Discover the Remarkable Features and Applications of a Large Worm Gear

By:Admin

Introduction:

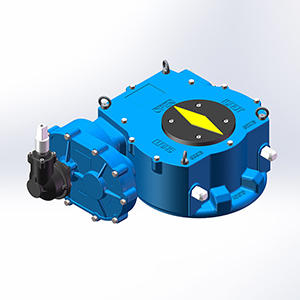

In the realm of large-scale industrial applications, a significant breakthrough has been achieved with the development of an advanced worm gear system. This cutting-edge technology, designed by an industry-leading company (), promises to revolutionize various sectors by enhancing efficiency, reliability, and sustainability. With its exceptional performance capabilities, this worm gear system is set to address challenges faced by industries worldwide and propel them towards a more productive and environmentally conscious future.

Section 1: Worm Gear Enigma Unveiled

The newly developed worm gear system showcases an innovative design that surpasses the limitations of traditional gearbox solutions. Its primary components, the worm wheel and gear, have been meticulously engineered to ensure exceptional power transmission efficiency. Through precision manufacturing techniques and advanced materials, this worm gear achieves higher torque capacity, reduced frictional losses, and improved wear resistance.

Section 2: Industry Applications

The versatility of this worm gear system enables its integration across various industries. In the mining sector, it offers a reliable and efficient solution for heavy machinery and extraction equipment. Additionally, the system's ability to handle large loads makes it ideal for applications in rail transportation, enabling smooth and precise movement of trains and trams.

In the renewable energy sector, the worm gear system proves to be a significant asset in wind turbine installations. Its robust design ensures optimal power transmission, enhancing the energy output and operational lifespan of these structures. By harnessing the power of this advanced gear system, renewable energy generation can be maximized, thereby contributing to a greener environment.

Section 3: Importance of Efficiency and Reliability

Efficiency and reliability are pivotal aspects in any industry. The worm gear system offers considerably higher efficiency compared to traditional gearboxes. Its advanced lubrication system reduces power losses and heat generation, resulting in more efficient operations. Moreover, the enhanced wear resistance capabilities of this system contribute to prolonged equipment lifespan, reducing maintenance costs and downtime.

Section 4: Sustainable Manufacturing Techniques

In line with the escalating global concern over sustainability, the company responsible for introducing this worm gear system () is committed to adopting sustainable manufacturing practices. By incorporating eco-friendly materials, reducing energy consumption during production, and optimizing resource usage, the company strives to minimize its carbon footprint. This dedication to sustainability aligns with the company's broader mission to contribute to a more environmentally friendly industrial landscape.

Section 5: Future Prospects and Conclusion

As industries continue to demand enhanced performance and sustainability, the worm gear system emerges as a game-changer. The innovative design, coupled with its ability to improve efficiency, reliability, and sustainability, positions this gear system as the ultimate solution for large-scale industrial applications. With its successful integration in various sectors, efficiency gains and cost savings are expected to be realized, benefitting both businesses and the environment alike.

In conclusion, the introduction of a state-of-the-art worm gear system showcases a breakthrough in the field of large-scale industrial applications. The advanced design, efficiency, and reliability offered by this gear system have the potential to transform industries such as mining, transportation, and renewable energy. By prioritizing sustainability in its manufacturing process, the company () demonstrates its commitment to a greener future. With the revolutionary worm gear technology, industries worldwide can achieve higher productivity, reduced costs, and a more sustainable approach to operations.

