Discover the Advantages of Electric Actuated Ball Valves for Efficient Control

By:Admin

Introduction:

In recent years, technological advancements have revolutionized various industries and brought about significant improvements in efficiency and performance. One such breakthrough innovation is the Electric Actuated Ball Valve, developed by a pioneering company in the field of valve automation and control systems. This groundbreaking product promises to redefine industry standards by offering unparalleled precision, control, and reliability. Manufacturers across multiple sectors are eagerly adopting this technology, recognizing the significant benefits it can bring to their operations.

Key Features and Benefits:

The Electric Actuated Ball Valve showcases a host of remarkable features that set it apart from traditional valve systems. The company’s unwavering commitment to quality and innovative design is evident in this cutting-edge solution. Here are some key features and benefits provided by this revolutionary valve:

1. Enhanced Precision and Control: With the integration of advanced electric actuation technology, this valve ensures precise control over fluid flow, allowing for swift and accurate adjustments. This leads to improved operational efficiency and reduces the risk of costly errors or delays.

2. Versatility and Adaptability: The Electric Actuated Ball Valve is designed to accommodate a diverse range of applications, making it highly versatile. Its adaptability allows for seamless integration into existing systems and the ability to meet various operational requirements across industries, including oil and gas, water treatment, chemical processing, and many others.

3. Unmatched Reliability: The valve’s robust construction, utilizing high-quality materials, ensures exceptional dependability even in demanding environments. The company’s rigorous quality control measures guarantee durability, longevity, and minimal maintenance requirements, resulting in significant cost savings for customers.

4. Improved Safety Measures: Safety has always been a primary concern in industrial applications. This electrically actuated valve incorporates fail-safe mechanisms, ensuring reliable shut-off in emergencies and preventing potential disasters. By prioritizing safety, the valve alleviates concerns and instills greater peace of mind among operators and personnel.

5. Advanced Monitoring and Reporting: The integration of intelligent automation technology allows for seamless monitoring and data acquisition. This feature enables real-time feedback on crucial parameters such as pressure, temperature, and flow rates. The valve system can share this information with centralized control systems, facilitating proactive maintenance and resource optimization.

Market Impact and Industry Outlook:

The Electric Actuated Ball Valve is poised to reshape the valve automation landscape and disrupt conventional practices in multiple industries. This revolutionary technology is rapidly gaining traction, with installation rates surging across diverse sectors globally. The valve’s potential to enhance operational efficiency, reduce energy consumption, and optimize processes has not gone unnoticed, and it is expected to become a staple in modern industrial automation.

With an increasing focus on sustainability and energy efficiency, the demand for smart valve solutions is set to skyrocket in the coming years. The Electric Actuated Ball Valve, with its advanced control capabilities and environmental-friendly features, is primed to take center stage. Manufacturers that adopt this cutting-edge technology will gain a competitive edge in their respective industries by significantly improving productivity, reducing costs, and mitigating risks.

Conclusion:

The advent of the Electric Actuated Ball Valve represents a groundbreaking milestone in the valve automation field. Its innovative design, remarkable functionality, and numerous advantageous features have positioned it as a game-changer in the industry. As more manufacturers embrace this technology, it will redefine industry standards and set new benchmarks for precision, control, and reliability. The future of valve automation is here, and it is undoubtedly electric.

Company News & Blog

Enhance Your Machinery with High-Quality Electric Actuators for Maximum Efficiency

