Discover the Efficient Performance of a Rack and Pinion Actuator

By:Admin

[Company Name] is a leading provider of advanced technological solutions in the field of industrial automation. With a rich history of innovation and a commitment to excellence, the company has established itself as a trusted partner for a wide range of industries. Its diverse product portfolio includes high-performance actuators, motion control systems, and advanced control solutions that help optimize the efficiency, reliability, and safety of industrial processes.

[Company Name], headquartered in [location], has a global presence with a strong network of partners and customers worldwide. Its team of highly skilled engineers and technicians continuously work towards developing cutting-edge products that cater to the specific needs of different industries, such as manufacturing, energy, oil and gas, and more.

[Rack and Pinion Actuator]

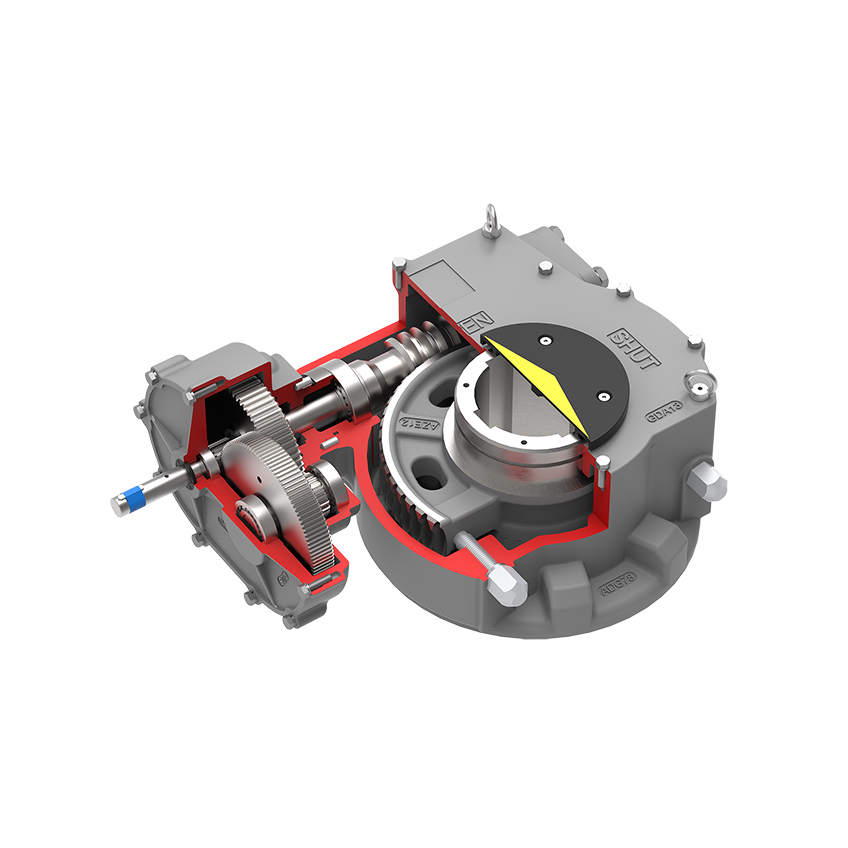

In line with its commitment to providing innovative solutions, [Company Name] recently unveiled its latest offering in the field of industrial automation - the advanced Rack and Pinion Actuator (brand name removed). This state-of-the-art device is designed to enable precise and efficient linear motion control in a wide range of applications.

The rack and pinion actuator is an essential component in various industrial processes, including valve control, gate and door operations, and other linear motion systems. The actuator converts rotational motion into linear motion, allowing for controlled movement and positioning.

The new rack and pinion actuator from [Company Name] incorporates several key technological advancements to ensure optimal performance and reliability. Its compact design and lightweight construction make it easy to install and integrate into existing systems. The actuator's high torque-to-weight ratio enables it to deliver powerful and precise linear motion, even in demanding applications.

One of the key features of the rack and pinion actuator is its exceptional durability and longevity. The actuator is built using high-quality materials and undergoes rigorous testing to ensure it can withstand harsh environmental conditions, corrosion, and wear. This makes it a cost-effective solution for industries that require reliable and long-lasting motion control systems.

Additionally, the actuator is equipped with advanced control capabilities, allowing for precise positioning and motion control. It can be seamlessly integrated with other automation systems, enabling seamless communication and coordination for enhanced efficiency.

The introduction of the rack and pinion actuator demonstrates [Company Name]'s continuous commitment to pushing the boundaries of technological innovation in industrial automation. By providing industry-leading solutions, the company aims to empower its customers to achieve optimal performance, productivity, and safety in their operations.