Company News & Blog

Discover the Latest Advancements in Worm and Bevel Gears

Breaking News: Revolutionary Worm and Bevel Gear Partnership Sets New Industry StandardIn a groundbreaking move, a leading manufacturer in the mechanical engineering industry has announced a strategic partnership between its innovative "Worm" and "Bevel Gear" technologies. This landmark collaboration is poised to reshape the landscape of gear systems, offering enhanced performance and efficiency across various industrial applications. With a commitment to excellence and a focus on providing cutting-edge solutions, this partnership represents a significant milestone for both companies and the industry as a whole.The "Worm" and "Bevel Gear" technologies, developed independently by two reputable brands, have long been renowned for their exceptional engineering prowess and reliability. By combining these two revolutionary technologies, the new partnership aims to deliver a gear system that surpasses all expectations in terms of mechanical efficiency, power transmission, and durability.The Worm technology, known for its unique helical screw design, has been widely used in various industries for decades. Its ability to provide high gear ratios and transmit power smoothly makes it a preferred choice for applications requiring precision motion control, such as robotics, packaging, and conveyor systems.On the other hand, Bevel Gear, which features interlocking, cone-shaped gears, is sought after for its ability to transmit power at different angles. This technology has found widespread use in automotive differentials, printing presses, and industrial machinery where the torque must be efficiently transferred between intersecting shafts. Its versatility and reliability make it an indispensable component in many critical applications.The collaborative efforts between the two technologies have resulted in a gear system that promises unparalleled performance and efficiency. By combining the unique strengths of the Worm and Bevel Gear technologies, this partnership aims to create a new benchmark in the industry, setting higher standards for gear systems' power transmission, reliability, and lifespan.The unified gear system is expected to bring numerous advantages to end-users across various industries. These include increased torque transmission, reduced energy consumption, enhanced system stability, and improved overall performance. By optimizing the gear's design, utilizing the latest manufacturing techniques, and implementing advanced materials, the partnership intends to offer a gear system that meets and exceeds the evolving demands of today's industries.Additionally, with a focus on sustainability, the partnership aims to minimize the environmental impact of their gear systems. Through innovative design modifications and material selection, they aim to reduce the overall carbon footprint while maintaining top-notch performance and reliability.As leaders in their respective fields, both companies bring a wealth of knowledge, expertise, and experience to this partnership. Together, they are committed to driving innovation, enhancing industrial productivity, and delivering solutions that inspire confidence in their customers.The Worm and Bevel Gear partnership will undoubtedly disrupt the industry, igniting a new era of gear system design and engineering excellence. By combining their expertise and resources, the collaborators are poised to transform the way industries utilize gear systems, setting new standards for efficiency, reliability, and sustainability.For more information about the revolutionary Worm and Bevel Gear partnership and the forthcoming gear system, please visit [Company website] and get ready to witness the future of mechanical engineering.

Top Multi-Turn Worm Gearbox Suppliers in China Unveiled

Title: China's Multi-Turn Worm Gearbox Suppliers: Delivering Excellence in Precision EngineeringIntroduction:China's manufacturing industry has made monumental strides over the years, solidifying its position as a global leader in providing high-quality industrial products. In particular, the multi-turn worm gearbox sector has witnessed remarkable growth, largely thanks to a cohort of dependable suppliers implementing advanced precision engineering techniques. This article delves into the thriving market of multi-turn worm gearbox suppliers in China, shedding light on the prowess of these companies in delivering excellence in precision engineering.1. A Booming Market for Multi-Turn Worm Gearbox Suppliers in China:China's industrial landscape has expanded rapidly, paving the way for significant advancements in various sectors. One such sector gaining prominence is the production and distribution of multi-turn worm gearbox, an essential mechanical component extensively used in diverse fields such as automation, robotics, and industrial machinery. To meet the surging demand for precision-driven products, a multitude of suppliers have emerged across China, offering cutting-edge solutions to both domestic and international markets.2. Emphasizing Precision Engineering:Precision engineering lies at the core of successful multi-turn worm gearbox production, ensuring durability, efficiency, and accuracy. To address this essential aspect, suppliers in China are utilizing state-of-the-art technology and employing highly skilled engineers and technicians. By leveraging advanced machinery and adhering to stringent quality control measures, Chinese suppliers are consistently delivering stellar products that meet and exceed international standards.3. Commitment to Research and Development:China's multi-turn worm gearbox suppliers comprehend the significance of relentless innovation and understand that staying at the forefront of technological advancements is crucial for sustained growth. Companies are investing substantial resources in research and development, striving to improve the functional capabilities of their gearboxes while simultaneously enhancing energy efficiency, reducing noise levels, and expanding load-bearing capacities.4. Tailored Solutions for Diverse Industries:The versatility of multi-turn worm gearboxes is one of their primary advantages, making them suitable for a wide range of industries. Recognizing this, Chinese suppliers are dedicated to designing and manufacturing gearboxes that cater specifically to each industry's unique requirements. Whether it is for industrial automation, agriculture, or renewable energy applications, China's suppliers can customize their gearboxes to enhance system performance, adaptability, and overall productivity.5. Quality Assurance: Certifications and Standards:Chinese multi-turn worm gearbox suppliers understand the significance of quality assurance in gaining the confidence of global markets. Reliable suppliers comply with international quality management systems, often holding certifications such as ISO 9001, ISO 14001, and OHSAS 18001. Adhering to these rigorous standards ensures that customers receive products that adhere to global benchmarks of quality, reliability, and safety.6. Steadfast Commitment to Customer Satisfaction:Drawing upon the rich tradition of excellent customer service, Chinese multi-turn worm gearbox suppliers prioritize client satisfaction as paramount. By nurturing long-standing partnerships with their customers, suppliers in China establish trust and foster open communication channels throughout the entire procurement process. This commitment to customer-centricity further solidifies China's position as a preferred source for multi-turn worm gearbox solutions worldwide.Conclusion:As China's manufacturing industry continues to grow, the country's multi-turn worm gearbox suppliers stand out as reliable and technologically advanced contributors to the global precision engineering market. With a focus on quality, innovation, and customer satisfaction, these Chinese suppliers are seamlessly integrating cutting-edge technology into their products, enabling industries across the globe to optimize their operations and precision machinery. As the sector continues to flourish, the world can expect China's multi-turn worm gearbox suppliers to maintain their path of excellence, spreading their wings and conquering new horizons.