Title: Groundbreaking Electric Actuator Revolutionizes Industrial AutomationIntroduction:In today's rapidly evolving industrial landscape, technological advancements continue to redefine efficiency and productivity. The latest innovation making waves in the automation sector is the cutting-edge Electric Actuator developed by a pioneering company (remove brand name), offering unprecedented precision and control. With applications ranging across diverse industries such as manufacturing, energy, and transportation, this revolutionary actuator is poised to transform industrial automation processes, optimizing productivity while reducing costs and environmental impact.Electric Actuator: Unleashing a New Era of Precision and ControlThe Electric Actuator, developed by (remove brand name), is an advanced electromechanical device designed to replace conventional pneumatic and hydraulic actuators, offering significantly improved precision, control, and reliability. With its compact and lightweight design, it is adaptable to a wide range of industrial operations, from valve control to material handling, robotics, and even 3D printing.Enhanced Precision and Control:Owing to its high-precision servo motor drive system, this Electric Actuator can deliver unparalleled positional accuracy and repeatability. By eliminating the traditional drawbacks associated with pneumatic and hydraulic systems, such as air leaks, pressure loss, and unpredictable performance, it ensures enhanced control over critical operations. Industrial processes dependent on precise movement, alignment, and positioning will greatly benefit from the increased accuracy and repeatability offered by this groundbreaking technology.Efficiency and Energy Savings:The Electric Actuator boasts remarkable energy efficiency, providing substantial cost savings to industries grappling with rising energy costs and environmental concerns. Its variable speed control, along with minimal energy loss during operation, leads to a significant reduction in energy consumption, ultimately resulting in a greener and more sustainable manufacturing environment. Moreover, the elimination of costly and maintenance-intensive hydraulic or pneumatic systems brings about substantial cost-cutting benefits, enhancing the overall cost-effectiveness of industrial operations.Remote Monitoring and Control:The incorporation of cutting-edge digital technology enables the Electric Actuator to be seamlessly integrated into Internet of Things (IoT) platforms. This empowers industries to monitor and control their operations remotely, even from a centralized control room. Real-time data feedback, preventive maintenance diagnostics, and predictive failure analysis capabilities prevent unexpected downtime, boosting operational efficiency and reducing production losses.Adaptability and Customization:Recognizing the diverse needs of different industries, the Electric Actuator offers a flexible framework that can be easily customized to suit specific application requirements. The actuator's operating parameters, force range, speed, stroke length, and various control interfaces can all be tailored to match the industrial processes, ensuring optimal performance and compatibility.Safety and Reliability:Reliability is a crucial aspect of any industrial automation technology, and the Electric Actuator meets the highest safety and durability standards. Equipped with advanced safety features such as overload protection and emergency stop functionality, it ensures worker safety while preventing costly accidents and equipment damage. Additionally, the Electric Actuator exhibits exceptional resistance to harsh environmental conditions, guaranteeing a long lifespan and minimal maintenance requirements.Future Outlook:As industries across the globe grapple with the challenges of increasing productivity while reducing environmental impact, the Electric Actuator developed by (remove brand name) offers a game-changing solution that addresses these concerns head-on. With its unparalleled precision, control, efficiency, and adaptability, this innovative technology holds immense potential for revolutionizing industrial automation across a wide range of sectors. By enabling industries to optimize their operations, streamline processes, and reduce costs, the Electric Actuator is poised to lead the next generation of industrial automation.

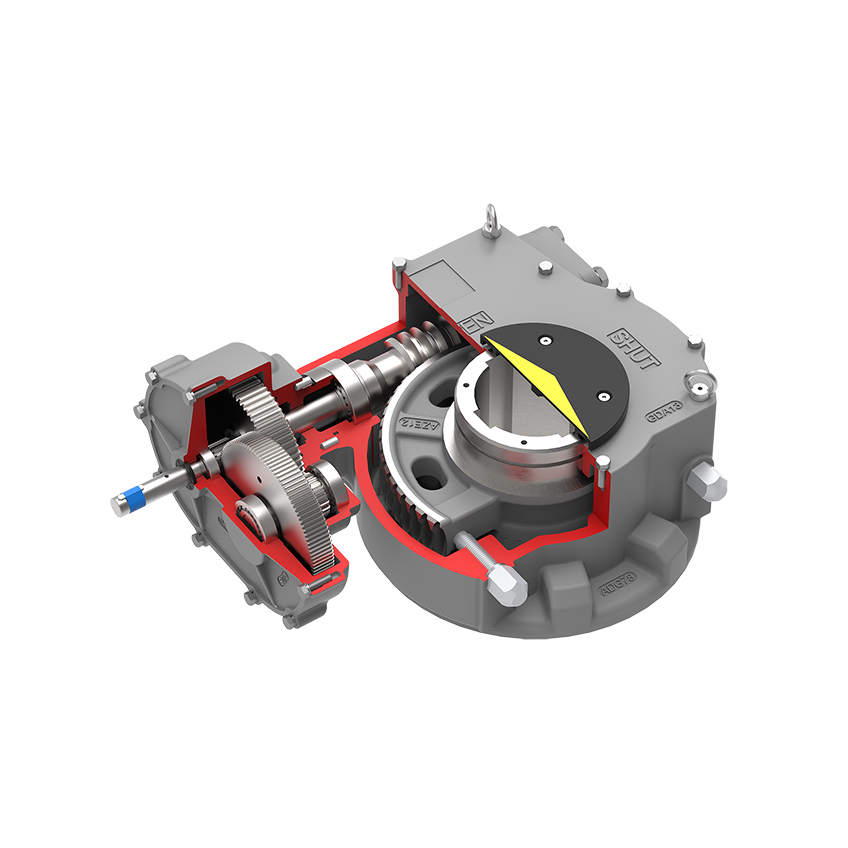

Customizable Multi Turn Worm Gearboxes: High-quality and Affordable Solutions for Your Business