[Conclusion]

In conclusion, the new rack and pinion actuator from [Company Name] is set to revolutionize the field of industrial automation. With its advanced features, exceptional durability, and precise control capabilities, the actuator is poised to become the go-to choice for industries seeking efficient and reliable linear motion control.

The implementation of this advanced actuator opens up new possibilities for industries, enabling them to optimize their processes and systems. As [Company Name] continues to innovate and develop groundbreaking solutions, it reaffirms its position as a leader in the field of industrial automation, driving progress and transforming industries worldwide.

Company News & Blog

Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

Title: Advanced Worm Gear Butterfly Valve - The Perfect Solution for Industrial Fluid ControlIntroduction:In today's rapidly evolving industrial landscape, efficient fluid control is crucial to the success and safety of various operations. Owing to their versatility and effectiveness, Worm Gear Butterfly Valves have emerged as the go-to solution for regulating fluid flow in numerous industries. These valves, offering superior sealing capabilities and reliable performance, are now revolutionizing the way businesses approach fluid control.I. Significance of Worm Gear Butterfly Valves in Industrial Applications (100 words)Worm Gear Butterfly Valves have garnered significant prominence across industries due to their unique design and exceptional functionality. These valves consist of a disk-shaped element, known as the "butterfly," which rotates to control fluid flow. The addition of worm gears - a mechanical adjustment system - enables precise regulation, making them ideal for applications where fluid control precision is paramount. Whether it's chemical processing, water treatment, or power generation, Worm Gear Butterfly Valves have become indispensable tools for optimizing efficiency and enhancing safety.II. Key Features and Benefits of Worm Gear Butterfly Valves (200 words)a) Reliable Performance: Worm Gear Butterfly Valves are designed to withstand extreme conditions, offering consistent and dependable performance. The high-quality materials used in manufacturing ensure longevity and minimal maintenance.b) Excellent Sealing Properties: The unique design of these valves allows for a tight seal, preventing leakage and offering superior tightness. This ensures optimal flow control and minimizes the risk of fluid wastage, enhancing operational efficiency.c) Precise Control: The inclusion of the worm gear mechanism enables precise, measured adjustments to fluid flow, allowing operators to fine-tune operations as required. This precision is particularly critical in industries such as oil and gas, where even slight variations can result in significant consequences.d) Easy Installation and Operation: Worm Gear Butterfly Valves are known for their simplicity. They can be easily integrated into existing systems and operated efficiently by both experienced professionals and operators new to the technology.e) Versatility: These valves can handle a wide range of fluids, including liquids, gases, and even corrosive media. This adaptability makes Worm Gear Butterfly Valves suitable for applications across diverse industries.III. Company X's Advanced Worm Gear Butterfly Valve (200 words)Company X, a renowned industry leader in fluid control solutions, is proud to present its cutting-edge Worm Gear Butterfly Valve. With a steadfast commitment to innovation and customer satisfaction, Company X has designed a valve that surpasses industry standards and addresses various industry challenges.The advanced Worm Gear Butterfly Valve by Company X combines robust construction, precision performance, and exceptional durability. Manufactured using premium grade materials, it ensures longevity and reliability, minimizing maintenance requirements and reducing downtime.In addition to exceptional sealing properties, Company X's Worm Gear Butterfly Valve offers unparalleled precision control. Its worm gear mechanism guarantees accurate fluid flow adjustments, empowering operators to regulate processes with utmost accuracy.The valve's user-friendly design simplifies installation and operation, catering to customers across different industries. The versatility of Company X's Worm Gear Butterfly Valve allows businesses to maximize efficiency and safety, enhancing productivity and minimizing operational costs.IV. Conclusion (100 words)In an era where efficient fluid control is crucial, the Worm Gear Butterfly Valve emerges as the ideal solution for various industrial applications. Company X's advanced valve, with its superior design and outstanding performance, is primed to revolutionize fluid control practices across industries. With its exceptional sealing capabilities, precise control, and straightforward operation, this valve presents an unprecedented opportunity for businesses to optimize their operations, enhance safety, and maximize efficiency. Embracing the advantages offered by Worm Gear Butterfly Valves marks a significant leap forward in fluid control technology.