Innovative Turbine Wheel: Unleashing the Power of Efficient Energy Generation

Turbine Wheel, a leading provider of turbine wheel technology, is revolutionizing the energy industry with its innovative products that improve efficiency, reliability, and performance. The company's state-of-the-art technology is designed to meet the needs of power generation and other industrial applications, helping businesses reduce their carbon footprint while improving their bottom line.The company's turbine wheels are manufactured using advanced materials and technologies that make them lighter, stronger, and more durable than traditional designs. They are designed to operate at high temperatures and pressures, making them ideal for use in demanding applications such as gas turbines, steam turbines, and other power generation systems.One of the key advantages of Turbine Wheel's products is their ability to improve energy efficiency. Turbine wheels are responsible for converting the energy from fuel into mechanical energy, which is then used to generate electricity. By improving the efficiency of this process, Turbine Wheel's products help businesses reduce their energy costs while also reducing their carbon footprint.In addition to improving energy efficiency, Turbine Wheel's products also improve reliability and performance. Their state-of-the-art design reduces stresses on the wheel, extending its lifespan and reducing the likelihood of failure. This means that power plants and other industrial facilities can operate more reliably, with less downtime and fewer costly repairs.Turbine Wheel's commitment to innovation has also led to the development of specialized products for specific applications. For example, the company has developed a range of turbine wheels specifically designed for use in renewable energy systems, such as wind turbines and hydroelectric power plants. These products are designed to operate in variable conditions, maximizing energy output while minimizing wear and tear on the equipment.The company's commitment to quality is evident in every aspect of its business operations. Turbine Wheel has a state-of-the-art manufacturing facility that utilizes the latest technologies and processes to produce high-quality products consistently. The company also has a rigorous quality control program that ensures every product meets or exceeds industry standards.Turbine Wheel's dedication to innovation, quality, and customer service has earned it a reputation as an industry leader. The company has a global presence, with operations in North America, Europe, and Asia. It is trusted by some of the world's leading energy companies, including ExxonMobil, Shell, and Siemens.Looking ahead, Turbine Wheel is continuing to invest in research and development to explore new technologies and applications for its products. The company is also exploring partnerships and collaborations with other leading companies in the energy industry to leverage the strengths of each organization and develop innovative solutions to meet the world's growing energy needs.In summary, Turbine Wheel is a leading provider of turbine wheel technology that is transforming the energy industry. Its innovative products improve efficiency, reliability, and performance while reducing costs and carbon footprint. With a commitment to innovation, quality, and customer service, Turbine Wheel is poised for continued success in the global energy market.

Leading Turbo Manufacturer in China Offers High-Quality Products in Growing Market