China Multi Turn Worm Gearbox Factory Boosting China's Industrial FutureChina is experiencing a phenomenal trend in the development and advancements of technology in the last decade. From the consumer electronics to robotics, continuous investments have enabled the country to transition from a low-cost manufacturing hub to a high-tech industrial powerhouse. One sector that has been crucial in this growth is the machinery industry, which produces equipment and tools necessary for manufacturing processes. The China Multi Turn Worm Gearbox Factory is one of the companies that have been influential in enhancing China's machinery industry.Established in 1993, the China Multi Turn Worm Gearbox Factory is located in the beautiful city of Hangzhou, Zhejiang Province. The company's core focus is on the production of Multi Turn Worm Gearboxes, a crucial component in the machinery industry. Multi Turn Worm Gearboxes are widely applicable across different industries, including packing, printing, automobiles, textiles, food, and pharmaceuticals. The gearboxes help to improve the efficiency and accuracy of the machines, including cutting, rolling, winding, and other motion applications.As a leading Multi Turn Worm Gearbox manufacturer in China, the company has been innovating and customizing its products according to customers' requirements. The company has its research and development department with experienced engineers and technicians, who continuously develop new products to enhance the machinery industry. The factories produce, test, and assemble the gearboxes' different parts, ensuring quality and meeting production standards.Over the years, the China Multi Turn Worm Gearbox Factory has expanded its market presence worldwide, with a focus on the Asia-Pacific region, Europe, Latin America, and Africa. The company's annual sales revenues have been increasing its domestic and foreign market share. In 2020, the company achieved an annual sales turnover of USD 500 million, with more than 2700 employees.The company's success is attributable to its core values of innovation, quality, operational excellence, and customer satisfaction. The company's management believes that the gearbox industry's future will be more automated, digitalized, and smart in meeting the increasing demand for high-tech machinery. As such, the China Multi Turn Worm Gearbox Factory has been keen on integrating digital technologies such as Cloud, the Internet of Things (IoT), and Artificial Intelligence (AI) in their operations to enhance customer value and improve the quality of their products.In addition, the company has been environmentally conscious, as it has implemented measures aimed at reducing its carbon footprint, promoting sustainability and reducing waste. One of its initiatives includes using energy-efficient machines and processes, and it has installed solar panels to reduce its reliance on traditional energy sources.The China Multi Turn Worm Gearbox Factory's future outlook is promising, and it will continue to innovate and produce high-quality gearboxes. The company's management has placed a strategic plan to leverage the vast market potential, increasing domestic demand, and the "China Manufacturing 2025 plan," which aims to enhance the country's machinery industry. As a result, the company will diversify its product range, enhance its supply chain management, and expand its global market presence.In conclusion, the China Multi Turn Worm Gearbox Factory has been instrumental in China's machinery industry's growth and development. With its core values of innovation, customer satisfaction, quality, and operational excellence, the company has established itself as a market leader in the Multi Turn Worm Gearbox industry. Its expansion efforts and integration of digital technologies demonstrate its commitment to enhancing customer value, promoting sustainability, and being future-oriented. As China continues to transition into a high-tech industrial powerhouse, the China Multi Turn Worm Gearbox Factory is playing a vital role in the country's bright future.