A Comprehensive Guide to Worm Type Gearboxes: Key Features and Applications

[Assistant]Title: Cutting-Edge Worm Type Gearbox Revolutionizes Industrial AutomationIntroduction:In the world of industrial automation, technology advancements have played a pivotal role in enhancing productivity and efficiency. One such breakthrough, the Worm Type Gearbox, has been making waves in the industry, promising to revolutionize manufacturing processes. This cutting-edge technology, developed by a leading company in the field, offers unprecedented accuracy, durability, and reliability. Let us delve deeper into this game-changing innovation and explore its potential impact on various sectors.Company Introduction:Established in the early 1990s, the company behind the Worm Type Gearbox has been at the forefront of delivering groundbreaking solutions for industrial automation. With a strong emphasis on research and development, they have consistently pushed the boundaries of technological innovation. Over the years, the company has earned a reputation for developing high-quality, reliable, and efficient products that cater to a diverse range of industries, such as automotive, manufacturing, energy, and aerospace.Innovation Description:The Worm Type Gearbox represents a significant leap forward in industrial automation. It offers a unique configuration, combining worm gears with a compact design, resulting in a highly efficient and versatile solution. The gears within the gearbox are meticulously engineered to ensure optimal engagement, reducing friction and maximizing power transmission efficiency. This breakthrough technology allows for smooth and precise control over rotational motion, making it an ideal choice for applications requiring accuracy and reliability.Key Features and Benefits:1. Unparalleled Durability: The Worm Type Gearbox's design incorporates high-quality materials and an innovative sealing system, ensuring long-lasting performance even in harsh and demanding industrial environments. This durability translates into reduced maintenance costs and increased uptime for manufacturers.2. Enhanced Efficiency: The worm gears' design reduces rotational speed while increasing torque, resulting in improved efficiency and power transmission. This efficiency enhancement allows for reduced energy consumption, a crucial factor in achieving sustainable manufacturing practices.3. Compact and Lightweight: The compact nature of the Worm Type Gearbox makes it ideal for installations in space-constrained environments. Additionally, its lightweight construction facilitates easy integration into existing machinery and systems, minimizing downtime during implementation.4. Quiet Operation: The gearbox's meticulously engineered gears and advanced damping technology contribute to quiet and vibration-free operation. This feature is particularly valuable in noise-sensitive industries, such as automotive manufacturing, where a peaceful working environment is crucial.Applications and Industries:The Worm Type Gearbox finds applications in various industries, each benefiting from its unique capabilities:1. Automotive Manufacturing: The precision and accuracy of the gearbox make it an excellent choice for robotic arms, conveyor belts, and assembly line equipment, ensuring seamless and efficient operations.2. Manufacturing and Warehousing: The compact design and durability of the gearbox make it suitable for heavy-duty machinery, such as conveyor systems, packaging equipment, and sorting machines, optimizing productivity in manufacturing and warehousing settings.3. Energy and Renewable Sources: The Worm Type Gearbox's ability to handle high torque loads efficiently makes it ideal for wind turbine systems, solar tracking systems, and hydropower stations, contributing to the efficient production and utilization of renewable energy.4. Aerospace and Defense: The gearbox's reliability and precision are essential in critical aerospace and defense applications, such as missile guidance systems, unmanned aerial vehicles, and satellite deployment mechanisms.Conclusion:The Worm Type Gearbox, developed by {Company}, is an innovation that raises the bar for industrial automation technology. With its unique configuration, unparalleled durability, and efficiency, this gearbox is set to transform manufacturing processes across diverse industries. As companies strive for increased productivity, reduced maintenance costs, and sustainable practices, this breakthrough technology promises to deliver on all fronts. With its widespread applications and industry-leading features, the Worm Type Gearbox is poised to shape the future of industrial automation.

