the World of Turbine Wheels Discovered by Experts

Title: Revolutionary Turbine Wheel Redefines Renewable Energy Production Introduction:In a groundbreaking development in the field of renewable energy, a cutting-edge turbine wheel has been unveiled, promising to revolutionize power generation around the world. Developed by an innovative company specializing in energy solutions, this turbine wheel harnesses the power of wind and converts it into clean and sustainable electricity. With its unprecedented efficiency and design, this new technology offers a shining beacon of hope for a greener future.[Provide a brief description of the company, highlighting its specialization in energy solutions and commitment to sustainable development. Emphasize their dedication to research and innovation in order to bring about positive changes in the global energy landscape.]Body:1. Turbine Wheel Unveiled - A New Era for Renewable Energy:The new turbine wheel, developed by the pioneering energy solutions company, marks a significant milestone in renewable energy technology. Designed to capitalize on wind energy, this innovative turbine wheel has been engineered to maximize efficiency and output, setting it apart from conventional wind turbines.2. Unleashing the Power of the Wind:The turbine wheel boasts state-of-the-art aerodynamic features that enable it to harness a greater amount of energy from even the slightest breeze. Its unique design enhances wind capture, enabling a more consistent and reliable power generation. Harnessing wind energy has never been more efficient or reliable than with this groundbreaking turbine wheel.3. Increased Efficiency Revolutionizes Energy Production:With its advanced technology, the turbine wheel surpasses its predecessors in terms of energy production. Through meticulous engineering, the company has vastly improved the turbine's ability to convert wind energy into electricity, significantly increasing its overall efficiency. This leap in efficiency is a significant step towards the widespread adoption of renewable energy solutions.4. Versatile Applications Open New Horizons:Efforts have been made to make this revolutionary turbine wheel applicable to a myriad of environments. By adapting and customizing the wheel design, it can be effectively utilized in various locations with different wind conditions. This versatility opens up new possibilities for renewable energy production, making it accessible for regions previously deemed unsuitable for wind-power generation.5. Paving the Way for Sustainable Future:By harnessing the immense power of the wind, this turbine wheel contributes directly to minimizing CO2 emissions and reducing reliance on fossil fuels. The implementation of this advanced technology will accelerate the transition towards a cleaner and more sustainable energy future. The turbine wheel is a testament to the company's commitment to combating climate change and mitigating its environmental impact.6. Overcoming Challenges and Ensuring Reliability:One of the key challenges faced in the renewable energy sector is intermittency. To combat this issue, the turbine wheel is equipped with mechanisms that ensure uninterrupted power supply regardless of wind variations. This innovative feature guarantees a more stable electricity generation, promoting grid reliability and minimizing any fluctuations in energy supply.7. Economic Benefits and Job Creation:The widespread adoption of this turbine wheel technology has the potential to stimulate economic growth. Investments in renewable energy projects using this groundbreaking technology would not only drive down energy costs over time but also create a significant number of sustainable jobs, boosting local economies in the process.8. Collaborative Efforts and Future Prospects:To maximize the impact of this revolutionary turbine wheel technology, the energy solutions company is actively engaging in partnerships and collaborations with governments, businesses, and scientific institutions. By fostering a cooperative spirit and sharing knowledge, they aim to facilitate the integration of this innovative technology into existing energy infrastructures worldwide, accelerating the global transition towards sustainable power generation.Conclusion:The unveiling of this groundbreaking turbine wheel represents a significant milestone in the renewable energy sector. With enhanced efficiency, reliability, and versatility, this technology promises to revolutionize wind energy generation and pave the way for a cleaner and greener future. By harnessing the power of the wind, the turbine wheel offers hope for a sustainable world, advancing the global fight against climate change and fostering economic growth through job creation. The energy solutions company has proven its commitment to innovation and sustainable development, solidifying its position as a leading force in the renewable energy revolution.