Title: Leading Chinese Turbo Manufacturer Expands its Reach in Global Markets Introduction:In a bid to strengthen its position in the turbocharger industry, a prominent Chinese turbo manufacturer, known for its expertise in cutting-edge technology and efficient production processes, is successfully expanding its reach in the global market. This strategic move comes as the company aims to meet the growing demand for turbochargers across various industries, including automotive, power generation, and marine applications. With a commitment to delivering high-quality turbochargers and exceptional customer service, the Chinese turbo manufacturer is poised to establish itself as a global leader in the industry.Company Overview:Established in [year], the company has consistently been at the forefront of innovation in turbocharger technology. Armed with state-of-the-art research and development facilities, the company has made significant strides in perfecting their turbocharging solutions. With a focus on energy efficiency, reliability, and performance, their product portfolio caters to a diverse range of customer requirements across different sectors.The company's commitment to quality has been recognized by various domestic and international certifications, including ISO 9001, ISO/TS 16949, and ISO 14001. Adhering to stringent quality control measures, the company ensures that its turbochargers meet the highest industry standards while also adopting eco-friendly manufacturing processes.Expanding Global Reach:In recent years, the Chinese turbo manufacturer has made significant inroads overseas, tapping into new markets worldwide. With an extensive distribution network and a strong presence in regions such as North America, Western Europe, and Asia-Pacific, the company has successfully established strong partnerships with leading original equipment manufacturers (OEMs) and aftermarket dealers in these regions.The company's ability to adapt its offerings to local market requirements has been a key driver of its success. By tailoring their turbochargers to suit specific applications, the manufacturer has been able to meet the diverse demands of different industries. This adaptability, coupled with a strong commitment to customer satisfaction, has resulted in accelerated growth in international markets.Technological Advancements:The Chinese turbo manufacturer's success can be attributed to its continuous investment in research and development. By collaborating with leading industry experts, the company has pushed the boundaries of turbocharging technology. This has led to improved efficiency, reduced emissions, and increased power output in their turbochargers, ensuring optimum performance across various applications.Additionally, the company has embraced the latest advancements in manufacturing processes, including intelligent automation and robotics. By implementing cutting-edge technology, they have achieved higher production capacities, enhanced precision, and improved product consistency. Through automated quality control systems, the company guarantees the reliability and durability of its turbochargers, thereby fostering trust among its customers.Future Growth Prospects:Looking ahead, the Chinese turbo manufacturer intends to further expand its global footprint by exploring emerging markets in Africa, the Middle East, and Latin America. With the rise in demand for energy-efficient and environmentally friendly solutions, these regions present significant growth opportunities for the company.Furthermore, ongoing investments in research and development will pave the way for the development of advanced turbocharging solutions, meeting the evolving needs of industries like electric vehicles and renewable energy. By continuously innovating and staying ahead of market trends, the company remains confident in its ability to meet global demand and maintain its position as a leading turbo manufacturer.Conclusion:As the global demand for turbochargers continues to rise, a reputable Chinese turbo manufacturer is strategically positioning itself as a key player in the industry. Through its unwavering commitment to cutting-edge technology, superior quality, and customer satisfaction, the company has successfully expanded its reach in global markets. With a combination of innovative solutions, adaptable offerings, and a dedication to research and development, the Chinese turbo manufacturer is poised for a promising future in the turbocharging industry.

Cutting-Edge Electromagnetic Valve Actuator Technology Unveiled - A Game-Changer in the Industry

ELECTROMAGNETIC VALVE ACTUATOR: THE FUTURE OF CONTROLThe world is transforming at an unprecedented rate, and new technologies are being developed to offer effective solutions to diverse problems. The industrial world is not exempt from this transformation as various cutting-edge technologies are being developed to improve precision, productivity, and efficiency. One such technology is the Electromagnetic Valve Actuator, which holds the key to better control systems and enhanced production processes.Electromagnetic Valve Actuators are the driving force behind the operation of control valves. This technology offers high precision and reliable control, which is essential in industrial plant automation. With an electromagnetic valve actuator, it is easier to regulate the flow, pressure, level, and temperature in a production process. Companies that prioritize precision, quality, and productivity have been quick to adopt this technology.One such company is ***, a leading industrial valve control system provider, with a reputation for quality and reliability. With decades of experience in providing innovative solutions for industrial process control, ***, has been at the forefront of developing and adopting cutting-edge technologies. The company has consistently been at the forefront of providing innovative solutions to complex industrial problems. The integration of the Electromagnetic Valve Actuator in their products is just one example of their commitment to customer satisfaction, innovation, and quality delivery.*** offers an array of high-quality products, with a range of specifications to suit various applications in industries such as oil and gas, chemical, power generation, and petrochemical. With the Electromagnetic Valve Actuator technology integrated into their valve control systems, customers are assured of high-precision control of their production processes. The electromagnetic valve actuator offers a quick response, and high accuracy in controlling valve position, and in turn, the flow and pressure in a process. This attribute is essential for obtaining a consistent and reliable outcome in production.One benefit of electromagnetic valve actuators is their maintenance-free operation. This feature offers reliable operations in harsh environments without exposure to wear and corrosion. Conventional actuator technologies may require periodic maintenance, which could be costly and time-consuming. However, with the electromagnetic actuator, periodic maintenance is unnecessary, leading to a reduction in downtime, and increased productivity.***(company name) boasts of a skilled team of professionals with a wealth of knowledge and experience in industrial process control. Their expertise combined with the electromagnetic valve actuator technology has enabled ***(company name) to develop bespoke solutions for clients with unique process requirements. The company works closely with customers to ensure their specific needs are met, and solutions are tailored to achieve optimal performance.In conclusion, the advent of the Electromagnetic Valve Actuator technology is revolutionary in the industrial world, and companies that prioritize productivity, quality, and efficiency are embracing this technology. The benefits of the electromagnetic valve actuator technology are vast, including high-precision control, maintenance-free operation, and reliability in harsh environments. ***(company name), a leading industrial valve control system provider, is at the forefront of adopting this technology, offering high-quality products and bespoke solutions to customers. Their commitment to customer satisfaction, innovation, and quality delivery ensures that customers benefit from the best technology available in the market.