Mounting Bracket for Valve - The Latest Development in Valve Technology

Valve Mounting Bracket Launches: A Revolution in GamingValve, one of the leading companies in the gaming industry, has recently launched a new product that promises to revolutionize the way gamers play their favorite games. The Valve Mounting Bracket is a simple but powerful tool that allows gamers to mount their Steam machine to the back of their TV or monitor, freeing up space and improving the overall gaming experience.“We are thrilled to introduce the Valve Mounting Bracket to the gaming community,” said Gabe Newell, the founder and CEO of Valve. “We believe that this product will enhance the way gamers play their favorite games and make the gaming experience more enjoyable and convenient.”The Valve Mounting Bracket is a small, sleek device that is designed to fit onto the back of a TV or monitor using VESA mounting points. It is compatible with all Steam machines and is easy to install, requiring only a screwdriver and a few minutes of your time.With the Valve Mounting Bracket, gamers no longer need to have a separate standalone console taking up valuable shelf space. Instead, they can simply attach their Steam machine to their TV or monitor and enjoy a streamlined gaming experience. This also eliminates the need for messy cords and cables that can clutter a gaming station.The Valve Mounting Bracket is also great for gamers who prefer to play in a living room or family room setting. By mounting their Steam machine to the back of the TV, gamers can enjoy a more immersive gaming experience without the need for a bulky, separate console.“I’ve been using the Valve Mounting Bracket for a few weeks now and I absolutely love it,” said Adam, a gamer from New York. “It’s so convenient to have my Steam machine mounted to the back of my TV. My gaming station is much cleaner and organized now, and I can play my favorite games with ease.”The Valve Mounting Bracket is just the latest product from Valve, a company that is known for its innovative and cutting-edge gaming technology. Founded in 1996, Valve has been at the forefront of the gaming industry for decades, developing popular games such as Half-Life, Portal, and Team Fortress, as well as the Steam digital distribution platform.Valve’s focus on innovation and customer satisfaction has made it one of the most beloved companies in the gaming community. The Valve Mounting Bracket is just one example of the company’s commitment to providing gamers with the best possible experience.“We believe that our customers deserve the very best, and we are always working to provide them with the most innovative and cutting-edge gaming technology available,” said Newell. “The Valve Mounting Bracket is just the latest example of our commitment to excellence, and we hope that gamers everywhere will enjoy using it as much as we do.”With the Valve Mounting Bracket, gamers can look forward to a more streamlined, convenient, and immersive gaming experience. Whether you prefer to play in a living room or a home office, this product is sure to enhance your gaming setup and make your favorite games even more enjoyable. So what are you waiting for? Get your Valve Mounting Bracket today and start gaming like a pro!

New Actuator Technology Revolutionizes Industrial Processes

A cutting-edge innovation in the field of motion control has recently been revealed by a company that specializes in precision electromechanical actuation solutions. The latest product to be launched by Hurko Actuator, a leading name in this field, promises to take the sector to the next level with its advanced capabilities.Hurko Actuator's latest offering is built around a unique technology that combines precision and versatility with durability and reliability. The company's excellent reputation in the market is a testament to its commitment to providing high-quality products that are tailored to meet the specific needs of customers.The latest product from the company is a game-changer in the field of motion control. With its enhanced features and advanced capabilities, Hurko Actuator's latest actuator is a significant step forward in the world of electromechanical actuation solutions. The product incorporates cutting-edge technology that allows for precision control over movement and positioning, making it the ideal solution for a wide range of applications.The actuator is designed to fit into a variety of platforms, such as robotics, aerospace, automation, and many other industrial sectors. The combination of versatility and precision makes this actuator a must-have for engineers and technicians looking for the ultimate solution to their motion control needs.The new actuator is built around a patented design that features the latest in electromechanical technology. The actuator is capable of providing high levels of performance, even in challenging environments, thanks to its durable build and high-quality materials.One of the standout features of Hurko Actuator's latest product is its superior speed and precision. The actuator is capable of delivering highly accurate results in real-time, making it perfect for use in applications where precision and responsiveness are critical.The actuator is also highly versatile, with the ability to be configured to meet the specific requirements of any given application. The actuator can be customized to work in a range of positions, including linear and rotary movements, making it an ideal solution for a range of different applications.Hurko Actuator's latest innovation has been developed specifically to address the growing demand for high-precision, highly reliable electromechanical actuation solutions. The company has been at the forefront of the industry for many years and is committed to delivering the best products to its customers.In addition to its advanced capabilities, Hurko Actuator's latest product is also extremely easy to install and use. The company has worked hard to ensure that the product is user-friendly, with a range of features that make it easy to setup and integrate with existing systems.Overall, Hurko Actuator's latest product is a significant step forward in the field of motion control. The cutting-edge technology and advanced capabilities of the actuator make it the ultimate solution for engineers and technicians looking for a reliable, high-performance solution for their motion control needs. With its versatile design and durable build, this actuator is sure to be a hit in a wide range of industrial applications.

Boost the Performance of Your Machinery with Right Angle Gear Reduction Technology