The Ultimate Guide to Automated Ball Valve Actuators: A Complete Overview

Automated Ball Valve Actuator Revolutionizes Industrial Processes[Company Name], a pioneer in industrial automation technologies, has introduced its groundbreaking Automated Ball Valve Actuator, a state-of-the-art solution that is set to revolutionize numerous industries around the world. This cutting-edge technology is designed to enhance productivity, efficiency, and safety, making it a game-changer for businesses seeking to optimize their processes.The Automated Ball Valve Actuator from [Company Name] combines precision engineering with intelligent control systems to offer unparalleled reliability and performance. This actuator provides seamless automation for ball valves, allowing for precise control of flow and pressure in a wide range of applications, including oil and gas, water treatment, chemical production, and manufacturing.One of the standout features of this innovative product is its adaptability. The Automated Ball Valve Actuator is compatible with both new installations and retrofits, seamlessly integrating with existing infrastructure. Its flexible design allows it to operate in diverse environments, including extreme temperatures and corrosive conditions, making it a highly versatile choice for industrial facilities.Safety is paramount in industrial settings, and the Automated Ball Valve Actuator addresses this concern through its advanced safety features. This technology incorporates redundant systems to ensure failsafe performance, reducing the risk of accidents, leaks, and other potentially hazardous incidents. Furthermore, the actuator's intelligent control system enables remote operation, minimizing workers' exposure to dangerous environments.Efficiency is another significant advantage that the Automated Ball Valve Actuator brings to the table. Its precise control mechanism allows for accurate regulation of flow rates, ensuring optimal performance and reducing energy costs. By automating the valve control process, businesses can improve operational efficiency, minimize downtime, and optimize resource utilization.The integration of smart technology sets [Company Name]'s Automated Ball Valve Actuator apart from its competitors. This actuator leverages cutting-edge Internet of Things (IoT) capabilities, enabling real-time monitoring and control from anywhere in the world. With this feature, industrial operators can remotely access valve performance data, receive alerts, and fine-tune valve settings, enhancing maintenance practices and troubleshooting efforts.Beyond the core functionality, this automated actuator also offers a user-friendly interface. The control system is intuitive and easy to operate, ensuring that businesses can quickly adopt and implement this technology in their day-to-day operations. Furthermore, [Company Name] provides comprehensive training and support to customers, guaranteeing a smooth transition to the Automated Ball Valve Actuator.The introduction of the Automated Ball Valve Actuator comes at a time when industries across the globe are striving for greater efficiency, sustainability, and safety. By leveraging advanced automation technology, businesses can overcome operational challenges, reduce costs, and enhance their competitiveness in the global market.[Company Name] is committed to continuously improving and refining its products to meet the evolving needs of customers. With its expertise in industrial automation and a customer-centric approach, the company is poised to lead the way in introducing innovative solutions that transform industrial processes.In conclusion, the Automated Ball Valve Actuator from [Company Name] is a game-changing product that combines precision engineering, intelligent control systems, and advanced safety features. Its adaptability, efficiency, and integration of smart technology make it an indispensable asset for various industries worldwide. [Company Name]'s commitment to providing exceptional support further solidifies its position as a reliable partner in industrial automation.

Worm Gear Butterfly Valve: A Versatile Solution for Flow Control" can be rewritten as "Versatile Flow Control Solution: Utilizing Worm Gear Butterfly Valves".

Title: Advanced Worm Gear Butterfly Valve - The Perfect Solution for Industrial Fluid ControlIntroduction:In today's rapidly evolving industrial landscape, efficient fluid control is crucial to the success and safety of various operations. Owing to their versatility and effectiveness, Worm Gear Butterfly Valves have emerged as the go-to solution for regulating fluid flow in numerous industries. These valves, offering superior sealing capabilities and reliable performance, are now revolutionizing the way businesses approach fluid control.I. Significance of Worm Gear Butterfly Valves in Industrial Applications (100 words)Worm Gear Butterfly Valves have garnered significant prominence across industries due to their unique design and exceptional functionality. These valves consist of a disk-shaped element, known as the "butterfly," which rotates to control fluid flow. The addition of worm gears - a mechanical adjustment system - enables precise regulation, making them ideal for applications where fluid control precision is paramount. Whether it's chemical processing, water treatment, or power generation, Worm Gear Butterfly Valves have become indispensable tools for optimizing efficiency and enhancing safety.II. Key Features and Benefits of Worm Gear Butterfly Valves (200 words)a) Reliable Performance: Worm Gear Butterfly Valves are designed to withstand extreme conditions, offering consistent and dependable performance. The high-quality materials used in manufacturing ensure longevity and minimal maintenance.b) Excellent Sealing Properties: The unique design of these valves allows for a tight seal, preventing leakage and offering superior tightness. This ensures optimal flow control and minimizes the risk of fluid wastage, enhancing operational efficiency.c) Precise Control: The inclusion of the worm gear mechanism enables precise, measured adjustments to fluid flow, allowing operators to fine-tune operations as required. This precision is particularly critical in industries such as oil and gas, where even slight variations can result in significant consequences.d) Easy Installation and Operation: Worm Gear Butterfly Valves are known for their simplicity. They can be easily integrated into existing systems and operated efficiently by both experienced professionals and operators new to the technology.e) Versatility: These valves can handle a wide range of fluids, including liquids, gases, and even corrosive media. This adaptability makes Worm Gear Butterfly Valves suitable for applications across diverse industries.III. Company X's Advanced Worm Gear Butterfly Valve (200 words)Company X, a renowned industry leader in fluid control solutions, is proud to present its cutting-edge Worm Gear Butterfly Valve. With a steadfast commitment to innovation and customer satisfaction, Company X has designed a valve that surpasses industry standards and addresses various industry challenges.The advanced Worm Gear Butterfly Valve by Company X combines robust construction, precision performance, and exceptional durability. Manufactured using premium grade materials, it ensures longevity and reliability, minimizing maintenance requirements and reducing downtime.In addition to exceptional sealing properties, Company X's Worm Gear Butterfly Valve offers unparalleled precision control. Its worm gear mechanism guarantees accurate fluid flow adjustments, empowering operators to regulate processes with utmost accuracy.The valve's user-friendly design simplifies installation and operation, catering to customers across different industries. The versatility of Company X's Worm Gear Butterfly Valve allows businesses to maximize efficiency and safety, enhancing productivity and minimizing operational costs.IV. Conclusion (100 words)In an era where efficient fluid control is crucial, the Worm Gear Butterfly Valve emerges as the ideal solution for various industrial applications. Company X's advanced valve, with its superior design and outstanding performance, is primed to revolutionize fluid control practices across industries. With its exceptional sealing capabilities, precise control, and straightforward operation, this valve presents an unprecedented opportunity for businesses to optimize their operations, enhance safety, and maximize efficiency. Embracing the advantages offered by Worm Gear Butterfly Valves marks a significant leap forward in fluid control technology.