Durable and Efficient Gear Solutions for Enhanced Performance

Title: Gear Manufacturing Company Introduces Innovative Worm and Bevel Gear TechnologyIntroduction:[Company Name], a renowned gear manufacturing company with a rich history in producing high-quality gears, is proud to introduce its latest innovation in mechanical power transmission – advanced Worm and Bevel Gear technology. This cutting-edge gear solution aims to revolutionize various industries by enhancing efficiency, durability, and performance in diverse applications.Company Overview:Established for over four decades, [Company Name] has been at the forefront of gear manufacturing, catering to a wide range of industries including automotive, aerospace, industrial machinery, and renewable energy. Our commitment to excellence, combined with state-of-the-art technology, has enabled us to develop and deliver reliable gear solutions that meet the evolving market demands.Developing Worm and Bevel Gear Technology:Recognizing the need for more efficient, reliable, and cost-effective gear solutions, [Company Name] invested substantial resources into research and development, culminating in the creation of the advanced Worm and Bevel Gear technology. This groundbreaking gear system combines the strengths of both worm gears and bevel gears, resulting in an innovative solution that surpasses conventional gear designs in various applications.Enhanced Efficiency:The patented Worm and Bevel Gear design optimizes power transmission efficiency, reducing energy loss and enhancing overall system performance. The precise machining techniques employed by [Company Name] produce gears with exceptional accuracy, minimizing friction and decreasing wear and tear on the gear components. This reduction in energy loss translates to significant cost savings for end-users, offering improved operational sustainability.Durability and Reliability:The Worm and Bevel Gear technology developed by [Company Name] incorporates state-of-the-art materials, advanced heat treatment processes, and stringent quality control procedures. This ensures that the gear components exhibit superior durability, resistance to wear, and exceptional load-bearing capacity. With extended longevity and reduced maintenance requirements, [Company Name]'s Worm and Bevel Gear technology provides reliability and peace of mind to industries operating in demanding conditions.Versatile Applications:This innovative gear technology finds applications in several industries. In the automotive sector, it delivers efficient power transmission from the engine to the wheels, resulting in improved fuel efficiency. In the aerospace industry, the gear technology ensures smooth and reliable operation of landing gears, reducing maintenance costs and increasing flight safety. Additionally, the Worm and Bevel Gear technology can be used in industrial machinery, mining equipment, renewable energy systems, and more, offering enhanced performance and reliability across a wide range of applications.Partnerships and Collaborations:[Company Name] has forged strategic partnerships and collaborations with leading industry players and research institutions to continually refine and advance its Worm and Bevel Gear technology. The company believes in fostering technological advancements by exchanging knowledge, skills, and expertise. Leveraging these collaborative efforts, [Company Name] endeavors to push the boundaries of gear innovation and reinforce its position as a global leader in gear manufacturing.Conclusion:[Company Name]'s introduction of its advanced Worm and Bevel Gear technology reflects its commitment to shaping the future of mechanical power transmission. With increased efficiency, durability, and reliability, this innovative gear solution holds immense potential to transform various industries, ensuring seamless power transmission and optimizing overall system performance. As [Company Name] continues to focus on delivering cutting-edge gear solutions, the company remains poised to revolutionize the gear manufacturing industry and propel it towards a more advanced and sustainable future.