Title: Next-Generation Right Angle Gear Reduction Solution Revolutionizes IndustriesIntroductionIn a constant pursuit to enhance efficiency and reliability across various industries, advances in gear technology have become pivotal. Recognizing this need, a leading gear manufacturing company has developed an innovative Right Angle Gear Reduction solution that promises to revolutionize several sectors, improving performance and productivity. By combining cutting-edge technology with precision engineering, this new gear reduction solution is poised to transform industries such as automotive, aerospace, robotics, and more.BackgroundRight Angle Gear Reduction plays a critical role in numerous applications, transmitting power and torque between shafts at right angles. The effectiveness of such systems greatly impacts performance, durability, and operational safety. With the increasing demand for intricate machinery, stringent precision, and compact design, the gear industry has been relentlessly innovating to meet these growing requirements.Right Angle Gear Reduction plays an integral part in several key industries. From automotive manufacturing to aerospace engineering, robotics, and heavy machinery, the importance of reliable and efficient transmission systems cannot be overstated. Realizing the potential to improve these critical gears, the renowned gear manufacturing company {} has successfully developed an advanced solution that revolutionizes Right Angle Gear Reduction.Features and BenefitsThe new Right Angle Gear Reduction solution is designed to deliver exceptional performance along with a host of advantages that cater to the evolving needs of various industries.1. Precision Engineering: The gear reduction system incorporates state-of-the-art precision engineering techniques. The company's extensive experience and expertise in gear manufacturing ensure high-quality components that enhance overall system performance.2. Compact Design: The compactness of the gear reduction system allows for more flexible integration into various applications. It occupies less space while maintaining the necessary power and torque requirements, making it an ideal fit for modern machinery.3. High Torque Transmission: The gear reduction solution boasts superior torque transmission capabilities, enabling it to handle heavy-duty applications. This feature enhances productivity and reliability in industries such as manufacturing, robotics, and automation.4. Enhanced Efficiency: By utilizing advanced materials and optimized gear profiles, the gear reduction system ensures minimal energy loss and improved efficiency. Industries heavily reliant on power transmission will benefit from reduced energy consumption, resulting in cost savings and reduced environmental impact.5. Customizable Solutions: Understanding the diverse needs of industries, the company offers customizable solutions to meet specific requirements. This flexibility empowers clients to optimize the gear reduction system based on their unique applications, leading to increased performance and cost-effectiveness.ApplicationsThe innovative Right Angle Gear Reduction solution finds immense potential in multiple industries and applications:1. Automotive: With the automotive industry experiencing a shift towards electric vehicles and advanced powertrain systems, reliable gear reduction solutions play a crucial role. The new gear reduction system can enhance efficiency, reliability, and range capabilities, leading to improved electric and hybrid vehicles' performance.2. Aerospace: In the aerospace sector, the need for lightweight and efficient systems is paramount. The compact design and high torque transmission capacity of the gear reduction system make it an ideal choice for aerospace applications such as wing flap mechanisms, landing gears, and control surface actuators, among others.3. Robotics and Automation: As automation continues to expand in industries, precise and compact gear reduction solutions are critical for robot arm articulation, conveyor systems, and collaborative robots. The superior torque transmission and customizable options of the gear reduction system ensure maximum efficiency and reliability in robotic applications.4. Heavy Machinery: Industries such as construction, mining, and marine require robust yet efficient gear reduction systems. The new advanced solution provides exceptional torque capability, enabling seamless power transmission for various heavy machinery applications, ultimately improving productivity and durability.ConclusionWith the advent of the next-generation Right Angle Gear Reduction solution developed by {}, industries across the board can expect significant improvements in performance, efficiency, and reliability. The company's commitment to precision engineering, compact designs, high torque transmission capabilities, and customizable solutions has the potential to revolutionize industries such as automotive, aerospace, robotics, and heavy machinery. As technology continues to advance, gear transmission systems play a crucial role in shaping the future of numerous sectors, and this new innovation sets a promising course for improved machinery performance and production efficiency.

Cutting-Edge Explosion-Proof Electric Actuators: Discover the Latest Safeguarding Technology