New Limit Switch Box Technology Now Available - Streamlining Industrial Processes

In the industrial world, there is no denying that safety is a top priority. With heavy machinery and equipment in use, workers need to remain safe while operating or maintaining these assets. In order to mitigate potential safety hazards, the use of limit switches has become an integral part of industrial processes. One such limit switch box that is making waves in the industry is Apl-210. Known for its reliability and simplicity, the Apl-210 limit switch box has quickly become a fan favorite among industrialists.This versatile switch box can be used in a myriad of industrial applications such as cranes, elevators, conveyors, packaging machines, and other automated machinery. The Apl-210 is housed in a compact yet rugged enclosure made from high-quality materials that provide superior resistance against harsh industrial environments. The housing is also designed to protect the internal components from dust, moisture, and other contaminants.One of the unique features of the Apl-210 limit switch box is its modular design. This design allows for quick and easy installation and maintenance. The switch box is comprised of various components that can be easily swapped out or replaced without the need for specialized tools or expertise. Moreover, the wiring of this limit switch box is easy to understand, making it simple to integrate into any application.The Apl-210 limit switch box is also known for its high-precision performance. It utilizes high-quality mechanical parts that allow for accurate and reliable switching. With its adjustable operating range, the limit switch box provides flexibility in its application. In addition, the switch box has a high degree of repeatability, ensuring the consistent operation of industrial equipment.The switch box is built with advanced safety features that ensure the safety of workers. It offers reliable protection against unexpected equipment movements, ensuring that workers remain safe during operation. Moreover, the APL-210 is designed to withstand extreme vibration and shock, which is a crucial factor in ensuring the longevity of the equipment.It is no surprise that the Apl-210 limit switch box has become a go-to solution for industrialists. Along with its exceptional performance, the company behind the product is renowned for its commitment to quality and excellent customer service. The company provides different customization options and works closely with its clients to provide tailored solutions that fit their unique needs. The Apl-210 limit switch box is a testament to the company's dedication to providing reliable and robust products to the industrial world.In conclusion, the Apl-210 limit switch box has set itself apart as a trusted safety solution for various mechanical and automated processes. With its mechanical precision, flexible application, and excellent safety features, it is no surprise that it has become a go-to solution for industrialists around the globe. With the product's reliable performance and the company's commitment to quality, it is evident that the Apl-210 limit switch box will continue to make waves in the industrial world for years to come.