Durable Worm Gear for Industrial Applications: A Game-Changer in the Market

Title: Industry-Leading Metal Worm Gear: Revolutionizing Efficiency and ReliabilityIntroductionInnovation has been the cornerstone of the mechanical engineering industry, ensuring constant evolution and improvement. Among the slew of advancements, the Metal Worm Gear has become an indispensable component, providing unparalleled efficiency and reliability to various sectors worldwide. Today, we explore the company's groundbreaking contribution towards this remarkable feat.Company BackgroundWith a rich legacy spanning over three decades, the company has emerged as a global leader in manufacturing high-quality metal worm gears. Situated in the heart of industrial excellence, the company prides itself on its cutting-edge research and development facilities, state-of-the-art manufacturing units, and a team of experienced engineers.Metal Worm Gear: Revolutionizing EfficiencyThe Metal Worm Gear has revolutionized the industry by offering a range of benefits, including enhanced efficiency, durability, and versatility across multiple applications. Offering impressive torque output in even the most demanding environments, this gear has proven to be a game-changer in countless industries.The company's unwavering commitment to excellence shines through in the manufacturing process. The worm gears are meticulously crafted using top-grade, industrial-quality alloy materials, ensuring exceptional strength and durability. The precise engineering and advanced manufacturing techniques employed guarantee consistent performance, efficient power transmission, and reduced energy loss.The superior efficiency of the Metal Worm Gear is attributed to its unique design features. The gear's helical shape enables smoother motion and engagement, resulting in reduced noise, vibration, and wear. This remarkable design ensures long-lasting functionality and minimal maintenance requirements, leading to substantial cost savings for companies that rely on these gears for their operations.Furthermore, the Metal Worm Gear offers exceptional versatility, seamlessly integrating into various mechanical systems across industries like automotive, aerospace, robotics, and more. Its compact size and adaptability make it an ideal choice for space-constrained applications while ensuring uncompromised performance under heavy loads.Meeting the Highest Quality StandardsThe company's unwavering commitment to quality is the backbone of its success. Adhering to stringent international quality standards, like ISO 9001:2015, the Metal Worm Gear undergoes rigorous testing at every stage of manufacturing. This guarantees the utmost precision, reliability, and performance on every product that leaves the production line.Continuous Research and DevelopmentTo maintain its position as an industry leader, the company invests heavily in research and development efforts. Collaborating with renowned universities, industry experts, and customers, the company focuses on constantly improving its gear designs, materials, and manufacturing techniques. This dedication to innovation ensures that customers receive cutting-edge products that meet and exceed their evolving industry requirements.Sustainability and Environmental ResponsibilityContributing to a greener future, the Metal Worm Gear reflects the company's dedication to sustainability. By optimizing production processes, reducing waste, and prioritizing energy efficiency, the company aims to minimize its ecological footprint. Additionally, the long lifespan and durability of the Metal Worm Gear further contribute to resource conservation and waste reduction.ConclusionThe Metal Worm Gear has undoubtedly emerged as a game-changer in the mechanical engineering industry. Its extraordinary efficiency, reliability, and versatility have found widespread applications across multiple sectors. With its unwavering commitment to superior quality, continuous innovation, and environmental responsibility, the company behind this groundbreaking gear has solidified its place as an industry leader. As technology continues to advance, the Metal Worm Gear remains at the forefront, driving efficiency and reliability for countless businesses worldwide.

Boost the Performance of Your Machinery with Right Angle Gear Reduction Technology