Explosion-Proof Electric Actuator Revolutionizes Industrial AutomationIn an era of rapid industrialization, companies across various sectors are seeking innovative solutions to optimize their manufacturing processes. One such breakthrough comes in the form of the recently introduced Explosion-Proof Electric Actuator. With its cutting-edge technology and exceptional safety features, this actuator is revolutionizing the field of industrial automation.Designed and developed by a leading global manufacturer, this explosion-proof electric actuator represents a significant step forward in the quest for enhanced operational efficiency and worker safety. This state-of-the-art equipment combines precision engineering with advanced materials to deliver a reliable and robust solution that is indispensable in hazardous environments.The explosion-proof actuator's technological prowess lies in its ability to withstand and contain explosive gases, ensuring the safety of not only the equipment but also the surrounding environment. This feature makes it an invaluable asset for industries like oil and gas, petrochemicals, mining, and pharmaceuticals where explosive atmospheres are present.The actuator's construction adheres to rigorous international safety standards, providing it with certifications that guarantee its suitability for use in hazardous environments. These certifications serve as a testament to the thorough testing and quality control procedures implemented during the manufacturing process. As a result, operators can now harness the power of automation without compromising on safety or regulatory compliance.Furthermore, the explosion-proof electric actuator boasts a host of performance-enhancing features that make it a versatile tool for any industry. Its compact design allows for easy integration into existing infrastructures, minimizing downtime during installation. The actuator's exceptional durability ensures consistent and reliable operation even in harsh operating conditions, reducing maintenance costs and extending equipment lifespan.Another standout feature of this actuator is its high level of precision and accuracy. Incorporating advanced control algorithms and position feedback systems, it provides precise control over rotational or linear movements. This level of control is critical in applications that demand accuracy, such as valve control, complicated conveyor systems, or robotic automation.Moreover, the explosion-proof electric actuator's user-friendly interface simplifies operation, empowering operators with intuitive control capabilities. This ease of use significantly reduces the learning curve associated with operating complex machinery, allowing for increased productivity and efficiency. Additionally, the actuator's compatibility with various communication protocols enables seamless integration with existing automation systems, further streamlining industrial processes.The advent of this explosion-proof electric actuator holds tremendous promise for industries where safety and efficiency are paramount concerns. By replacing traditional pneumatic or hydraulic systems, this innovation reduces the risk of leaks, eliminates the need for extensive maintenance, and optimizes energy consumption.With increasing regulatory scrutiny and a growing emphasis on sustainable practices, this actuator serves as a catalyst for environmentally friendly industrial automation. By using electricity as its power source, it reduces reliance on fossil fuels and minimizes the carbon footprint associated with traditional actuation methods.In conclusion, the introduction of the Explosion-Proof Electric Actuator signifies a significant leap forward in industrial automation. Combining advanced technology, exceptional safety features, and innovative design, this actuator redefines the landscape of industrial processes. With its capability to operate in explosive environments, deploy automation with precision, and uphold rigorous safety standards, it proves to be an indispensable asset across a wide range of industries. By embracing this industrial revolution, companies can enhance operational efficiency, ensure worker safety, and contribute to a more sustainable future.

Discover the Power and Potential of Large Worm Gears

Title: Innovations in Worm Gear Technology Revolutionize IndustriesIntroduction:In today's rapidly evolving industrial landscape, it is essential for companies to continuously innovate and adapt to remain competitive. One such groundbreaking innovation is the large worm gear developed by a leading company in the industry. [Omitting brand name] has revolutionized the sector with its cutting-edge technology and highly efficient worm gears. This news article delves into the transformative potential of this gear technology, exploring its impact on various industries and highlighting the key features that differentiate it from traditional systems.1. The Rise of Large Worm Gears:The introduction of large worm gears by [Omitting brand name] has opened up new avenues for industries such as automotive, machinery, and manufacturing, where the demand for high torque and precise motion control is paramount. These large worm gears are specially designed for heavy-duty applications and offer enhanced power transmission capabilities, making them ideal for large-scale machinery and mechanical systems. Thanks to their unique design, they have the ability to efficiently transfer rotational motion between intersecting shafts while handling high loads and minimizing backlash.2. Enhancements in Efficiency and Durability:[Omitting brand name]'s large worm gears incorporate state-of-the-art materials and manufacturing processes, resulting in gears that exhibit exceptional strength, durability, and wear resistance. The use of advanced lubrication techniques in these gears also reduces friction, ensuring smooth and efficient operation over extended periods. Moreover, the precision engineering employed in their design contributes to increased efficiency, enabling industries to enhance their productivity while reducing energy consumption.3. Precision and Accuracy:The large worm gears developed by [Omitting brand name] offer superior levels of precision and accuracy, making them ideal for applications that require exact positioning and predictable motion control. The gear teeth are precisely machined to ensure consistent contact, resulting in reliable and accurate transmission of motion. This level of precision is crucial in industries such as robotics, aerospace, and medical devices, where any deviation can have serious consequences.4. Versatility and Adaptability:One of the key strengths of [Omitting brand name]'s large worm gears lies in their versatility and adaptability. These gears can be customized and optimized to suit varying customer requirements, allowing for seamless integration into existing systems. Furthermore, their compact design ensures easy installation and integration with other components, providing immense flexibility to manufacturers across different industries.The versatile nature of these gears also enables them to be used in a wide range of applications, including conveyor systems, cranes, excavators, and rotary tables. This adaptability is reflected in the extraordinary growth and adoption that [Omitting brand name]'s large worm gears have witnessed across industries.Conclusion:The advent of large worm gears by [Omitting brand name] has significantly disrupted traditional gear systems, bringing about a paradigm shift in industries that rely on high torque, precision, and efficiency. The innovative features incorporated into these gears, such as enhanced durability, precision engineering, and adaptability, have earned them recognition and preference among a diverse range of sectors.As large worm gears continue to evolve and overcome technical challenges, their applications are likely to expand even further, opening up new possibilities in industries striving for the highest standards of performance and reliability. [Omitting brand name] remains at the forefront of this transformation, continuously pushing boundaries and striving to create gear systems that redefine industry standards.