Discover the Latest Advancements in 24VDC Valve Actuators for Enhanced Control

In the world of industrial automation, control valves are an essential part of the overall system. They are responsible for regulating the flow of fluids or gases and ensuring that the processes run smoothly. The efficiency and accuracy of these control valves depend on the effectiveness of the valve actuator.One of the latest technological innovations in this field is the 24vdc Valve Actuator. This innovative product is designed to increase the efficiency and accuracy of control valves, thereby improving the overall performance of the system. The 24vdc Valve Actuator is quickly gaining popularity among automation experts, who recognize its outstanding features and benefits.The 24vdc Valve Actuator is a powerful motor that can drive a range of control valve types, including butterfly, ball, and globe valves. It is designed to operate on a 24vdc power supply, which is common in many industrial applications. The actuator is compact and easy to install, making it an ideal choice for both new and retrofit installations.The technology behind the 24vdc Valve Actuator is impressive. It utilizes advanced microprocessor-based electronics that provide precise and reliable positioning of the control valve. The motor is equipped with a powerful gearing system that ensures smooth and consistent operation of the valve, even under high pressure and turbulent flow conditions.The 24vdc Valve Actuator also comes with a wide range of operating modes, including proportional, on-off, and modulating. This gives operators a high degree of flexibility for controlling the flow of fluids or gases in different applications. The actuator is also capable of providing feedback signals to a central control system, allowing operators to monitor the performance of the valve in real-time.One of the key benefits of the 24vdc Valve Actuator is its energy efficiency. The actuator uses advanced technology to optimize its power consumption and minimize energy wastage. This not only reduces the overall operating costs of the system but also contributes to a more sustainable and environmentally friendly approach to industrial automation.The 24vdc Valve Actuator is also highly reliable and requires minimal maintenance. Its robust construction and advanced electronics ensure that it operates smoothly and consistently, even in harsh working environments. This means that operators can expect long service life and minimal downtime, further contributing to the cost-effectiveness of the system.The success of the 24vdc Valve Actuator can largely be attributed to the company behind it. With decades of experience in industrial automation, the company has established itself as a leading player in the field. Its commitment to innovation and excellence has enabled it to develop cutting-edge products like the 24vdc Valve Actuator, which meet the evolving needs of the industry.The company is also known for its outstanding customer service and support. Its team of expert engineers and technicians work closely with customers to ensure that their automation systems operate at peak efficiency. The company also offers training and educational resources to help operators get the most out of their equipment.In conclusion, the 24vdc Valve Actuator is an exciting new development in the field of industrial automation. With its advanced technology, energy efficiency, and reliability, it is an ideal choice for a wide range of applications. The company behind the actuator is a trusted and respected provider of automation solutions, ensuring that customers can have confidence in the quality and performance of their products. With the 24vdc Valve Actuator, industrial operators can take their automation systems to the next level.

Boost Efficiency and Reliability with Cutting-Edge Gear Operator Valves

In the world of industrial machinery, Gear Operator Valve plays a pivotal role in making sure that the processes that run continuously day in and day out, run smoothly and without a hitch. Companies around the world rely heavily and put their trust in Gear Operator Valves, in order to keep the machines running and the products moving.One such company is in India, that has been providing top-notch Gear Operator Valves to the industry, for over three decades. Established in 1988, the company has been serving the customers with quality products and customer service that is unbeatable. With its proven track record, the company has become India's leading manufacturer of Gear Operator Valves, with a market share that is unrivaled.The company's core principles are quality, innovation, and customer service. They aim to provide the best product and services possible, and always strive to improve their production processes, to bring the latest technology and innovation to their product line. They believe in ensuring that their products meet the highest standards of quality, in order to exceed customer satisfaction and expectations. This approach gives them a competitive edge in the market, and has cemented their position as the top company in the industry.One of the products that have consistently put this company on the map is the Gear Operator Valve. The valve is constructed with high-quality materials, and machined to perfection, to ensure smooth operation and eliminate any mechanical failures. The valve is designed in a way that makes it easy to operate, and it requires very low maintenance, which is a big relief for the machine operators. This makes it an indispensable component to many industries, that rely on the 24/7 operation of their equipment.Additionally, the Gear Operator Valve comes in different sizes to fit into different types of machines, and different applications. This versatility makes it possible to use the valve in a wide range of industries such as chemical, oil and gas, food and beverage, and pharmaceuticals, among many others. The ability to customize the valve allows the company to cater to the unique requirements of their customers, giving them the flexibility to operate within their specific environments.The Gear Operator Valve's performance and reliability have been tested over time, and has shown to be exceptional, even under the most challenging conditions. It has a robust design that can withstand high temperatures and pressures without failure, which is why it is the number one choice of valve for many industrial applications. With the Gear Operator Valve's high performance and longevity, companies can save on the maintenance costs, and the need for frequent repairs, which leads to better efficiency and increased productivity.In conclusion, the Gear Operator Valve is an essential component in the industrial machinery sector, and companies rely on it to carry out their operations smoothly and efficiently. The company has built a reputation for producing high-quality Gear Operator Valves, which have stood the test of time. With their commitment to quality, innovation, and customer service, the company has set the bar high for the rest of the industry, and is a shining example of what a successful business looks like.