Title: Next-Generation Right Angle Gear Reduction Solution Revolutionizes IndustriesIntroductionIn a constant pursuit to enhance efficiency and reliability across various industries, advances in gear technology have become pivotal. Recognizing this need, a leading gear manufacturing company has developed an innovative Right Angle Gear Reduction solution that promises to revolutionize several sectors, improving performance and productivity. By combining cutting-edge technology with precision engineering, this new gear reduction solution is poised to transform industries such as automotive, aerospace, robotics, and more.BackgroundRight Angle Gear Reduction plays a critical role in numerous applications, transmitting power and torque between shafts at right angles. The effectiveness of such systems greatly impacts performance, durability, and operational safety. With the increasing demand for intricate machinery, stringent precision, and compact design, the gear industry has been relentlessly innovating to meet these growing requirements.Right Angle Gear Reduction plays an integral part in several key industries. From automotive manufacturing to aerospace engineering, robotics, and heavy machinery, the importance of reliable and efficient transmission systems cannot be overstated. Realizing the potential to improve these critical gears, the renowned gear manufacturing company {} has successfully developed an advanced solution that revolutionizes Right Angle Gear Reduction.Features and BenefitsThe new Right Angle Gear Reduction solution is designed to deliver exceptional performance along with a host of advantages that cater to the evolving needs of various industries.1. Precision Engineering: The gear reduction system incorporates state-of-the-art precision engineering techniques. The company's extensive experience and expertise in gear manufacturing ensure high-quality components that enhance overall system performance.2. Compact Design: The compactness of the gear reduction system allows for more flexible integration into various applications. It occupies less space while maintaining the necessary power and torque requirements, making it an ideal fit for modern machinery.3. High Torque Transmission: The gear reduction solution boasts superior torque transmission capabilities, enabling it to handle heavy-duty applications. This feature enhances productivity and reliability in industries such as manufacturing, robotics, and automation.4. Enhanced Efficiency: By utilizing advanced materials and optimized gear profiles, the gear reduction system ensures minimal energy loss and improved efficiency. Industries heavily reliant on power transmission will benefit from reduced energy consumption, resulting in cost savings and reduced environmental impact.5. Customizable Solutions: Understanding the diverse needs of industries, the company offers customizable solutions to meet specific requirements. This flexibility empowers clients to optimize the gear reduction system based on their unique applications, leading to increased performance and cost-effectiveness.ApplicationsThe innovative Right Angle Gear Reduction solution finds immense potential in multiple industries and applications:1. Automotive: With the automotive industry experiencing a shift towards electric vehicles and advanced powertrain systems, reliable gear reduction solutions play a crucial role. The new gear reduction system can enhance efficiency, reliability, and range capabilities, leading to improved electric and hybrid vehicles' performance.2. Aerospace: In the aerospace sector, the need for lightweight and efficient systems is paramount. The compact design and high torque transmission capacity of the gear reduction system make it an ideal choice for aerospace applications such as wing flap mechanisms, landing gears, and control surface actuators, among others.3. Robotics and Automation: As automation continues to expand in industries, precise and compact gear reduction solutions are critical for robot arm articulation, conveyor systems, and collaborative robots. The superior torque transmission and customizable options of the gear reduction system ensure maximum efficiency and reliability in robotic applications.4. Heavy Machinery: Industries such as construction, mining, and marine require robust yet efficient gear reduction systems. The new advanced solution provides exceptional torque capability, enabling seamless power transmission for various heavy machinery applications, ultimately improving productivity and durability.ConclusionWith the advent of the next-generation Right Angle Gear Reduction solution developed by {}, industries across the board can expect significant improvements in performance, efficiency, and reliability. The company's commitment to precision engineering, compact designs, high torque transmission capabilities, and customizable solutions has the potential to revolutionize industries such as automotive, aerospace, robotics, and heavy machinery. As technology continues to advance, gear transmission systems play a crucial role in shaping the future of numerous sectors, and this new innovation sets a promising course for improved machinery performance and production efficiency.

Leading Supplier of High-Quality Gearbox Gate Valves in China Revealed

Title: Prominent Chinese Manufacturer Emerges as Leading Gearbox Gate Valve Supplier in the Global MarketIntroduction:[Company name], a well-established industrial equipment manufacturer based in China, has emerged as a leading supplier of gearbox gate valves not only within the domestic market but also globally. The company's dedication to excellence, strict quality control, and advanced technological capabilities have contributed to its rise in prominence. By focusing on customer satisfaction, continuous innovation, and maintaining high standards, [Company name] has successfully positioned itself as a trusted partner for numerous industries across the globe.Paragraph 1:[Company name], founded in [year], has built a solid reputation as a manufacturer and supplier of industrial equipment over the past several decades. The company specializes in designing, producing, and marketing a wide range of high-quality gearbox gate valves. By employing a team of experienced engineers and technicians, [Company name] ensures that all its products are reliable, durable, and meet the strictest quality requirements.Paragraph 2:One of the key factors that contribute to [Company name]'s success is its commitment to research and development. By investing significantly in cutting-edge technologies and innovation, the company consistently introduces enhanced and efficient gearbox gate valves to the market. This strong focus on advancement has enabled [Company name] to remain at the forefront of the industry, giving it a competitive edge over its counterparts.Paragraph 3:In recent years, [Company name] has gained substantial recognition and trust globally, thanks to its reliable and efficient gearbox gate valves. By undertaking extensive research and analysis of varying customer needs, the company has developed an extensive range of valve models to meet diverse industrial requirements. From heavy industries such as oil and gas, petrochemicals, and power generation to more specialized sectors like water treatment and pharmaceuticals, [Company name] ensures that its gearbox gate valves provide optimal performance and durability.Paragraph 4:[Company name] understands the importance of customer satisfaction and adheres to a customer-centric approach. The company is committed to providing tailored solutions to specific industry demands, ensuring that its valves are durable, resilient, and can withstand even the most demanding operational conditions. Additionally, prompt after-sales services, technical support, and continuous communication with customers have made [Company name] a preferred choice for many customers globally.Paragraph 5:To maintain its high standards, [Company name] adheres strictly to international quality certifications and manufacturing processes. The company's state-of-the-art manufacturing facilities are equipped with advanced machinery and tools, ensuring precision and efficiency in production. [Company name]'s commitment to quality control has earned it numerous certifications, including ISO 9001, ISO 14001, CE, and API. These certifications guarantee that its gearbox gate valves adhere to the highest industry standards worldwide.Paragraph 6:As a responsible manufacturer, [Company name] has also prioritized sustainable production practices. The company actively endeavors to reduce its carbon footprint and implements environmentally friendly processes throughout its manufacturing operations. By adhering to ethical practices and incorporating advanced energy-saving technologies, [Company name] aims to contribute to a greener and more sustainable future.Paragraph 7:Looking ahead, [Company name] is poised to further expand into newer markets and strengthen its presence as a reliable supplier of gearbox gate valves worldwide. By continuously enhancing their products' performance, diversifying their range of valves, and exploring potential collaborations with global partners, [Company name] continues to solidify its position as a trusted industry leader.Conclusion:With its commitment to innovation, customer satisfaction, and maintaining international quality standards, [Company name] has successfully positioned itself as the leading gearbox gate valve supplier in China and beyond. As the company expands its global footprint, it looks to build on its success and continue providing reliable and efficient solutions to industries worldwide.