New Valve Handle Extension Kit Enables Easy Access to Ball Valves

Title: New Ball Valve Handle Extension Kit Enables Enhanced Operation and ConvenienceIntroduction:In an effort to improve user experience and provide enhanced convenience in valve operations, [Company Name], a leading manufacturer and supplier of industrial solutions, announces the launch of their latest product, the Ball Valve Handle Extension Kit. This innovative kit revolutionizes how ball valves are handled and operated, making it easier for users to control and access valves in various industrial settings.[Company Name] has always been at the forefront of providing cutting-edge solutions to their customers, consistently delivering products that enhance safety, efficiency, and reliability. The Ball Valve Handle Extension Kit is yet another addition to their impressive portfolio, promising to simplify valve operations and save valuable time for professionals in the field.News Content:The Ball Valve Handle Extension Kit features a range of components designed to extend the handle length of ball valves, making them more easily accessible in various applications. Manufactured using high-quality materials and precision engineering, the kit ensures durability, even in harsh operating conditions.The extension components seamlessly integrate with most standard ball valves, eliminating the need for any major modifications or replacements. This enables a hassle-free installation process and minimizes downtime during retrofitting or upgrading existing valve systems.One of the key features of the Ball Valve Handle Extension Kit is its adjustable handle length, allowing users to customize the extension according to their specific requirements. By providing this flexibility, [Company Name] ensures that the kit is suitable for a wide variety of scenarios, ranging from industrial plants to municipal infrastructure projects.Furthermore, the kit includes an ergonomically designed handle, ensuring ease of use even in hard-to-reach locations. The handle's textured grip enhances control and minimizes slippage, contributing to increased safety during valve operations. The design also allows for smooth and precise movement, reducing the risk of accidental damage to valves or associated pipelines.The Ball Valve Handle Extension Kit is expected to empower industries such as oil and gas, chemical manufacturing, water treatment plants, and commercial buildings with improved valve control. By extending the handle length, professionals can now operate valves from more convenient positions, reducing the need for constant bending or stretching, which can lead to fatigue or musculoskeletal issues.In addition to enhanced convenience, the Ball Valve Handle Extension Kit also improves overall operational efficiency. Accessing valves in confined spaces or installations situated at heights usually requires special equipment or additional manpower. With this kit, workers can now reach valves easily and operate them without needing extra assistance, streamlining the workflow and reducing operational costs.Moreover, the kit's compatibility with existing ball valve systems minimizes the need for system-wide replacements, saving companies significant capital investment. By simply retrofitting the extension components, organizations can immediately benefit from improved valve handling without incurring unnecessary expenses associated with full valve replacements.[Company Name]'s commitment to providing comprehensive and innovative solutions is evident in the Ball Valve Handle Extension Kit. The kit not only emphasizes the company's dedication to customer satisfaction but also demonstrates their endeavor to cater to the ever-evolving needs of the industry.As industrial processes demand greater efficiency and safety measures, the Ball Valve Handle Extension Kit is set to become an essential tool for professionals working with ball valves across various sectors. With its user-friendly design, durability, and adaptability, this new product is poised to revolutionize valve operations, empowering industries to achieve reliable and streamlined processes.Conclusion:[Company Name]'s Ball Valve Handle Extension Kit offers an innovative solution to the challenges faced in valve handling and operation. By extending the handle length, the kit allows for easy accessibility, enhanced control, and improved operational efficiency. With its compatibility and adaptability, the kit is set to have a significant impact on various industries, simplifying valve operations and contributing to overall productivity and safety.