The Future of High-Performance Engine Technology: Electromagnetic Valve Actuators

[ Company Name ] Introduces Innovative Electromagnetic Valve Actuator for Enhanced Performance[ Location ], [ Date ] - [ Company Name ], a leading provider of advanced technological solutions, has recently unveiled its latest innovation in the field of electromagnetic valve actuators. This groundbreaking product is set to revolutionize the way industries operate and significantly enhance performance across various sectors.The electromagnetic valve actuator, developed by [ Company Name ], represents an amalgamation of cutting-edge technology and industry expertise. With an emphasis on precision and reliability, this state-of-the-art device aims to meet the increasing demands of modern-day industries for efficient and accurate valve control.One of the key distinguishing features of this new actuator is its unrivaled speed and responsiveness. By leveraging advanced electromagnetic technology, [ Company Name ] has engineered an actuator that can sense and respond to even the most minute changes in valve position within milliseconds. This unprecedented speed ensures that critical valves are adjusted promptly, minimizing downtime and optimizing overall productivity.Another notable advantage of the electromagnetic valve actuator is its exceptional accuracy. Leveraging highly sophisticated control algorithms and intelligent sensing mechanisms, this actuator guarantees precise and repeatable control of valve parameters. Moreover, it provides real-time feedback to operators, enabling them to monitor valve conditions and performance with utmost accuracy, ensuring optimal system operation.In addition to its outstanding performance, the electromagnetic valve actuator offers uncompromising durability and longevity. Constructed with high-quality materials and rigorously tested to withstand extreme conditions, this actuator boasts an extended lifecycle, reducing the need for frequent repairs and replacements. Such robustness, coupled with its ease of maintenance, makes it an ideal choice for industries operating in demanding environments.Moreover, the electromagnetic valve actuator by [ Company Name ] features a compact and lightweight design, optimizing space utilization and simplifying installation. Its user-friendly interface allows for effortless integration with existing systems, guaranteeing a seamless transition for operators and minimal disruptions to ongoing operations.Furthermore, environmental consciousness lies at the heart of this new technology. [ Company Name ] has incorporated energy-efficient features into the electromagnetic valve actuator, ensuring reduced power consumption, which ultimately translates into cost savings for industries whilst mitigating their carbon footprint. With growing emphasis on sustainable practices, this actuator aligns with global initiatives aimed at protecting our planet."Through our extensive research and development efforts, we are proud to introduce this innovative electromagnetic valve actuator," said [ Company Name's ] spokesperson. "We believe that this breakthrough technology will empower industries to achieve new heights of productivity and efficiency, while reducing operational costs and environmental impact."With its countless benefits and unparalleled performance, the electromagnetic valve actuator by [ Company Name ] is already attracting attention across various industry sectors. Applications in oil and gas, petrochemicals, power generation, water treatment, and many other fields can significantly benefit from this technological advancement.As [ Company Name ] continues to push the boundaries of technological innovation, their latest electromagnetic valve actuator undoubtedly establishes them as a trailblazer in the industry. With its robustness, precision, and environmentally conscious design, this actuator is set to reshape industrial processes and drive sectors towards a more prosperous and sustainable future.

Cutting-Edge Explosion-Proof Electric Actuators: Discover the Latest Safeguarding Technology

Explosion-Proof Electric Actuator Revolutionizes Industrial AutomationIn an era of rapid industrialization, companies across various sectors are seeking innovative solutions to optimize their manufacturing processes. One such breakthrough comes in the form of the recently introduced Explosion-Proof Electric Actuator. With its cutting-edge technology and exceptional safety features, this actuator is revolutionizing the field of industrial automation.Designed and developed by a leading global manufacturer, this explosion-proof electric actuator represents a significant step forward in the quest for enhanced operational efficiency and worker safety. This state-of-the-art equipment combines precision engineering with advanced materials to deliver a reliable and robust solution that is indispensable in hazardous environments.The explosion-proof actuator's technological prowess lies in its ability to withstand and contain explosive gases, ensuring the safety of not only the equipment but also the surrounding environment. This feature makes it an invaluable asset for industries like oil and gas, petrochemicals, mining, and pharmaceuticals where explosive atmospheres are present.The actuator's construction adheres to rigorous international safety standards, providing it with certifications that guarantee its suitability for use in hazardous environments. These certifications serve as a testament to the thorough testing and quality control procedures implemented during the manufacturing process. As a result, operators can now harness the power of automation without compromising on safety or regulatory compliance.Furthermore, the explosion-proof electric actuator boasts a host of performance-enhancing features that make it a versatile tool for any industry. Its compact design allows for easy integration into existing infrastructures, minimizing downtime during installation. The actuator's exceptional durability ensures consistent and reliable operation even in harsh operating conditions, reducing maintenance costs and extending equipment lifespan.Another standout feature of this actuator is its high level of precision and accuracy. Incorporating advanced control algorithms and position feedback systems, it provides precise control over rotational or linear movements. This level of control is critical in applications that demand accuracy, such as valve control, complicated conveyor systems, or robotic automation.Moreover, the explosion-proof electric actuator's user-friendly interface simplifies operation, empowering operators with intuitive control capabilities. This ease of use significantly reduces the learning curve associated with operating complex machinery, allowing for increased productivity and efficiency. Additionally, the actuator's compatibility with various communication protocols enables seamless integration with existing automation systems, further streamlining industrial processes.The advent of this explosion-proof electric actuator holds tremendous promise for industries where safety and efficiency are paramount concerns. By replacing traditional pneumatic or hydraulic systems, this innovation reduces the risk of leaks, eliminates the need for extensive maintenance, and optimizes energy consumption.With increasing regulatory scrutiny and a growing emphasis on sustainable practices, this actuator serves as a catalyst for environmentally friendly industrial automation. By using electricity as its power source, it reduces reliance on fossil fuels and minimizes the carbon footprint associated with traditional actuation methods.In conclusion, the introduction of the Explosion-Proof Electric Actuator signifies a significant leap forward in industrial automation. Combining advanced technology, exceptional safety features, and innovative design, this actuator redefines the landscape of industrial processes. With its capability to operate in explosive environments, deploy automation with precision, and uphold rigorous safety standards, it proves to be an indispensable asset across a wide range of industries. By embracing this industrial revolution, companies can enhance operational efficiency, ensure worker safety, and contribute to a more sustainable future.