Enhance Control: Explore the Versatility of Limit Switch Enabled Ball Valves

Innovative Ball Valve With Limit Switch Enhances Performance and Safety in Industrial Applications[City], [Date] – Leading industrial solution provider [Company Name] has unveiled its latest offering, the Ball Valve With Limit Switch, designed to revolutionize the industrial sector with its advanced features and enhanced functionality. The introduction of this cutting-edge technology underlines the company's commitment to delivering high-performance products that prioritize both efficiency and safety.The Ball Valve With Limit Switch complies with international quality standards and has been meticulously engineered to meet the diverse needs of industries such as oil and gas, chemical production, water treatment, and many more. By leveraging the latest advancements in technology, [Company Name] has created a comprehensive solution that improves operational performance, minimizes downtime, and ensures maximum safety.One of the standout features of the Ball Valve With Limit Switch is its integrated limit switch mechanism. This innovative addition allows for remote control and monitoring of valve position, eliminating the need for manual intervention in critical situations. The limit switch is designed to send real-time feedback regarding the valve's position, enabling quick identification of any operational anomalies or potential failures.Furthermore, the Ball Valve With Limit Switch incorporates a fail-safe mechanism, which ensures that in the event of power failure or other critical malfunctions, the valve automatically goes into a predetermined position that guarantees the safety of operation. This built-in safety feature acts as an added layer of protection, minimizing the risk of accidents and ensuring uninterrupted workflow.The high-quality materials used in manufacturing the Ball Valve With Limit Switch provide exceptional resistance to harsh operating conditions such as extreme temperatures, corrosive fluids, and high-pressure environments. Its durable construction ensures long-lasting performance and minimal maintenance requirements, reducing operational costs significantly.[Company Name], known for its expertise in industrial solutions, prides itself on its commitment to innovation and customer satisfaction. The introduction of the Ball Valve With Limit Switch further establishes the company's reputation as a leader in the industry. With a dedicated team of experienced engineers and state-of-the-art facilities, [Company Name] continues to push the boundaries of technological advancements and fulfill the evolving needs of industrial sectors worldwide.Moreover, the Ball Valve With Limit Switch guarantees seamless integration with existing automation systems, making it a versatile choice for both new installations and retrofitting projects. This feature empowers industries to optimize operational efficiency and reduce human error during routine operations while maximizing the utilization of existing resources.The compact design of the Ball Valve With Limit Switch allows for easy installation and maintenance, even in space-constrained environments. The valve's intelligent design also enables streamlined processes during regular maintenance, minimizing downtime and maximizing productivity.The introduction of the Ball Valve With Limit Switch reaffirms [Company Name]'s dedication to providing reliable and top-of-the-line industrial solutions. The company's commitment to continuous improvement and technological advancement, coupled with its extensive industry experience, positions it as a preferred partner in achieving operational excellence.For more information about the Ball Valve With Limit Switch and other outstanding industrial solutions offered by [Company Name], please visit their website at [Company Website]. With its comprehensive range of products and unwavering commitment to quality, [Company Name] is poised to revolutionize the industrial sector and empower businesses to thrive in today's competitive landscape.