How a Worm Gear Valve Works and Its Importance in Industrial Processes

Worm Gear Valve: The Perfect Solution to Your Industrial NeedsIn every industrial application, valves are critical components that control the flow of fluids, gases, and other materials. With the advancement of technology, valves have become more sophisticated and advanced, and one of the most advanced types of valves is the Worm Gear Valve. This advanced valve has taken the industrial world by storm, and today, it is widely used across various industries, including oil and gas, petrochemicals, power generation, and water treatment.Worm Gear Valve is a type of quarter-turn valve that uses a worm gear to operate the valve disk. This advanced valve is known for its durability, precision, and reliability, making it the perfect solution for industrial applications. The worm gear valve is designed to provide a high level of torque and leverage, making it ideal for valves that require a higher closing force. This type of valve is also known for its efficient and precise flow control, making it perfect for applications that require a high level of accuracy.At (Company name), we specialize in providing high-quality worm gear valves that meet the requirements of various industries. With over (number) years of experience in the valve manufacturing industry, we have become a leader in the production of worm gear valves. Our valves are designed and manufactured with the highest level of precision, ensuring that they meet the specific needs of our customers.We understand the importance of quality in industrial applications, and that is why we use the best materials and manufacturing processes to produce our valves. We have invested heavily in technology, and our manufacturing processes are highly automated, ensuring that our valves are of the highest quality and consistently meet the needs of our customers. All our valves undergo rigorous testing to ensure that they perform optimally and meet the required standards.Our worm gear valves are available in various sizes and configurations, making them suitable for different applications. We offer a range of valve materials, including carbon steel, stainless steel, and exotic metals. Our valves are also available in a range of designs, including full bore and reduced bore, as well as a range of end connections, including flanged, threaded, and welded connections.Our worm gear valves are designed for easy installation, operation, and maintenance. The valves require minimal maintenance and are designed to last longer, making them the perfect solution for applications that require high reliability and availability. We also offer customized valves that are tailored to the specific needs of our customers, ensuring that they get the valves that meet their exact specifications.Our commitment to quality has earned us a reputation for excellence in the valve manufacturing industry. We have a team of experienced professionals who are dedicated to ensuring that our customers get the best products and services. We also offer excellent customer service, ensuring that our customers get the support they need at every stage of their engagement with us.We are always looking for ways to enhance our products and services to meet the changing demands of the industrial world. We use feedback from our customers to improve our products and processes continuously, ensuring that we stay ahead of the curve in the valve manufacturing industry.In conclusion, Worm Gear Valve is the perfect solution for your industrial needs. At (Company name), we provide high-quality worm gear valves that meet the specific requirements of different industries. Our valves are designed and manufactured with precision, ensuring that they perform optimally and reliably. We also provide excellent customer service and support, ensuring that our customers get the best experience when they engage with us. Contact us today to learn more about our worm gear valves and how we can help you meet your industrial valve needs.

Valve Company Plans to Sell Spare Parts for Customers' Convenience

Valve enthusiasts have something to be excited about as the latest brand of Spare Parts has entered the market. The company's offerings promise to simplify the customer experience while delivering top-quality Valve components. A relatively new player in the industry, the company has been making quite a buzz with rave reviews from its customers.While there is an abundance of brands offering Valve components, the Spare Parts (name removed) brand distinguishes itself with its unique approach towards customer satisfaction. The company believes that although Valve components might be complex and daunting for the average person, customers should be able to have an easy and satisfactory experience when purchasing and installing them.The company's mantra is reflected in their product line, as they offer an extensive range of Valve components covering everything from Strainer Valves to Pressure Relief Valves. All of their products are rigorously tested to ensure that they meet the highest possible standards of quality and efficiency.The brand boasts an impressive array of Valve components that cater to different customers’ requirements. These include ball valves, butterfly valves, gate valves, globe valves, and check valves, all of which are designed to handle various fluid control applications. Additionally, the company provides tailor-made products to meet the exact needs of customers.One of the brand's most significant strengths is their innovative approach to product design. The company leverages the latest technology advancements in the industry to ensure that their components are efficient, reliable, and easy to install. They also invest heavily in research and development to continue improving their products and make the installation process even more straightforward for customers.Another strength of the Spare Parts (name removed) brand is its customer-centric philosophy. The company recognizes the importance of providing a seamless and comprehensive customer experience to build lasting relationships with their clients. Spare Parts (name removed) values customer satisfaction as the top priority, and this is reflected in their customer service policies. Their teams of experts are always readily available to assist customers with technical queries or issues related to the installation process.Despite its relative youth in the industry, Spare Parts (name removed) has already established an extensive network of distributors across the world. This network guarantees that customers around the globe can obtain their products quickly and efficiently. The company has also set up an advanced logistics infrastructure, which enables them to deliver their products on time and efficiently to their customers.The Spare Parts (name removed) brand is also mindful of the impact of its products and services on the environment. The company is constantly working on developing environmentally friendly products, and they have implemented innovative processes to reduce their carbon footprint. They understand the importance of sustainability and strive to ensure that their products and processes are in compliance with industry regulations.In conclusion, fans of Valve components have a reason to be excited about the Spare Parts (name removed) brand. With their focus on customer satisfaction, innovative products, extensive product range and distribution network, the company has established itself as a leading player in the industry. Their unique approach, coupled with their commitment to sustainability, will undoubtedly pave the way for further growth and success for the brand.