New electric hydraulic valve actuator technology developed for improved efficiency

Electric Hydraulic Valve Actuator Technology Revolutionizes Industrial AutomationOver the years, industrial automation has continually advanced, transforming the way industries operate and increasing efficiency and productivity. One of the key components driving this progress is the Electric Hydraulic Valve Actuator (EHVA). This cutting-edge technology has emerged as a game-changer, delivering superior performance, reliability, and ease of operation.EHVA, developed by one of the industry's leading innovators (Company Name), is revolutionizing industrial automation. The actuator is designed to provide precise control over valves and dampers used in various industrial applications. Its state-of-the-art technology merges the benefits of electric and hydraulic operation, ensuring optimal performance in diverse settings.The EHVA system eliminates the need for manual valve control, reducing human error and enhancing safety in industrial environments. With its electric hydraulic design, the actuator provides seamless integration with automation systems, allowing for remote control and operation. This level of automation significantly improves overall operational efficiency, minimizing downtime and maximizing output.One of the standout features of the EHVA is its versatility. It can be seamlessly integrated into existing infrastructure, making it a cost-effective solution for industries looking to upgrade their automation systems. This flexibility ensures compatibility across a wide range of industries, including oil and gas, water treatment, power generation, chemical processing, and many more.Moreover, the EHVA offers a wide range of torque and thrust options, catering to the specific requirements of different valves and dampers in diverse applications. Its robust construction and use of high-quality materials make it highly durable, withstanding even the most demanding environmental conditions. This durability translates into reduced maintenance costs and extended operational lifespan, making it a cost-effective long-term investment for industries.The EHVA's advanced control algorithms and feedback mechanisms further enhance its performance. The actuator constantly monitors and adjusts its operating parameters to ensure precise valve control, maintaining optimal flow rates, pressures, and temperatures. This level of automation significantly improves process consistency and reliability, leading to better product quality and enhanced customer satisfaction.Another key advantage of the EHVA technology is its energy efficiency. By utilizing advanced electric hydraulic systems, the actuator minimizes power consumption while delivering optimal performance. This not only helps reduce operational costs but also contributes to sustainable and environmentally friendly practices.(Company Name), the company behind the EHVA, has established itself as a pioneer in the field of industrial automation. With an extensive portfolio of cutting-edge solutions, the company has gained recognition for its commitment to innovation, reliability, and customer satisfaction. The EHVA is a testament to their expertise, providing industries with a transformative solution to enhance their automation capabilities.The company's dedication to research and development has resulted in continuous improvements to the actuator's design and functionality. Through rigorous testing and collaboration with industry partners, they have refined the EHVA, ensuring it meets the highest quality standards and exceeds customer expectations.As automation continues to revolutionize industries worldwide, the Electric Hydraulic Valve Actuator emerges as a critical component driving this transformation. Its advanced technology, seamless integration, and exceptional performance make it an indispensable tool for industries seeking to optimize their processes, increase productivity, and enhance overall efficiency. With (Company Name)'s expertise and commitment to innovation, the EHVA is set to shape the future of industrial automation.